Generator stator leak monitoring can deliver ROI in spades to your bottom line

John Deyette

November 14, 2025

3-minute read

Prefer to listen?

This audio content was developed with the use of Generative AI.

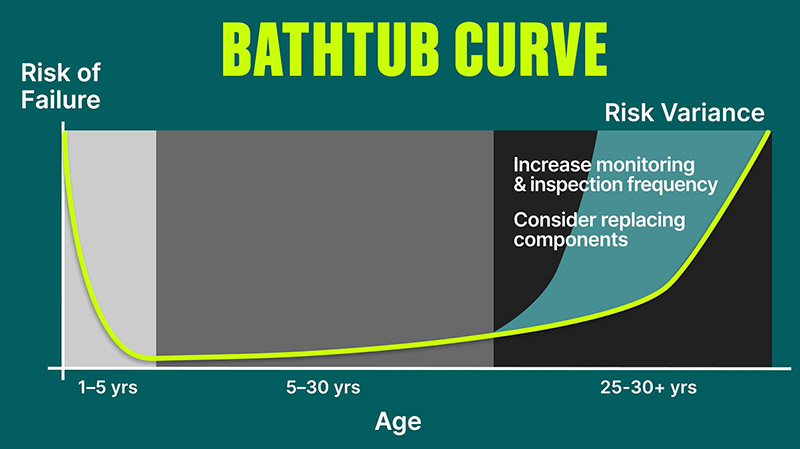

The bathtub curve—a long-standing illustration of probability modeling—spotlights the ways risks of failure can increase exponentially, especially with equipment like a generator late in its life cycle.

Water-cooled generators in fossil plants are built for longevity—typically 30 to 40 years of operation, depending on the site’s load and duty cycle. When these units near the end of that span, risk increases. One of the most common late-life issues is hydrogen leakage into the stator winding. Once a generator passes 25 years of service, the probability of encountering this issue within the next six years climbs to 65%.*

A leak left undetected can cause the windings to run hotter than designed, accelerating insulation breakdown. Over time, that heat stress can lead to stator bar failure, generator core damage, and contamination of the rotating field—the kind of cascading issue that can force an unplanned outage and disrupt operations far beyond the repair itself.

The deeper the damage, the steeper the cost. Beyond repair expenses, every hour of downtime cuts into revenue and reliability. Stator-related failures alone can run into the millions, with costs compounding if the core or field are affected. When left undetected, a single fault can escalate into tens of millions in total impact. This is where software becomes a safeguard—turning data into early warning and prevention into performance.

Once a generator reaches 25 years of age, the probability of experiencing hydrogen leakage within the next six years is 65%*.

By applying sensors and associated components to your generator, you can monitor the unit- in real time- and benefit from an early detection warning of hydrogen leaks. Beyond detection, SLMS enables you to monitor the rate of leakage, which informs operating adjustments that can be made to mitigate damage progression until service can be performed. In parallel, the technology helps maintain the cooling water oxygen level… also delaying further damage and allowing for more planning time to resolve the issue.

By equipping your generator with sensors and supporting components, you can monitor performance in real time and detect hydrogen leaks before they escalate. Beyond detection, SLMS tracks the rate of leakage, giving operators the insight to make short-term adjustments that slow damage progression until maintenance can be scheduled. At the same time, the system helps regulate cooling water oxygen levels, extending asset health and providing valuable lead time for planning repairs.

Your generator’s data can also be shared with GE Vernova’s Monitoring & Diagnostics (M&D) team, who can assess unit health and track any leak’s progression. Prefer to keep data in-house? Your team can monitor generator activity on site, independently and securely.

Installation is straightforward—typically completed within days—and can be integrated easily into a planned outage. In many cases, SLMS insights even shorten outage timelines by reducing the need for on-site stator testing. And if an issue arises before maintenance is scheduled, the system helps minimize downtime and avoid far greater financial risk.

For fossil plant operators managing late life cycle assets, it’s a simple choice: protect performance before problems appear.

Learn more about our stator leak monitoring, and other generator health monitoring capabilities, or contact us for more information.

*Source: GE Vernova engineering

**Requires having Phos-Free stator bars & cx-rings.

On-site Services Specialist, GE Vernova

With 12 years of experience in the energy sector—including a decade with GE Vernova—John Deyette is a specialist in electro-mechanical testing and software technologies. In this role, he manages on site activities including the installation, commissioning, testing and repairs of digital technologies including stator leak monitoring (SLMS). Additionally, he trains plant operators on how to use the SLMS system, and coordinates with engineering specialists to develop enhancements to infuse the latest technologies and address evolving customer needs.

Ready to talk about SLMS for your generator?