MM300

Low voltage motor management

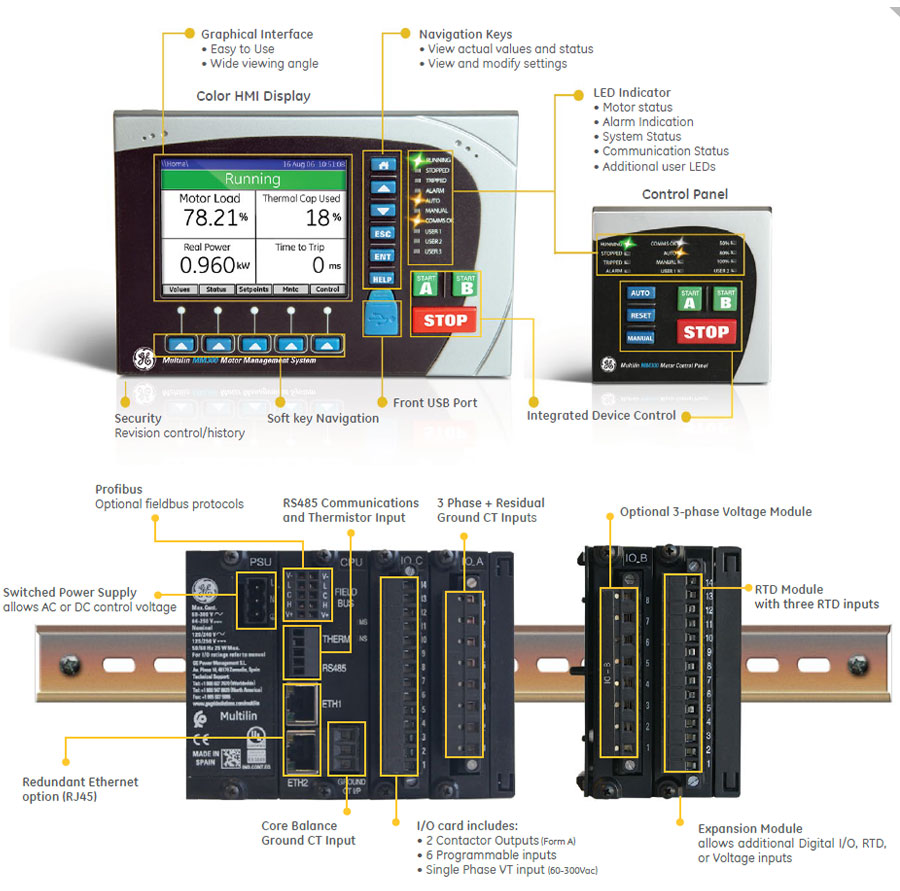

The MM300 integrates protection, control, automation, metering, diagnostics and multiple communication protocols in a rugged compact device for low voltage motor applications. Designed for NEMA and IEC Motor Control Centers, the MM300 delivers superior protection and control to extend equipment life and maximize process uptime.

Key benefits

- Full-featured protection for low voltage AC motors

- Advanced automation capabilities for providing customized protection and integrated process control

- Reduced space requirements through integration of multiple devices

- Application flexibility with multiple I/O options and programmable logic options (FlexLogic™)

- Enhanced troubleshooting tools including sequence of event records, waveform capture, motor start records and motor health report

- Small form factor and remote display options designed to fit in MCC buckets

- Powerful communications including Modbus RTU/TCP, IEC61850 Ed.2, IEC62349-3 (PRP/HSR), IEEE1588 and Profibus protocols

Applications

- Low Voltage three phase AC motors

- MCC or stand alone panel mount applications

- Reversing and Reduced Voltage applications

- Applications requiring Automation or Control i.e. conveyor systems or well recovery pumps

- IEC or NEMA class motors

MM300

Low voltage motor management

The MM300 integrates protection, control, automation, metering, diagnostics and multiple communication protocols in a rugged compact device for low voltage motor applications. Designed for NEMA and IEC Motor Control Centers, the MM300 delivers superior protection and control to extend equipment life and maximize process uptime.

Key benefits

- Full-featured protection for low voltage AC motors

- Advanced automation capabilities for providing customized protection and integrated process control

- Reduced space requirements through integration of multiple devices

- Application flexibility with multiple I/O options and programmable logic options (FlexLogic™)

- Enhanced troubleshooting tools including sequence of event records, waveform capture, motor start records and motor health report

- Small form factor and remote display options designed to fit in MCC buckets

- Powerful communications including Modbus RTU/TCP, IEC61850 Ed.2, IEC62349-3 (PRP/HSR), IEEE1588 and Profibus protocols

Applications

- Low Voltage three phase AC motors

- MCC or stand alone panel mount applications

- Reversing and Reduced Voltage applications

- Applications requiring Automation or Control i.e. conveyor systems or well recovery pumps

- IEC or NEMA class motors

Overview

The MM300 integrates protection, control, automation, metering, diagnostics and multiple communication protocols in a rugged compact device for low voltage motor applications. Designed for NEMA and IEC Motor Control Centers, the MM300 delivers superior protection and control to extend equipment life and maximize process uptime.

Two variants are available within the MM300 range:

- MM300 Enhanced

- MM300 (DeviceNet Application) Manufacturing for the MM300 has been Discontinued. Please contact GE Vernova for availability. As an alternative, please refer to MM300 Enhanced.

The MM300 Enhanced supports higher processing capability which enables advance communication options including latest IEC61850 Ed.2 protocol, Ethernet redundancy according to IEC62359-3 (PRP/HSR) ensuring higher availability and zero loss of data. Other communication options include Modbus serial/TCP & Profibus. The Protection, Monitoring & Control capability has been greatly enhanced with support for Event, Fault, Disturbance recorder, Data logger, Motor Health Records, Motor Learned Data etc. The MM300 Enhanced delivers a host of cybersecurity features that help operators to comply with NIS and NERC CIP guidelines, or other security regulations.

The MM300 Enhanced is built upon the same powerful shared platform as the P40 Agile Enhanced and 8 Series. This encourages mixed usage in projects without additional training needs.

The MM300 (DevcieNet Application) supports standard Motor Protection, Monitoring & Control options. The device is fully scalable, supports various digital input/output options to suit application needs. The device support host of industry protocols including DevicenNet. Other protocols supported include Modbus serial/TCP & Profibus. Only single Ethernet interface is supported as an ordering option.

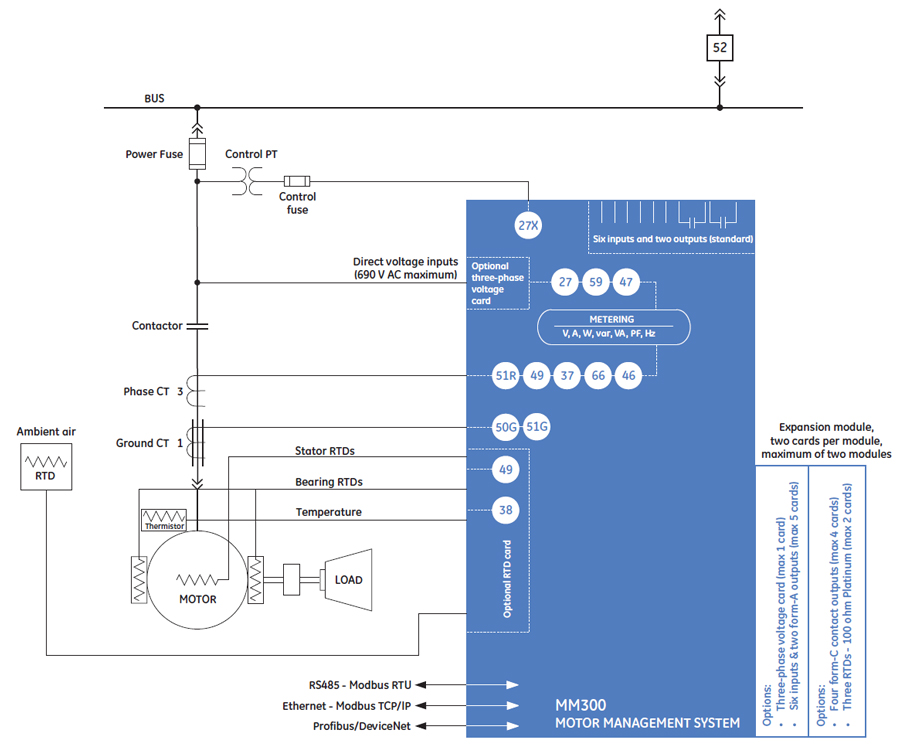

Protection & Control

The MM300 Enhanced is a digital motor protection and control system, designed for Low Voltage motor applications. Flexible and powerful, the MM300 Enhanced’s protection can be scaled to the specific requirements of your system.

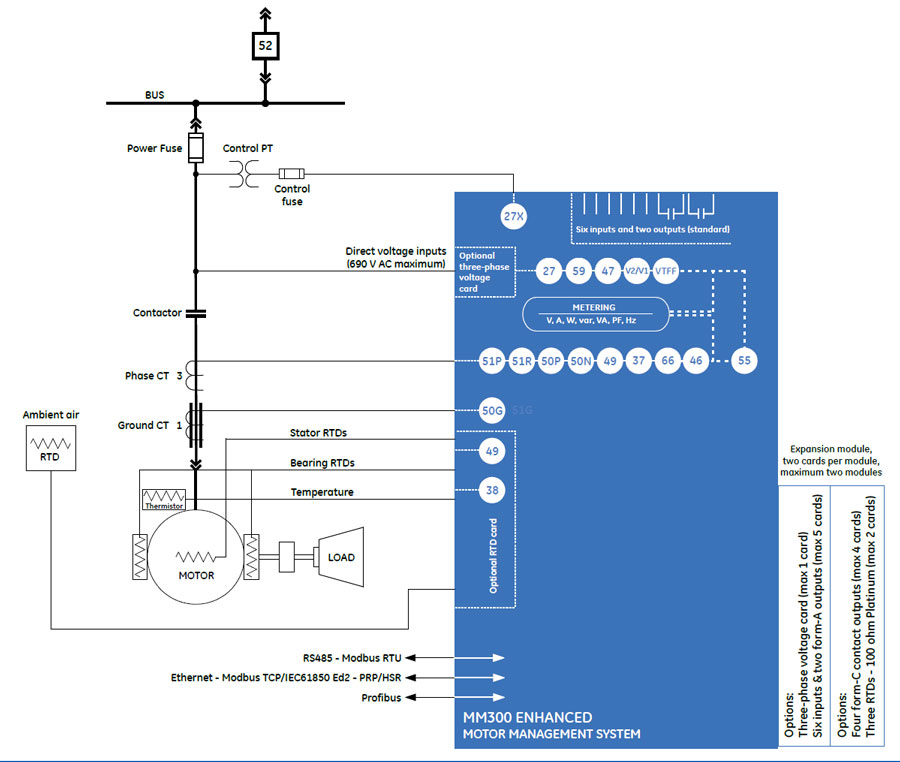

Functional block diagram

ANSI Device Numbers & Functions

| DEVICE NUMBER | FUNCTION |

|---|---|

| 27AUX | Undervoltage - Auxiliary Input |

| 27 | Undervoltage - Three Phase |

| 37 | Undercurrent/Underpower |

| 38 | Bearing Temperature RTD |

| 46 | Current Unbalance |

| 47 | Voltage Phase Reversal |

| 49 | Thermal Overload |

| 50P | Phase Instantaneous Overcurrent |

| 51P | Phase Time Overcurrent |

| 50G | Ground Instantaneous Overcurrent |

| 50N | Neutral Instantenous Overcurrent |

| 51R | Locked/Stalled Rotor/Mechanical Jam |

| 55 | Power Factor |

| 59 | Overvoltage - Three Phase |

| 60VTS | Fuse Failure |

| 66 | Starts/Hour & Time Between Starts |

Key Features

- Metering - current, voltage, power, energy, frequency, power factor, RTD, Thermistor

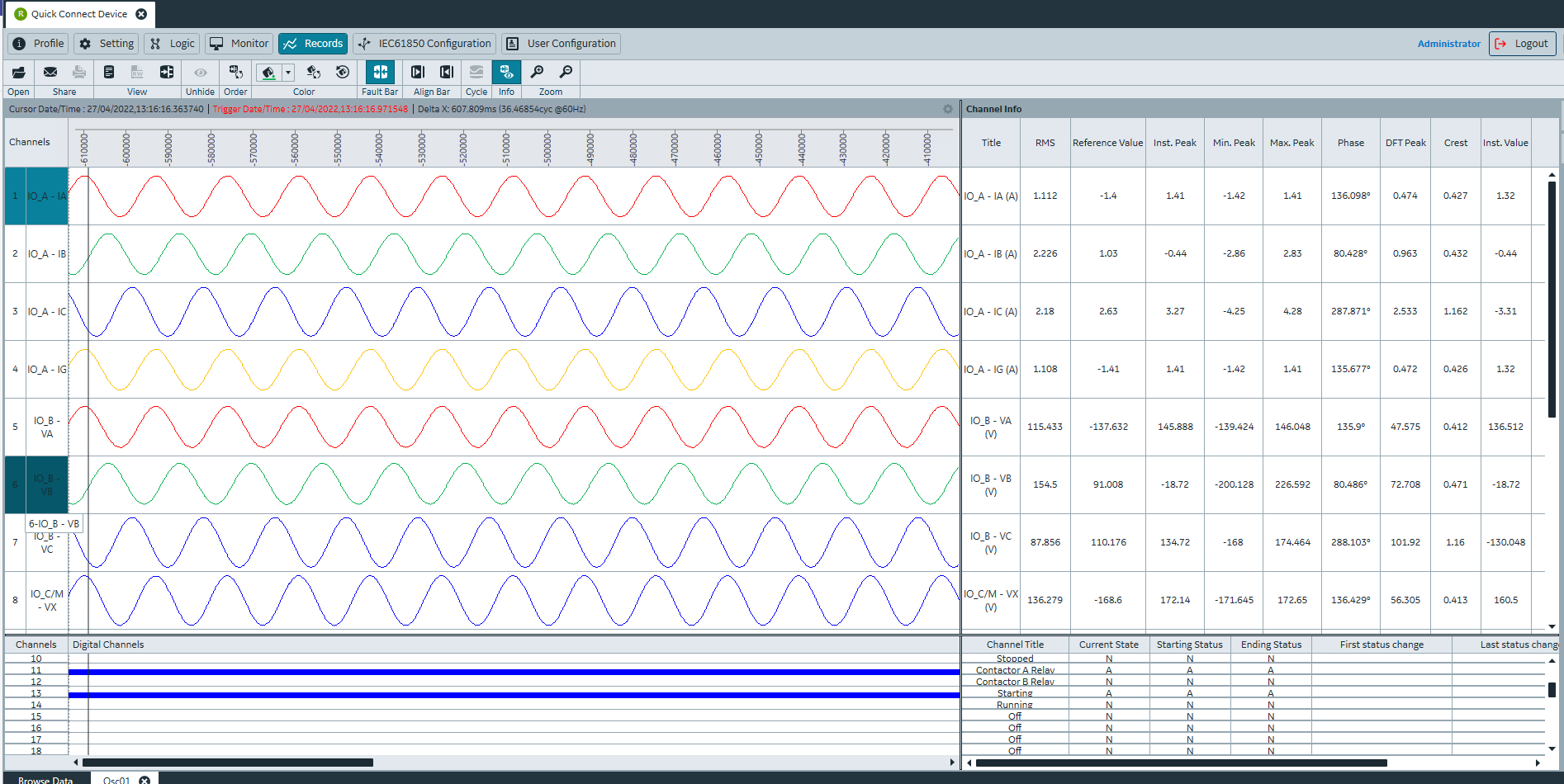

- Oscillography – analog values at 32 samples/cycle and digital states

- Event Recorder - Up to 1024 time tagged events with 1ms resolution

- Fault recorder (up to 5)

- Motor Start records

- Last Trip data

- Data logger

- Advanced Motor Health report

- Advanced Device Health diagnostics

Monitoring & Metering

The MM300 Enhanced includes high accuracy metering for all AC signals, voltage, current, power metering, and temperature all available options. Current and voltage parameters are available as total RMS magnitude and angle

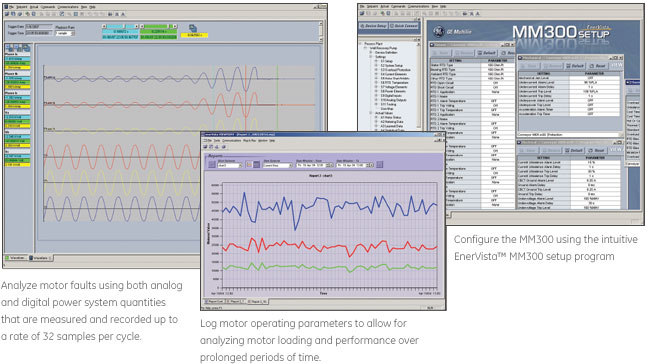

Motor faults analysis using both analog and digital power system quantities that are measured and recorded up to a rate of 32 samples per cycle.

Motor faults analysis using both analog and digital power system quantities that are measured and recorded up to a rate of 32 samples per cycle.

The MM300 Enhanced provides motor start recording in COMTRADE file format. The recording includes thermal profile, phase and ground currents & voltages, current unbalance, real, reactive, and apparent power, frequency, and motor status.

Motor Start Record showing motor operating conditions during starts

Motor Start Record showing motor operating conditions during starts

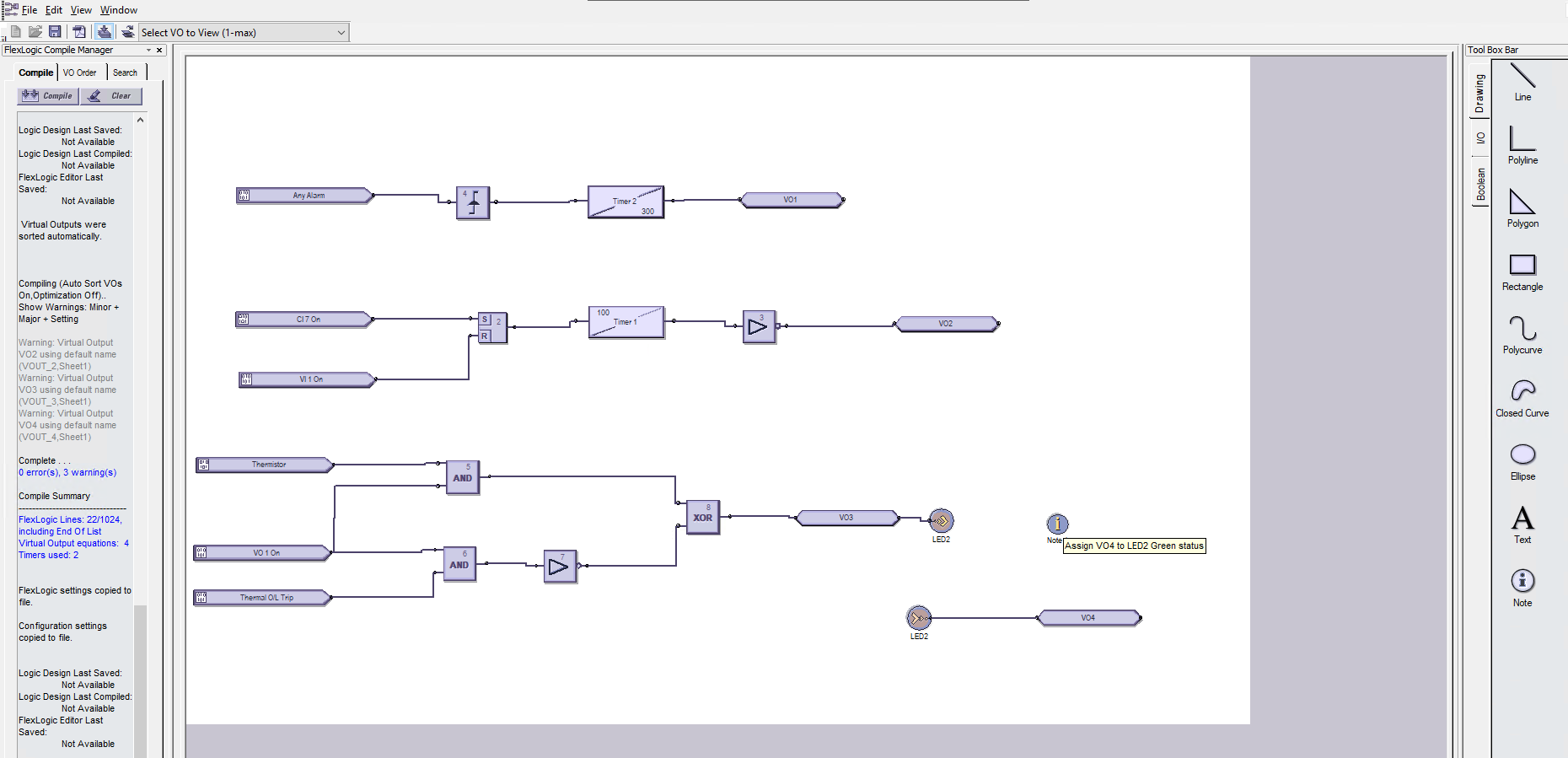

The MM300 Enhanced’s powerful I/O and programmable FlexLogic options offer advanced automation control, reducing the need for additional programmable controllers or discrete control relays.

FlexLogic™ and additional I/O options allow the MM300 to replace local programmable controllers in LV applications.

FlexLogic™ and additional I/O options allow the MM300 to replace local programmable controllers in LV applications.

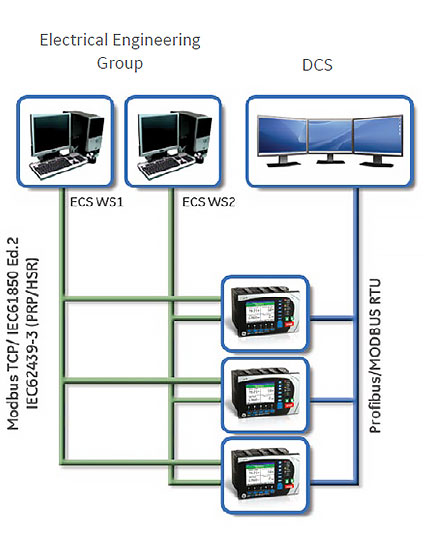

MM300 Enhanced Dual Architecture Communication

MM300 Enhanced Dual Architecture Communication

Communication

Key Features

- Networking Interfaces - Two Wire RS485, up to 2x RJ45 Ethernet

- Multiple Protocols (Modbus RTU, Modbus TCP, IEC61850 Ed.2, IEC62359-3 (PRP/HSR), internally powered Profibus)

- Programming Ports - USB, RS485, RJ45

- Network Time Protocol, IEEE1588 Precision Time Protocol

The MM300 Enhanced supports the most popular industry standard protocols enabling easy, direct integration into HMI and electrical SCADA systems. Modbus RTU and Modbus TCP is provided standard with a RS485 and RJ45 Ethernet networking port respectively.

The MM300 Enhanced can support concurrent operation of Serial, Fieldbus and Ethernet protocols. This enables MM300 Enhanced to communicate with DCS, Electrical Control System simultaneously and Integrate seamlessly with other protection & control devices on station bus. The Ethernet option in a device initially connected with a serial protocol can provision for a future communications upgrade to Ethernet.

User interface

Software

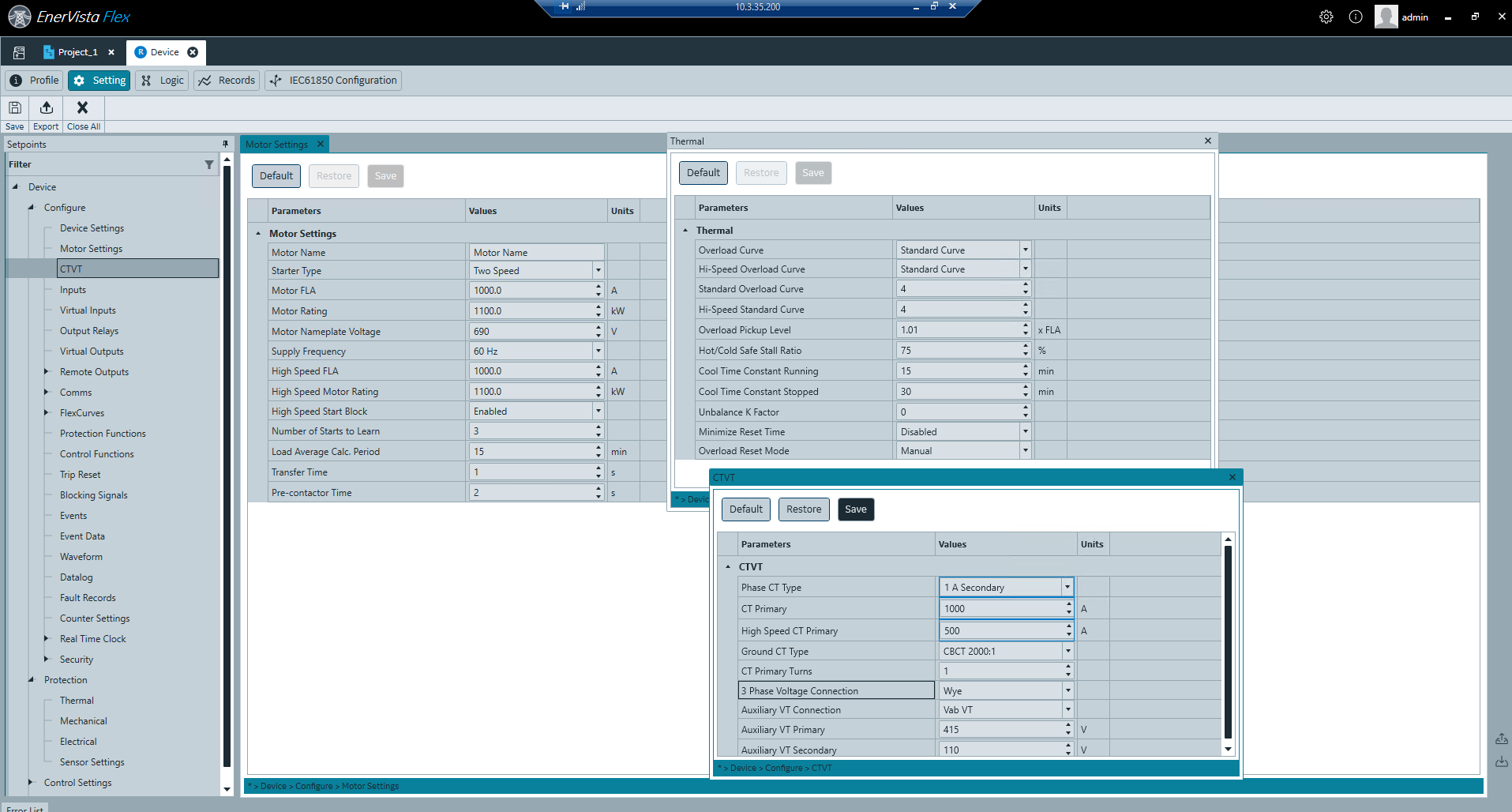

EnerVista Flex Toolsuite

The EnerVista toolsuite provides all the tools to monitor the status of the protected asset, maintain the relay, and integrate information measured by the MM300 Enhanced into DCS or SCADA monitoring systems. Convenient COMTRADE and Sequence of Events viewers are an integral part included with every MM300 Enhanced to carry out postmortem event analysis to ensure proper protection system operation.

Configure MM300 Enhanced using intuitive EnervistaFlex setup program.

Configure MM300 Enhanced using intuitive EnervistaFlex setup program.

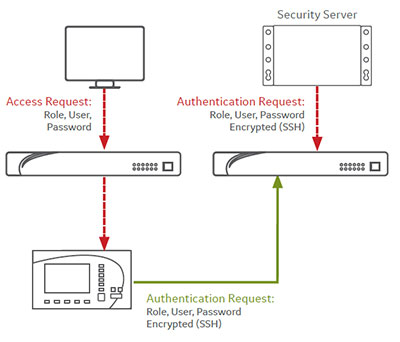

Cybersecurity

The MM300 Enhanced delivers a host of cybersecurity features that help operators to comply with NIS and NERC CIP guidelines, or other security regulations.

- Authentication/authorization/accounting server support (AAA - Radius)

- Role Based Access Control (RBAC)

- Non-erasable cyber event recorder (Syslog for SEM)

Cybersecurity with Radius Authentication

Cybersecurity with Radius Authentication

Protection and Control

The MM300 is a digital motor protection and control system, designed for Low Voltage motor applications. Flexible and powerful, the MM300’s protection can be scaled to the specific requirements of your system. Manufacturing for the MM300 has been Discontinued. Please contact GE Vernova for availability. As an alternative, please refer to MM300 Enhanced.

Key Features

- Enhanced Thermal Modeling

- Mechanical Jam / Stalled Rotor

- Undercurrent

- Underpower

- Acceleration Time

- Current Unbalance

- Ground Fault

- Sensitive Ground Fault

- Phase Overvoltage / Undervoltage

- Auxiliary Undervoltage

- Phase Reversal

- VT Fuse Failure

- Thermistor RTD

- Overtemperature

| DEVICE NUMBER | FUNCTION |

|---|---|

| 27AUX | Undervoltage - Auxiliary Input |

| 27 | Undervoltage - Three Phase |

| 37 | Undercurrent/Underpower |

| 38 | Bearing Temperature RTD |

| 46 | Current Unbalance |

| 47 | Voltage Phase Reversal |

| 49 | Thermal Overload |

| 50G | Ground Instantaneous Overcurrent |

| 50N | Neutral Instantenous Overcurrent |

| 51R | Locked/Stalled Rotor/Mechanical Jam |

| 59 | Overvoltage - Three Phase |

| 66 | Starts/Hour & Time Between Starts |

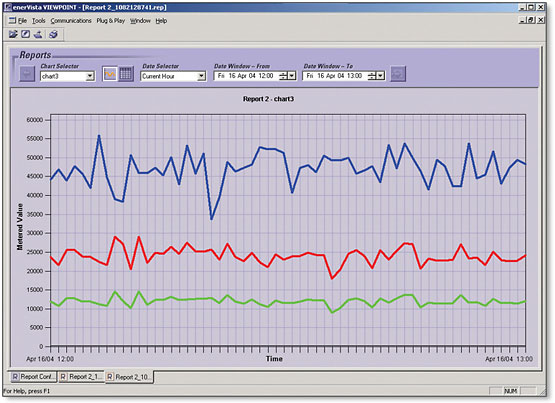

Monitoring & Metering

The MM300 includes high accuracy metering for all AC signals. Voltage, current, power metering, and temperature all available options. Current and voltage parameters are available as total RMS magnitude and angle.

Key Features

- Metering - current, voltage, power, energy, frequency, RTD, Thermistor

- Oscillography – analog values at 32 samples/cycle and digital states

- Event Recorder - Up to 256 time tagged events with 1ms res

- Advanced device health diagnostics

Log motor operating parameters to allow for analyzing motor loading and performance over prolonged periods of time.

Log motor operating parameters to allow for analyzing motor loading and performance over prolonged periods of time.

Advanced Automation

The MM300’s powerful I/O and programmable FlexLogic options offer advanced automation control, reducing the need for additional programmable controllers or discrete control relays.

FlexLogic™ and additional I/O options allow the MM300 to replace local programmable controllers in LV applications, like conveyor belts as in this example

FlexLogic™ and additional I/O options allow the MM300 to replace local programmable controllers in LV applications, like conveyor belts as in this example

Advanced Communications

The MM300 utilizes the most advanced communications technologies available today making it the easiest and most flexible motor protection relay to use and integrate into new and existing infrastructures. Multiple communication ports and protocols allow control and easy access to information from the MM300. All communication ports are capable of communication simultaneously.

The MM300 supports the most popular industry standard protocols enabling easy, direct integration into HMI and electrical SCADA systems. Modbus RTU is provided standard with a RS485 networking port. The following optional protocols and communication ports are available:

Key Features

- Fieldbus Protocol with dedicated port

- ODVA Compliant DeviceNet

- Internally powered Profibus

- Modbus TCP/IP with RJ45 10/100baseT Ethernet port

User Interface

EnerVista™

The EnerVista™ Suite is an industry-leading set of software programs that simplifies every aspect of using the MM300. The EnerVista™ suite provides all the tools to monitor the status of the protected asset, maintain the relay, and integrate information measured by the MM300 into DCS or SCADA monitoring systems. Convenient COMTRADE and Sequence of Events viewers are an integral part of the EnerVista Setup software included with every MM300, to carry out postmortem event analysis to ensure proper protection system operation.