Summary

At Sanliurfa Hydro Power Plant, GE’s hydro remote Monitoring & Diagnostic (rM&D) team detected a gradual temperature increase on the Oil lubricated bearing system of a horizontal Francis turbine using Machine Learning technology within Predix APM. This early notification has triggered a predictive maintenance action; the site team prioritized the troubleshooting and correct the filter clogging issue earlier than the maintenance schedule planned to.

This helped to avoid a potential forced unit outage and thrust bearing repair work, avoiding 149,000€ in costs (production loss + repair work).

What did our service find?

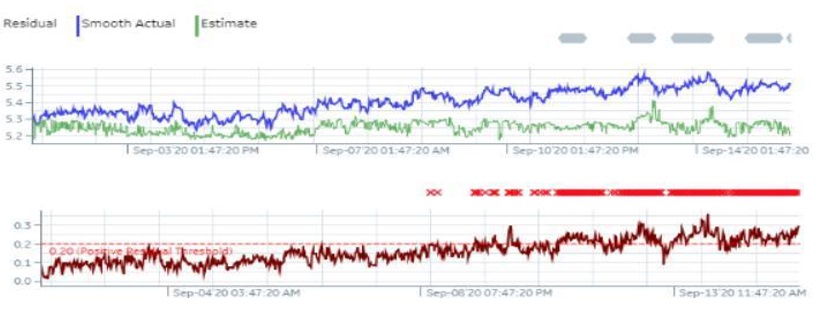

GE Renewable Energy’s remote Monitoring & Diagnostic (rM&D) team using Digital Twin technology within Predix APM detected a gradual temperature increase on the oil lubricated bearing system on one horizontal Francis Hydro Power Unit. Specifically, the rM&D team noticed a continuous increase in temperature for the Combined Thrust Bearing for the past 3 weeks. After a unit shutdown on Aug 26th, the temperatures on the thrust bearing increased from 76 C to 80 C.

The team sent out a notification to the customer and added this item to the weekly report.

What was the underlying cause?

After receiving the early notification, the customer decided to prioritize the check of the cleanliness of the cooling water filter compartment; the verification and maintenance date of the filter was forecasted for later, but the early notification has anticipated the action right after the alert. Customer confirmed a filter clogging condition impacting the water flow. The filter has been cleaned in time prior to the trip of the unit. After these actions, the thrust bearing temperature came back to normal.

What was the value to the customer?

With this predictive maintenance action, the Customer avoided a potential Unit trip and a thrust bearing damage. This early catch have a global saving estimation of approximately €149,000. (1 week production loss and thrust bearing repair works)