Key benefits

Efficiency and flexibility adapted to your plant

Configuration flexibility

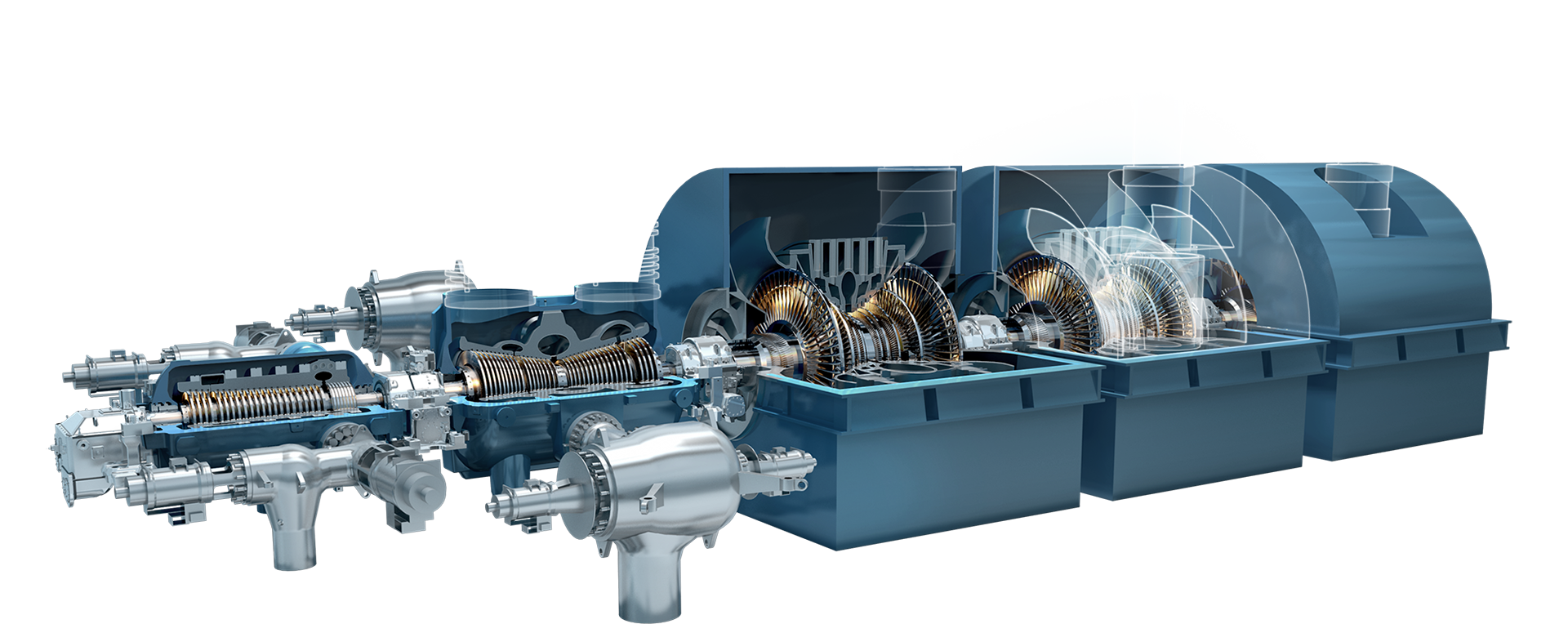

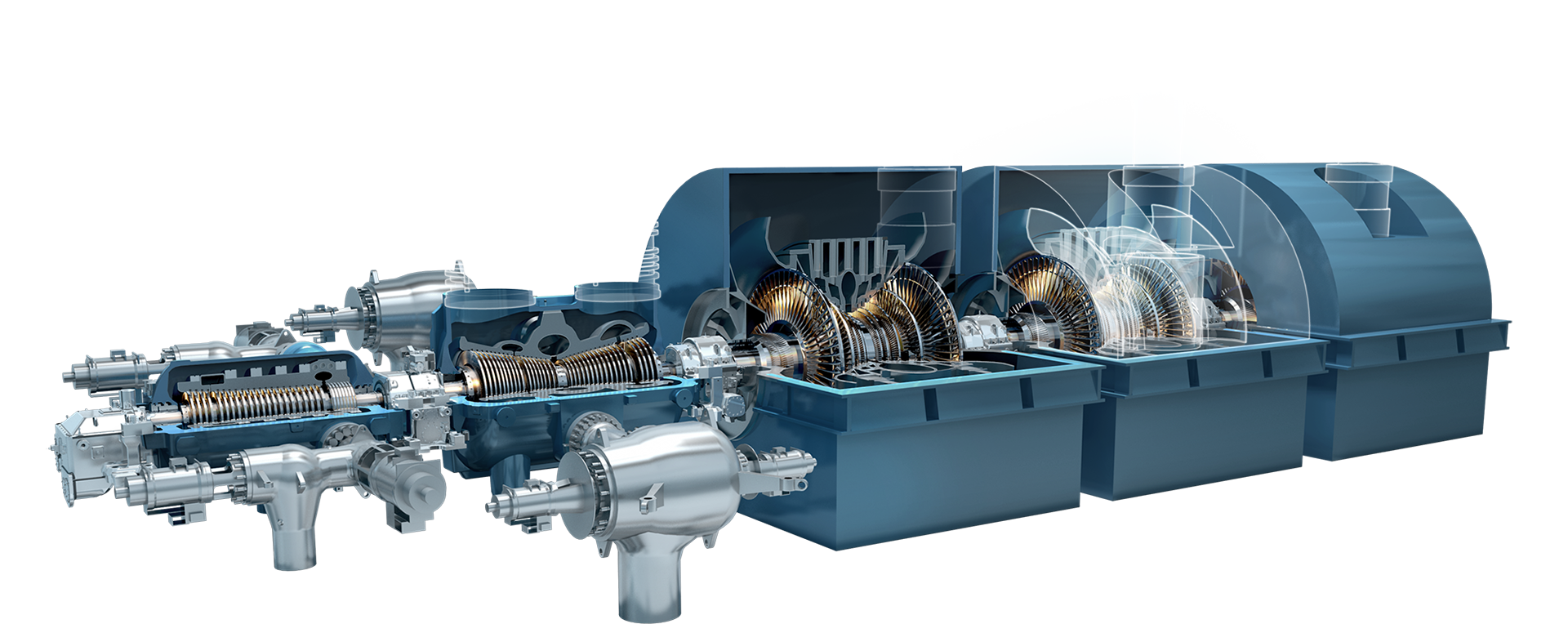

The fully modular architecture facilitates configuration of reheat steam turbines for even the most demanding applications. Options include multiple controlled extractions, overload valves, and a wide range of LP configurations.

Consistent product quality

GE’s extensive knowledge base and experience, combined with rigorously standardized engineering, design and manufacturing processes allow extensive customizing for any application without compromising on quality, lead time, or operating reliability.

Optimized cold end for best performance and cost

GE’s extensive portfolio of modern last stages ranges from 34” to 50” and allows configuration of exhaust areas between 6.5m2 and a massive 72m2. All rear stages feature GE’s proven nub-and-sleeve damping system, which ensures superior damping behavior at any flow condition.

Key features

STF-A1050 and STF-D1050 USC reheat steam turbine platforms

A high-performance reheat steam turbine platform designed to enhance the economics and flexibility of USC boiler plant applications in either 50 or 60 Hz grids.

- Robust and versatile reheat turbines with a successful track record spanning more than 20 years.

- Outstanding configuration flexibility including a wide range of HP and IP module sizes and multiple LP configurations from a single flow to three double flow LP modules as well as internally or externally controlled steam extractions for steam export.

- Cost effective layout options including LP modules with axial or lateral exhausts, which are particularly cost effective for low-level arrangement and outdoor installation

- Time-saving installation thanks to fully assembled HP and IP modules, pre-assembled LP shipping modules, skid mounted auxiliaries, and expansion sleeve type couplings that facilitate alignment and ensure smooth operation

- Overload capacity at constant boiler pressure and reliable trip-free emergency de-loading thanks to optional overload valves and start-up valve (TAL) configurations

- Increased steam turbine efficiency, cycling capacity, and back pressure capability with GE’s unique shrink ring HP module design and GE’s latest nub and sleeve/free tip rear stages with low stress root design

Product specifications

STF-1050 &STF-D1050 product specifications

Specifications shown are for 50 Hz and 60 Hz.

| STF-A1050 | STF-D1050 | |

|---|---|---|

| Main Steam | 300 bar (4,350 psig) | 300 bar (4,350 psig) |

| Main Steam / Reheat Steam Temperature | 600 °C / 600 °C (1,112 °F / 1,112 °F) | 600 °C / 620 °C (1,112 °F / 1,148 °F) |

| Output | 150 - 300 MW | 200 - 1,200 MW |

| Efficiency | ≤ 50% | ≤ 50% |

| Maximum Backpressure | ≤ 700 mbar (20.7 in. Hg) | ≤ 700 mbar (20.7 in. Hg) |

| Control Concept | Sliding pressure mode, Hybrid mode with or without overload valve | Sliding pressure mode, Hybrid mode with or without overload valve |