Providing advanced protection for a wide range of bus protection applications.

Providing advanced protection for a wide range of bus protection applications.

The BUS 1000/2000 is a solid state, high speed protection system for the detection of phase-to-phase and phase-to-ground faults on bus bar installations. It can be used to protect high voltage bus bar installations of any voltage.

BUS 2000 models add to the functionality of the BUS 1000 through the metering, monitoring, event recording, waveform capture, and IRIG-B time synchronization capabilities of the DMS metering and monitoring module.

The BUS 1000/2000 is a solid state, high speed protection system for the detection of phase-to-phase and phase-to-ground faults on bus bar installations. It can be used to protect high voltage bus bar installations of any voltage.

BUS 2000 models add to the functionality of the BUS 1000 through the metering, monitoring, event recording, waveform capture, and IRIG-B time synchronization capabilities of the DMS metering and monitoring module.

Manufacturing for this product has been discontinued.

Manufacturing for this product has been discontinued.

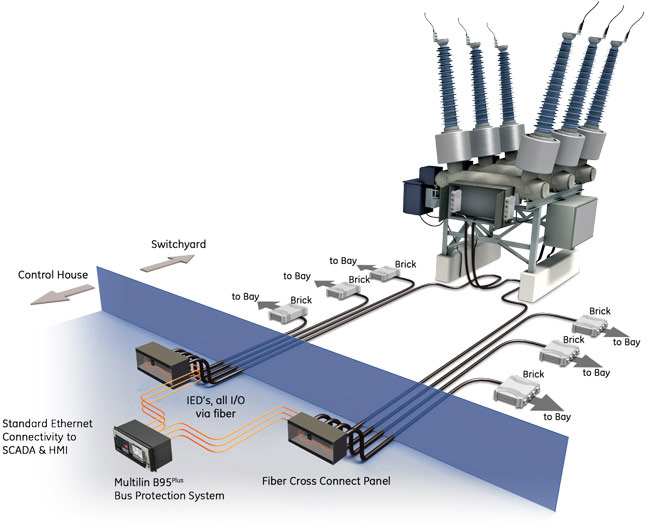

We Solve the Field Wiring Challenge with the B95Plus Bus Protection System

The Multilin B95Plus Bus Protection System changes the focus of bus protection to that of application by replacing most of the field wiring with distributed I/O and fiber optic cables. The bus protection system consists of a distributed process interface (data acquisition and tripping) architecture using HardFiber Bricks as bay units, with centralized processing performed by the B95Plus protection relay. All copper field wiring is between primary equipment in the switchyard and Bricks, which ideally should be located at the primary equipment in the switchyard. Fiber optic cables connect Bricks to the B95Plus. For all applications, the installation is then identical: the physical interface consists of Bricks connected to a fiber optic cable. A single B95Plus is mounted in a relay cabinet, with the process cards in the unit patched to the fiber optic cables coming from the Bricks.

The HardFiber Brick System can easily be incrementally scaled to include new equipment as stations evolve. Duplicated Bricks in the switchyard provide a drastic improvement in reliability and security over today’s technology.

The B95Plus bus protection relay unit is the heart of the system. This unit performs all processing functionality, including protection functions, metering, monitoring, FlexLogic and SCADA communications.

The HardFiber Brick uses connectorized cables to interface with primary equipment and with system measurements, and to interface to the B95Plus itself. The cables at the Brick end uses an IP67 certified industry standard connector designed for rugged environments. These connectors screw onto the Brick for a simple, tools-free connection. Three of the cables are copper cables used to acquire AC measurements, acquire equipment status, and provide equipment control. The fourth cable provides the fiber interface to the B95Plus central unit as well as DC power to the Brick. These cables therefore can become standard parts, manufactured in advance of installation by any cable manufacturer. These cables are also directly available from GE Vernova.

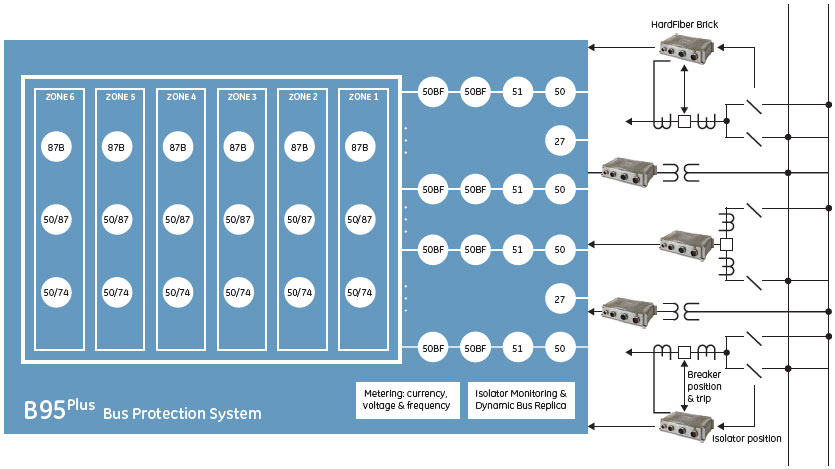

The B95Plus bus protection relay system provides robust and reliable protection for all bus protection applications. Highlights of the protection functions related to bus protection include:

| Device Number | Function |

|---|---|

| 87B | Percent bus differential |

| 27 | Undervoltage |

| 50 | Instantaneous overcurrent |

| 50/74 | CT Trouble |

| Device Number | Function |

|---|---|

| 50/87 | Unrestrained Bus Differential |

| 51EF | End fault protection |

| 51 | Time overcurrent |

| 50BF | Breaker failure |

The B95Plus can be applied on a multitude of bus configurations due to the distributed architecture, and includes support for up to 6 zones of bus differential protection and support for up to 24 bus sources. The physical connection and wiring architecture for the B95Plus system will be identical for any bus configuration: Bricks installed to acquire measurements and equipment status, with the B95Plus unit connected to Bricks via fiber optic cables. The relay panel design will be identical for all applications, for all bus configurations. The only difference from application to application is the number and location of Bricks, and the programming of the B95Plus unit.

Some typical bus configurations that can be protected by the B95Plus:

Two single buses with a bus coupler

Two single buses with a bus coupler

Double bus with a bus coupler

Double bus with a bus coupler

Breaker-and-a-half arrangement

Breaker-and-a-half arrangement

The B95Plus Bus Protection System is intended to operate as a standalone, distributed bus protection system. The bay units for this system are Bricks, part of the HardFiber IEC 61850 process bus solution. Once the Bricks for the B95Plus are installed process bus data is available for use for any other zone of protection. The Bricks, then, are a distributed I/O interface for all protection functions and zones, not just the B95Plus. With the B95Plus in place, installing line protection or feeder protection is a simple process: mount the relays in a panel, and patch to the fiber optic cable from the appropriate Bricks. The only requirement is the relays must implement the appropriate IEC 61850 datasets to interface successfully with the Bricks. All members of the Universal Relay family have the ability to interface with Bricks.

Expand protection through process bus

Expand protection through process bus

| BUS DIFFERENTIAL PROTECTION | |

|---|---|

| Number of differential zones | Six 3-phase zones |

| Max number of currents: | Total dynamic number of bus source to zone connections closed at any one moment in time up to 120 |

| CT ratio compensation range | 32:1 |

| Operating time | < 1 power system cycle - typical bus fault |

| BUS REPLICA | |

|---|---|

| Features | Dynamic bus source current assignment to each zone, dynamic zone trip assignment to each bus source, dynamic blocking of zones on CT bypassed, 1 user programmable auxiliary zone trip inputs, 3 user programmable bus source trip inputs, dynamic zone expansion/reduction |

| BUS SOURCES | |

|---|---|

| Number of bus sources | 12 per process card included in the order code |

| Current inputs | 3-phase currents |

| CT rated primary | 1 to 65000 A |

| CT rated secondary | 1 A or 5 A |

| Nominal frequency | 50 or 60 Hz |

| CT Trouble Monitoring | 1 element per bus source |

| Breaker failure protection | 1 element per bus source |

| Instantaneous Phase Overcurrent | 1 element per bus source |

| Inverse Time Phase Overcurrent | 1 element per bus source |

| VOLTAGE SOURCES | |

|---|---|

| Number of voltage sources | 2 per process card included in the order code |

| Voltage inputs | 3-phase voltages, wye or delta |

| VT ratio | 1.00 V to 24000.00 /td> |

| VT rated secondary | 25.0 V to 240.0 V |

| Nominal frequency | 50 or 60 Hz |

| ISOLATORS | |

|---|---|

| Number of isolators | 48 per process card included in the order code |

| Isolator status inputs | Form “a” and form “b” contact inputs, each optionally dual redundant |

| Configurable failsafe modes | 2Open, closed, last valid state |

| Monitoring | Alarm on inconsistent inputs persisting longer than a user set time |

| TRANSIENT RECORDER | |

|---|---|

| Storage capacity | Five records with all channels recorded, at 128 samples per cycle, spanning 1 second with no retriggers |

| Number of records | 1, 2, 5, 10, 20, 30, 40, or 50 records |

| Sampling rate | 16, 32, 64 or 128 samples per power cycle |

| AC waveform channels | All enabled bus sources and voltages sources |

| Analog channels | Magnitudes and angles of all ac waveforms recorded plus all enabled zone differential and zone restraint phase current magnitudes and angles |

| Digital channels | 128 user configurable channels on the main card and 128 user configurable channels on each process card |

| Configurable digital data | Any FlexLogic™ operand |

| Storage modes | Automatic overwrite, protected |

| Triggering modes | Time window from rising edge of trigger, continuous recording up to 4 additional basic record lengths as long as retrigger is active |

| Pre-trigger window | 0 to 100% of the basic record length |

| Data storage | non-volatile memory |

| EVENT RECORDER | |

|---|---|

| Storage capacity | 8,192 events plus 8,192 events on each process card |

| Time tag: | to 1 µs |

| Triggers | all FlexLogic™ operand activations |

| PROCESS I/O | |

|---|---|

| Number of process bus ports | 8 per process card |

| Port type | 100Base-BX-D, in SFP package with LC 50/125µm multi-mode connector |

| Transceiver diagnostics | per SFF-8472 |

| Brick synch frame jitter | ±1µs |

| POWER SUPPLY | |

|---|---|

| Nominal DC voltage | 125 to 250 V |

| Minimum DC voltage | 80 V |

| 1Maximum DC voltage | 300 V |

| Nominal AC voltage | 100 to 240 V at 50/60 Hz |

| Minimum AC voltage | 80 V at 48 to 62 Hz |

| Maximum AC voltage | 275 V at 48 to 62 Hz |

| Voltage withstand | 2 × highest nominal voltage for 10 ms |

| Voltage loss ride-through | 200 ms duration at nominal input voltage |

| Power consumption | 150 VA maximum |

| PROCESS CARD OPTICAL | |

|---|---|

| Number of transceivers | 8 |

| Transceiver type: | Transmit 1550 nm, receive 1310 nm, 100Mb/s, bi-directional single-fiber 50/125µm multi-mode module (levels comply with IEEE 802.3 standard 100Base-BX-D) |

| Optical transmit power | –14 to –8 dBm |

| Maximum optical input power | –8dBm |

| Optical receiver sensitivity | –30dBm |

| Termination | LC fiber connector |

| Laser class | Class 1. This product is eye-safe under all operating conditions. |

| REMOTE RESOURCE SPECIFICATIONS | |

|---|---|

| Number of field units | 8 per process card |

| Number of field contact inputs | 1 for each brick contact input |

| Number of field contact outputs | 1 for each brick contact output |

| Number of field latching outputs | 1 for each brick latching output |

| Number of shared inputs | 16 per process card |

| Number of shared outputs | 16 per process card |

| APPROVALS AND CERTIFICATION | |

|---|---|

| Compliance | CE, UL, ISO |

| Compliance | Applicable Council | Directive According To |

|---|---|---|

| CE | Low voltage directive | EN 60255-27 (normative sections) |

| EMC directive | EN 60255-26 / EN 50263 EN 61000-6-5 (Area G) | |

| UL | cULus | UL 508 UL 1053 C22.2 No 14 |

| ISO | Quality management system | ISO 9001 |