DT1-245P 63

Dead Tank Circuit Breaker for 245 kV / 63 kA

State-of-the-Art Technology

GE Vernova’s DT series of dead tank circuit breakers are characterized by advanced self-blast interrupters, leak-resistant, cast aluminum single piece enclosures and durable, low-energy spring-operated mechanisms. More than 120,000 circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

DT1-245P 63

Dead Tank Circuit Breaker for 245 kV / 63 kA

State-of-the-Art Technology

GE Vernova’s DT series of dead tank circuit breakers are characterized by advanced self-blast interrupters, leak-resistant, cast aluminum single piece enclosures and durable, low-energy spring-operated mechanisms. More than 120,000 circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

Spring-Spring-Operated Mechanism

The reduced energy requirements within the breaking chamber allows for the utilization of GE Vernova’s world class FK spring-spring mechanism. The combination of the proven FK drive mechanism and interrupter technology results in a significant reduction of reaction forces, thereby reducing foundation design requirements.

SF6-Gas Tightness Guarantee

GE Vernova is a leader in the industry in SF6 gas tightness testing technology including seals, castings, and plumbing systems. Each breaker is factory tested using GE Vernova’s proprietary gas tightness testing system which provides measurable, quantifiable test results on the breaker in its fully assembled, as-shipped condition.

Certified Quality

GE Vernova designs, manufactures, tests and delivers its circuit breakers in accordance with the latest IEEE/ANSI and IEC standards, maintaining a quality assurance system according to ISO 9011 and ISO 14001 certifications.

Superior Manufacturing & Domestic Content

The center of excellence for dead tank circuit breakers is located in Charleroi, PA (USA), where dead tank circuit breakers up to 550 kV and live tank circuit breakers up to 800 kV are assembled. The production lines feature high degree of domestic content, which can help to facilitate compliance with national requirements. In addition, the complete wiring and assembling of low voltage control cabinets and mechanism cabinets is done locally, resulting in greater flexibility to respond to utility needs.

Simplified Installation and Maintenance

The DT1-245P 63 model is factory tested and prepared for shipment with bushings assembled and pre-filled with SF6 gas. As a result, the on-site installation requires only a few simple steps without requiring any special tools. The DT1-245P 63 circuit breaker range has lower maintenance costs and requirements owing to an engineering and design philosophy that has focused on these key needs since the inception of the development process.

Specifications

| IEEE/ANSI | IEC | Value | Units |

|---|---|---|---|

| Rated maximum voltage | Rated Voltage | 245 | kV |

| Rated power frequency | Rated frequency | 60/50 | Hz |

| Dry withstand | At power frequency dry | 425/460 | kV |

| Rated Lighning impulse withstand voltage | At lighting impulse | 900/1,050 | kV |

| Rated chopped wave impulse voltage 2 µs | 1,160 | kV | |

| Rated continuous current | Rated normal current | 3,000/4,000/5,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 63 | kA |

| Rated closing, latching and short time carrying | 164 | kA | |

| Rated short-circuit making current | 164 | kA | |

| Rated capacitance switching* | |||

| Rated Interrupting time | 2/3 | cycles | |

| Rated break time | 33/50 | ms | |

| Rated standard operating duty | 0-0,3s-CO-15s-CO |

* Ratings available upon request. Contact GE Vernova for special purpose, high TRV, high X/R or other ratings requirements.

| Technical Data | Value | Units |

|---|---|---|

| Ambient temperature range* | -30 +40 | degree C |

| Seismic withstand in accordance with IEEE 693-2018 | ||

| Creepage distance | 168/4,257 | inches/mm |

| Closing resistor (optional)* | ||

| Weight (without current transformers) | 8,015/3,643 (GO) and 8,894/4,043 (IPO) | lbs/kg |

| Weight of SF6 | 143/65 | lbs/kg |

* Alternate values upon request

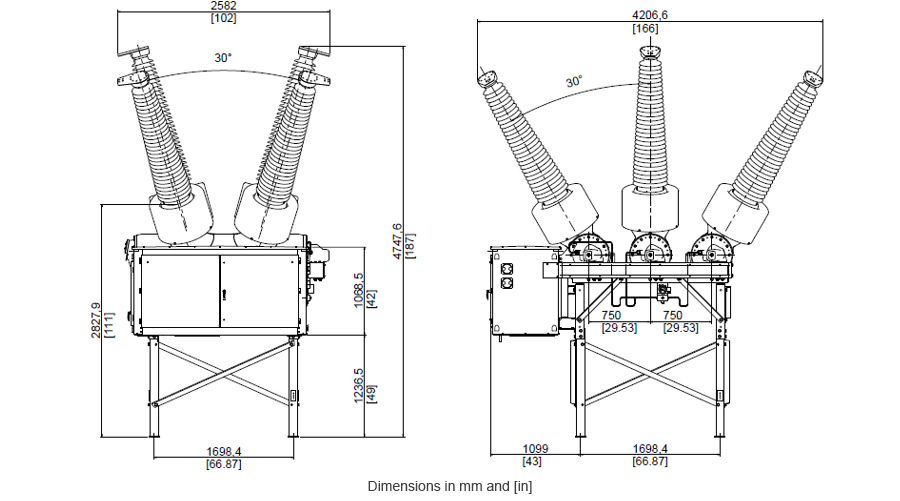

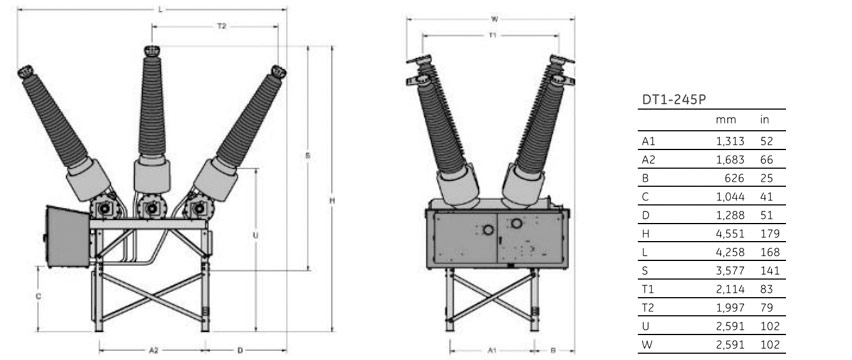

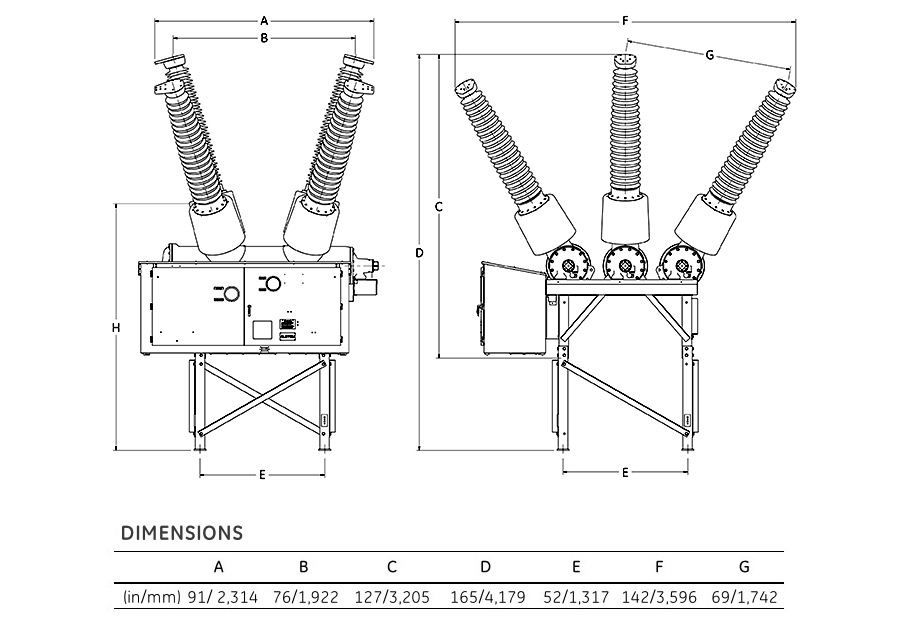

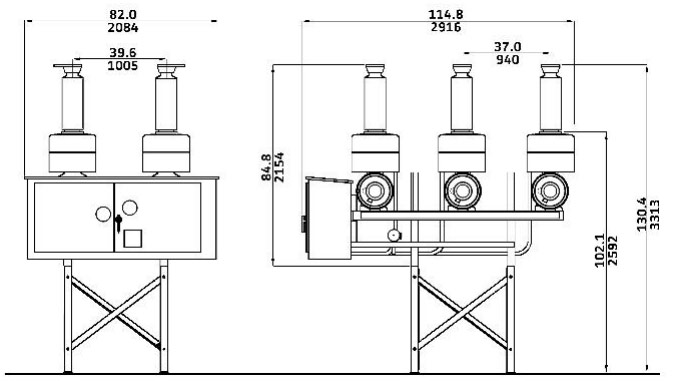

Drawings

Three-pole gang operation

Three-pole gang operation

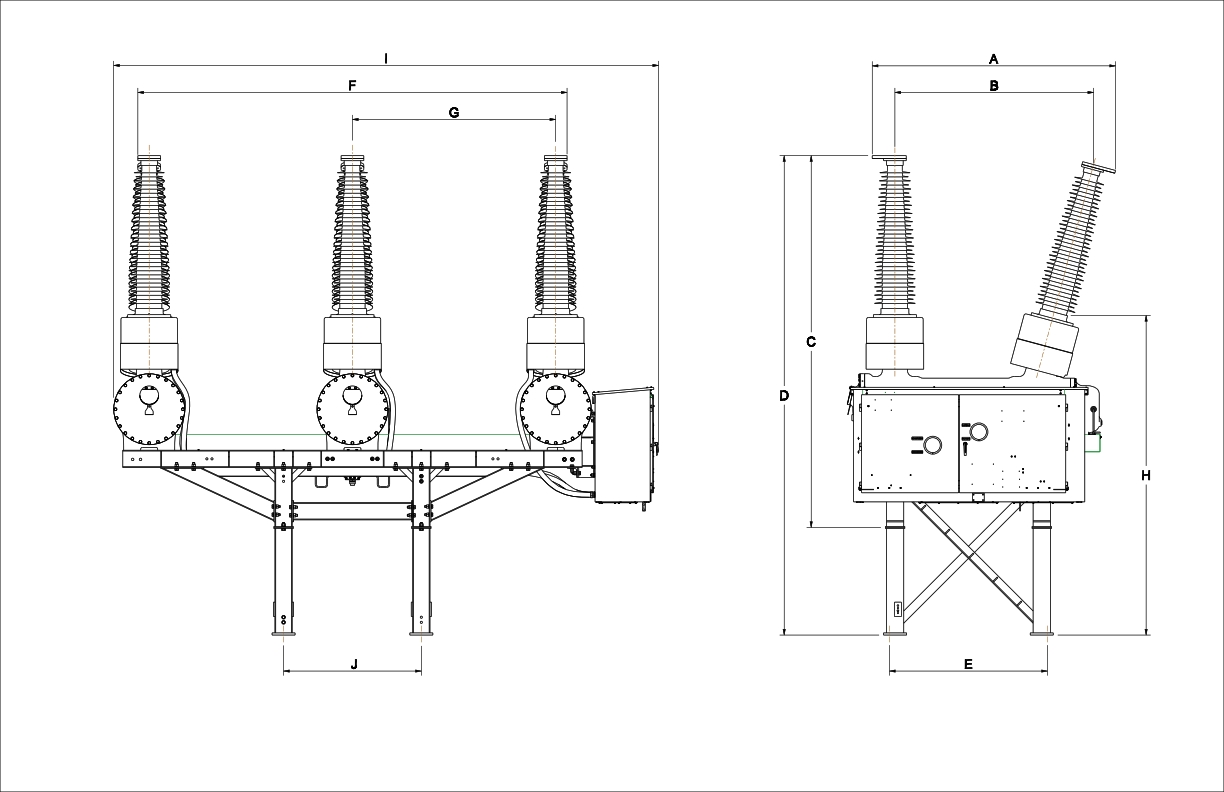

Independent pole operation

Independent pole operation

Recommended Products & services

DT1-245P

Dead Tank Circuit Breaker for 245 kV

State-of-the-Art Technology

GE Vernova’s DT series of dead tank circuit breakers are characterized by advanced self-blast interrupters, leak-resistant, cast aluminum enclosures and durable, low-energy spring-operated mechanisms. More than 100,000 circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

DT1-245P

Dead Tank Circuit Breaker for 245 kV

State-of-the-Art Technology

GE Vernova’s DT series of dead tank circuit breakers are characterized by advanced self-blast interrupters, leak-resistant, cast aluminum enclosures and durable, low-energy spring-operated mechanisms. More than 100,000 circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

Spring-spring mechanism

The reduced energy requirements of the breaking chamber allows for the utilization of the world class FK spring-spring mechanism. The combination of the proven FK drive mechanism and interrupter technology results in a significant reduction of reaction forces, thus reducing foundation design requirements.

Gas Tightness Guarantee

GE Vernova leads the industry in SF6 gas tightness testing technology including seals, castings, and plumbing systems. Each breaker is factory tested using GE Vernova’s proprietary gas tightness testing system which provides measurable, quantifiable test results on the breaker in its fully assembled, as-shipped condition.

Certified Quality

GE Vernova designs, manufactures, tests and delivers its circuit breakers in accordance with the latest IEEE/ANSI and IEC standards, maintaining a quality assurance system according to ISO-9011 and ISO-14001 certifications. The center of excellence for dead tank circuit breakers is located in Charleroi, PA.

Installation and Maintenance

The DT1-245 series is factory tested and prepared for shipment with bushings assembled and prefilled with SF6 gas, therefore the on-site installation requires only a few simple steps without requiring any special tools. The DT1-245 circuit breaker range has lower maintenance costs and requirements, thanks to an engineering and design philosophy that has focused on these key needs since the inception of the development process.

Specifications

| IEEE/ANSI | IEC | Value | Units |

|---|---|---|---|

| Rated maximum voltage | Rated voltage | 245 | kV |

| Rated power frequency | Rated frequency | 50/60 | Hz |

| Dry withstand | At power frequency,dry | 425/460 | kV |

| Rated lightning impulse withstand voltage | At lightning impulse | 900/1,050 | kV |

| Rated chopped wave impulse voltage 2us | 1,160 | kV | |

| Rated continuous current | Rated normal current | 3,000/4,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 40 | kA |

| Rated closing,latching and short time carrying | 104 | kA | |

| Rated short-circuit making current | 104 | kA | |

| Rated capacitance switching* | |||

| Rated interrupting time | 3 | cycles | |

| Rated break time | 50 | ms | |

| Rated standard operating duty | O-CO-15s-CO O-0.3s-CO-180s-CO | ||

| *Rating available upoon request **Contact Grid Solutions for special purpose, high TRV, high X/R or other ratings requirements. | |||

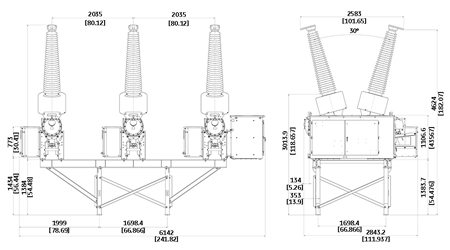

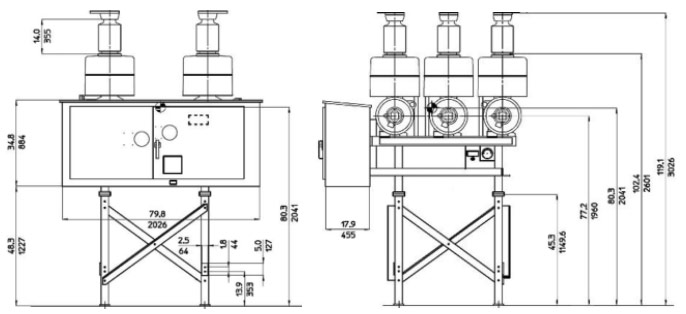

Drawings

Recommended Products & services

DT1-145R-40

Dead Tank Circuit Breaker with Pre-Insertion Resistors

State-of-the-Art Technology

The DT1-145R-40 is a dead tank circuit breaker furnished with integral pre-insertion resistors (PIRs). It may be used for switching of lines, transformers, shunt capacitors, or shunt reactors. It is specifically designed and tested for general or definite purpose applications as well as for severe environmental conditions including low temperatures, highly active seismic areas, and regions with high pollution levels or corrosive atmospheres.

DT1-145R-40

Dead Tank Circuit Breaker with Pre-Insertion Resistors

State-of-the-Art Technology

The DT1-145R-40 is a dead tank circuit breaker furnished with integral pre-insertion resistors (PIRs). It may be used for switching of lines, transformers, shunt capacitors, or shunt reactors. It is specifically designed and tested for general or definite purpose applications as well as for severe environmental conditions including low temperatures, highly active seismic areas, and regions with high pollution levels or corrosive atmospheres.

Gas Tightness Guarantee

Grid Solutions at GE Vernova leads the industry in SF6 gas tightness testing technology including seals, castings, and plumbing systems. Each breaker is factory tested using Grid Solutions at GE Vernova’s proprietary gas tightness testing system which provides measurable, quantifiable test results on the breaker in its fully assembled, as-shipped condition.

Quality

Grid Solutions at GE Vernova designs, manufactures, tests and delivers its circuit breakers in accordance with the latest IEEE/ANSI and IEC standards, maintaining a quality assurance system according to ISO-9011 and ISO-14001 certifications. The center of excellence for dead tank circuit breakers is located in Charleroi, PA.

Installation and Maintenance

The DT1-145R is factory tested and adjusted and don’t require any special tools for installation. Designed with the smallest symmetrical footprint to allow for minimized foundation costs, they are recognized worldwide as easy-to-install and operate circuit breakers. Thanks to the low energy mechanism and lifetime lubricants, the DT series is virtually maintenance free.

The DT1 series on-site installation requires only a few simple steps. For installations where truck shipment is impossible, all DT series circuit breakers can be readied for standard container shipment with only their bushings disassembled.

Pre-insertion Resistors (PIRs)

The circuit breaker random switching can generate voltage disturbances on electrical lines. Placed in parallel of the main contacts of a circuit breaker, a pre-insertion resistor is a technique consisting in operating the circuit-breaker while briefly inserting a resistor during closing operation to reduce overvoltage phenomena such as switching transient voltage. This helps limit the power quality issues and accelerated aging, thus minimizing risks and operation costs. Integral PIRs may be used for switching of lines, transformers, shunt capacitors or shunt reactors.

Ratings

| IEEE/ANSI | IEC | Value | Units |

|---|---|---|---|

| Rated maximum voltage* | Rated voltage | 72.5/123/145 | kV |

| Rated power frequency | Rated frequency | 50/60 | Hz |

| Rated dielectric withstand capability: - dry withstand - wet withstand | Rated insulation level - at power frequency, dry - at power frequency, wet | 160/260/310/365 140/230/275/315 | kV kV |

| Rated lightning impulse withstand voltage | - at lightning impulse | 350/550/650/750 | kV |

| Rated chopped wave impulse voltage 2us | 452/710/838/968 | kV | |

| Rated continuous current | Rated normal current | 1,200/2,000/3,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 40 | kA |

| Rated short-time current (1s) | 63 | kA | |

| Rated peak withstand current | 164 | kA | |

| Rated capacitance switching* | Class C2 | ||

| Rated interrupting time | 3 | cycles | |

| Rated break time | 50 | ms | |

| Rated standard operating duty | Rated operating sequence | O-CO-15s-CO O-0.3s-CO-180s-CO | |

| *Standard values: further data is available on request. | |||

| **Please contact Grid Solutions for special purpose, high TRV, high X/R or other ratings requirements. | |||

Dimensions

| Rated Max. Voltage | A (in/mm) | B (in/mm) | C (in/mm) | D (in/mm) | E (in/mm) | F (in/mm) | G (in/mm) | H (in/mm) | I (in/mm) | J (in/mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| 72.5 kV | 79/1996 | 63/1597 | 105/2676 | 143/3624 | 55/1393 | 149/3777 | 71/1793 | 112/2857 | 189/4806 | 48/1215 |

| 145 kV | 84/2145 | 69/1752 | 129/3279 | 166/4228 | 55/1393 | 149/3785 | 71/1793 | 111/2819 | 189/4806 | 48/1215 |

Weight

(without current transformers)

| 72.5 kV: | 5,658/2572 | lb/kg |

| 145 kV: | 6,170/2,798 | lb/kg |

Recommended Products & services

DT1-145 63

Dead Tank Circuit Breaker for 145 kV/63 kA

Leading Breaker with 63 kA Short-Circuit Current

The DT1-145 63 rated for 63 kA represents the latest dead tank circuit breaker technology. This circuit breaker is specifically designed and tested for general or definite purpose applications as well as for severe environmental conditions including low temperature, highly active seismic areas and regions with high pollution levels or corrosive atmospheres.

DT1-145 63

Dead Tank Circuit Breaker for 145 kV/63 kA

Leading Breaker with 63 kA Short-Circuit Current

The DT1-145 63 rated for 63 kA represents the latest dead tank circuit breaker technology. This circuit breaker is specifically designed and tested for general or definite purpose applications as well as for severe environmental conditions including low temperature, highly active seismic areas and regions with high pollution levels or corrosive atmospheres.

Gas Tightness Guarantee

GE Vernova leads the industry in SF6 gas tightness testing technology including seals, castings, and plumbing systems. Each breaker is factory tested using GE Vernova’s proprietary gas tightness testing system which provides measurable, quantifiable test results on the breaker in its fully assembled, as-shipped condition.

Quality

GE Vernova designs, manufactures, tests and delivers its circuit breakers in accordance with the latest IEEE/ANSI and IEC standards, maintaining a quality assurance system according to ISO-9011 and ISO-14001 certifications. The center of excellence for dead tank circuit breakers is located in Charleroi, PA.

Installation and Maintenance

The DT1-145 63 is factory tested and adjusted and don not require an y “special tools” for installation. Designed with the smallest symmetrical footprint to allow for minimized foundation costs, they are recognized worldwide as easy-to-install and operate circuit breakers. Thanks to the low energy mechanism and lifetime lubricants, the DT series is virtually maintenance free.

The DT1 series on-site installation requires only a few simple steps. For installations where truck shipment is impossible, all DT series circuit breakers can be readied for standard container shipment with only their bushings disassembled.

Specifications

| IEEE/ANSI | IEC | Value | Units |

|---|---|---|---|

| Rated maximum voltage | Rated voltage | 145 | kV |

| Rated power frequency | Rated frequency | 50/60 | Hz |

Rated dielectric withstand capability:

| Rated insulation level

|

310 |

kV |

| Rated lightning impulse withstand voltage |

| 650 | kV |

| Rated chopped wave impulse voltage 2us | 838 | kV | |

| Rated continuous current | Rated normal current | 3,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 63 | kA |

| Rated closing,latching and short time carrying | 164 | kA | |

| Rated capacitance switching* | |||

| Rated single capacitor bank breaking current | 400 | A | |

| Rated interrupting time | 3 | cycles | |

| Rated break time | 50 | ms | |

| Rated standard operating duty | Rated operating sequence | O-CO-15s-CO O-0.3s-CO-180s-CO | |

| *Rating available upoon request | |||

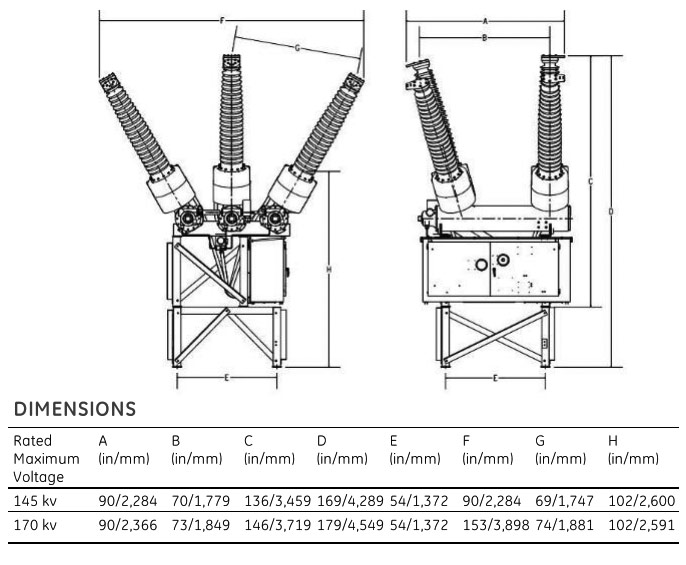

Drawings

Recommended Products & services

DT1-145 and DT1-170

Dead Tank Circuit Breaker for 123 kV to 170 kV

State-of-the-Art Technology

The DT1-145 and the DT1-170 are dead tank circuit breakers suitable for application at 170 kV and below. They are specifically designed and tested for general or definite purpose applications as well as for severe environmental conditions including low temperature, highly active seismic areas and regions with high pollution levels or corrosive atmospheres.

DT1-145 and DT1-170

Dead Tank Circuit Breaker for 123 kV to 170 kV

State-of-the-Art Technology

The DT1-145 and the DT1-170 are dead tank circuit breakers suitable for application at 170 kV and below. They are specifically designed and tested for general or definite purpose applications as well as for severe environmental conditions including low temperature, highly active seismic areas and regions with high pollution levels or corrosive atmospheres.

Gas Tightness Guarantee

GE Vernova leads the industry in SF₆ gas tightness testing technology including seals, castings, and plumbing systems. Each breaker is factory tested using GE Vernova’s proprietary gas tightness testing system which provides measurable, quantifiable test results on the breaker in its fully assembled, as-shipped condition.

Quality

GE Vernova designs, manufactures, tests and delivers its circuit breakers in accordance with the latest IEEE/ANSI and IEC standards, maintaining a quality assurance system according to ISO-9011 and ISO-14001 certifications. The center of excellence for dead tank circuit breakers is located in Charleroi, PA.

Installation and Maintenance

The DT1-145/170 are factory tested and adjusted and don not require an y “special tools” for installation. Designed with the smallest symmetrical footprint to allow for minimized foundation costs, they are recognized worldwide as easy-to-install and operate circuit breakers. Thanks to the low energy mechanism and lifetime lubricants, the DT series is virtually maintenance free.

The DT1 series on-site installation requires only a few simple steps. For installations where truck shipment is impossible, all DT series circuit breakers can be readied for standard container shipment with only their bushings disassembled.

Specifications

| IEEE/ANSI | IEC | Value | Units |

|---|---|---|---|

| Rated maximum voltage | Rated voltage | 123/145/170 | kV |

| Rated power frequency | Rated frequency | 50/60 | Hz |

Rated dielectric withstand capability:

| Rated insulation level

|

260/310/365 |

kV |

| Rated lightning impulse withstand voltage |

| 550/650/750 | kV |

| Rated chopped wave impulse voltage 2us | 710/838/968 | kV | |

| Rated continuous current | Rated normal current | 1,200/2,000/3,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 40 | kA |

| Rated closing,latching and short time carrying current | 104 | kA | |

| Rated capacitance switching* | |||

| Rated single capacitor bank breaking current | 400 | A | |

| Rated interrupting time | 3 | cycles | |

| Rated break time | 50 | ms | |

| Rated standard operating duty | Rated operating sequence | O-CO-15s-CO O-0.3s-CO-180s-CO | |

| *Standard values: further data is available on request. **Please contact Grid Solutions for special purpose, high TRV, high X/R or other ratings requirements. | |||

Drawings

Recommended Products & services

DT1-72.5

Dead Tank Circuit Breaker for 72.5 kV

State-of-the-Art Technology

GE Vernova's DT series of dead tank circuit breakers are known for their advanced self-blast interrupters, leak resistant cast aluminum enclosures and durable low energy spring operated mechanisms. More than 100,000 GE Vernova circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

DT1-72.5

Dead Tank Circuit Breaker for 72.5 kV

State-of-the-Art Technology

GE Vernova's DT series of dead tank circuit breakers are known for their advanced self-blast interrupters, leak resistant cast aluminum enclosures and durable low energy spring operated mechanisms. More than 100,000 GE Vernova circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

Performance

Thanks to its robust design, the DT1-72.5 is a highly reliable circuit breaker even under the most severe operating conditions and is tested to meet or exceed IEEE/ANSI and IEC as C2 class for capacitance switching including back-to-back (low restrike probability) and reactor switching applications. Extensive mechanical operation design testing ensures trouble-free operation for the lifetime of the circuit breaker. Intensive production leak testing ensures superior in-service SF6 performance.

Certified Quality

GE Vernova designs, manufactures, tests and delivers its circuit breakers in accordance with IEEE/ANSI and IEC standards, maintaining a quality assurance system according to ISO-9001 and ISO-14001. The competence center for dead tank circuit breakers is located in Charleroi, PA, USA.

Specifications

| IEEE/ANSI | IEC | Value | Units |

|---|---|---|---|

| Rated maximum voltage | Rated voltage | 72.5 | kV |

| Rated power freouency | Rated frequency | 50/60 | Hz |

Rated dielectric withstand capability:

| Rated insulation level

|

160 |

kV |

| Rated lightning impulse withstand voltage |

| 350 | kV |

| Rated chopped wave impulse voltage 2us/3us | 452/402 | kV | |

| Rated continuous current | Rated normal current | 1,200/2,000/3,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 40 | kA |

| Rated closing,latching and short time carrying current | 108 | kA | |

| Rated short-circuit making current | 100 | kA | |

| Rated capacitance switching | 630 | A | |

| Rated single capacitor bank breaking current | 1,200 | A | |

| Rated interrupting time | 3 | cycles | |

| Rated break time | 50 | ms | |

| Rated standard operating duty | Rated operating sequence | O-CO-15s-CO O-0.3s-CO-180s-CO | |

| *Standard values: further data is available on request. **Please contact Grid Solutions for special purpose, high TRV, high X/R or other ratings requirements. | |||

Drawings

Recommended Products & services

DT1-38

Dead Tank Circuit Breaker for 38 kV

State-of-the-Art Technology

GE Vernova's DT series of dead tank circuit breakers are known for their advanced self-blast interrupters, leak resistant cast aluminum enclosures and durable low energy spring operated mechanisms. More than 100,000 GE Vernova circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

DT1-38

Dead Tank Circuit Breaker for 38 kV

State-of-the-Art Technology

GE Vernova's DT series of dead tank circuit breakers are known for their advanced self-blast interrupters, leak resistant cast aluminum enclosures and durable low energy spring operated mechanisms. More than 100,000 GE Vernova circuit breakers with self-blast interrupters and FK spring-operated mechanisms have been in service since 1989.

Performance

Thanks to its robust design, the DT1-38 is a highly reliable circuit breaker even under the most severe operating conditions and is tested to meet or exceed IEEE/ANSI and IEC as C2 class for capacitance switching including back-to-back (low restrike probability) and reactor switching applications. Extensive mechanical operation design testing ensures trouble-free operation for the lifetime of the circuit breaker. Intensive production leak testing ensures superior in-service SF₆ performance.

Quality components play a key role in the high performance of the unit. DT1-38 components include:

- Third-generation self-blast interrupter chamber

- Pressure relief system for passive protection of both substation and personnel

- Generous space for current transformers

- Field-proven, temperature-compensated density monitor with two-stage pressure switch and three-color dial

- DILO SF₆ filling connection

- Galvanized steel base frame

- Reliable spring-spring-operated mechanism

Certified Quality

GE Vernova designs, manufactures, tests and delivers its circuit breakers in accordance with IEEE/ANSI and IEC standards, maintaining a quality assurance system according to ISO-9001 and ISO-14001. The competence center for dead tank circuit breakers is located in Charleroi, PA (USA).

Specifications

| IEEE/ANSI | IEC | Value | Units |

|---|---|---|---|

| Rated maximum valtage | Rated voltage | 38 | kV |

| Rated power frequency | Rated frequency | 50/60 | Hz |

Rated dielectric withstand capability:

| Rated insulation level

|

80 |

kV |

| Rated lightning impulse withstand voltage |

| 200* | kV |

| Rated chopped wave impulse voltage 2us | 258 | kV | |

| Rated continuous current | Rated normal current | 1,200/2,000/3,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 40 | kA |

| Rated closing,latching and short time carrying current | 104 | kA | |

| Rated short-circuit making current | 100 | kA | |

| Rated capacitance switching | 630 | A | |

| Rated single capacitor bank breaking current | 1,200 | A | |

| Rated interrupting time | 3 | cycles | |

| Rated break time | 50 | ms | |

| Rated standard operating duty | Rated operating sequence | O-CO-15s-CO O-0.3s-CO-180s-CO | |

| *Standard values: further data is available on request. **Please contact Grid Solutions for special purpose, high TRV, high X/R or other ratings requirements. | |||

Drawings

Recommended Products & services

GL 318 / GL 318X

Live tank circuit breaker up to 800 kV

Reliable, Economical and Easy-to-Use

GE Vernova’s GL 318 and GL 318X live tank circuit breakers for outdoor installation feature third generation self-blast interrupter chambers and spring-operated mechanisms (FK). These field–proven interrupter chambers operate on the energy optimized self-blast principle. The FK3 type mechanisms equip the entire range of circuit breakers with more than 180,000 references worldwide.

GL 318 / GL 318X

Live tank circuit breaker up to 800 kV

Reliable, Economical and Easy-to-Use

GE Vernova’s GL 318 and GL 318X live tank circuit breakers for outdoor installation feature third generation self-blast interrupter chambers and spring-operated mechanisms (FK). These field–proven interrupter chambers operate on the energy optimized self-blast principle. The FK3 type mechanisms equip the entire range of circuit breakers with more than 180,000 references worldwide.

High Quality Components

The GL 318 and GL 318X live tank circuit breakers provide high reliability based in part on high quality components, including:

- Single pole operating design

- Four self-blast Interrupter chambers and two spring mechanisms per pole

- Spring mechanism FK3 equipped with a position indicator visible from outside

- Field-proven, temperature-compensated density monitor with two-stage transducer and three-color dial

- Easy access to the SF₆ filling connection (type DILO)

- Sealings suitable for temperatures down to -60 °C

- Hot-dip galvanized steel parts and mechanism housings made completely of aluminum

Flexible Options

- Standard low voltage equipment provided, additional equipment is available

- Composite insulators are available

- Seismic dampers for high seismic request can be provided

- Pressure relief system for passive protection of both substation and personnel

- RPH3 controller: Pont-on-wave tripping and closing relays

- CBWatch: compact and modular circuit breaker monitoring solution

- Closing resistors solutions (CL 315D) to limit high and damaging overvoltages

Installation and Maintenance

- Preset at factory before shipping; no adjustments necessary during installation and commissioning

- Disassembly of interrupter chamber without removal of entire pole column possible

Advanced Testing

The live tank circuit breakers meet the requirements of national and international standards. This has been confirmed by comprehensive type tests according to the latest IEC standards.

Certified Quality

GE Vernova’s quality (ISO 9001:2008), environmental (ISO 14001:2004) and occupational health and safety (OHSAS 18001:2007) management systems determine the development and production procedures for the high voltage circuit breakers. These systems ensure the high quality of the products and services, which are confirmed by regular audits.

Specifications

| Breaker Type | GL 318 / GL 318D | GL 318X / GL 318XD | ||

|---|---|---|---|---|

| Number of breaks / phase | 4 | 4 | ||

| Rated normal voltage | kV | 800 | 800 | |

| Rated normal current* | A | 4,000 | 5,500 | |

| Rated frequency | Hz | 50/60 | 50 | |

| Rated dielectric withstand (up to 1,000 m)* (to earth / accross open device) | ||||

| - At power frequency | kV | 830/1,150 | 830/1,150 | |

| - At lightning impulse (1.2 / 50 µs wave) | kV (peak) | 2,100/2,100 (+455) | 2,100/2,100 (+455) | |

| - At switching impulse | kV (peak) | 1,550/1,175 (+650) | 1,550/1,175 (+650) | |

| Rated short-circuit breaking capacity | ||||

| -Periodic component (r.m.s. value) | kA | 50 | 63 | |

| First pole-to-clear factor | 1.3 | 1.3 | ||

| Peak short-circuit withstand current | kA (peak) | 137 | 173 | |

| Rated line-charging capacitive switching | Class C2 | Class C2 | ||

| Mechanical endurance | Class M2 | Class M2 | ||

| Breaking time | cycles | 2 - 2,3 | 2 - 2,3 | |

| * For other values, please contact Grid Solutions. | ||||

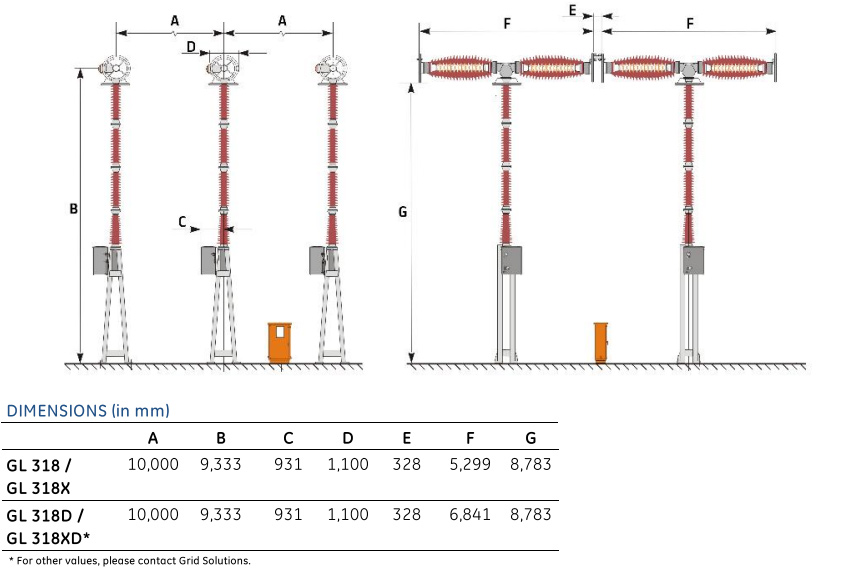

Drawings

Recommended Products & services

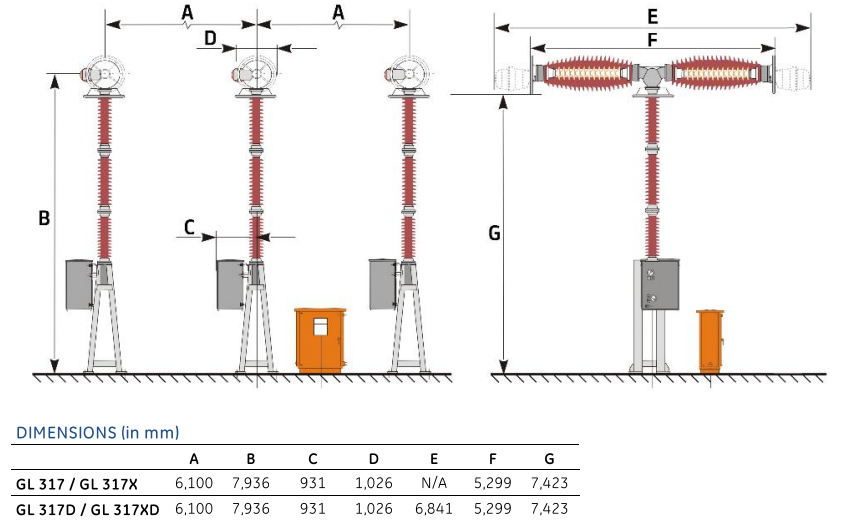

GL 317 / GL 317X

Live tank circuit breaker up to 550 kV

Reliable, Economical and Easy-to-Use

GE Vernova’s GL 317 and GL 317X live tank circuit breakers for outdoor installation feature third generation self-blast interrupter chambers and spring-operated mechanisms (FK). These field–proven interrupter chambers operate on the energy optimized self-blast principle. The FK3 type mechanisms equip the entire range of circuit breakers with more than 180,000 references worldwide.

GL 317 / GL 317X

Live tank circuit breaker up to 550 kV

Reliable, Economical and Easy-to-Use

GE Vernova’s GL 317 and GL 317X live tank circuit breakers for outdoor installation feature third generation self-blast interrupter chambers and spring-operated mechanisms (FK). These field–proven interrupter chambers operate on the energy optimized self-blast principle. The FK3 type mechanisms equip the entire range of circuit breakers with more than 180,000 references worldwide.

High Quality Components

The GL 317 and GL 317X live tank circuit breakers provide high reliability based in part on high quality components, including:

- Single pole operating design

- Two self-blast Interrupter chambers per pole

- Spring mechanism FK3 equipped with a position indicator visible from outside

- Field-proven, temperature-compensated density monitor with two-stage transducer and three-color dial

- Easy access to the SF₆ filling connection (type DILO)

- Sealings suitable for temperatures down to -60 °C

- Hot-dip galvanized steel parts and mechanism housings made completely of aluminum

Flexible Options

- Standard low voltage equipment provided, additional equipment is available

- Composite insulators are available

- Seismic dampers for high seismic request can be provided

- Pressure relief system for passive protection of both substation and personnel

- RPH3 controller: Pont-on-wave tripping and closing relays

- CBWatch: compact and modular circuit breaker monitoring solution

- Closing resistors solutions (CL 315D) to limit high and damaging overvoltages

Installation and Maintenance

- Preset at factory before shipping; no adjustments necessary during installation and commissioning

- Disassembly of interrupter chamber without removal of entire pole column possible

Advanced Testing

The live tank circuit breakers meet the requirements of national and international standards. This has been confirmed by comprehensive type tests according to the latest IEC standards.

Certified Quality

GE Vernova’s quality (ISO 9001:2008), environmental (ISO 14001:2004) and occupational health and safety (OHSAS 18001:2007) management systems determine the development and production procedures for the high voltage circuit breakers. These systems ensure the high quality of the products and services, which are confirmed by regular audits.

Specifications

| Breaker Type | GL 317 / GL 317D | GL 317X / GL 317XD | ||

|---|---|---|---|---|

| Number of breaks / phase | 2 | 2 | ||

| Rated normal voltage | kV | 550 | 550 | |

| Rated normal current | A | 4,000 | 5,500 | |

| Rated frequency | Hz | 50/60 | 50 | |

| Rated dielectric withstand (up to 1,000 m)* (to earth / accross open device) | ||||

| - At power frequency | kV | 620/800 | 620/800 | |

| - At lightning impulse (1.2 / 50 µs wave) | kV (peak) | 1,550/1,550 (+315) | 1,550/1,550 (+315) | |

| - At switching impulse | kV (peak) | 1,175/900 (+450) | 1,175/900 (+450) | |

| Rated short-circuit breaking capacity | ||||

| -Periodic component (r.m.s. value) | kA | 50 | 63 | |

| First pole-to-clear factor | 1.3 | 1.3 | ||

| Peak short-circuit withstand current | kA (peak) | 137 | 173 | |

| Rated line-charging capacitive switching | Class C2 | Class C2 | ||

| Mechanical endurance | Class M2 | Class M2 | ||

| Breaking time | cycles | 2 - 2,3 | 2 - 2,3 | |

| * For other value, please contact Grid Solutions. Grading capacitors should be removed depending on required performances. | ||||

Drawings

Recommended Products & services

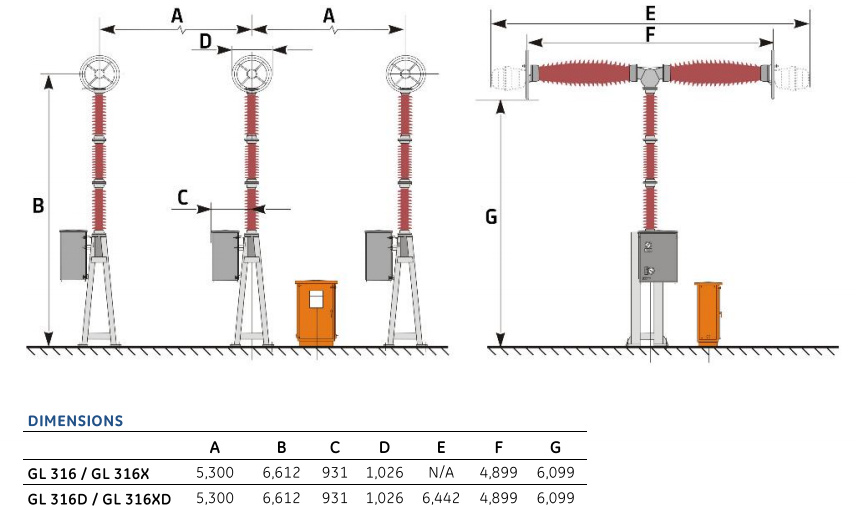

GL 316 / GL 316X

Live tank circuit breakers up to 420 kV

Reliable, Economical and Easy-to-Use

GE Vernova’s GL 316 and GL 316X live tank circuit breakers for outdoor installation feature third generation self-blast interrupter chambers and spring-operated mechanisms (FK). These field–proven interrupter chambers operate on the energy optimized self-blast principle. The FK3 type mechanisms equip the entire range of circuit breakers with more than 180,000 references worldwide.

GL 316 / GL 316X

Live tank circuit breakers up to 420 kV

Reliable, Economical and Easy-to-Use

GE Vernova’s GL 316 and GL 316X live tank circuit breakers for outdoor installation feature third generation self-blast interrupter chambers and spring-operated mechanisms (FK). These field–proven interrupter chambers operate on the energy optimized self-blast principle. The FK3 type mechanisms equip the entire range of circuit breakers with more than 180,000 references worldwide.

High Quality Components

The GL 316 and GL 316X live tank circuit breakers provide high reliability based in part on high quality components, including:

- Single pole operating design

- Two self-blast Interrupter chambers per pole

- Spring mechanism FK3 equipped with a position indicator visible from outside

- Field-proven, temperature-compensated density monitor with two-stage transducer and three-color dial

- Easy access to the SF₆ filling connection (type DILO)

- Sealings suitable for temperatures down to -60 °C

- Hot-dip galvanized steel parts and mechanism housings made completely of aluminum

Flexible Options

- Standard low voltage equipment provided, additional equipment is available

- Composite insulators are available

- Seismic dampers for high seismic request can be provided

- Pressure relief system for passive protection of both substation and personnel

- RPH3 controller: Pont-on-wave tripping and closing relays

- CBWatch: compact and modular circuit breaker monitoring solution

- Closing resistors solutions (CL 315D) to limit high and damaging overvoltages

- Grading capacitors depending on specifications

Installation and Maintenance

- Preset at factory before shipping; no adjustments necessary during installation and commissioning

- Disassembly of interrupter chamber without removal of entire pole column possible

Advanced Testing

The live tank circuit breakers meet the requirements of national and international standards. This has been confirmed by comprehensive type tests according to the latest IEC standards.

Certified Quality

GE Vernova's quality (ISO 9001:2008), environmental (ISO 14001:2004) and occupational health and safety (OHSAS 18001:2007) management systems determine the development and production procedures for the high voltage circuit breakers. These systems ensure the high quality of the products and services, which are confirmed by regular audits.

Specifications

| Breaker Type | GL 316 / GL 316D | GL 316X / GL 316XD | |

| Number of breaks / phase | 2 | 2 | |

| Rated normal voltage | kV | 420 | 420 |

| Rated normal current | A | 4,000 | 5,500 |

| Rated frequency | Hz | 50/60 | 50 |

| Rated dielectric withstand (up to 1,000 m)* (to earth / accross open device) - At power frequency - At lightning impulse (1.2 / 50 µs wave) - At switching impulse | kV kV (peak) kV (peak) | 520/700 1,425/1,425 (+240) 1,050/900 (+345) | 520/700 1,425/1,425 (+240) 1,050/900 (+345) |

| Rated short-circuit breaking capacity -Periodic component (r.m.s. value) | kA | 50 | 63 |

| First pole-to-clear factor | 1.3 | 1.3 | |

| Peak short-circuit withstand current | kA (peak) | 137 | 173 |

| Rated line-charging capacitive switching | Class C2 | Class C2 | |

| Mechanical endurance | Class M2 | Class M2 | |

| Breaking time | cycles | 2 - 2,3 | 2 - 2,3 |

| * For other values, please contact Grid Solutions. | |||

Drawings