Reactive power support for transient stability, voltage stability, increasing power transfer and power oscillation damping

Reactive power support for transient stability, voltage stability, increasing power transfer and power oscillation damping

GE Vernova’s Static Var Compensator (SVC) solutions are a cost-effective and efficient means to provide dynamic voltage support and maintain the reliability and efficiency of power supply. These solutions are highly reliable, easy to integrate into both existing and new infrastructures, and reduce the investment required for building new network extensions.

GE Vernova’s Static Var Compensator (SVC) solutions are a cost-effective and efficient means to provide dynamic voltage support and maintain the reliability and efficiency of power supply. These solutions are highly reliable, easy to integrate into both existing and new infrastructures, and reduce the investment required for building new network extensions.

GE Vernova’s SVC solutions are customized based on the utility’s technical and economic requirements for their network such as fault level and load parameters. GE Vernova provides an extensive services portfolio comprised of feasibility and network studies, project management, engineering capabilities, equipment, installation services and long term maintenance contracts, delivering an integrated and robust system that provides utilities with the following competitive advantages.

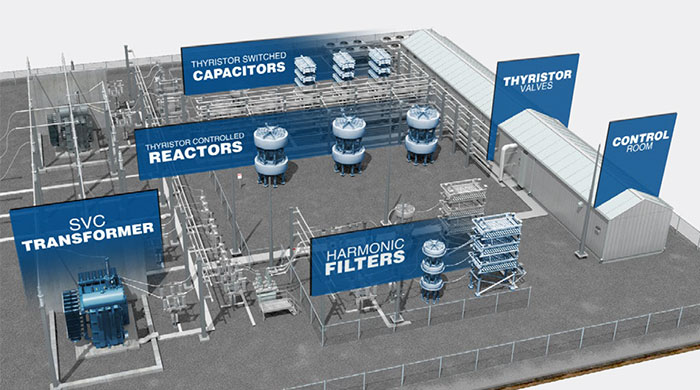

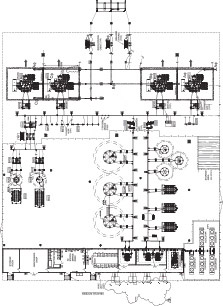

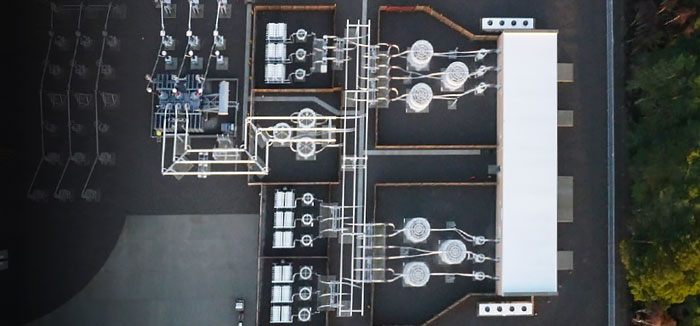

-100/+200Mvar classic SVC design

-100/+200Mvar classic SVC design

GE Vernova’s Classic SVC design is customized based on the utilities key requirements for system performance. Every system is tested extensively during factory acceptance testing and site commissioning to ensure guaranteed performance.

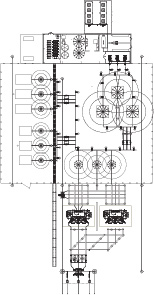

-100/+200Mvar Main Reactor design, with smaller footprint

-100/+200Mvar Main Reactor design, with smaller footprint

GE Vernova’s patented Main Reactor SVC design is customized based on the utility’s key requirements for system performance. Every system is tested extensively during factory acceptance testing and site commissioning to ensure guaranteed performance.

Traditionally, the SVC medium voltage bus is connected directly to the SVC coupling transformer, but with the main reactor configuration there is a reactor connected between SVC bus and coupling transformer.

The Main Reactor concept efficiently isolates harmonics, even in demanding network conditions. This design requires fewer harmonic filters enabling a compact, optimized SVC layout.

Advanced Digital Control platform for SVC systems

Advanced Digital Control platform for SVC systems

GE Vernova’s approach to SVC Control System represents the latest in design methodology by utilizing a powerful Model Based Design approach. With this approach the SVC Control System software is built using a core library of complex control algorithms that represents over 50 years of FACTS experience within GE Vernova. Model Based Design utilizes a graphical interface for the design stage and translation of control models with automatic code generation for all testing and verification stages. With this approach, GE Vernova has enhanced the quality, reliability, and maintainability of the Advanced Digital Control system for SVCs.

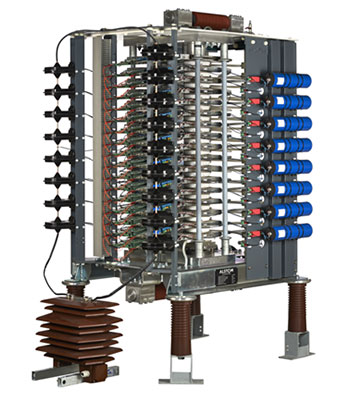

GE Vernova's Advanced Thyristor Valve

GE Vernova's Advanced Thyristor Valve

Thyristor valves are used for controlling reactive power in Static Var Compensators. Thyristor Controlled Reactor (TCR) valves are used to control the effective fundamental frequency current in the reactors by controlling the conducting ratio through varying the firing angle of the thyristors. Thyristor Switched Capacitors (TSC) bank valves are used for switching capacitor banks on or off according to the reactive power demand on a time scale of several periods or more.

The Advanced Thyristor Valve (ATV) is GE Vernova’s latest range of liquid-cooled thyristor valves for Static Var Compensator applications. These thyristor valves have been developed by drawing on GE Vernova’s extensive experience of more than 50 years of applying thyristor based SVCs both for transmission and industrial applications. The ATV provides a very compact, versatile and standardized platform for both TCR and TSC variants.

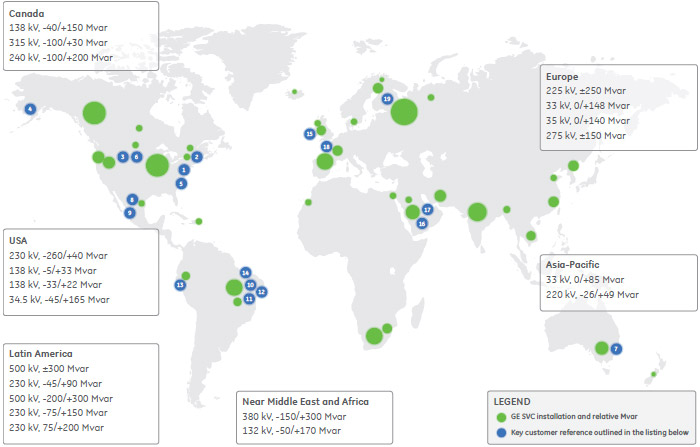

GE Vernova has designed, delivered and supports over 380 Static Var Compensator Systems globally in a broad range of applications and environments. The below details are a selected representation of recent projects, a complete reference list is available upon request.