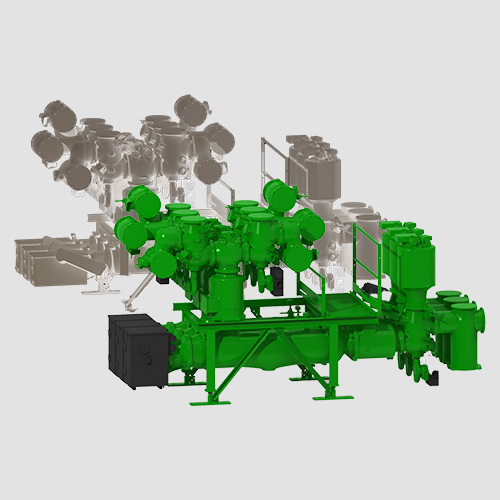

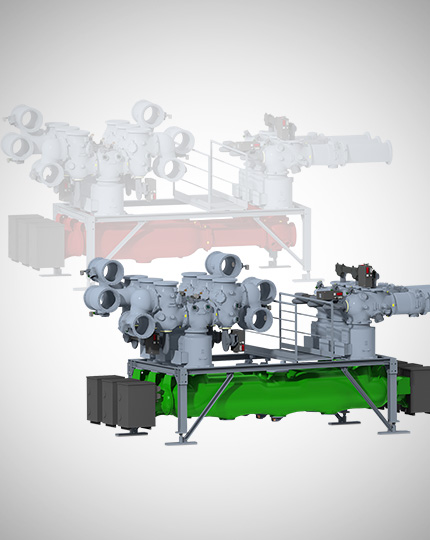

PDP components

Delivering actionable intelligence for improved reliability and efficiency

Sales of the ILMS offering has been discontinued

G's innovative Multilin™ Intelligent Line Monitoring System provides situational awareness along distribution feeders enabling distribution utilities to operate and respond based on prevailing conditions. The system provides utilities with high quality, time coherent data throughout their distribution networks, allowing them to improve performance, reliability and efficiency.

GE Vernova's expertise in distribution networks and system development provides the experience needed to address the utilities challenges and deliver proven and sustainable network performance improvement.

- Provides increased situational awareness along distribution feeders

- Enables utilities to operate and respond based on prevailing feeder conditions, not static or seasonal estimates

- Enables faster response reducing SAIDI and CAIDI indices

- Promotes targeted spend of maintenance funds based on performance instead of age of asset

- Provides the visibility to compute dynamic line ratings based on prevailing conditions

- Enables distribution utilities to better manage their feeders, avoid conductor degradation and knowledgeably deploy sustainable generation

PDP components

Delivering actionable intelligence for improved reliability and efficiency

Sales of the ILMS offering has been discontinued

G's innovative Multilin™ Intelligent Line Monitoring System provides situational awareness along distribution feeders enabling distribution utilities to operate and respond based on prevailing conditions. The system provides utilities with high quality, time coherent data throughout their distribution networks, allowing them to improve performance, reliability and efficiency.

GE Vernova's expertise in distribution networks and system development provides the experience needed to address the utilities challenges and deliver proven and sustainable network performance improvement.

- Provides increased situational awareness along distribution feeders

- Enables utilities to operate and respond based on prevailing feeder conditions, not static or seasonal estimates

- Enables faster response reducing SAIDI and CAIDI indices

- Promotes targeted spend of maintenance funds based on performance instead of age of asset

- Provides the visibility to compute dynamic line ratings based on prevailing conditions

- Enables distribution utilities to better manage their feeders, avoid conductor degradation and knowledgeably deploy sustainable generation

Overview

The Multilin Intelligent Line Monitoring System is an end-to-end line monitoring solution with advanced analytics that provides actionable intelligence to distribution utilities to improve the reliability and efficiency of their networks.

Analytical Applications

- Feeder visualization

- Fault detection, location and analysis and maintenance prioritization (Multilin X-NET)

- Dynamic line rating calculation and analysis (Multilin T-NET)

Line Sensors

- Provides periodic time synchronized measurements to facilitate improved situational awareness and operations:

- Electrical current, both amplitude and phase

- Conductor surface temperature

- Detects fault conditions facilitating rapid identification and notification

Sensor Network Gateway (SNG)

- Acts as a communications gateway for distribution network and weather information critical for supporting advanced applications

- Equipped with a GPS transceiver that synchronizes the entire system, enabling GE Vernova’s advanced analytics

- Provides multiple options for communications backhaul to analytical applications providing installation flexibility

Key Benefits

- Extended visibility into the distribution network

- Reduced cost of ownership with GE Vernova’s sensors designed for easy installation on live networks

- Designed to meet the challenges of capturing faults in both low and high impedance grounding treatments

- Advanced analytical applications enabled by GE Vernova’s patented time synchronized data

- Remote firmware upgrade enabling further application development and compliance with regulatory and operational requirements

- Time synchronized measured data in DNP3 format

Fault Detection, Location and Analysis Application (X-NET Software)

Test Caption

Test Caption

The advanced analytics delivered by the X-NET application are designed to meet the challenges of capturing faults in both low and high impedance grounding treatments. The Intelligent Line Monitoring System delivers the necessary field visibility and advanced analytics to capture and report the location of ground and phase to phase faults as well as cross country faults in high impedance grounding schemes.

Fault Detection, Location & Analysis

- Monitors the distribution network 24/7 for events and faults

- Automatically filters events from faults based on utility defined configuration to avoid nuisance reports

- Identifies fault location alerting operators visually and notifying repair crews via email and SMS messaging

- Provides a cycle by cycle plot of fault activity

Maintenance Prioritization

The X-NET Software enables the utility to effectively prioritize maintenance expenditure by:

- Maintaining a database of events to facilitate identification of repetitive incidences, comparison of feeder performance and definition of preventive maintenance programs

- Graphically depicting outage history for each feeder section

The X-NET Application enables utilities to:

- Target where to spend maintenance funds based on performance instead of age of assets

- Direct field crews to feeder sections where maintenance is needed

- Guide maintenance work required by the nature and frequency of feeder faults indicated by frequent re-closer activity

- Categorize maintenance required based upon repetitive transients indicative of:

- The need for tree trimming

- Salt build-up

- Equipment degradation

Power Transformers Bushings

OIP technology

Oil to air transformer bushings, for the connection to the HV transmission or distribution system

| 36-1200 kV | 52-170 kV | 25-765 kV |

| PNO | PSO | PAO |

Oil to SF6 for the connection to the SF6 metal enclosed bus ducts

| 72,5-1050 kV |

| POBO |

Oil to oil for the connection to the HV cables

| 72,5-1050 kV |

| PCTO |

RIP technology

Resin Impregnated Paper transformer bushings

| 24-550 kV | 72,5-245 kV | 24-52 kV | 72,5-420 kV |

| PNR Oil to air application | PCTR Oil to oil application | PTFR/PTHR Oil to air transformer bushings | POBR Oil to SF6 application |

Power Generator Bushings

RIP technology

Generator High Current RIP bushing up to 30 kV-45000 A

PGFR

Wall Bushings

Gas insulated technology air to air

up to 800 kV AC & DC applications

PWS (AC solution) and PWHS (DC solution)

OIP Technology

Up to 420 kV - PWO

DC converters bushings

Hybrid technology for DC converter bushings (OIP + SF6 up to 1,100 kV; RIP + SF6 above 420 kV)

PHI

GIS bushings

Up to 550 kV

PABS

Technical Specifications

| MULTI-SERVICE PLATFORM | ||

|---|---|---|

| Purpose-built, modular in design with layers of redundancy | ||

| Hot swap of all redundant components without service interruptions | ||

| Utility hardened ensure security and dependability | ||

| Non-blocking architecture | ||

| WIDE AREA NETWORK (WAN) OPTIONS | ||

|---|---|---|

| Optical WAN | Capacity | 24Gbps |

| Number of 10G Optical WAN ports | 2, SFP+, (up to 80km) | |

| Number of 1G Optical WAN ports | 4, SFP | ||

| NETWORK MANAGEMENT | ||

|---|---|---|

| Management | Device management | embedded Management System (eMS) |

| Network management | Optional Advanced NMS | |

| High availability mode | 1+1 protected | |

| Console port | USB | |

| Inbound / Outbound interfaces | CLI, WebUI (HTTPS), SNMPv3 *, NetConf | |

| PERFORMANCE | ||

|---|---|---|

| CORE Hardware protection | 1+1, 20G bypass | |

| Processors | Dual, Dedicated separately for Data (DP) & Management (eM) plane | |

| Transport Protocol | MPLS-TP, RFC 5654 | |

| Encapsulation | WAN-Interface Sublayer (WIS) (on/off) | |

| Quality of service | IEEE 802.1p/q with priority queues and priority scheduling | |

| Node transit delay | < 30 μs | |

| Switching | Capacity | 66G |

| Fabric | Redundant | |

| Backplane | Passive | Yes |

| Client services | TDM and Ethernet | TDM: Emulated TDM over PSN (CESoPSN,SAToP) Ethernet: E-Line, E-Tree and E-LAN Ethernet Virtual Connections, configurable max frame size (up to 12,000 bytes), 32k MAC addresses per node |

| Packetizer | T1/E1/CBUS TDM ports | 8 |

| Synchronization | WAN Synchronization method | SyncE |

| Internal Modes | Headend with SSM, Freerun | |

| Accuracy | 4.6ppm | |

| External modes | 2KHz, 10MHz, 1PPS, GPS * | |

| Quality | SSM, ESMC * | |

| Timing | Timing Protocols | NTP, IEEE 1588v2 (telecom and power) * |

| Accuracy | 1us, Grandmaster (1588v2) * | |

| OAM | Fault Detection | LDI, 256 HW-assisted BFD per CORE |

| Protection Switching | 1+1: <3 ms on fiber break, ~0 ms on CORE module extraction 1:1: <16 ms on fiber break, <50 ms on CORE module extraction | |

| SECURITY | ||

|---|---|---|

| Security | EtherWAN encryption engine | 6 independent encryption engines, Optionally enabled on each WAN port * |

| Encryption | AES 256 | |

| Authentication | SHA 256 | |

| Key distribution | Public/Private, User configurable rolling key frequency * | |

| Access Control | Role-based | |

| User Authentication | RADIUS | |

| Accounting | Syslog (local) | |

| Federal Information Processing Standard | 140-2 | |

| CERTIFICATION | ||

|---|---|---|

| Industry Compliance | SAFETY, UL, EU, CSA | UL 60950-1, ETSI EN/IEC 60950-1, CAN/CSA C22.2, RCM (Australia) |

| Conducted and Radiated emissions | FCC Part 15B, CISPR/EN 55022, EN 300 386, VCCI, AS/NZS CISPR 22, CNS13438, and KN 22 | |

| Immunity | EN 55024, EN 300 386 and KN 24 | |

| Power Substation | IEEE 1613 (no cooling fans) | |

| Hardening | IEEE 1613 (no cooling fans), SWC, EMI, RFI & ESD | |

| Environmental | Operating Temperature | -20°C to + 60°C |

| Storage Temperature | -40°C to +70°C, IEC60068-2 | |

| Humidity, %RH | 5 - 95%, non-condensing | |

| Altitude | 3000m | |

| Earthquake | NEBS ITL GR-63-CORE Issue 4* | |

| RoHS | RoHS / WEEE | |

| POWER MANAGEMENT | ||

|---|---|---|

| Power | DC | 48/130 VDC (ungrounded or +ve grounded), isolated inputs, hot swappable |

| AC | 120/240 VAC, 50/60 Hz, hot swappable | |

| Redundant | Yes | |

| Consumption | 160W, Overcurrent protection at 180W per power supply | |

| ACCESS CARD INTERFACES | ||

|---|---|---|

| Access Card interfaces | Number of Access slots | 16 |

| Hot swappable | Yes | |

| 4 x GigE slots | 3 | |

| EF-4A | 4 x 1G/FE fiber ports, SFP, per-port configurable native VLAN ID | |

| EC-4A | 4 x 10/100/1000 Mbps copper ports, RJ-45, per-port configurable native VLAN ID | |

| GigE slots | 6, using EF-4A and EC-4A units | |

| TDM slots | 4 (16 if xTDM-8A cards are used) | |

| T1E1-4A | 4 x T1/E1 ports, RJ-48c, G.704, G.706, G.826 E1 formats: PCM30/CAS, PCM31/CCS, Unframed | |

| CBUS-4A card | 4x CBUS ports, RJ-48C | |

| xTDM-8A | 8 x T1/E1 ports (G.704, G.706, G.826) or 4 x CBUS ports, RJ-48c * | |

| 64kbps slots | 10 | |

| C3794-1A | 1 x IEEE C37.94, mmf/smf, N x 64 kbps (N=1…12), SFP, LC connector | |

| C3794-4A | 4 x IEEE C37.94, mmf/smf, N x 64 kbps (N=1…12), SFP, LC connector | |

| DR-1A | 1 x RS-232/V.24/V.28 (up to 38.4 kbps) or 1x G.703 64 kbps codirectional | |

| DR-4A | 4 x RS-232/V.24/V.28 (up to 38.4 kbps) or 1 x G.703 64 kbps codirectional | |

| G703D-4A | 4 x G.703 64 kbps codirectional | |

| DTT-2A | 2 x DTT Tx/Rx @48VDC. 130VDC, 250VDC | |

GridNode Microgrid Solution Functions

Control Functions

Customer Benefits Include:

Autonomous Control and Flexibility

Planned And Unplanned Islanding

- Ability to transition between the Grid-connected mode and Islanded mode

Resynchronization

- Ability to seamlessly transition from the Islanded mode to the Grid-connected mode

Power Exchange at POI

- Ability to dispatch microgrid resources in order to manage power flow at the POI

Frequency Control

- Coordinate dispatch of various DERs to control the frequency of the island and control power flow during Grid Connected Mode

Power Factor Management

- Ability to dispatch microgrid resources to manage power factor at a reference point (e.g., POI)

PV Firming

- Ability to provide a firm the PV output on a real time basis

Voltage and Frequency Support

- Ability to dispatch microgrid resources in order to support the Voltage or Frequency of the Grid

Load Sharing

- Ability to control microgrid resources to regulate feeder voltage or the voltage at a reference point on the grid

Reserve Capacity Management

- Managing the reserved capacity of the microgrid to enhance remaining life of the island

Voltage Control

- Coordinate dispatch of various DERs to control the voltage of the island and control power flow during Grid Connected Mode

PV Curtailment

- Ability to curtail PV output to manage the power generation of the microgrid

Load Forecasting

- Ability to generate a day-ahead load forecast for optimal dispatch planning

Optimization Functions

Customer Benefits Include:

Energy savings, renewables enablement, emissions reduction

Optimal Dispatch

- Simplified/easy to use mode based DER optimal dispatch function

- Optimization Modes: Economics, Priority, Max Time of Life and Peak Shaving

- Incorporates load and renewable generation forecast

- Incorporates Grid Pricing

- Manages Reserve Capacity and BESS State of Charge

- Ability to consider Power Export and Grid Services

Microgrid Energy Management System (MEMs)

Customer Benefits Include:

Ability to actively manage, schedule, plan, and monitor your optimal dispatch plan

Energy Optimization Platform

- Optimization Modes: Economic Dispatch, Peak Shaving, Minimize Emissions, Minimize Grid, Maximize Time of Life, and Maximize Renewables

- Provides a day-ahead (24hr) schedule, with 15min granularity

- Incorporates load and renewable generation forecasts

- Incorporates Grid Pricing

- Optimizes across DERs and Loads

- Manages Reserve Capacity and Battery SOC (Hard and Soft Limits)

- Provides Event Based Optimization changes

- Ability to compare various optimization scenarios prior to activating

- Ability to consider Power Export and inclusion of grid services

Advanced Functions

Customer Benefits Include:

System Reliability

Seamless Unplanned Islanding (FLS)

- Ability to perform adaptive fast load shedding to facilitate seamless unplanned islanding for reliability-centric microgrids

Market Participation

Customer Benefits Include:

Revenue Generation and Renewables Enablement

Market Participation

- Ability to integrate your system into the energy markets

Services

GE Vernova's engineering and consulting services team provides a wide range of capabilities to assist you with implementing your microgrid project.

Our dedicated team of experienced engineers can provide end-to-end solutions or specific activities based on the specific project requirements. From new installations to understanding the best way to upgrade an existing system, GE Vernova’s engineering team has been trusted to analyze, design and implement modern power systems. Our broad range of services include activities such as:

Markets Served

GE Vernova's Projects teams serve a number of different market verticals including:

Utility Transmission Substations

GE Vernova leads the North American industry in successful completion of sophisticated and critical electric transmission projects varying from 69kV to 500kv. Typical project types include:

- Greenfield substations

- Capacity upgrades

- Bay additions

- Transformer and circuit breaker change-outs

- Bus reconfiguration and expansion (BAAH, Ring Bus)

- SCADA and protection and control upgrades

Industrial Substations

GE Vernova's solution is specifically engineered to provide the highest reliability possible, including redundant service if required. GE Vernova has extensive design and construction experience in building new or upgrading existing industrial substations including:

- Oil & Gas

- LNG/Petrochemical

- Metals & Mining

- Steel/paper/cement

Utility Distribution Substations

GE Vernova offers a wide variety of distribution substation solutions, varying from 12kV to 69kV, that incorporate the latest GE Vernova technologies and a modular design that allows for standardization and scalability to cover small, medium and large distribution substations upgrades. Typical project types include:

- Greenfield substations

- Transformer and circuit breaker change-outs

- SCADA and protection and control upgrades

Renewable Substations

(Wind & Solar)

GE Vernova provides Electrical Balance of Plant (EBoP) for wind and solar grid interconnect with a full line of solutions, products and services to support the development, design, installation and operations of renewable generation facilities. GE Vernova has designed and constructed nearly 10% of the wind generation connected to the North American grid.

Multi-year Upgrade Programs

GE Vernova provides multiyear programs to utilities and customers for a range of project types. A program approach is generally used for a group of projects that have a set criteria, common goals or anticipated results. For example, a customer may need to replace specific equipment or upgrade systems at multiple substations over an extended period of time. Typical project types can include:

- Protection and control hardware upgrades

- New or existing communications and SCADA upgrades

- Replacement of specific switchyard equipment, including transformer and circuit breaker change-outs

Modular Protection and Control System

GE Vernova's Modular Protection and Control System provides a flexible and fully integrated modular solution set comprised of engineering, design, manufacturing assembly, wiring, testing and commissioning support for protection and control of power system applications. The system is built on an advanced GE Vernova product base and features seamless integration with legacy and multi-vendor devices and systems.

For more information on GE Vernova’s modular Protection and Control system, visit the Packaged Solutions webpage.

Generation

Fully integrated sub-system solutions for protection and control of generators with sizes ranging from tens of KWs to hundreds of MWs

Transmission

Pre-designed modular protection, control and automation solutions for transmission system assets such as transmission lines, bus-bars, large transformers and capacitor banks

Distribution

Expandable modular solutions for assets within a distribution substation, e.g. transformers, breakers, cap-banks, and assets outside the 'substation fence', e.g. reclosers

Power Utilization and Automation

A wide variety of modular metering, automation, industrial process protection and control solutions for commercial and industrial customers

Generator Protection and Control Solution

- Leverages advanced GE Vernova protection relays

- Fully integrated, tested packaged solution

- High quality workmanship and accelerated delivery cycles

Advanced Bus Protection and Control Solution

- Pre-designed, configurable advanced protection schemes

- Bus differential protection and control package

- Engineered solutions for custom transmission applications

Pre-designed Distribution Solutions

- Pre-designed modular protection and control solutions for distribution applications such as feeder, transformer and breaker

- Designed for indoor or outdoor applications

- Library of modular designs for common distribution applications

Automation and Industrial Solutions

- Customized RTU solutions for variety of applications

- Supported by large host and IvED protocol libraries

- Fully configured, factory tested solutions

Specialized Technology Applications

Gas Insulated Switchgear Substations

GE Vernova provides Gas Insulated Switchgear (GIS) Substations ranging from 69kV to 500kV for utilities and industrial customers with a full complement of primary and secondary equipment, services and solutions to build and retrofit electrical infrastructure. GE Vernova's compact and modular design minimizes the installation footprint.

IEC 61850 Process Bus Solution

With the unique Multilin™ HardFiber Brick solution, GE Vernova offers customers an alternative to traditional copper wired substation designs that significantly reduces installation costs. This enabling technology creates a reliable high-speed network with the ability to connect and transmit data from the substation to an Advanced Distribution Management System (ADMS) or Energy Management System (EMS). The Multilin HardFiber Brick solution complies to the IEC 61850 global industry standard

Modular Control Buildings

GE Vernova provides electric utility and industrial customers with Modular Control Buildings intended for use in transmission and distribution substations. The Modular Control Building is manufactured in a controlled environment. The panels are wired and cabled to an intertie box that accepts the field cables from the switchyard equipment. The entire building and panels are pretested at the factory and shipped to site to be set on piers or a slab foundation.

F35g

SF6-FREE: g3-Gas-Insulated Substation up to 145 kV

F35

Gas-Insulated Substations up to 170 kV

B105

Gas-Insulated Substations up to 245 kV

B105 Dual Gas GIS

Gas-Insulated Substations 245 kV, up to 63 kA, 4000 A Compatible with SF6 or g³ gas

T155 Dual Gas

Ready for future SF6 gas regulations

T168

Gas-Insulated Substations up to 550 kV

T210

Gas-Insulated Substations up to 800 kV

GCB Portfolio

Equipment for Power Plants from 50 to 200 MW

FKG2S without enclosure

Generator circuit breaker for power plants from 50 to 150 MW

FKG2S

Generator circuit breaker for power plants from 50 to 150 MW

FKG2M

Generator circuit breaker for power plants from 100 to 200 MW

Equipment for Power Plants from 150 to 450 MW

FKG1N without enclosure

Generator circuit breaker for power plants from 150 to 300 MW

FKG1N

Generator circuit breaker for power plants from 200 to 300 MW

FKG1F

Generator circuit breaker for power plants from 300 to 450 MW

FKGA2

Generator circuit breaker for power plants from 200 to 450 MW