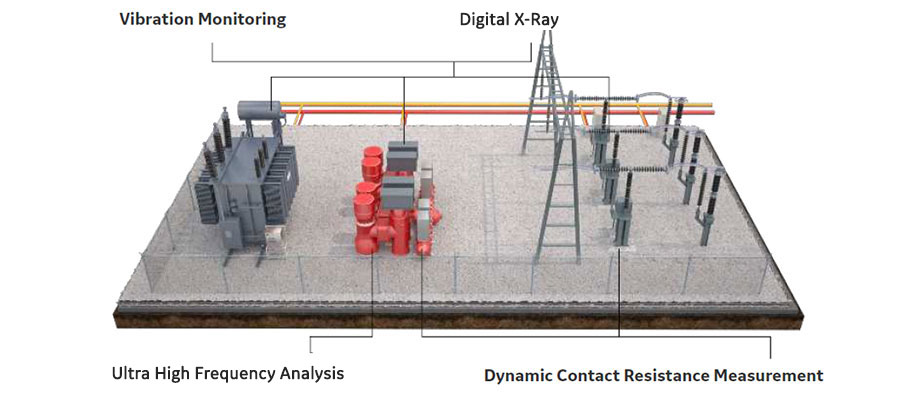

Advanced Non-Intrusive Inspection Services

For fast and cost-effective measurement and diagnostics, GE offers advanced inspection methods that do not require the asset to be opened, including;

- Digital X-Ray

- Vibration Monitoring

- Ultra High Frequency Analysis

- Dynamic Contact Resistance Measurement (DCRM)

The service includes recommendation in the choice of inspection methods, onsite inspections, diagnosis and maintenance recommendations captured in a condition assessment report.

GE’s advanced non-intrusive inspection services enable condition assessment of ageing High Voltage (HV) circuit breakers from GE and 3rd party OEMs including: Live and Dead Tank Circuit Breakers, Gas-Insulated Substations (GIS) and Generator Circuit Breakers They are applicable for various objectives:

- Fleet Performance Management

- Critical asset assessment

- Risk evaluation

- Diagnosis of defect root cause

- Routine maintenance

- Highly demanding application including shunt reactor or transformer protection

Advanced Non-Intrusive Inspection Services

For fast and cost-effective measurement and diagnostics, GE offers advanced inspection methods that do not require the asset to be opened, including;

- Digital X-Ray

- Vibration Monitoring

- Ultra High Frequency Analysis

- Dynamic Contact Resistance Measurement (DCRM)

The service includes recommendation in the choice of inspection methods, onsite inspections, diagnosis and maintenance recommendations captured in a condition assessment report.

GE’s advanced non-intrusive inspection services enable condition assessment of ageing High Voltage (HV) circuit breakers from GE and 3rd party OEMs including: Live and Dead Tank Circuit Breakers, Gas-Insulated Substations (GIS) and Generator Circuit Breakers They are applicable for various objectives:

- Fleet Performance Management

- Critical asset assessment

- Risk evaluation

- Diagnosis of defect root cause

- Routine maintenance

- Highly demanding application including shunt reactor or transformer protection

GE’s Advanced Methods for Non-Intrusive Inspection

Advisory for Method Selection

GE provides assistance in method selection. Depending on the asset, the component to assess and the type of defect to detect, one or more complementary methods of non-intrusive inspections could be recommended.

The selection of methods will take into account the application, the criticality, the history and events occurred. If the inspection requires the use of several advanced non-intrusive methods, they can be performed during the same short planned outage when mandatory.

Expert Diagnosis

In case of defect, the diagnosis can be generated remotely in a few hours by the GE expert. High quality measurement and data generated provides conclusive results which are compared to models created to evaluate the acceptable limits. Those models are developed by GE matter experts from R&D and manufacturing, this expertise in diagnosis is built on 125 years of experience in high voltage equipment engineering.

Maintenance Recommendation

As part of the service, GE provides a comprehensive inspection report including the results, the diagnosis, the expected remaining lifetime of the devices, and a detailed recommendation to plan the necessary maintenance or replacement actions.

Advanced non-intrusive inspection enables deployment of Asset Performance Management (APM) on a fleet of circuit breakers.

Customer Benefits

Cost Effective

- No or reduced planned outage compared to standard inspection of internal components

- Eliminating unnecessary opening of asset

- Minimizing risk of failure

Digitalized Results

- Data is transmitted remotely to expert for analysis

- Centralized data available for asset performance analytics

- Results of asset condition provided in few hours

Safe and Reliable

- 20% reduction in asset failure thanks to the use of non-intrusive methods

- Eliminating risk of failure during reenergizing

- No risk of SF6 leakage

Proven Methodologies

- Models based on +120 years of expertise in equipment design, manufacturing and service.

- Proven experience in diverse industries including rotating machines

- Diagnosis and recommendations delivered by subject matter experts

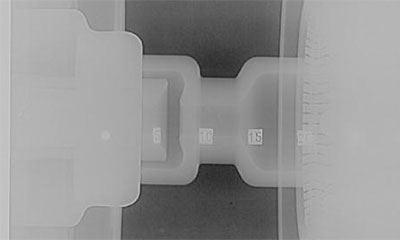

Internal component of the circuit breaker

Internal component of the circuit breaker

Digital X - Ray

Internal component image is printed on a flexible plate and runs through a high resolution (~40µm) laser scanner which reads and digitizes the film. The digital X-ray image produced is viewed and enhanced using powerful image processing software. Contrast, brightness, filtration and zoom can be customized.

Default Detection

Digital X-Ray inspection is suitable to evaluate the condition of aluminum, porcelain or polymer main, arcing and moving components. The defects that can be detected include:

- Damaged or deformed parts: crack and bent components

- Missing or loose components

- Corrosion and inclusion

- Misalignment of components

- Nozzles / Barrier / Resin Insulation

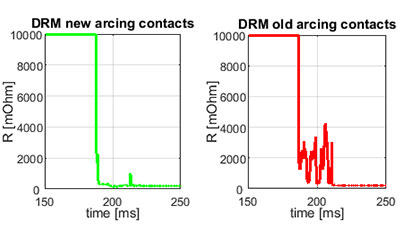

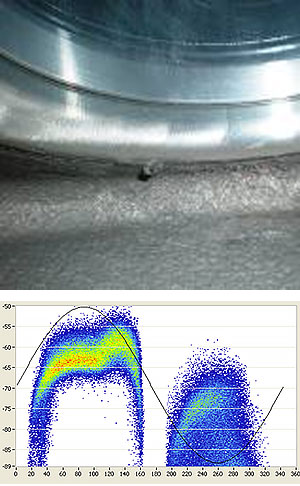

DCRM fingerprints with new contact (left) or ageing (right)

DCRM fingerprints with new contact (left) or ageing (right)

Dynamic Contact Resistance Measurement

Dynamic Contact Resistance Measurement (DCRM) is conducted by injecting a Direct Current through the breaker. The voltage drop is measured when the breaker operates a close-open cycle at rated speed. The acquisition unit then calculates the resistance value. During a phase of the motion, arcing contacts are the only parts which touch, the condition of these contacts can be assess.

Default Detection

The comparison between the pattern reference and the measurement curve supports the condition of the arcing contacts and the breaker chamber moving parts assessment. Any change in dynamic/frictional characteristics of the circuit breaker immediately reflects as a change in the dynamic resistance signature.

DCRM fingerprint deviation indicates various defects including:

- Misalignment of moving parts

- Contact wipe of main and arcing contacts

- Erosion of arcing and main contact

- Mechanical integrity of various components

- Measurement of the arcing contact length

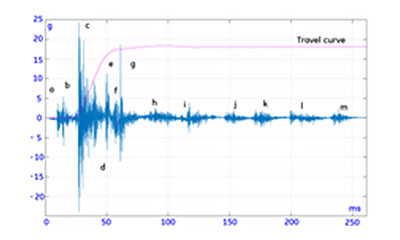

Vibration pattern of an operating mechanism

Vibration pattern of an operating mechanism

Vibration Monitoring

Any mechanical movement in equipment produces sounds and/or vibrations. The resulting signals are propagated to the external structure via various parts of the mechanism and through the interrupting medium. The accelerometers positioned on the external structure of the circuit breaker measure the vibration bursts. As the vibration fingerprints is highly repeatable for a healthy circuit-breaker, a change in dynamic/frictional characteristics immediately reflects a change in the vibration pattern and thus highlights a defect.

Mechanical Fault Detection

The main characteristic of vibration diagnostics is the detection of a change between a vibration fingerprints recorded during operation and the reference.

Typical problems indicated by deviation in the vibration pattern include:

- Over-travel of connecting rids

- Distortion of a drive shaft

- Release of a contact / frame / mobile mechanism

- Hydraulic/spring operating mechanism defect

Example of protrusion

Example of protrusion

Ultra High Frequency (UHF) Analysis

The monitoring of the Gas-Insulated Substation (GIS) insulation health through measurement of partial discharge is the most efficient and competitive solution to prevent potential high repair cost and long downtime.

Principal

Partial discharge is the source of electromagnetic waves in the range of ultra high frequency from 300 to 2000MHz. The signal goes along the GIS and is easily captured by the antenna. Both UHF internal or external sensors can be installed on any type of GIS up to 800kV. The system can monitor SF6 and g³ filled equipment. The frequency spectrum and time analysis of the UHF signal assist supervision of commissioning, operation and maintenance.

The pattern shape supports accurate identification of default type including:

- Presence of particle

- Protrusion

- Coronas

- Free potential

- Insulator void