Learning programs follow our tier 3 and 4 course structures as outlined below, and blend together e-learning, virtual classroom sessions and face-to-face workshops. All elements have on-line assessment testing. To attend you must have completed all the prerequisites needed.

Industrial Communications Classroom, Virtual and e-Learning Courses

A wide variety of classroom,virtual & e-learning courses at your fingertips

GE Vernova’s Industrial Communications training is offered in a wide variety of platforms and topics to provide flexibility in time, location and skill level. From attendance in on-site classroom courses to virtual course attendance, self-paced e-learning videos and customized courses, GE Vernova’s training provides customers with high-quality knowledge to be safe, efficient and successful in industrial wireless communications.

Industrial Communications Classroom, Virtual and e-Learning Courses

A wide variety of classroom,virtual & e-learning courses at your fingertips

GE Vernova’s Industrial Communications training is offered in a wide variety of platforms and topics to provide flexibility in time, location and skill level. From attendance in on-site classroom courses to virtual course attendance, self-paced e-learning videos and customized courses, GE Vernova’s training provides customers with high-quality knowledge to be safe, efficient and successful in industrial wireless communications.

Fundamentals of RF Communications

Instructors will remove the mysteries of RF communications by showing students the fundamentals of RF wireless theory, design, and installation. We will also discuss best practices for industry standard applications including Point-to-Point and Point-to-Multipoint radio systems. Students will also learn about the various types of radio interfaces including protocols and network fundamentals.

Factory Training Courses

Scheduled training classes are offered at regular intervals throughout the year at the GE Vernova MDS Technical Training facility located in Rochester New York, U.S.A. The Technical Training Center contains equipment for hands-on interaction with wireless communications products, test tools, and computers. Training class sizes are kept small so instructors can interact with each student. Students receive comprehensive course manuals, with course notes that include lab exercises.

Lentronics Hardened Optical Networks

Lentronics Hardened Optical Networks product specialists offer a variety of training courses for both SONET and SDH telecommunications standards. Customers can choose from holding training courses at their own physical location, or having their personnel take training at the GE Vernova main office located in Burnaby, just outside of Vancouver, Canada. Courses range from 2 to 5 days in length depending on customer requirements and the depth of training desired. Customized courses can also be provided.

Customer Site Training Courses

To increase the number of employees who can benefit from our training, GE Vernova MDS Technical Training offers the option of conducting training courses in person at customer facilities. These on-site courses can be customized to a specific range of topics.

Regional Training

Regularly scheduled Regional Training courses are offered at selected locations around North America. Contact your factory representative to discuss course offerings. Click here here to request more information on regional training courses.

Training for JungleMUX & TN1U/TN1Ue

Recommended Products & services

Learning & Development

Technical Training for Protection & Control and Substation Automation Solutions

GE Vernova’s portfolio of Protection & Control and Substation Automation learning and development courses feature a wide variety of integrated and flexible programs taught across multiple platforms. The courses create an ideal environment for students to learn about GE Vernova’s Protection & Control and Substation Automation products, services and solutions offerings, and to build upon their knowledge to create integrated systems capability.

Learning & Development

Technical Training for Protection & Control and Substation Automation Solutions

GE Vernova’s portfolio of Protection & Control and Substation Automation learning and development courses feature a wide variety of integrated and flexible programs taught across multiple platforms. The courses create an ideal environment for students to learn about GE Vernova’s Protection & Control and Substation Automation products, services and solutions offerings, and to build upon their knowledge to create integrated systems capability.

Virtual Courses

Each Virtual Course uses e-learning self-paced course work, virtual class sessions and on-line testing/assessment of what you have learned. These courses follow our tier 1 and 2 course structures as outlined below, and are prerequisites for any of our workshop sessions.

Course structure tier 1 and 2

|

|

|

|

|

Course tools

|

|

|

|

Learning Programs

|

|

|

|

|

|

|

Key attributes:

- Build on the content learned in the virtual class offerings and move into system integration of GE Vernova products to create customer solutions.

- Both the Essentials and Advanced course follow this model with the advanced course building on the essentials course activities to build more complex solutions.

- Both courses starts with an initial virtual class session. This is then followed with e-learning coursework and testing, leading to a second virtual classroom session and then a hands-on face to face workshop. We will conclude with a final test and a final virtual class to close out the course.

- The aim of the final virtual session is to allow students time to reflect on the course and ask any question they might have about the course and its content.

- Throughout the course students are encouraged to collaborate with the instructor and their peers through the collaboration tool.

- Its all about learning, it is much more than a training course!

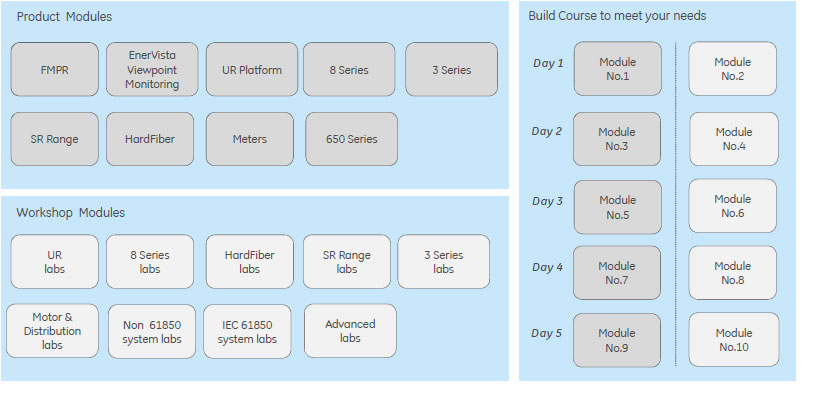

Customized Learning

To better suit the needs of your business, course customization has been designed to allow you with the flexibility of customizing your own program. Both customized and standard course offerings can be delivered at one of our Learning Centers or at a location of your choice. Our product training courses comfortably accommodates a learning audience of 12.

How does it work?

Begin with selecting a combination of Product Training and Lab modules as shown below. Customized programs must meet the minimum of six modules which is the equivalent of three business days with a class size of 8-12 participants.

Use our Protection & Control or Substation Automation custom course configurator to structure your course and get an instant quote. Contact your Grid Automation sales representative.

Example of the Protection & Control custom course configurator

Recommended Products & services

Technical Training and Certifications

for HV/MV Equipment and EHS

Training matters. It’s the key to enabling substation operators’ staff to maintain peak equipment performance in a safe environment. Gaining hands-on experience and enhancing technical skills will add long-term value to your business and career. You can rely on GE Vernova’s technical expertise to support your team’s development.

Technical Training and Certifications

for HV/MV Equipment and EHS

Training matters. It’s the key to enabling substation operators’ staff to maintain peak equipment performance in a safe environment. Gaining hands-on experience and enhancing technical skills will add long-term value to your business and career. You can rely on GE Vernova’s technical expertise to support your team’s development.

Virtual Reality Technical Training – Safe, Hands-on and Engaging!

Designed to simulate the real experience, Virtual Reality (VR) modules are the fastest and most efficient methods for field employees to safely learn products’ technical overview, operations and maintenance procedures as well as safety instructions.

The solution includes:

- VR training experiences developed by subject matter experts and used in GE Vernova Training facilities

- Licenses to use VR modules at customer premises

- Services to develop customized modules and to provide recommendations to select the best learning path

Modular Training

Focus on knowledge and know-how:

- Standardized and proven technical content

- Training on real equipment led by field experienced trainers

- Certified delivery options

- Customized training

- Complete curriculum

Real products for hands-on training:

- GIS bays

- AIS poles

- FK breaker operating spring mechanism

- Disconnectors

- Current and capacitor voltage transformer

- Bushing and transformer tap changers

Benefits of Technical Training

GE Vernova’s Technical Institute works with you to build the training plan best adapted to your teams’ needs and provides training through advanced methodologies with e-learning, theoretical courses, hands-on training on real size equipment or competence development programs.

Improved efficiency and safety at work

Training is the most efficient tool to develop know-how and enhance employee performance.

Better technical expertise

As GE Vernova develops and manufactures leading transmission products and solutions, its experienced trainers benefit from engineering and maintenance service expertise.

Training perfectly adapted to the audience

With more than 200 training courses in different languages, you will find one adapted to the trainee level of knowledge (operators, managers, engineers…) and objectives. If not, you can ask for customized training!

Industry experience

With more than 13,500 trainee days per year and 30 years of experience in training, our Technical Institutes, all located in our manufacturing sites, provide hands-on training using real equipment and sandbox for practical application.

State-of-the-art methods and tools

To better answer your needs, choose from a large range of training methods: tutored e-learning, classroom course, hands-on, set curriculums, 3D modules and competence development.

The latest knowledge content

We continuously improve existing training modules and develop new ones according to local regulations, new technologies, products and solutions.

Competence Development Training - Excellence Through Certification on Your Equipment

Grid Solutions' Technical Institute is committed to your success. Our intensive, customer-specific Competence Development program complies with the highest standards of safety and operational excellence.

Fast-track experience development

It is the ideal solution for companies where there has been growth or restructuring and where a new group of employees must acquire technical skills in a short period of time, or for electricity intensive industries, where electricity management is not a core business.

Tailored to your specific needs

It is an extremely in-depth program, giving you the support you need to maintain your installation in optimum operating conditions. And since it is designed to train your people to your required skill level, it also serves to boost your employees’ career development, allowing them to become certified technical leaders.

While training can involve time spent at an Grid Solutions Technical Institute, it focuses on hands-on application training at your site. The program begins and ends with skill assessment. Evaluations are essential to understanding the depth of knowledge transfer and the teaching program required to best fulfill your needs.

A measured result

Our training methodology continues through to the end and culminates in a structured evaluation with on-line quiz and off-line assessments, face-to-face interviews and hands-on tests. This proven process provides a clear competence picture and measurable results.

Technical Institute Training Global Contact Centers

GE Vernova’s Technical Institute for training on HV/MV equipment and systems offers hands-on training in state-of-art facilities around the world. Our global contact centers are shown below, or you can email the Technical Institute.

Chile

Primary Equipment, Safety and Environment

Salar de Ascotán 1288

Parque de Negocios ENEA – Pudahuel

9031135, Santiago

Tel: +56 2 2652 6566

Germany

Primary Equipment, Safety and Environment

Lilienthal Str.150

34123 Kassel

Tel: +49 561 502 2663

Switzerland

Primary Equipment, Safety and Environment

Carl-Sprecher-Strasse 3

CH-5036 Oberentfelden

Tel: +41 58 506 13 01

France

Primary Equipment, safety and environment

1 rue Paul Doumer - BP601

73106 Aix-Les-Bains Cedex

Tel: +33(0) 4 79 34 78 00

India

Primary Equipment, safety and environment

142 Vadalur Walajhbad Road

Salamangalam Village, Kanchipuram District

Paddapai – 601301, T.N.

Tel: +91 44 67126874

Turkey

Power Transformer

Baris Mh Güney Yanyol Cd. No. 320

41410 Gebze Kocaeli

Tel: +90 533 380 14 69

Recommended Products & services

HVDC & FACTS Services

To ensure the performance of power electronics system equipment, which are critical asset in transmission network, GE Vernova provides comprehensive services throughout the systems lifecycle. The services can be provided by our local team and with the support of our global Competence Centers when the equipment is installed, during the warranty period and beyond.

GE Vernova’s services for systems cover wide range of power system equipment.

HVDC & FACTS Services

To ensure the performance of power electronics system equipment, which are critical asset in transmission network, GE Vernova provides comprehensive services throughout the systems lifecycle. The services can be provided by our local team and with the support of our global Competence Centers when the equipment is installed, during the warranty period and beyond.

GE Vernova’s services for systems cover wide range of power system equipment.

Asset Lifecycle Management Services

Optimize asset maintenance and replacement strategies with GE Vernova’s Asset Lifecycle Management services, including site inspection, oil analysis, and online monitoring.

Site inspection

- Visual and internal inspections

- Functional checks and electrical tests

- Standard protocol for condition data collection with digital apps

- Data checks and firsthand diagnostics

- Investigation on failed electronic part used in controls

- Capacitance measurement

Continuous online monitoring solutions

- Remote monitoring of SVC controls

- Thyristors and HV capacitors condition assessment

- Remote monitoring and troubleshooting of HVDC systems

Added value services

- Flexible service agreements providing GE Vernova’s specialized expertise

- Expert consulting services for data and alarm management using network simulation tools

- Remote technical diagnostic, analysis & support

- Enhancement, bug analysis, workaround procedure

- Comprehensive centralized asset monitoring

- Obsolescence management

Maintenance & Repair

Maximize the life cycle performance of HVDC and FACTS systems with maintenance and repair services.

Maintenance

- Preventive and corrective maintenance

- Faulty components replacement including thyristor valves, capacitors, reactors, cooling systems and yard components

- Functional tests

- Devices reprogramming

- Equipment with thermal camera monitoring

- Control system overhaul

Repair

- Diagnostic and repair of electronics components

- Repair or replacement of defective or obsolete parts

- Valves test validation in real condition

Spare parts management

- Spare parts for legacy and recent systems

- Strategic spare parts stock for critical, long lead or out-phased equipment

- Reverse engineering of obsolete parts

Permanent hotline

- 24/7 technical support

- Guaranteed response time

- Escalation to technical experts

Modernization

Leverage GE Vernova’s technical expertise to provide custom engineered solutions.

By integrating cost effective solutions based on innovate and proven technology customers increase systems’ reliability and reduce risk of failure.

Upgrade solutions can solve obsolescence of ageing equipment, get the systems ready to evolving network needs or to meet new regulation requirements. It includes:

- New designs and technology adaptation to equipment in operation

- Condition monitoring system addition

- Refurbishment of installations to ensure equipment safety, reliability and performance

- Replacement of critical components including control and protection equipment, valves, platform components, spark gaps, communication systems

- Upgrade from analog to digital control

- Partial or complete retrofit of Static VAR Compensator, Synchronous Condensers and Series Compensation systems

Technical Training

Enhance your team’s know-how and productivity with technical training.

Comprehensive training methodologies

- E-learning

- Modular training

- Software training

- Competence development training

- Educational partnership

Complete scope for all employees

- Electrical safety and environmental risk prevention

- Applicable for power transformers, instrument transformers, circuit breakers, disconnectors, gas-insulated switchgear and HVDC systems

- Protection and control systems

- Network management solutions

- Telecommunications

- Grid modernization solutions for the smart grid

Standard training courses

- HVDC Fundamentals and Maintenance

- SVC/STATCOM Fundamentals and Maintenance

- SVC Expert training

- FSC Fundamentals and Maintenance

- Industrial Rectifiers Fundamentals and Maintenance

- Power Electronics Systems Operation

- Basics of Protection & Control

Recommended Products & services

Services for Disconnectors

Disconnectors guarantee the safety of the people working on high voltage networks, providing a visible and reliable air gap isolation. With the experience of more than 100,000 high voltage disconnectors manufactured and installed, GE Vernova supports customers’ needs to minimize equipment failure rates while maximizing employees’ safety.

These services, performed by local trained and certified Field service engineers, allow fast response time and cost effective service for optimized customer asset availability and life time.

Services for Disconnectors

Disconnectors guarantee the safety of the people working on high voltage networks, providing a visible and reliable air gap isolation. With the experience of more than 100,000 high voltage disconnectors manufactured and installed, GE Vernova supports customers’ needs to minimize equipment failure rates while maximizing employees’ safety.

These services, performed by local trained and certified Field service engineers, allow fast response time and cost effective service for optimized customer asset availability and life time.

Asset Lifecycle Management Services

Optimize asset maintenance and replacement strategies with GE Vernova’s Asset Lifecycle Management services.

Site inspection

- Visual, functional inspections and electrical tests

- data checks and firsthand diagnostics by GE Vernova Experts

Disconnector online monitoring

- Online condition monitoring device as retrofit solution for all types of disconnectors

- Monitoring of active parts temperatures and motors

- Measurement of travel curve and speed control of the live part during opening and closing

- Remote condition monitoring data analysis and alarm management

Added value Services

- Flexible service agreements providing GE Vernova's specialized expertise

- Analytics for asset health management

- Expert diagnostics and advisory services

Maintenance & Repair

Maximize the life cycle performance of disconnectors with maintenance and repair services.

Maintenance

- Preventive and condition based maintenance

- End-of-life management

- Decommissioning solutions

Spare parts management

- Spare parts kits for maintenance & repair

- Strategic spare parts stock for critical or out-phased equipment

Permanent hotline

- 24/7 technical support

- Guaranteed response time

- Escalation to technical experts

Modernization & Extension

Leverage GE Vernova's technical expertise to provide custom engineered solutions.

Modernization (retrofit and upgrade) to solve obsolescence of ageing equipment)

- Replacement of live parts

- Upgrade with the latest technologies including motorization

- Implementation of online monitoring device on operating assets

Extension for evolving network needs

- Installation of additional bays and poles to existing substations

- Turnkey solutions for air-insulated substation extensions

Technical Training

Enhance your team’s know-how and productivity with technical training.

Comprehensive training methodologies

- E-learning

- Modular training

- Software training

- Competence development training

- Educational partnership

Complete scope for all employees

- Electrical safety and environmental risk prevention

- Applicable for power transformers, instrument transformers, circuit breakers, disconnectors, gas-insulated switchgear and HVDC systems

- Protection and control systems

- Network management solutions

- Telecommunications

- Grid modernization solutions for the smart grid

Recommended Products & services

Circuit Breaker Services

For Air & Gas Insulated and Generator Circuit Breakers

Circuit breakers automatically protect installations against phase-to-phase short circuits as well as phase-to-earth short circuits and optimize the reliability and efficiency of operating networks. Operators require cost-effective solutions to avoid unscheduled downtime, major failure and the subsequent penalties.

GE Vernova provides a full range of services on the three different types of insulating technologies: minimum oil, air blast and SF6 circuit breakers.

Circuit Breaker Services

For Air & Gas Insulated and Generator Circuit Breakers

Circuit breakers automatically protect installations against phase-to-phase short circuits as well as phase-to-earth short circuits and optimize the reliability and efficiency of operating networks. Operators require cost-effective solutions to avoid unscheduled downtime, major failure and the subsequent penalties.

GE Vernova provides a full range of services on the three different types of insulating technologies: minimum oil, air blast and SF6 circuit breakers.

Asset Lifecycle Management Services

Optimize asset maintenance and replacement strategies with GE Vernova’s Asset Lifecycle Management services, including site inspection, and online monitoring.

Site inspection

- Visual, functional inspections and electrical tests

- Condition assessment with advanced non-intrusive methods

- Standard protocol for condition data collection including digital applications

- Data check and firsthand diagnostics by GE Vernova experts

Circuit breaker online monitoring

- Online condition monitoring device as retrofit solution for all breaker types

- Monitoring of active parts, mechanisms and auxiliaries

- SF6 gas usage, electrical wear and temperature monitoring

- Remote condition monitoring data analysis and alarm management

Added value services

- Flexible service agreements providing GE Vernova's specialized expertise

- Analytics for asset health management

- Substation and fleet digital management

- Comprehensive centralized asset monitoring

- Mobile workforce access

- Expert diagnostics and advisory services

- End of Life Management

Maintenance & Repair

Maximizing the life cycle performance of circuit breakers and generator circuit breakers.

Maintenance and repair

- Preventive maintenance

- Condition based maintenance

- Trouble shooting repair

- End-of-life management

- Decommissioning solutions including SF6 and oil recycling

Spare parts management Brochure

- Spare parts kits for maintenance & repair

- Strategic spare parts stock for critical or out-phased equipment

- Critical spare parts rotation programs

- Spare Parts Pooling reducing outage duration and inventory cost

Permanent hotline

- 24/7 technical support

- Guaranteed response time

- Escalation to technical experts

Renovation & Modernization

Technical expertise to deliver custom engineered solutions.

Renovation and overhaul to expand the life of aging equipment

- Conduct the overhauling of the circuit breaker

- Change specified parts based on real condition of the equipment

Modernization (retrofit and upgrade) to solve obsolescence of aging equipment

- Implement latest technology solution on brownfield assets

- Change or retrofit specified parts to upgrade performance and safety

- Shorten intervention with engineered solutions to minimize outage

- Add monitoring on operating assets including continuous online monitoring

Extension for evolving network needs

- Install additional bays and poles to an existing substation

- Offer turnkey solutions for air-insulated substation extensions

Technical Training

Enhance your team’s know-how and productivity with technical training.

Comprehensive training methodologies

- E-learning

- Modular training - at GE Vernova training Center or at customer site

- Software training

- Competence development training

- Educational partnership

Complete scope for all employees

- Electrical safety and environmental risk prevention

- Applicable for power transformers, instrument transformers, circuit breakers, disconnectors, gas-insulated switchgear and HVDC systems

- Protection and control systems

- Network management solutions

- Telecommunications

- Grid modernization solutions for the smart grid

Supporting a Broad Range

of High Voltage Circuit Breakers

Benefiting from Centers

of Excellence Expertise

Providing partnership

through multi-year agreement

Supporting a Broad Range of High Voltage Circuit Breakers & Generator Circuit Breakers

GE Vernova maintains and repairs all types of circuit breakers, from recent to legacy assets that have been designed and installed for over a century including Sprecher+Schuh, AEG, Alsthom, Gec Alsthom, Areva, GE VERNOVA and GE Vernova equipment . Continuously developing new technologies, GE Vernova has the cumulated experience that allows GE Vernova field specialists to support any type of pneumatic, hydraulic or spring mechanism and any type of air, oil or SF6 insulation methods.

GE Vernova also provides condition assessment using non intrusive technologies and replacement of other OEM circuit breakers and generator circuit breakers.

4 Worldwide Centers of Excellence providing HV Circuit breaker services expertise

The local field service and engineering teams are supported by Centers of Excellence fully dedicated to design the maintenance plans, repair, monitoring, modernization and replacement solutions and to deliver customer training. There capabilities include:

- High voltage dielectric, electronic and mechanical testing capabilities

- Located at GE Vernova circuit breaker manufacturing and R&D facilities

- Certified ISO9001, ISO14001 and OHSAS18001

- Training centers with on-hands capabilities

Multi-Year Service Agreement & Outcome Based Contract

GE Vernova’s multi-year service years agreements are tailored to complement customers in-house resources and capabilities. Helping customers from increasing the reliability and availability of their systems to optimizing the total cost of ownership of their assets with:

- Close Partnership: To help achieve business goals, GE Vernova’s expertise on asset behavior and operations excellence is available as part of the customer service

- Fix cost and planned outage: Costs are contractually guaranteed while onsite jobs can be planned months ahead during customer scheduled outages

- Customized agreement: Long term agreements can include 24/7 support, obsolescence and parts management, maintenance and operations services, fleet management whatever the brands of the circuit breaker and generator circuit breaker

- Outcome based: Through outcome based contract, GE Vernova can guarantee the performance and the availability of any asset for long-term value. Contracts are tailored to serve power generation plant business objectives.

Transformer Services

Power transformers are critical for ensuring a sustainable supply of power to prevent outages. With the loss of insulation being irrecoverable, transformer failure risk can be minimized only if oil quality is maintained, moisture is controlled, temperatures are managed, incipient faults are detected and corrected, and an overhaul is conducted at midlife.

GE Vernova provides specialized technical services during the whole lifecycle of all high voltage transformers:

Transformer Services

Power transformers are critical for ensuring a sustainable supply of power to prevent outages. With the loss of insulation being irrecoverable, transformer failure risk can be minimized only if oil quality is maintained, moisture is controlled, temperatures are managed, incipient faults are detected and corrected, and an overhaul is conducted at midlife.

GE Vernova provides specialized technical services during the whole lifecycle of all high voltage transformers:

Installation & Relocation

GE Vernova offers the assembly and disassembly services of GE Vernova and other OEM installations including:

- Complete turn-key

- Full relocation services

- Rigging

- Transportation (rail, barge, truck)

- Installation

- ISO-phase modification

- Erection and commissioning

- Complete acceptance and commission testing including:

- Power factor measurement

- SFRA testing

- Engineering review

Asset Lifecycle Management Services

Optimize asset maintenance and replacement strategies with GE Vernova’s Asset Lifecycle Management services.

Site inspection

- Visual inspection, functional checks and electrical tests including infrared thermography

- Electrical tests including Power factor measurement, SFRA testing and engineering review

- Standard protocol for condition data collection with digital apps

- Data checks and firsthand diagnostics

- Internal inspections

- HV testing with mobile facilities

Transformer oil analysis in lab and diagnostics

- Dissolved gas analysis (DGA)

- Water content, breakdown voltage, acidity index, corrosive sulphur, PCB, inhibitor analysis, ageing markers: furans and methanol

- Oil analysis plan

Continuous online monitoring solutions

- Transformer retrofitting with monitoring devices and systems covering:

- Single- and multi-gas DGA for active part or tap changer (OLTC)

- Bushing, OLTC, cooling system and oil conservator monitoring

- Partial discharge, transient overvoltage sensors

- Expert consulting services for data analysis and alarm management

Added value services

- Flexible service agreements providing GE Vernova’s specialized expertise

- Transformer condition assessments, diagnostics and recommendations by GE Vernova experts

- Advanced diagnostics & prognostics models developed by our experts as part of our EnergyAPM solution

- Substation and transformer fleet digital management

- Comprehensive centralized asset monitoring

- Mobile workforce tools and processes

Maintenance & Repair

Maximizing the life cycle performance of transformers.

Maintenance

- Corrective and preventive maintenance

- End-of-life and decommissioning solutions

Repair & Mid-life overhaul

- Preliminary inspections and tests up to internal inspection (see detail in Asset Performance Management)

- Repair or replacement of defective or obsolete parts including bushings, small and main components, and accessories

- On load and no load tap changers inspection, repair or replacement

- Major repair or replacement of active part core components up to complete rewind – in repair workshop or at site with HV testing

- Treatment of corrosion points and oil leakages

- Oil processing, treatment and drying or replacement

- Complete regasketing

Spare parts management

- Spare parts for legacy and other transformers including tap changer components, bushings, Buchholz relays, pumps, motor fans, coolers, accessories and gaskets

- Strategic spare parts stock for critical, long lead or out-phased equipment

Oil Processing Services

- Oil testing and consultation

- Physical and chemical oil treatment: oil reclamation

- Oil reinhibiting and passivation

- Hot oil cleaning and drying

- Vacuum filling

- Oil degasification

Permanent hotline

- 24/7 technical support

- Guaranteed response time

- Escalation to technical experts

RB Watkins, an industry leader in power transformer and circuit breaker services, is now a GE Vernova company.

Modernization & Upgrade

Leverage GE Vernova's technical expertise to provide custom engineered solutions.

Modernization

- Life-extension program

- Change obsolescence main components

Upgrade

- Cooling upgrade for power upgrade and life time extension

- Ratio and voltage regulation upgrade to new needs

- Oil preservation system upgrade for Rubber bag or Drycol

- Bushing upgrade for risks mitigation, safety improvement and new practices compliance and new technologies

- Thermal upgrade of winding insulation to increase rated power or life time

Technical Training

Enhance your team’s know-how and productivity with technical training.

Comprehensive training methodologies

- E-learning

- Modular training

- Software training

- Competence development training

- Educational partnership

Complete scope for all employees

- Electrical safety and environmental risk prevention

- Applicable for power transformers, instrument transformers, circuit breakers, disconnectors, gas-insulated switchgear and HVDC systems

- Protection and control systems

- Network management solutions

- Telecommunications

- Grid modernization solutions for the smart grid

Recommended Products & services

Gas-insulated substation Services

Services are performed by local trained and certified field service experts fully equipped for SF6 gas handling up to decommissioning and SF6 reclamation process. GE Vernova provides a wide set of services that allow fast response time and cost effective solution for optimized customer asset availability and life time.

Gas-insulated substation Services

Services are performed by local trained and certified field service experts fully equipped for SF6 gas handling up to decommissioning and SF6 reclamation process. GE Vernova provides a wide set of services that allow fast response time and cost effective solution for optimized customer asset availability and life time.

Asset Lifecycle Management Services

Optimize asset maintenance and replacement strategies with GE Vernova’s Asset Lifecycle Management services.

Site inspection

- Visual, functional inspections and electrical tests

- Condition assessment with advanced non intrusive inspection services including digital X-ray, DCRM, vibration monitoring and UHF frequency analysis

- Standard protocol for condition data collection with digital apps

- Data checks and firsthand diagnostics by GE Vernova experts

Gas-Insulated Substation online monitoring LEARN MORE

- Retrofit with continuous online condition monitoring system

- Gas density monitoring and forecasting

- Internal arc localization, circuit breaker condition monitoring

- Analysis of partial discharge events

- Remote condition monitoring data analysis and alarm management

Value added services

- Flexible service agreements providing GE Vernova's specialized expertise

- Analytics for asset health management

- GIS and fleet digital management

- Comprehensive centralized asset monitoring

- Mobile workforce access

- Expert diagnostics and advisory services

- End of Life Management

Maintenance & Repair

Maximizing GIS performance throughout its lifecycle.

Maintenance

- Corrective and preventive maintenance

- End-of-life and decommissioning solutions

Spare parts management BROCHURE

- Spare parts for maintenance

- Strategic spare parts stock for critical or phased-out equipment

- Spare Parts Pooling reducing outage duration and inventory cost

Permanent hotline

- 24/7 technical support

- Guaranteed response time

- Escalation to technical experts

Renovation & Modernization

Leverage GE Vernova's technical expertise to provide custom engineered solutions

Renovation and overhaul

- Conduct the overhauling of each bay of the GIS including SF6 circuit breaker, switches, measurement reducers, surge arrestors, electrical cubicles.

Modernization and retrofit to solve obsolescence of ageing equipment

- Add monitoring on operating assets including continuous online monitoring

- Implement latest technology solution on brownfield assets

- Change or retrofit specified parts with major upgrade

- Replace aging or obsolete circuit breakers manufactured by GE Vernova or a 3rd party with a new GE Vernova vertical circuit breaker with pure spring mechanism.

Extension for evolving network needs

- Install additional bays and poles to an existing substation

Technical Training

Enhance your team’s know-how and productivity with technical training.

Comprehensive training methodologies

- E-learning

- Modular training

- Software training

- Competence development training

- Educational partnership

Complete scope for all employees

- Electrical safety and environmental risk prevention

- Applicable for power transformers, instrument transformers, circuit breakers, disconnectors, gas-insulated switchgear and HVDC systems

- Protection and control systems

- Network management solutions

- Telecommunications

- Grid modernization solutions for the smart grid

Recommended Products & services

HV/MV Services by Application

Optimizing asset reliability, up-time and performance

GE Vernova’s innovative and high-quality services help maintain and optimize high-voltage electrical assets throughout their entire lifecycle. Leveraging the design and manufacturing knowledge of our skilled engineers, the customized service solutions ensure the substations and networks perform as planned. Field and technical experts deliver services for applications across the power system, keeping assets up-to-date, safe, reliable and efficient while improving customers’ return-on-investment.

HV/MV Services by Application

Optimizing asset reliability, up-time and performance

GE Vernova’s innovative and high-quality services help maintain and optimize high-voltage electrical assets throughout their entire lifecycle. Leveraging the design and manufacturing knowledge of our skilled engineers, the customized service solutions ensure the substations and networks perform as planned. Field and technical experts deliver services for applications across the power system, keeping assets up-to-date, safe, reliable and efficient while improving customers’ return-on-investment.

Asset Lifecycle Management Services

GE Vernova’s Asset Lifecycle Management (ALM) services encompass a set of flexible solutions to optimize transmission and distribution electrical substations maintenance and replacement strategy. The services are designed to meet the customers desired level of outcome in terms of asset availability, risk management and total cost of ownership.

ALM services combine GE Vernova’s expertise in grid asset maintenance and reliability management with an innovative end-to-end set of digital applications and tools suitable for all types of asset independently of the original equipment manufacturer.

The ALM Services include:

- A comprehensive portfolio of methods to collect asset health data, including advanced non-intrusive inspection services and online condition monitoring solutions and Oil analysis.

- A set of proven analytics supplied by EnergyAPM, the GE Vernova's Asset Performance Management software designed for T&D assets software delivering Asset Health Status, Estimated Residual Life, Probability of Failure and Maintenance Recommendations.

- Flexible service agreements providing specialized expertise and guaranteed performance that fit specific customer requirements to achieved their operational objectives

- Customized consulting services to build and maintain a solution tailored to support operators to achieve their asset lifecycle management goals.

Explore Grid Asset Lifecycle Management Solutions Developed by Grid Field Experts

Whether its transmission, generation, distribution or industry and infrastructure electrical assets, GE Vernova provides the models and tools to enable customers to meet their company objectives in terms of:

- Reliability - by reducing outages, assessing and mitigating operational risks

- Cost efficiency - by maximizing asset life while optimizing maintenance costs and hedging risk costs, with particular care taken for ageing infrastructures

- Strategy - by providing the information needed to establish corporate asset investment plans and performance objectives with regulators and shareholders

- Organization - by capitalizing on electrical know-how in the context of an ageing workforce and aligning departments with consistent goals for increased efficiency

Visit the Asset Lifecycle Management webpage to learn more about these services, as well as the ALM services tailored to HV/MV equipment including circuit breakers, instrument transformers, disconnectors, gas-insulated substations, transformers and systems.

Maintenance & Repair Services

GE Vernova recommends regular maintenance on equipment to ensure optimal operation and to reduce the risk of failure. Maintenance plans must be carried out by a qualified field services supervisor with the prerequisite technical levels. During warranty period, various maintenance levels must be conducted by the manufacturer on a regular basis related to the equipment. GE Vernova’s local teams can support its customers with emergency repairs, time-based, predictive and corrective maintenance.

Maintenance

- Preventive maintenance

- Condition based maintenance

- Trouble shooting repair

- End-of-life management

- Decommissioning solutions

Spare parts management

- Spare parts kits for maintenance & repair

- Strategic spare parts stock for critical or out-phased equipment

- Spare Parts Pooling reducing outage duration and inventory cost

Permanent hotline

- 24/7 technical support

- Guaranteed response time

- Grid Experts Escalation

Learn more about the specific maintenance and repair services available for HV/MV equipment, including circuit breakers, instrument transformers, disconnectors, gas-insulated substations, transformers and systems.

Renovation & Modernization Services

High voltage substations are very valuable grid assets, and are critical for grid reliability and availability. After decades of operation, grid operators may foresee risks of increasing failure rates in these assets due to electrical and environmental stress. Operators may also have needs for evolving power demand or for standard or technological enhancement.

GE Vernova supports the decision-making process by providing a cost efficient solution for substations and products requiring improved performance, or to resolve some obsolescence issues. GE Vernova’s engineered solutions are based on condition and life assessment of any high voltage equipment including third party original equipment manufacturer.

Renovation and overhaul to expand the life of ageing equipment

- Conduct the overhauling of the substation

- Change some key parts with no major upgrade

Modernization (retrofit and upgrade) to solve obsolescence

- Add monitoring on operating assets, including continuous online monitoring

- Implement last technology solution on brownfield assets

- Change/retrofit some key parts with major upgrade, including circuit breaker retrofit for GIS

Extension to address evolving network needs

- Install additional bays and/or poles to an existing substation (legacy, third party or mix)

Learn more about the specific maintenance and repair services available for HV/MV equipment, including circuit breakers, instrument transformers, disconnectors, gas-insulated substations, transformers and systems.

Technical Training and Certification

Training matters. It’s the key to enabling staff to maintain peak equipment performance in a safe environment. Gaining hands-on experience and enhancing technical skills will add long-term value to your business and career. You can rely on GE Vernova’s technical expertise to support your team’s development.

GE Vernova’s network of Technical Institutes offers a full range of training in electrical grid safety, operations and maintenance of our power equipment, protection and control, and network management solutions, near your location. These value-adding courses encompass all aspects of electricity from fundamentals to in-depth equipment knowledge. Trainees benefit from trainers’ expertise in techniques and field experience combined with pedagogy.

Learn more about our HV/MV technical training.

Global Expertise Delivered Locally

GE Vernova aims to deliver continuous field operational excellence through its broad service experts network. Providing the highest level of quality of services as well as the competence development of the technicians and supervisors is GE Vernova’s top priority. GE Vernova’s subject matter experts’ competencies, qualification levels and certifications are checked regularly in compliance with local regulations and strict internal GE Vernova standards. As a result, wherever our customers are located, GE Vernova provides the best field experts to ensure complete satisfaction.

Services for Instrument Transformers

Internal dielectric strength degradation is the main risk affecting the lifetime performance of an instrument transformer. Contributing to 70% of the failures, it can ultimately cause a fire or explosion that can damage nearby high voltage assets. The degradation can be due to overheating, short circuit, oil leakage from gasket deterioration caused by tough environmental conditions, or the humidity contained in oil-impregnated cellulose insulation.

Services for Instrument Transformers

Internal dielectric strength degradation is the main risk affecting the lifetime performance of an instrument transformer. Contributing to 70% of the failures, it can ultimately cause a fire or explosion that can damage nearby high voltage assets. The degradation can be due to overheating, short circuit, oil leakage from gasket deterioration caused by tough environmental conditions, or the humidity contained in oil-impregnated cellulose insulation.

Asset Lifecycle Management Services

Maximizing instrument transformers’ life cycle performance.

Site inspection

- Visual, functional inspections

- Infrared thermography

- Standard protocol for condition data collection

- Data checks, diagnostics and advisory service by GE Vernova experts

Oil analysis Learn More

- Oil sampling

- Oil analysis by experts in GE Vernova laboratories or by a local partner

- Dissolved gas analysis on standard gases and complementary ones including oil quality, dielectric breakdown voltage, furans, moisture, and acidity

- Report including remedial actions and condition severity as per IEEE® or IEC® standards

Flexible service agreements providing GE Vernova's specialized expertise Learn More

GE Vernova Advantage

GE Vernova supports customers’ targets for minimum equipment failure rates while maximizing employees’ safety by leveraging its expertise to provide services that optimize cost and asset lifetime.

Cost optimization

- Increased equipment availability with condition based maintenance

- Optimized frequency of interventions

- Instrument transformer fleets better managed to avoid premature replacement that requires adaptation and civil work

Extended lifetime

- Expanded instrument cell lifetime up to 10 years with refurbishment

- Reduced risk of explosion with an accurate diagnosis of equipment condition based on oil analysis

Proven expertise

- GE Vernova services 400,000+ high voltage instrument transformers installed worldwide

- More than 50 years of experience in instrument transformers fleet management and oil analysis

Maintenance & Repair

Maximizing the life cycle performance Instrument transformers.

Preventive maintenance on powered equipment

- Regular visual inspection coupled with infrared thermography to identify oil leakage and hotspots

Condition assessment

- Humidity level in the cellulose evaluation through oil analysis and infrared thermography

- Results analysis and recommendation for arbitrage between maintenance and replacement by GE Vernova experts

Spare parts management Brochure

- Spare part kit dedicated to each design of oil-filled high voltage instrument transformers

- Strategic spare parts stock for critical or phased out equipment

Modernization & Extension

Leveraging GE Vernova’s technical expertise to provide custom engineered solutions

Modernization (retrofit and upgrade) to solve obsolescence of ageing equipment

- Upgrade with humidity regulation solution: membrane replacement by either metallic cell and addition of molecular sieve in oil

- Upgrade with optical sensors

Replacement

- Turnkey replacement services with GE Vernova’s state of the art high voltage instrument transformer including g3 filled AIS current transformer up to 245 kV, to benefit from the latest technological advances.

- Decommissioning solution with oil disposal

Extension with additional bays for evolving network needs

- Turnkey solutions for air-insulated substation extensions

Technical Training

Enhance your team’s know-how and productivity with technical training.

Comprehensive training methodologies

- E-learning

- Modular training

- Software training

- Competence development training

- Educational partnership

Complete scope for all employees

- Electrical safety and environmental risk prevention

- Applicable for power transformers, instrument transformers, circuit breakers, disconnectors, gas-insulated switchgear and HVDC systems

- Protection and control systems

- Network management solutions

- Telecommunications

- Grid modernization solutions for the smart grid