Multilin 850

Innovative feeder and bay controller in one box

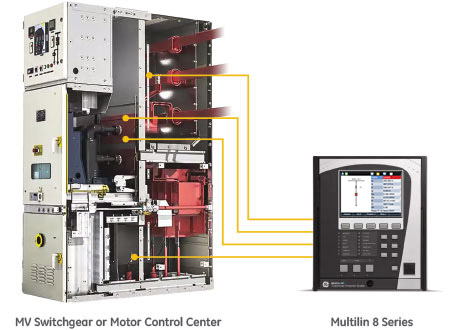

The Multilin™ 850 relay is a member of the Multilin 8 Series protective relay platform and has been designed for the management, protection and control of feeder applications. The Multilin 850 is an integrated, one box solution, used to provide comprehensive protection, control and monitoring of underground and overhead single or dual feeders in industrial and utility power networks.

The Multilin 850 is also an ideal choice for bay control applications, with features including 12 switchgear control elements, a large color graphical display that supports configurable single line diagrams, an integrated annunciator panel, and 20 user configurable virtual pushbuttons.

With support for industry leading communications protocols and technologies, the 850 provides easy integration into new or existing SCADA or DCS for enhanced situational awareness. To simplify the migration and upgrade from an existing SR 750/760 or 735 protection relays, retrofit kits have been developed which significantly simplify the upgrade process.

Multilin 850

Innovative feeder and bay controller in one box

The Multilin™ 850 relay is a member of the Multilin 8 Series protective relay platform and has been designed for the management, protection and control of feeder applications. The Multilin 850 is an integrated, one box solution, used to provide comprehensive protection, control and monitoring of underground and overhead single or dual feeders in industrial and utility power networks.

The Multilin 850 is also an ideal choice for bay control applications, with features including 12 switchgear control elements, a large color graphical display that supports configurable single line diagrams, an integrated annunciator panel, and 20 user configurable virtual pushbuttons.

With support for industry leading communications protocols and technologies, the 850 provides easy integration into new or existing SCADA or DCS for enhanced situational awareness. To simplify the migration and upgrade from an existing SR 750/760 or 735 protection relays, retrofit kits have been developed which significantly simplify the upgrade process.

Multilin 850 Overview

The Multilin 850 is an advanced feeder protection relay that provides high performance protection, high density I/O, extensive programmable logic and flexible configuration capabilities. With protection and control logic, the 850 allows for simplified coordination with upstream and downstream disconnect devices. The Multilin 850 supports both industrial and distribution utility feeders. Dual feeders (850D) and multi feeder (850P) in electrical applications are also supported.

As part of the 8 Series platform of relays, the Multilin 850 shares the advanced communications and cyber security features and EnerVista software suite that is common to the platform. Learn more about the Multilin 8 Series platform.

Comprehensive feeder protection

- One box solution with advanced logic and configuration flexibility to provide comprehensive primary or backup protection, control and monitoring for 2 feeders or for feeders with 2 sets of voltage inputs.

- breaker diagnostics with high-end fault and disturbance recording

- Integrated arc flash detection using light sensors supervised by overcurrent to reduce incident energy and equipment damage.

- High-end cyber security such as AAA, Radius, RBAC and Syslog, enabling NERC CIP requirements.

- Draw-out design simplifies testing, commissioning and maintenance, increasing process uptime.

- Optional Wi-Fi connectivity minimizes system configuration and provides safe relay programming and diagnostic retrieval.

- Patented environmental monitoring, providing visibility to changes in environmental conditions that can affect relay life.

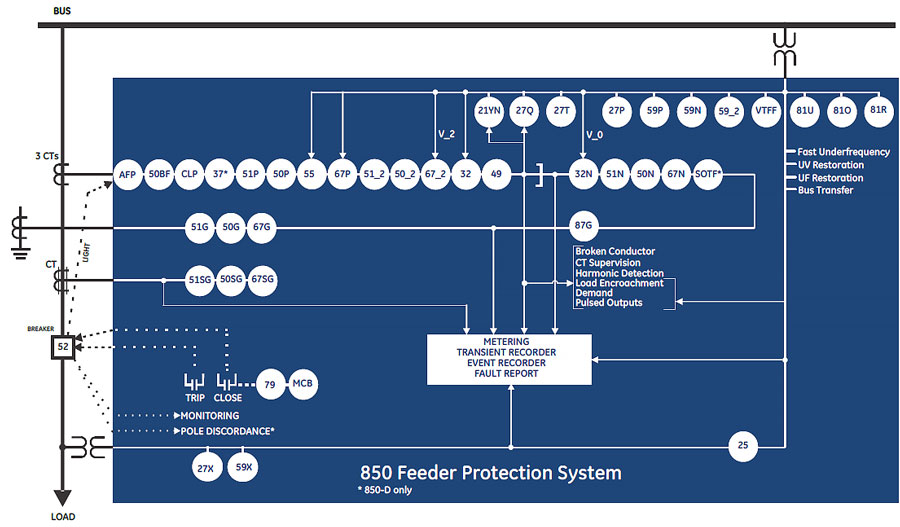

Multilin 850 feeder protection relay functional block diagram

ANSI Device Numbers & Functions

| Device Number | Function |

|---|---|

| 21 YN | YN Neutral Admittance |

| 25 | Synchrocheck |

| 27P | Phase Undervoltage |

| 27Q | UV Reactive Power |

| 27T | Timed Undervoltage Protection |

| 27X | Auxiliary Undervoltage |

| 32 | Directional Power |

| 32N | Wattmetric Ground Fault (Wattmetric zero sequence directional) |

| 37 | Undercurrent |

| 49 | Thermal Overload |

| 50BF | Breaker Failure |

| 50G | Ground Instantaneous Overcurrent |

| 50SG | Sensitive Ground Instantaneous Overcurrent |

| 50N | Neutral Instantaneous Overcurrent |

| Device Number | Function |

|---|---|

| 50P | Phase Instantaneous Overcurrent |

| 50_2 | Negative Sequence Instantaneous Overcurrent |

| 51G | Ground Time Overcurrent |

| 51SG | Sensitive Ground Time Overcurrent |

| 51N | Neutral Time Overcurrent |

| 51P | Phase Time Overcurrent |

| 51_2 | Negative Sequence Time Overcurrent |

| 52 | AC Circuit Breaker |

| 55 | Power Factor |

| 59N | Neutral Overvoltage |

| 59P | Phase Overvoltage |

| 59X | Auxiliary Overvoltage |

| 59_2 | Negative Sequence Overvoltage |

| 67G | Ground Directional Element |

| Device Number | Function |

|---|---|

| 67SG | Sensitive Ground Directional Element |

| 67N | Neutral Directional Element |

| 67P | Phase Directional Element |

| 67_2 | Negative Sequence Directional Element |

| 79 | Automatic Recloser |

| 81O | Overfrequency |

| 81U | Underfrequency |

| 81R | Frequency Rate of Change |

| 87G | Restricted Ground Fault (RGF) |

| AFP | Arc Flash Protection |

| CLP | Cold Load Pickup |

| I1/12 | Broken Conductor |

| MCB | Manual Close Blocking |

| SOTF | Switch Onto Fault |

| VTFF | Voltage Transformer Fuse Failure |

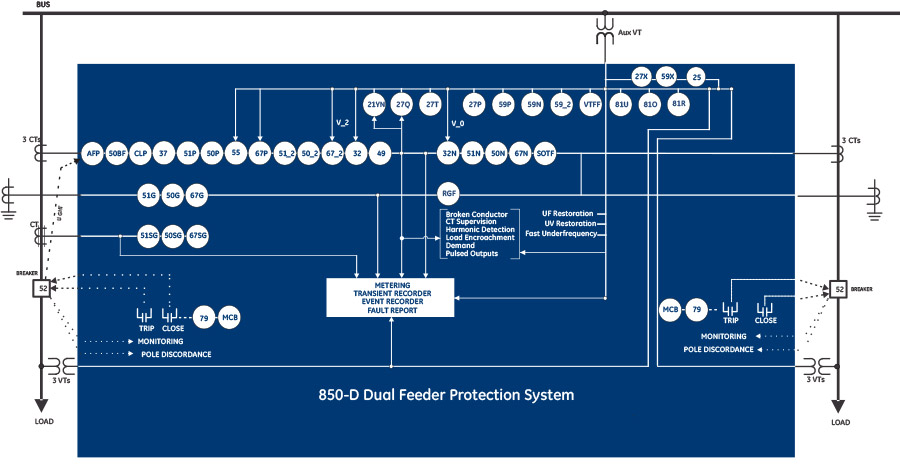

Dual Feeder Protection

The Multilin 850D is designed for high performance protection, control and monitoring of up to two distribution feeders, and provides all the functionalities required for a distribution feeder including SOFT, under current and pole discordance. Extensive programmable logic and flexible configuration capabilities along with sequence coordination enable the 850D to comply with system coordination requirements.

850D key features

- Up to 2 feeders within one relay

- Dual voltage banks with single feeder

- High-end cyber security such as AAA, Radius, RBAC, and Syslog helps enable NERC® CIP requirements

- Draw-out design simplifies testing, commissioning and maintenance, thereby increasing process uptime

- Wi-Fi connectivity minimizes system configuration and provides safe relay programming and diagnostic retrieval

- Relay environmental diagnostic information helps reduce system downtime

Multilin 850D functional block diagram

ANSI Device Numbers & Functions

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* Only for 850D | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

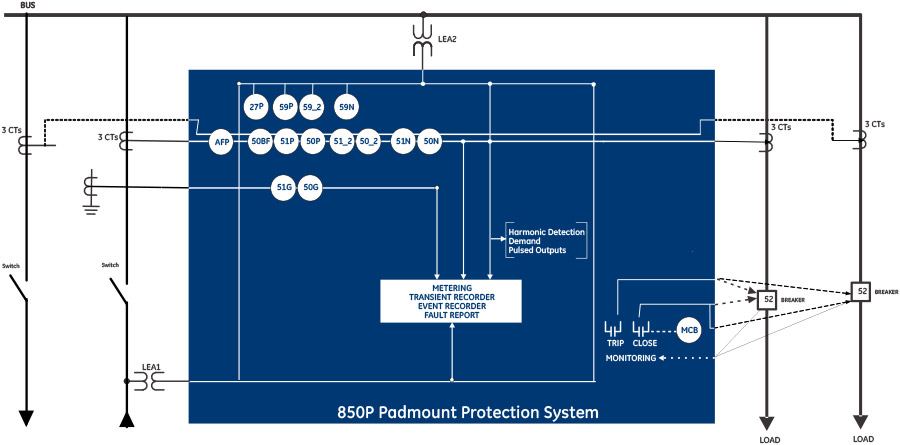

Multi Feeder Protection

Manufacturing for the 850P has been discontinued. As an alternative, please refer to the 850D

The Multilin 850P relay has been designed for the management, protection and control of multi feeder applications supporting both traditional voltage inputs as well as Low Energy Analog (LEA) inputs. A maximum of 4 feeders can be supported by the 850P.

The 850P addresses the following customer challenges:

|

|

Key benefits

- Reduce number of IEDs in the system, resulting in lower capital and O&M costs, and smaller battery sizing

- Mean time to repair less than 15mins with field swappable PSU, draw out construction and ready to consume service reports

- Extend asset life with built-in environmental monitoring, battery and advanced breaker monitoring

- Same device-based solution (850D/P) reduces training needs, standardizes SKUs and harmonizes the user and operational experience

Multilin 850P functional block diagram

ANSI Device Numbers & Functions

|

|

| ||||||||||||||||||||||||||||||||

Note: Ground option is not available for 4 sets of phase protection. | ||||||||||||||||||||||||||||||||||

Fast, reliable arc flash protection with light-based arc flash sensors integrated within the Multilin 8 Series of protection & control devices. With arc flash detection in as fast as 2msec, the costs associated with equipment damage and unplanned down

Fast, reliable arc flash protection with light-based arc flash sensors integrated within the Multilin 8 Series of protection & control devices. With arc flash detection in as fast as 2msec, the costs associated with equipment damage and unplanned down

Monitoring & Diagnostics

The Multilin 850 includes high accuracy metering and recording for all AC signals. Voltage, current, and power metering are built into the relay as a standard feature. Current and voltage parameters are available as total RMS magnitude, and as fundamental frequency magnitude and angle.

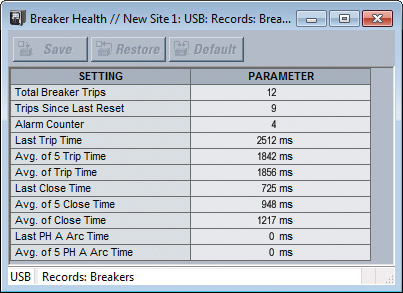

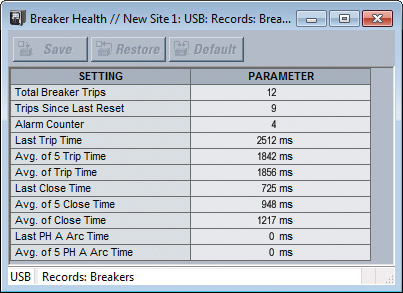

Breaker Health Monitoring

The breaker is monitored by the relay not only for detection of breaker failure, but also for the overall “breaker health” which includes:

- Breaker close and breaker open times

- Trip circuit monitoring

- Spring charging time

- Per-phase arcing current

- Trip counters

Data Logging

The Multilin 850 delivers comprehensive data logging providing the recording of 16 analog values selected from any analog values calculated by the relay. This data capture flexibility allows the operator to measure power factor or reactive power flow (for example), for several hours or even days, enabling detailed analysis and corrective action to be taken.

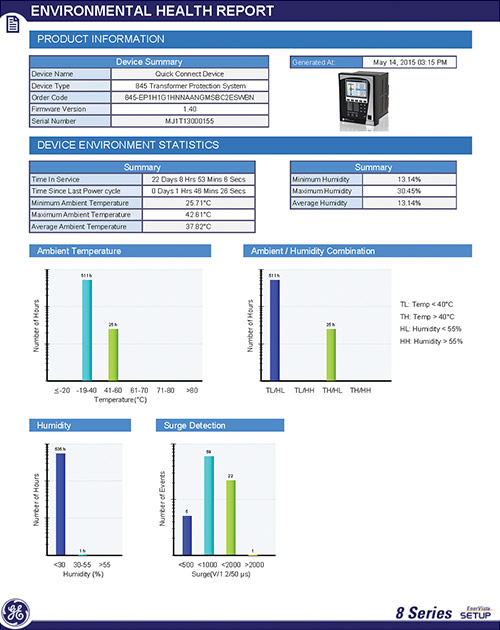

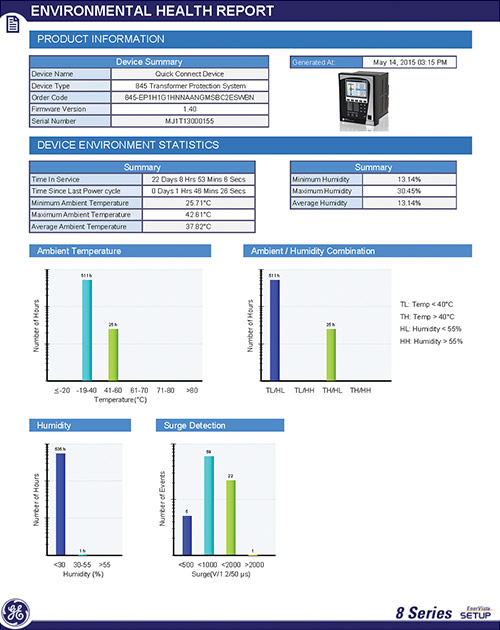

Environmental Monitoring

The 8 Series built-in environmental awareness feature (patent “Systems and methods for predicting maintenance of intelligent electronic devices”) collects the histograms of each operating condition from the point the device is put into service. Monitored environmental conditions include temperature, humidity and transient voltage. These parameters are now available as FlexElement to output alarms in case of limits reached due to Temperature, humidity or surges.

Trip and Close Circuit Monitoring

The 850 relay provides Trip and Close Circuit Monitoring elements

Breaker Arcing Current

This element calculates an estimate of the per-phase wear on the breaker contacts by measuring and integrating the current squared passing through the breaker contacts as an arc. When the threshold is exceeded in any phase, the relay can set an output operand and set an alarm.

Monitoring & Diagnostics

The Multilin 850 includes high accuracy metering and recording for all AC signals. Voltage, current, and power metering are built into the relay as a standard feature. Current and voltage parameters are available as total RMS magnitude, and as fundamental frequency magnitude and angle.

Breaker Health Monitoring

The breaker is monitored by the relay not only for detection of breaker failure, but also for the overall “breaker health” which includes:

- Breaker close and breaker open times

- Trip circuit monitoring

- Spring charging time

- Per-phase arcing current

- Trip counters

Data Logging

The Multilin 850 delivers comprehensive data logging providing the recording of 16 analog values selected from any analog values calculated by the relay. This data capture flexibility allows the operator to measure power factor or reactive power flow (for example), for several hours or even days, enabling detailed analysis and corrective action to be taken.

Environmental Monitoring

The 8 Series built-in environmental awareness feature (patent “Systems and methods for predicting maintenance of intelligent electronic devices”) collects the histograms of each operating condition from the point the device is put into service. Monitored environmental conditions include temperature, humidity and transient voltage. These parameters are now available as FlexElement to output alarms in case of limits reached due to Temperature, humidity or surges.

Trip and Close Circuit Monitoring

The 850 relay provides Trip and Close Circuit Monitoring elements

Breaker Arcing Current

This element calculates an estimate of the per-phase wear on the breaker contacts by measuring and integrating the current squared passing through the breaker contacts as an arc. When the threshold is exceeded in any phase, the relay can set an output operand and set an alarm.

8 Series Retrofit Kit

Retrofit Existing SR 735 or SR 750/760 Devices to the Multilin 850 in Minutes

Traditionally, retrofitting an existing relay has been a challenging, time consuming task often requiring re-engineering, new drawings, panel modifications, re-wiring and re-testing.

The 8 Series Retrofit Kit provides a quick, 3-step solution to upgrade previously installed SR 735 or SR 750/760 Devices. With the new 8 Series Retrofit Kit users are able to install the 850 Feeder Management System without modifying existing cutouts and wiring, and without any drawing changes or re-engineering.

Buy 750/760 to 850 Retrofit Kit

Easy 3-Step Process to Upgrade in as Fast as 21 Minutes

EnerVista 8 Series Setup Software provides automated setting file conversion. Once completed, a graphical report is provided to verify and call out any settings that need attention.

Simply remove the terminal blocks and then remove the SR chassis from the panel. No need to disconnect any of the field wiring.

Insert the new 8 Series Retrofit chassis into the switchgear and simply plug-in the old terminal blocks - there is no need to make any cut-out modifications or push and pull cables.