EPM 4600 Power Meter

Consolidated, Cost Effective, Multiple Point Metering

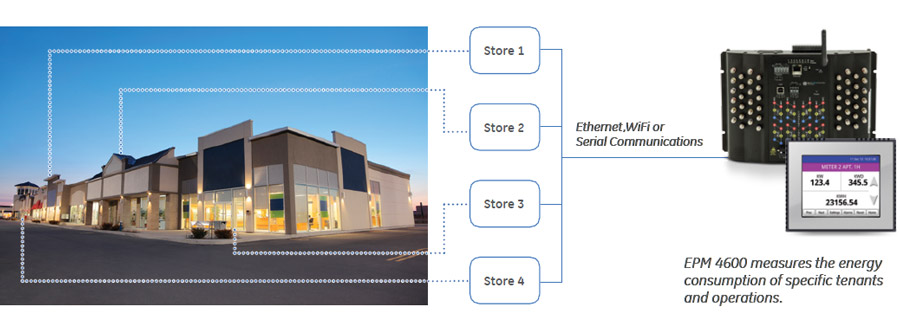

To support and implement an effective energy management strategy, a baseline of energy measurements are required. The Multilin EPM 4600 Multi-feed Power and Energy Meter is a submetering solution that allows owners and operators to quickly, accurately and centrally measure power and energy usage of specific areas to reduce operating expenses. The EPM 4600 empowers users with greater energy awareness leading to improved tenant attraction and retention and greater overall efficiency throughout facilities.

By combining the capability of multiple meters in a single unit, the EPM 4600 provides simple, space saving installation that saves costs over individual meter installations.

Key Benefits

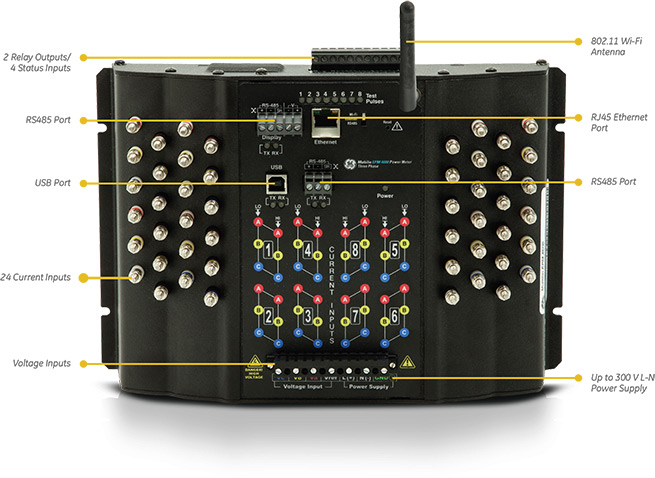

- Simple space and cost saving installation with the capability of measuring 8 – Three phase or 24 – Single phase inputs

- Powerful Ethernet, Wi-Fi, RS485 and USB communications capabilities allowing easy installation in existing or new infrastructure

- Class 0.5% revenue accuracy measurements with comprehensive logging capabilities providing intelligent insight to bill individual sub-tenants for energy usage

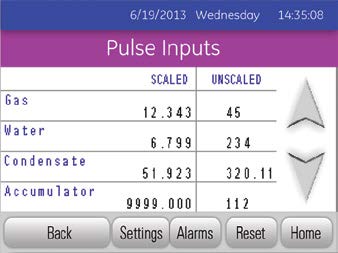

- 4 KYZ pulse counting inputs to aggregate energy information from other devices such as gas, water and steam meter sources and 2 relay outputs for control applications

- Identification of departmental usage costs to specific groups or processes to reduce energy Inefficiencies and carbon footprint through end user awareness and ownership of energy savings

- Support energy management initiatives such as peak demand reduction by identifying peak energy usage periods and initiating energy reduction control schemes at a detailed user level

EPM 4600 Power Meter

Consolidated, Cost Effective, Multiple Point Metering

To support and implement an effective energy management strategy, a baseline of energy measurements are required. The Multilin EPM 4600 Multi-feed Power and Energy Meter is a submetering solution that allows owners and operators to quickly, accurately and centrally measure power and energy usage of specific areas to reduce operating expenses. The EPM 4600 empowers users with greater energy awareness leading to improved tenant attraction and retention and greater overall efficiency throughout facilities.

By combining the capability of multiple meters in a single unit, the EPM 4600 provides simple, space saving installation that saves costs over individual meter installations.

Key Benefits

- Simple space and cost saving installation with the capability of measuring 8 – Three phase or 24 – Single phase inputs

- Powerful Ethernet, Wi-Fi, RS485 and USB communications capabilities allowing easy installation in existing or new infrastructure

- Class 0.5% revenue accuracy measurements with comprehensive logging capabilities providing intelligent insight to bill individual sub-tenants for energy usage

- 4 KYZ pulse counting inputs to aggregate energy information from other devices such as gas, water and steam meter sources and 2 relay outputs for control applications

- Identification of departmental usage costs to specific groups or processes to reduce energy Inefficiencies and carbon footprint through end user awareness and ownership of energy savings

- Support energy management initiatives such as peak demand reduction by identifying peak energy usage periods and initiating energy reduction control schemes at a detailed user level

Application Example: Multi-Tenant Metering

Challenge

In a commercial shopping mall, multiple tenants distributed throughout the building and various building operation elements such as heating/cooling systems, water management, lighting and transportation (escalators/elevators) all consume energy. Often, it is difficult for building owners and operators to know the amount of energy consumed by each element.

Solution

The EPM 4600 provides a multi-feed energy submetering solution that allows owners and operators to quickly, accurately and centrally measure power and energy usage of specific areas. With its extensive communications capabilities, installation of the single multi-feed meter is simple and allows for existing secure Wi-Fi networks to be utilized to perform data collection.

User-Friendly Touch Screen Display

Two Size Options for Flexible Installation

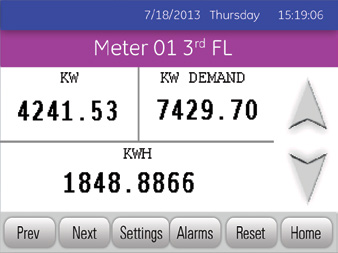

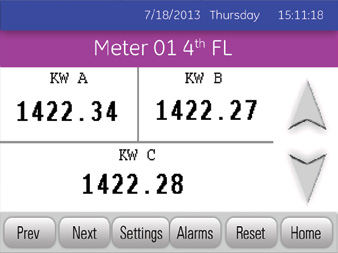

Energy and metering information is easily presented to users via pre-configured, user friendly, optional, touch-screen, color LED displays that connect to the EPM 4600. These low power consumption, 65K color displays are available in two sizes: a larger 5.7” (PL4600-DIS5700) and a smaller 3.5” (PL4600-DIS3500) display.

User-Friendly Installation and Setup

Installation is quick and simple using the included display installation kit and a standardized 22mm panel mount, circular cutout. The lower power consumption display is remotely powered by a supplied 24VDC standard plug power supply. Each display comes with pre-configured screens and communications for plug-and-play, out of the box use. Further customization of the display settings such as changing the default display screen or communications settings are available through on-screen setup menus.

Local and Remote Display Connectivity

Communications to the display are provided via the EPM 4600 RS485 serial communications port and/or optional RJ45 Ethernet port. This allows users the capability and flexibility of installing local or remote displays depending upon visualization requirements.

User Interface: Touch Screen Display

Single Phase Energy Readings (EPM4600-S) KWatts, KW Demand, KWatt-hours

Three Phase Energy Readings (EPM4600-T) KWatts Phase A, KWatts Phase B, KWatts Phase C

Consolidate Pulse Inputs to Measure Various Energy Types

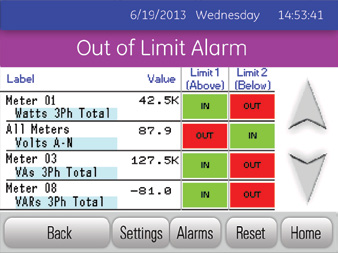

Limit Based Alarms

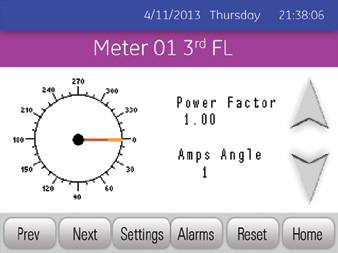

Single Phase Phasor Diagram (EPM4600-S)

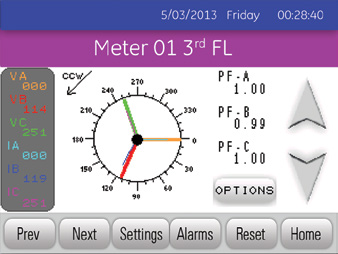

Three Phase Phasor Diagram (EPM4600-T)

User Interface: EPM 4600

Visualize and analyze energy and maximum demand information from the EPM 4600

Visualize and analyze energy and maximum demand information from the EPM 4600

GE Vernova Communicator Software

GE Vernova Communicator connects to meters via serial, Ethernet or modem. It allows users to configure a meter; view real-time metered data and analyze collected information from remote EPM power meters. GE Vernova Communicator works with the entire family of EPM meters: EPM 2200, EPM 4600, EPM 6000 Series, EPM 7000 Series, EPM 9450, EPM 9650, EPM 9800 and EPM 9900 meters.

GE Vernova Communicator displays real time data from supported meters in a user-friendly, simple and powerful graphical format. The software offers many views, including capabilities to display various specific meter functionality such as:

- Voltage, Current, Power & Energy

- Time of Usage & Accumulations

- Power Quality

- Harmonics to the 255th Order

- Actual Real-time Waveform Scopes

- Alarms & Limits

- Max. & Min. for Each Parameter

- I/O Device Information

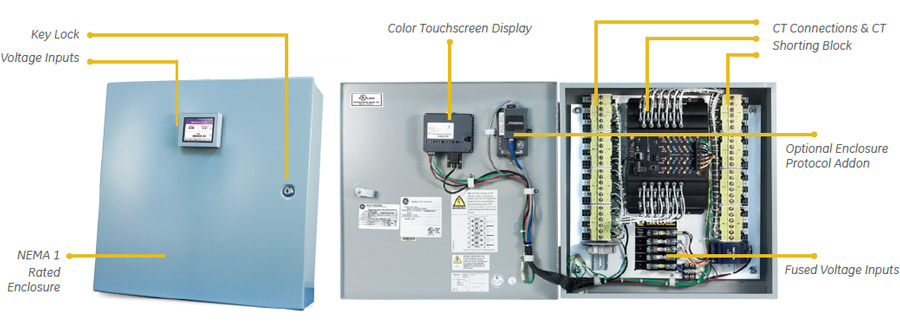

Multilin Meter Enclosure

The EPM 4600 enclosure provides a cost-effective, low commissioning effort solution with the EPM 4600 meter and component factory prewired, tested and configured greatly reducing facility and integration effort. Operator safety and ease of maintenance is provided through the NEMA 1 rating which houses standard components such as voltage fuses and shorting blocks for current transformers. The enclosure solution will work directly with 120/208 and 277/480 Volt power systems.

The enclosure can be ordered with single or three-phase configurations as per the EPM 4600 meter configuration along with the EPM 4600 supported communications (Ethernet, Serial). Optional BACnet®* and LonWorks®* enclosure protocol add-ons enable the EPM 4600 to integrate seamlessly into new and existing Building/Energy Automation Systems (BMS).

Finally the enclosure is equipped with either a user friendly, prewired and configured 3.5” or 5.7” color touchscreen display easing startup and ongoing monitoring. The display provides extensive circuit data for every load, including circuit analysis.

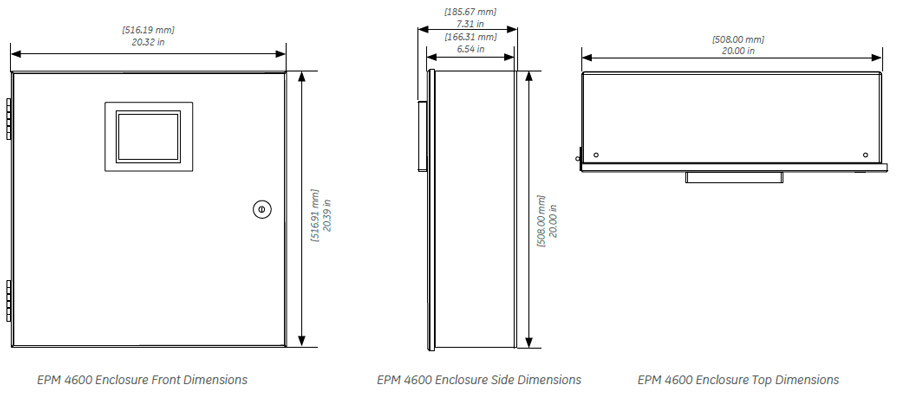

Meter Enclosure Dimensional Drawings

System Requirements

| VOLTAGE INPUTS |

|---|

|

| WIRING |

|---|

|

| CURRENT INPUTS |

|---|

|

| ISOLATION |

|---|

|

| TEMPERATURE RATING |

|---|

|

| SENSING METHOD |

|---|

|

| UPDATE TIME |

|---|

|

| POWER SUPPLY |

|---|

|

| COMMUNICATION |

|---|

| RS485 (COM 1 AND COM 3) |

|---|

|

| ETHERNET/WI-FI (OPTIONAL FOR COM 1) |

|---|

|

| USB (COM 2) |

|---|

|

| SHIPPING |

|---|

|

| METER ACCURACY |

|---|

|

| COMPLIANCE |

|---|

|