Reactors

Long life with maintenance-free operation and environmentally friendly design

For more than 50 years, GE Vernova has supplied a broad range of reactors to markets around the world. With proven industry expertise, stringent quality controls, first class materials and full international compliance, GE Vernova’s reactors are designed to meet a wide variety of customer needs.

GE Vernova’s environmental-friendly, long-life, maintenance-free reactors enhance system performance and power quality from transmission and distribution to industrials, improving network operational efficiency. This results in considerable savings for customers and reduces the environmental impact of their operations.

GE Vernova’s team of experts analyze our customer’s power compensation needs from low voltage current limiting to high voltage shunt/series applications and engineer the right solutions to provide optimal efficiency and economy.

Reactors

Long life with maintenance-free operation and environmentally friendly design

For more than 50 years, GE Vernova has supplied a broad range of reactors to markets around the world. With proven industry expertise, stringent quality controls, first class materials and full international compliance, GE Vernova’s reactors are designed to meet a wide variety of customer needs.

GE Vernova’s environmental-friendly, long-life, maintenance-free reactors enhance system performance and power quality from transmission and distribution to industrials, improving network operational efficiency. This results in considerable savings for customers and reduces the environmental impact of their operations.

GE Vernova’s team of experts analyze our customer’s power compensation needs from low voltage current limiting to high voltage shunt/series applications and engineer the right solutions to provide optimal efficiency and economy.

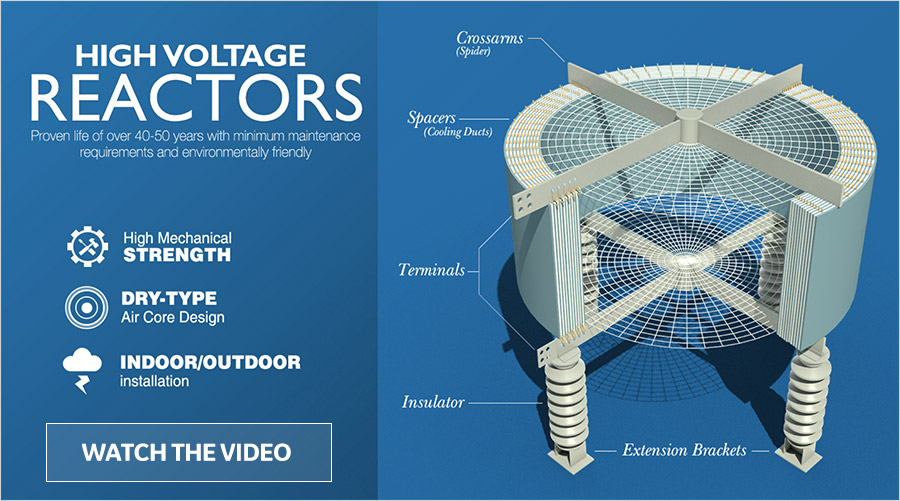

Air-core Reactors

GE Vernova’s air-core reactors (ACR) provide a linear response of impedance versus current which is essential for numerous applications. GE Vernova’s reactors consist of aluminum or copper conductors, which are insulated with first class insulation materials. In encapsulated design, the conductors are mechanically immobilized and encapsulated by epoxy impregnated fiberglass, which assure high hygroscopic characteristic and long service life.

Why GE Vernova’s air-core reactors?

- Complete range of products and solutions in power compensation

- Long term expertise and know-how in power compensation projects

- Full line supplier with synergies between business and product lines

- Proven quality and performance of the products

- Worldwide presence with customer intimacy and proximity

- State-of-the-art in manufacturing process and machinery

Solution portfolio

Our portfolio of air-core reactors includes cost-effective solutions for power generation, transmission and distribution utilities, and industry:

- Shunt reactors

- Current-limiting reactors

- Neutral-earthing reactors

- Harmonic filter reactors

- Damping reactors

- Smoothing reactors

- Arc-furnace series reactors

- Power flow control reactors

- Motor starting reactors

- Special applications, such as test lab reactors

Series Application

Challenge

Integration of new power plants, transmission lines, power transformers and capacitor banks typically increases the normal, transient and short-circuit currents of the transmission and distribution networks. These new current levels exceed the current carrying capabilities of existing equipment.

Solution

GE Vernova’s series reactors provide a cost-effective solution to limit and/or reduce the excessive current levels under normal, transient and short time conditions, assuring quality, reliability and continuity of the power supply.

Shunt Application

Challenge

Transmission and distribution systems operating at low loading levels cause voltage increases in busbars and lines, resulting in insulation failures of the equipment on the grid and overall system instability.

Solution

GE Vernova’s shunt reactors provide system voltage control, operational flexibility, stability and reliability assuring long equipment life and continuity of power supply.

Iron-core Reactors

HV iron-core reactors are connected in series with the capacitor units to form a series resonant circuit with very low impedance. GE Vernova’s line of iron-core reactors are ideal for a variety of applications including capacitor banks formed by several steps, several capacitor banks connected in the same busbar, and capacitor bank installations with risk of resonance or with presence of harmonics.

Key benefits

- Reactive power compensation (power factor correction) in networks with harmonics

- Reduction of inrush currents that flow from step to step of the capacitor banks when switched

- Avoiding the risk of resonance as the LC circuit is having a resonance frequency below the first existing harmonic

- Decrease the level of harmonic distortion, as the circuit is also having a certain tuning frequency at which the branch will offer low impedance path for harmonic currents

Applications for renewable generation, wind and solar farms:

- Shunt reactors (up to 500kV)

- Short-circuit current-limiting reactors (up to 800kV)

- Tuning reactors for harmonic filters and MSCDN

- Damping reactors for shunt capacitor banks

Applications for FACTS, HVDC LCC and VSC, and transmission and distribution substations:

- Thyristor-controlled and thyristor-switched reactors for SVC

- Phase-reactors for STATCOM

- Tuning/blocking reactors for AC/DC, harmonic filters and MSCDN

- Damping reactors for TSC and shunt banks

- Smoothing and valve reactors for HVDC

- Shunt reactors (up to 500kV)

- Short-circuit current-limiting reactors (up to 800kV)

- Power-flow control reactors

- Neutral grounding reactors

Applications for buildings and cities, oil and gas, and industry and infrastructure:

- Shunt reactors (up to 500kV)

- Short-circuit current-limiting reactors (up to 800kV)

- Tuning reactors for harmonic filters and MSCDN

- Damping reactors for shunt capacitor banks

- Arc-furnace reactors

- Motor-starting reactors

- Laboratory reactors (special applications)

Manufacturing Excellence

GE Vernova manufacturing plants are highly automated digital factories that use the GE Vernova Predix platform for machine learning and modeling.

Itajubá, Brazil

Our Itajubá factory supplies a broad range of engineered equipment for all segments and commercial regions, by means of state-of-the-art machinery and design criteria, first class raw material, strict production and quality controls, and very experienced staff.

Products manufactured in Itajubá, Brazil:

- Air-core dry-type reactors

- High voltage capacitor units and banks

- High voltage harmonic filters

- AIS products (instrument transformers, circuit breakers, disconnectors and line traps)

References

For more than 50 years, GE Vernova has provided global support and advanced technologies to +1,000 customers in 80 countries, offering a broad range of reactors for many market segments. GE Vernova is an industry leader in design and manufacturing process with compliance in international technical and certification standards. Below are a select representation of our projects, a complete reference list is available upon request.

1. Canada (2016)

HVDC Smoothing Reactors

AC/DC Filter Reactors

2. USA (1995-2018)

FACTS – SVC & FSC

Shunt Reactors

Current Limiting Reactors

Neutral Grounding Reactors

Damping & Filter Reactors

3. Mexico (2000-201)

FACTS – SVC & FSC

Current Limiting Reactors

Damping & Filter Reactors

4. Brazil (2012)

Rio Madeira HVDC

5. Peru & Colombia (2012-2018)

Current Limiting Reactors

Neutral Grounding Reactors

Damping & Filter Reactors

6. Chile (2010-2017)

FACTS – SVC & FSC

Current Limiting Reactors

Neutral Grounding Reactors

Damping & Filter Reactors

7. Uruguay (2010)

Melo HVDC

8. Brazil (1976-2018)

FACTS (SVC & FSC)

Current Limiting Reactors

Neutral Grounding Reactors

Damping & Filter Reactors

Arc-Furnace Reactors

Laboratory Reactors

9. Scotland (2002)

FACTS (SVC)

10. France, Germany and Netherlands (2002-2018)

Damping & Filter Reactors

Neutral Grounding Reactors

11 Turkey (2008)

FACTS (SVC)

12. South Africa (1998-2018)

Current Limiting Reactors

Damping & Filter Reactors

13. South Korea (2014)

HVDC Smoothing Reactors

14. Thailand (2006-2018)

Damping & Filter Reactors

15. Malaysia (2002-2018)

Damping & Filter Reactors

16. Australia (2010-2018)

Shunt Reactors

Damping & Filter Reactors