Series Compensation Systems

Cost Effective Power Transfer

GE Vernova’s Series Compensation System allows utilities to cost effectively increase power transfer capabilities of their existing infrastructure and new transmission lines.

Series compensation systems are installed in series with the High Voltage transmission line, and consist of an integrated, custom-designed system with many power capacitors arranged in series and parallel. The most critical equipment is the parallel protective system that prevents damage to the capacitors during power system faults.

GE Vernova also offers an extensive portfolio of project management and engineering services, physical equipment and installation services, which results in an integrated and robust system for customers.

Series Compensation Systems

Cost Effective Power Transfer

GE Vernova’s Series Compensation System allows utilities to cost effectively increase power transfer capabilities of their existing infrastructure and new transmission lines.

Series compensation systems are installed in series with the High Voltage transmission line, and consist of an integrated, custom-designed system with many power capacitors arranged in series and parallel. The most critical equipment is the parallel protective system that prevents damage to the capacitors during power system faults.

GE Vernova also offers an extensive portfolio of project management and engineering services, physical equipment and installation services, which results in an integrated and robust system for customers.

Overview

Today’s transmission system is becoming increasingly complex and is expected to carry bulk power in ways it was never designed for. The expectation is that transmission requirements will only increase, as power generation sources continue to evolve. GE Vernova’s Series Compensation System allows utilities to cost effectively increase the power transfer capabilities of their existing infrastructure and new transmission lines, leveraging GE Vernova’s capabilities as outlined below.

Extensive Global and Unmatched Technical Experience

A worldwide leader in executing and delivering series compensation projects, in a broad range of utility environments resulting in reduced implementation risk.

- More than a century of experience designing transmission networks, including the first series compensation project in 1928

- Leading the industry by delivering over 30,000 Mvars of series compensation systems in the last three years

- Globally recognized as the foremost technical experts for power system projects since 1928

Industry Leading Patented Technology

Providing superior systems enabled by GE Vernova’s innovate products resulting in project cost savings and increased quality and reliability.

- Fastest Triggered Air Gap (TAG) available in the industry

- Newly patented TAG and Platform Damping Technologies

- Pioneered the use of SSR filter technology in a series capacitor system

Best-in-class Quality and Process Standards

Industry leading and well-established set of project management processes and procedures, certified to ISO® 9001 standards, resulting in on-time and on-budget execution.

- 99% record of on-time project completion

- Greater than 98% on-budget execution

- Over 3.6 million hours of project execution without an OSHA® recordable incident

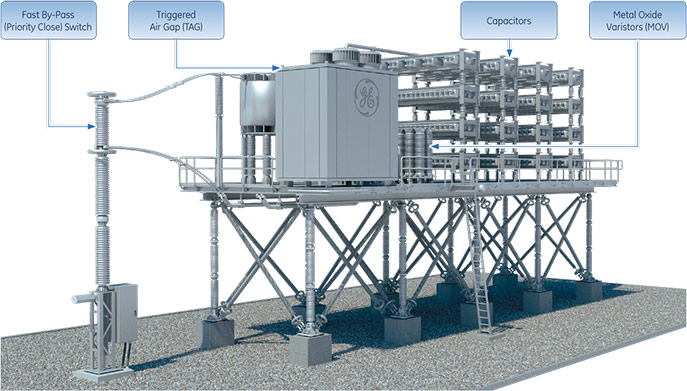

Components of a Series Capacitor Bank

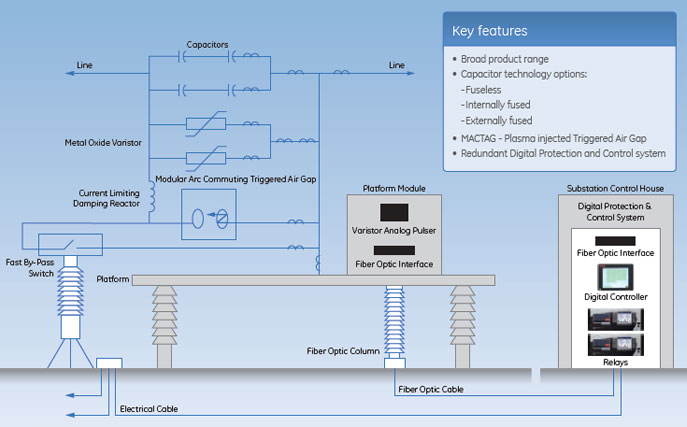

Series Compensation System Components

GE Vernova’s Series Compensation System is comprised with industry leading and patented technology, helping customers achieve high reliability and lowest possible losses on their transmission lines. The major components of the Series Compensation System include Capacitors, Metal Oxide Varistors, Triggered Air Gap, and Fast By-Pass Switches.

Capacitors

The capacitors are placed in series on a transmission circuit intended to reduce the overall line impedance and offers improved load division on parallel circuits, system transient and steady state system stability and allows for increased power transfer capability.

Modular Arc Commutating Triggered Air Gap (MACTAG)

A MACTAG is often used as an intermediate bypass device and is faster than the bypass switch, but not instantaneous like the Metal Oxide Varistor (MOV). GE Vernova’s patented design uses plasma injection to establish an arc which bypasses the capacitors and MOV until the bypass switch can close. GE Vernova’s MACTAG is the fastest in the industry (< 0.3 ms) as it does not rely on ground-based controls to initiate a bypass. A MACTAG lowers MOV cost by reducing the required MOV energy absorption.

Metal Oxide Varistor (MOV)

MOV are the primary device that protects the capacitors from overvoltage by diverting fault current. The MOV are semiconductors that conduct above a specific voltage, known as the Protective Level Voltage. The MOV limits the voltage across the capacitor bank to a safe value for the capacitors handling very high current for short periods of time and protect the capacitors until another bypass path is established.

Fast By-Pass (Priority Close) Switch

The Fast By-Pass Switch closes rapidly to limit both MOV and TAG energy, removing the series capacitors from service. This switch is also used for normal switching to insert the series capacitors or bypass them.

Series Capacitor Bank – One Line Diagram

Capacitor Options

GE Vernova’s Series Compensation offerings include three capacitor options: fuseless, internally fused or externally fused. GE Vernova works with customers to evaluate their requirements and determine the best technical solution to meet customer needs to ensure, reliable and cost effective system.

Fuseless Design

- Lowest losses, typically < 0.12 watts/kvar

- High reliability: A lower internal element voltage stress rise for the same number of internal failures in comparison to an internally fused option

- A higher unbalanced current for the same internal element voltage stress

- Fault tolerance with continued operation even with failed rolls

- GE Vernova recommended option

Internally Fused Design

- Losses typically > 0.15 watts/kvar

- One fuse per internal roll. Each roll is protected by an internal fuse element

- The fuse allows a roll to fail as an open circuit

- There are multiple rolls in parallel. This places a very small incremental stress on adjacent rolls when a fuse operates. This helps prevent a cascading failure within an individual can

Externally Fused Design

- One fuse per capacitor unit. Fewer connections mean fewer points of failure

- Facilitates easy identification of a failed unit as the blown fuse is obvious

- Once the standard, now limited specialty applications

GE Vernova's Fuseless Design

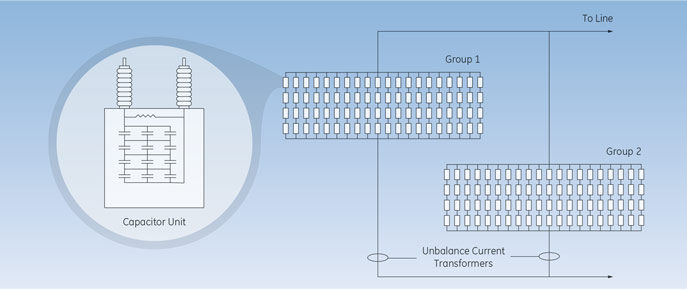

GE Vernova recommends the fuseless option, which has been the dominant technology since the late 1990’s and is proven with a long term field failure rate of less than 0.03% per year. The film foil capacitor is a proven GE Vernova design that has been in use since the 1970s. The fuseless design produces the highest unbalance current (easy to detect a failed roll) with the lowest voltage stress on the remaining units (lower chance for a cascading failure). The diagram below depicts the two capacitor groups.

Project Management Approach

The GE Vernova project team represents unsurpassed worldwide power system engineering capabilities, comprehensive system design expertise, and unequaled project management experience. Our strength in each of these areas enables us to deliver a highly reliable solution that will fully meet your power system requirements. With each reactive compensation project GE Vernova undertakes, this team is committed to delivering 100% satisfaction.

Professional Services Process and Key Activities

Global Experience and Application Examples

GE Vernova’s Series Compensation Systems brings together an extensive portfolio of products, services and engineering excellence to deliver the next generation systems for customers based on specific requirements to address both technical and business objectives as well as support several applications. GE Vernova provides highly reliable and efficient designs that have low overall maintenance and cost of ownership. Below are just a few of GE Vernova’s selection of customer applications.

Cross Texas Transmission

Three Phase Bank Rating: 2 x 716 Mvar

Substations: Turkey, Texas – Cross Station 1 & 2

Customer Challenge

Maintain voltage stability and efficient operations of the Texas Transmission System under minimum and maximum export of wind power.

Customer Application

50% compensation on 2 transmission lines from Tule Canyon to Tesla required series compensation to reduce the inductive line impedance compiled due to long line length.

Customer Benefit

Ability to maximize amount of wind power to be transferred across the new 345 kV transmission lines.

Electricity of Vietnam

18 banks from 2012 - 2016

6,588 total Mvar in operation and awarded

Customer Challenge

Improve capacity of the 500 kV Vietnam transmission system with a compressed amount of time of less than 12 months to install systems.

Customer Application

Increase in the power transfer capability of existing transmission lines.

Customer Benefit

Increased reliability of existing transmission systems, improved voltage support and amount of power transfer capability and timely delivery of equipment meeting compact schedule requirements.

Electric Transmission Texas, LLC

Joint venture a joint venture between subsidiaries of American Electric Power and Berkshire Hathaway Energy

Edison, Gauss, Kirschoff, and Orsted Substations.

Customer Challenge

Need to provide reliable and efficient power across the new 345-kV transmission lines required to maximize the transfer of renewable generation. Must not negatively interact with the existing generation or system – Sub Synchronous Resonance concerns.

Customer Application

Eight series compensation banks located at four different sites to enable the maximum amount of power transfer capability on new 345-kV transmission lines in the CREZ regions throughout Texas.

Customer Benefit

Reliable and efficient means to transfer power from renewable generation on the new 345-kV transmission lines in the CREZ areas.

BPA (Bonneville Power Administration)

Three Phase Bank Rating: 2 X 675 Mvar

Substations: Bakeoven 1 & 2

Customer Challenge

Need to provide reliable and efficient power across the 500 kV California-Oregon Intertie . Required to increase the overall power transfer capability across the tie to facilitate the increase in capacity requirements from renewable generation projects being added to the regional system.

Customer Application

To enable the maximum amount of power transfer capability on the California-Oregon 500 kV transmission intertie.

Customer Benefit

Reliable and efficient means to transfer power from renewable generation on the new 500 kV transmission California-Oregon Intertie. GE Vernova supported a staged fault test performed by BPA, which demonstrated the capability of the GE Vernova Series Capacitor banks to withstand a close-in fault with no damage.

Modular Arc Commutating Triggered Air Gap (MACTAG)

GE Vernova’s family of Modular Arc Commutating Triggered Air Gap (MACTAG) solutions represent the industries leading technology for fast protective devices. The patented technology provides fast, reliable bypass protection, which can reduce the amount of Metal Oxide Varistors (MOV) required on a series capacitor bank resulting in project cost savings.

Customers can realize the following potential advantages with GE Vernova’s MACTAG solutions including:

- Enhanced Fault Durability and Voltage Withstand Performance

- Higher Protective Level Ratings with Fast Recovery Time Validated by Independent 3rd Party

- 50% Smaller Footprint with Reduced Installation Time

GE Vernova’s MACTAG is available in two models: MACTAG 240 and MACTAG 360. The MACTAG models are the fastest TAG’s in the industry and suitable for fast recovery applications. For applications where fast recovery time is not required, a Pilot Gap only option is available. The models include:

Modular Arc Commutating Triggered Air Gap

- MACTAG 240, maximum protective level of 240-250kV*

- MACTAG 360, maximum protective level of 360-400kV*

( * Depends on the application )

MACTAG 360

MACTAG 360

MACTAG 240

MACTAG 240

Pilot Gap (Suitable where fast recovery is not required)

- PG 240, maximum protective level of 240-250kV*

- PG 360, maximum protective level of 360-400kV*

PG 240

PG 240

PG 360

PG 360