Materials and Eco-Design Studies

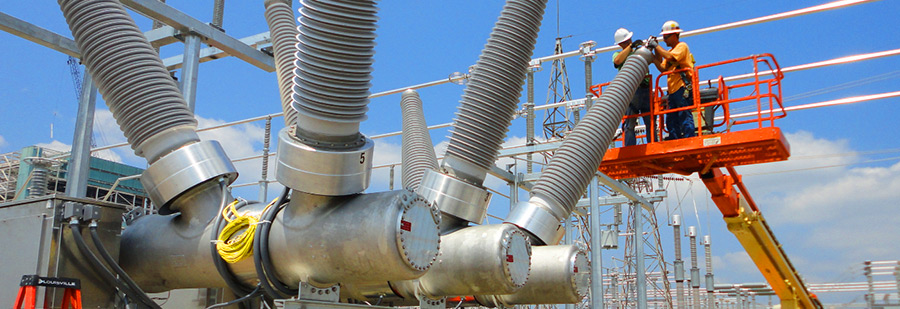

For High Voltage Solutions

GE Vernova delivers materials and eco-design studies for high voltage solutions to accelerate insulation and environmental innovation. GE Vernova’s services provide the expertise and methods that enable new value to support customer engineering, sourcing, quality control and EHS activities.

The technical studies, tests and impact evaluations support:

Materials and Eco-Design Studies

For High Voltage Solutions

GE Vernova delivers materials and eco-design studies for high voltage solutions to accelerate insulation and environmental innovation. GE Vernova’s services provide the expertise and methods that enable new value to support customer engineering, sourcing, quality control and EHS activities.

The technical studies, tests and impact evaluations support:

Reducing Environmental Footprint

Eco-Design

- Life cycle assessment

- Environmental regulations studies

- End-of-life manuals

- Eco-design methodology training

Inspections & Homologations

- Characterization of solid, liquid and gaseous materials

- Compatibility tests

- Supplier homologation

- Material homologation

- Post event analysis

Analyzing Corrosion & Metallic Materials

Investigation

- In-depth investigation of corroded parts and corrosive material

- Moist heat cycling, salt fog tests

- Mechanical tests, microscopy

Anti Corrosion

- Selection of the anti corrosion coating including paint and grease

Material Selection

- Selecting the correct material class based on atmosphere corrosivity

Supporting Development of Insulation Materials

Solid Insulation

- Mechanical characterizations

- Thermal and electrical aging studies

- Lifetime study

Liquid Insulation

- Development of mineral and ester oils

- Diagnostic techniques

- Composite systems

Gaseous Insulation

- Development of environmentally friendly gas and mixture

- Gas analysis: new and arced SF6 and g3

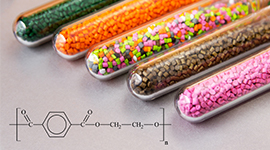

The R&D studies support the development of many types of insulation material, provide corrosion and metallic material analysis and help reduce the environmental footprint of equipment and technologies. Type of materials supported:

Solid Insulation

- Epoxy

- Thermoplastics

- Composite insulators

- Ceramic insulators

Liquid Insulation

- Mineral oil

- Ester oil

- Silicone oil

Gaseous Insulation

- SF6

- Environmentally friendly alternative

Benefit of Working With The “Disruptive” Team With Extensive Expertise

Studies are delivered by GE Vernova’s Subject Matter Experts based in the Global Technology Center. The team is active in international working groups and delivers lectures at technical conferences including CIGRÉ, Matpost, IEEE, CEIDP, IEC.

The GE Vernova materials and eco-design team members have filed over 35 patents in the last 15 years and bring disruptive technologies to the industry, examples include:

DWatch

Intelligent Monitoring and Control of Disconnectors

GE Vernova's DWatch performs permanent real time monitoring of the operational parameters of disconnectors and records all operating curves locally.

The DWatch also controls the speed of the live part during opening and closing in a specific and programmable manner for all disconnector types. These profiles can be easily set by internal dip-switches. Such control helps in always having a constant operating time in different conditions of power supply and load.

DWatch

Intelligent Monitoring and Control of Disconnectors

GE Vernova's DWatch performs permanent real time monitoring of the operational parameters of disconnectors and records all operating curves locally.

The DWatch also controls the speed of the live part during opening and closing in a specific and programmable manner for all disconnector types. These profiles can be easily set by internal dip-switches. Such control helps in always having a constant operating time in different conditions of power supply and load.

Recommended Products & services

Power Connectors

Simply Connecting Power

Power connectors join two or more conductors for the purpose of providing a continuous electrical path. GE Vernova offers tap, terminal, splice and non current carrying connectors.

The GE Vernova portfolio offers an extensive range of HV power connectors for substations. Several other types of connectors not mentioned are available, or can be specifically designed.

Power Connectors

Simply Connecting Power

Power connectors join two or more conductors for the purpose of providing a continuous electrical path. GE Vernova offers tap, terminal, splice and non current carrying connectors.

The GE Vernova portfolio offers an extensive range of HV power connectors for substations. Several other types of connectors not mentioned are available, or can be specifically designed.

Recommended Products & services

HYpact

Hybrid compact switchgear assembly

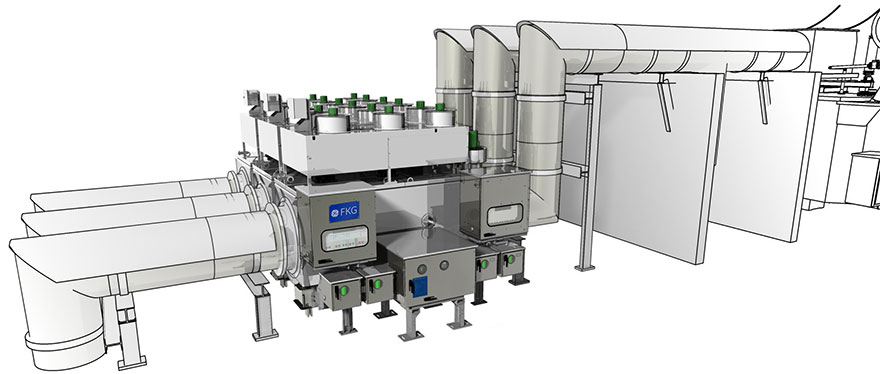

HYpact is a hybrid compact switchgear assembly that typically consists of circuit breakers, disconnectors, and earthing switches located in a common gas tank. Current and voltage transformers can be added and the standard SF6 to air bushings can be replaced with cable connectors. Its modular design allows for a large variety of different layout configurations and enables a more economical substation design.

HYpact

Hybrid compact switchgear assembly

HYpact is a hybrid compact switchgear assembly that typically consists of circuit breakers, disconnectors, and earthing switches located in a common gas tank. Current and voltage transformers can be added and the standard SF6 to air bushings can be replaced with cable connectors. Its modular design allows for a large variety of different layout configurations and enables a more economical substation design.

GE Vernova Advantage

HYpact assembly enables more economical substation design and operation, with savings to be achieved in space consumption, preparation planning, transport and at-site installation, switchyard cost and maintenance. Operators also choose HYpact where space is ample to benefit from the long maintenance periods. Compared to conventional air insulated substations, the maintenance-free periods of substations using HYpact can be tripled or even quadrupled.

In addition to savings in space and maintenance, HYpact largely reduces the switchgear’s exposure to environmental influences, thus providing an economic alternative to gas-insulated substations in places being heavily polluted, or under extreme weather conditions.

- Space-saving thanks to the integration of the circuit breaker, disconnector and earthing switch into one gas tank

- Reduced civil works

- Very limited substation engineering

- Use of standardized components

- Easy installation and commissioning

Key Features

The HYpact hybrid compact switchgear assembly is uniquely suited for a variety of situations, including space constrained installations and use in polluted or seismic environments. In addition, it also qualifies for mobile applications, either installed on trailers or on skids.

Due to the low number of bushings and the avoidance of movable contacts, pure SF6 gas Hypact units perform well in harsh climates, even under heavy snow and ice load, or at temperatures as low as -60°C (GOST FK certification).

- Rated voltage: from 123 kV up to 170 kV

- Rated normal current: 2 500 A

- Rated short-circuit current: 40 kA

- Encapsulated switchgear in SF6 gas

- Slip over current transformers

- Different versions available:

- Current transformer on both sides

- Single and three pole operation

- Disconnector/earthing module on both sides

- Single or double busbar

- Cable sealing

Benefits

- Space-saving thanks to the integration of the circuit breaker, disconnector and earthing switch into one gas tank

- Reduced civil works

- Very limited substation engineering

- Use of standardized components

- Easy installation and commissioning

Recommended Products & services

Generator Circuit Breakers

Increased Availability, Enhanced Protection and Simplified Operations for Power Plants

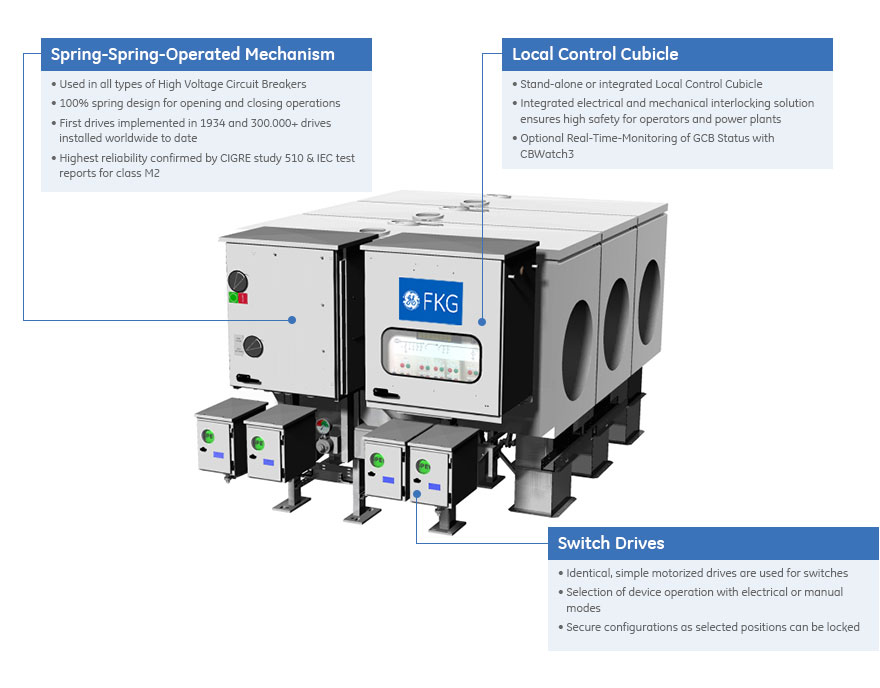

GE Vernova's Generator Circuit Breakers (GCBs) are ideally suited for new and refurbished power plants from 50 MW to 1,500 MW and feature advanced technology with spring-spring-operated mechanisms. The comprehensive GCB portfolio provides solutions from generator circuit breakers without enclosure to customized solutions including disconnector, earthing switch, starting switch and instrument transformers.

Generator Circuit Breakers

Increased Availability, Enhanced Protection and Simplified Operations for Power Plants

GE Vernova's Generator Circuit Breakers (GCBs) are ideally suited for new and refurbished power plants from 50 MW to 1,500 MW and feature advanced technology with spring-spring-operated mechanisms. The comprehensive GCB portfolio provides solutions from generator circuit breakers without enclosure to customized solutions including disconnector, earthing switch, starting switch and instrument transformers.

Today's Challenging Environment

For most utilities ensuring grid reliability, efficiency, and security is a primary concern. As the grid evolves and load profiles change, stresses are being put onto transmission and distribution networks, making the work of grid management much more challenging. Globally, utilities are facing many grid challenges and market condition changes including:

- Changes in generation mix

- Decrease in conventional generation

- Increase in renewable and distributed generation

- Environmental and regulatory policy changes

Utilities must respond to these challenges and generate energy economically and safely. They face additionally following business challenges:

- Calculable investments costs

- Maximum power plant availability

- Reliable power plant operation

- Long life-time of equipment

GE Vernova's Solution

GE Vernova offers utilities a reliable and robust solution to address the commercial and operational requirements with a comprehensive range of Generator Circuit Breakers (GCB) with advanced technology and 40+ years of deep domain expertise. GE Vernova is a world leader for GCB with 3,000+ installed breakers worldwide in applications including hydro, pump-storage, gas and steam turbines, combined cycle, nuclear and geothermal power plants from 50 MW to 1,500 MW.

Key Benefits

Power plant owners must generate energy economically and safely with the highest availability of their equipment. Most operational managers recognize the need for reliable and robust generator circuit breakers. The modular diagram - which uses a generator circuit breaker compared to the block type diagram solution - has several advantages, which are summarized as following:

| Increased power plant operational availability |  | Easier operation particularly regarding the transfer of auxiliaries |  | Improved safety in faults management | ||

| Increased protection especially for the power transformer |  | More flexibility and potential combinations |  | Substantial cost advantages |

Components

The design of the generator circuit breakers is compliant with IEC/IEEE 62271-37-013 standard and other relevant international standards. The following components are commonly used in the GCB range with proven robustness and reliability.

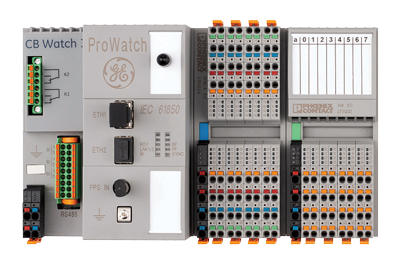

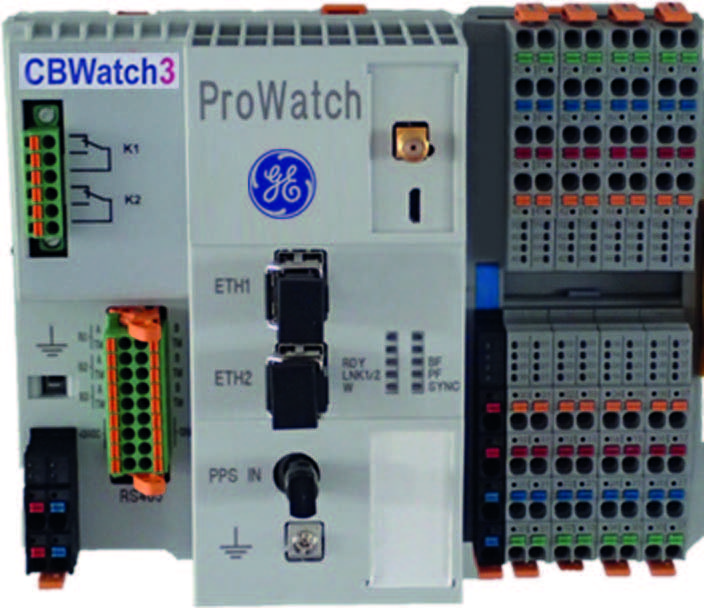

Circuit Breaker Monitoring Solution CBWatch3

CBWatch3 is a universal and compact device suitable for any kind of HV circuit breaker.

- Compact and modular solution adaptable to any circuit breaker type

- Delivers reduced and optimized operating maintenance costs

- Enables health/condition based asset replacement strategy

- Help reduce costly SF6 gas losses into the environment

- Seamless integration into digital control systems and easy web server interface

- GE Vernova as single vendor to monitor all key substation assets

GCB Portfolio

Equipment for Power Plants from 50 to 200 MW

FKG2S without enclosure

Generator circuit breaker for power plants from 50 to 150 MW

FKG2S

Generator circuit breaker for power plants from 50 to 150 MW

FKG2M

Generator circuit breaker for power plants from 100 to 200 MW

Equipment for Power Plants from 150 to 450 MW

FKG1N without enclosure

Generator circuit breaker for power plants from 150 to 300 MW

FKG1N

Generator circuit breaker for power plants from 200 to 300 MW

FKG1F

Generator circuit breaker for power plants from 300 to 450 MW

FKGA2

Generator circuit breaker for power plants from 200 to 450 MW

Equipment for Power Plants from 450 to 1,000 MW

FKG1X

Generator circuit breaker for power plants from 450 to 600 MW

FKG1XV

Generator circuit breaker for power plants from 750 to 900 MW

FKG1XP

Generator circuit breaker for power plants from 600 to 750 MW

FKG1XW

Generator circuit breaker for power plants from 900 to 1000 MW

Equipment for Power Plants from 700 to 1,500 MW

FKGA8

Generator circuit breaker for power plants from 700 to 1,500 MW

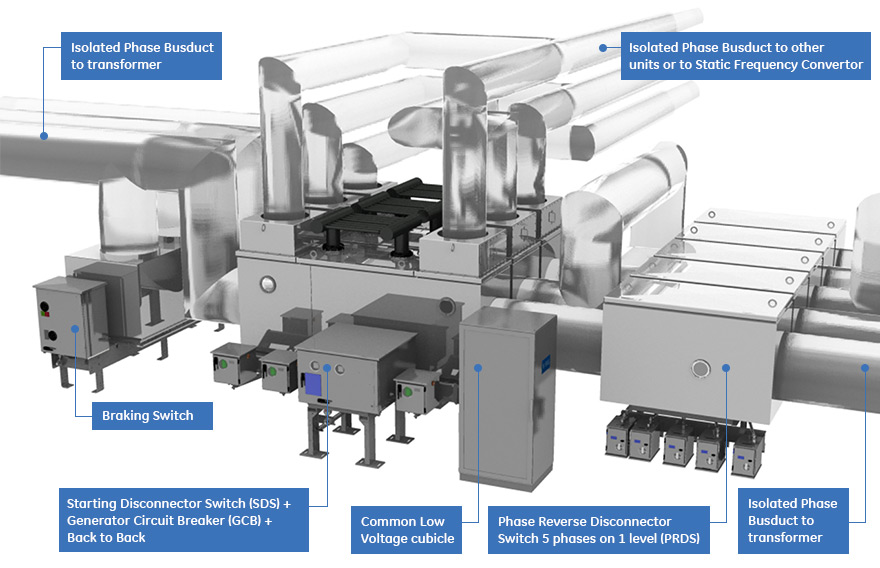

Pump Storage Solution

Modular Arrangement and Switching Devices for Pump Storage Operation and Protection

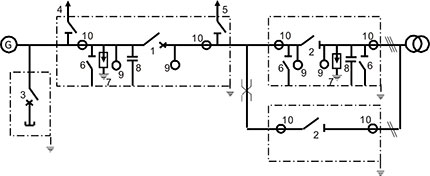

GE Vernova's solution for Pumped Storage Power Plant (PSPP) offers an integrated package of protection schemes, including generator circuit breaker, phase reverse disconnector, braking, starting and back-to-back switches.

Braking Switch

Braking switch is designed to perform an electromagnetic braking of the generator by carrying out a circuit of the 3 phases, allowing to reduce the time of shutdown before being able to reverse the operation cycle.

Generator Circuit Breaker (GCB)

The use of GCB increases the overall availability of the power plant. It also insures safe, reliable, economical operation and protection of the power plant.

Starting Disconnector Switch (SDS) on generator side and Back-to-Back Switch on transformer side

Starting Disconnector and Back-to-Back switches are the mechanical isolation devices located on the generator and transformer sides of the GCB. These switches ensure busbars connection between units and allow starting in pumping mode for Pumped Storage Power Plant. SDS alone or combined SDS with back-to-back solution are available according to power plant layout.

Phase Reverse Disconnector Switch (PRDS)

Phase Reverse Disconnector Switch provides 3 phases closing in pumping or generation mode, it also makes breaking capability for active parts to ensure the safety and electrical insulation of the open device.

Single-Line-Diagram and Components

|

|

Example: Pump Storage Solution with Phase Reverse Disconnector Switch (PRDS) with 5 Phases in line

Service & Retrofit

Based on manufacturing expertise and time-proven field experience, GE Vernova offers cost-effective and efficient solutions to help increase the life span of your generator circuit breakers and drastically reduce the risks of failure. Benefiting from GE Vernova’s innovative technical services will keep your equipment up-to-date, safe, reliable and efficient all along its lifecycle. From onsite assessment, periodic maintenance and mid-life overhaul to complete retrofit and emergency solutions, GE Vernova provides customized solutions for your generator circuit breaker according to its type, age, operating conditions and ratings.

Maintenance & Repair

- Preventive maintenance (every year, 5, 10 and 20 years)

- Condition based maintenance based on operations numbers and cumulative current broken by the GCB or earthing switch

- Trouble shooting repair

- Long Term Service Agreement

Strategic Spare Parts Management

- Emergency management with strategic stock including poles, complete active parts, disconnecting switches, coils, motors and protection sets

- Spare parts kits for maintenance and repair

- Critical spare parts rotation programs

Emergency Support

- Guaranteed response time by a certified expert

- 24/7 on-line technical support

Modernization and Retrofit

Solving Obsolescence of Equipment and Saving Maintenance Cost

- Perform on-site assessment prior recommendation

- Develop engineered solutions to minimize power plant downtime

- Implement latest technology solution on GE Vernova and 3rd party OEM brownfield assets

- Optimize site modification and intervention duration

- Guarantee full turnkey solution and engineering capabilities

- Benefit from decades of retrofit projects know how

Renovation and Overhaul

Expanding the Life of Aging Equipment

- Customized recommendations based on high voltage expert site survey

- Conduct the overhauling of the generator circuit breaker

- Change specified parts based on real condition

Recommended Products & services

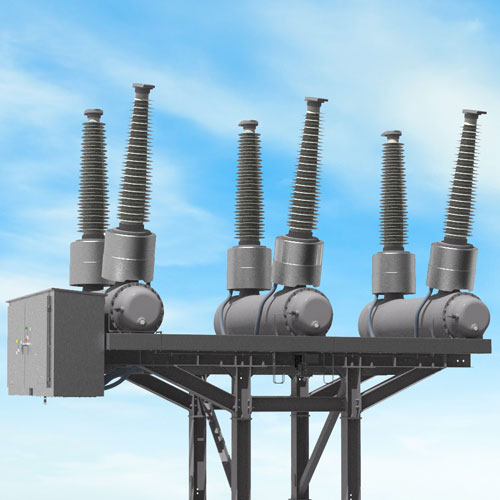

Dead Tank Circuit Breakers

Advanced Switchgear Technology for Reliable Performance

Grid Solutions, a GE Vernova business, offers a comprehensive range of dead tank circuit breakers that support a voltage rating up to 550 kV, and are capable of carrying a continuous current up to 5,000 A. Our circuit breakers meet or exceed the latest IEEE/ANSI and IEC standards, including C2 and M2. They can be gang operated up to 245 kV, and Independent Pole Operation (IPO) is available at all voltage levels.

Dead Tank Circuit Breakers

Advanced Switchgear Technology for Reliable Performance

Grid Solutions, a GE Vernova business, offers a comprehensive range of dead tank circuit breakers that support a voltage rating up to 550 kV, and are capable of carrying a continuous current up to 5,000 A. Our circuit breakers meet or exceed the latest IEEE/ANSI and IEC standards, including C2 and M2. They can be gang operated up to 245 kV, and Independent Pole Operation (IPO) is available at all voltage levels.

Today's Challenging Environment

Utilities are heavily struggling with the decentralization of power generation and especially with the integration of renewable energy sources into the grid. Integration can conflict with existing modernization and optimization plans. Issues of reliability, safety, power quality and economics have to be taken into account when planning substations and choosing the right switchgear.

Additionally, power systems are already interconnected, highly complex networks that are susceptible to instability. Utilities face several challenges in managing and maintaining today‘s complex grid, including:

- Increasing grid efficiency and resilience without the necessary funding to invest in new capital equipment.

- Expertise to manage the grid is rapidly diminishing due to the exit of skilled, technical resources from the workplace.

- Environmental impact and lifecycle cost of substation equipment

Overall, utilities are under intense scrutiny, by both regulatory agencies and the public, to prevent power system failures today, and in the future.

GE Vernova's Solution

GE Vernova offers utilities very reliable high voltage circuit breakers with advanced switchgear technology to improve grid stability and increase the efficiency of the transmission system infrastructure. The role of circuit breakers is to protect electrical equipment and system infrastructure, by fulfilling critical operational and safety functions. In normal operation, they carry nominal load currents, and depending on the installation, switch various equipment such as lines or transformers.

GE Vernova Advantage

GE Vernova's dead tank circuit breakers are developed based on the highest standards for performance, ratings, user convenience and reliability. Every circuit breaker model is thoroughly tested to meet or exceed the latest IEEE and IEC standards including Class C2, Class M2, fast TRV and high asymmetry.

Unique and Superior Design Provides Optimal Performance and Lower Total Cost of Ownership

- Durable spring-spring mechanism provides 5 times more reliability than hydraulic, pneumatic or hydraulic-spring designs according to CIGRE report 510.

- Innovative interrupter design with self-blast technology reduces required mechanical energy to clear fault currents without any sacrifice in performance or reliability.

- Designed to operate within extreme environmental conditions with available options for high elevation, very low and high temperatures (-60 °C to +60 °C), seismic zones, polluted areas, and corrosive atmospheres.

Manufacturing Excellence to Ensure Highest Quality Standards

- Global manufacturing sites are certified according to ISO 9001 and ISO 14001.

- Products are manufactured using GE Vernova's Advanced Production System ensuring the highest level of quality.

- Available customization expertise to meet customer unique application requirements.

Extensive Research, Testing and Proven Field Experience Resulting in Enhanced Reliability

- R&D Competence Center and associated testing laboratories located at GE Vernova‘s Charleroi, Pennsylvania, United States facility.

- Dead Tank Circuit Breakers are type tested for more than 10,000 mechanical operations exceeding IEEE and IEC Class M2 standards.

- Industry-best SF6 tightness testing system. guaranteeing lower than 0.5 % annual emission rate through quantified routine tests for every Dead Tank Circuit Breaker manufactured in the Charleroi plant.

- To date there are over 25,000 dead tank circuit breakers installed and in service in more than 60 countries.

Optional Features for Enhanced System Compatibility, Digital Integration and In-House Expertise

- Complete monitoring system available for asset management and digital substation integration.

- Independent pole operation with Point-on-Wave switching available when required for specific applications.

- Full life-cycle support for products, spare parts management and technical training by circuit breaker experts.

- Local Product Sales Specialists provide strong product and technical support.

Portfolio

GE Vernova's Dead Tank Circuit Breakers, the DT Series, supports system voltages from 38 kV to 550 kV and are designed for reliable performance, maximized safety and lower cost of ownership. The DT Series is designed to operate within extreme environmental conditions including high elevation, very low and high temperatures (-60 °C to +60 °C ), seismic zones, polluted areas and corrosive atmospheres.

DT1-38

Dead Tank Circuit Breaker for 38 kV / 40 kA

DT1-72.5

Dead Tank Circuit Breaker for 72.5 kV / 40 kA

DT1-145g 63

SF6-Free Dead Tank Circuit Breaker for 145 kV / 63 kA

DT1-145 and DT1-170

Dead Tank Circuit Breakers for 123 kV, 145 kV and

170 kV / 40 kA

DT1-145 63

Dead Tank Circuit Breaker for 123 kV and 145 kV / 63 kA

DT1-245P

Dead Tank Circuit Breaker for 245 kV / 40 kA

DT1-245P 63

Dead Tank Circuit Breaker for 245 kV / 63 kA

DT1-362

Dead Tank Circuit Breaker for 362 kV / 63 kA

DT2-550

Dead Tank Circuit Breaker for 550 kV / 63 kA

DT1-145R-40

Dead Tank Circuit Breaker with Pre-Insertion Resistors

Advanced Switchgear Technology

GE Vernova's DT Series is characterized by advanced self-blast interrupters, leak resistant cast aluminum enclosures and durable low energy mechanisms.

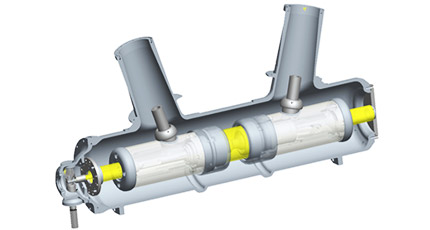

Interrupting Chamber

GE Vernovacircuit breakers use a proven innovative interrupter design with self-blast technology that significantly reduces the mechanical energy required to clear short-circuit currents. The interrupter design uses the arc energy to generate gas compression for efficient quenching of the arc itself.

As a member of the puffer family, the interrupter has two gas volumes within the chamber, one mechanical and one thermal. The design of the interrupter ensures that the circuit breaker will interrupt short-circuit fault current from low level faults to the full nameplate rating.

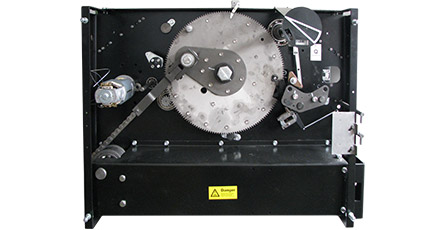

Spring-Spring-Operated Mechanism

GE Vernova has been developing and manufacturing spring-spring-operated mechanisms since 1938. The most recent state-of-the art evolution for these mechanisms is the FK3 range, which is used for all GE Vernova high voltage switchgear applications including dead tank, live tank, generator circuit breakers, GIS and hybrid solutions. Over 300,000 FK3 mechanisms are in operation worldwide.

The FK3 low energy spring-spring mechanism provides the highest level of reliability with Class M2 performance for 10,000 no-load close-open operations without the need for routine maintenance. With a spring-spring-operated mechanism there are no pneumatics or hydraulics, ensuring safe, reliable and maintenance-free operation for the normal circuit breaker service life of 50 years or more.

Circuit Breaker Monitoring Solution CBWatch3

CBWatch3 is a universal and compact device suitable for any kind of high voltage circuit breaker.

- Compact and modular solution adaptable to any circuit breaker type

- Delivers reduced and optimized operating maintenance costs

- Enables health/condition based asset replacement strategy

- Help reduce costly SF6 gas losses into the environment

- Seamless integration into digital control systems and easy web server interface

- GE Vernova as single vendor to monitor all key substation assets

Superior Manufacturing

Manufacturing Excellence

GE Vernova's investments in Research and Development (R&D) are significant, allowing utilities and grid operators to benefit from the latest technologies and innovations. The Center of Excellence for dead tank circuit breakers is located in Charleroi, PA (USA), where dead tank circuit breakers up to 550 kV and live tank circuit breakers up to 800 kV are assembled.

The production lines feature high degree of domestic content which can help to facilitate compliance with national requirements. In addition, the complete wiring and assembling of low voltage control cabinets and mechanism cabinets is done locally, resulting in greater flexibility to respond to utility needs.

Certified Quality

Research and Development (R&D), manufacturing and commercial units are fully certified according to ISO 9001. This means that during the entire production process, all employees, all equipment and all of the company's operations are dedicated to the highest quality standards and permanent improvement.

Advanced Production System

The Advanced Production System (APS) is the framework for contemporary manufacturing excellence in all Grid Solutions sites. It is based on lean tools for continuous improvement of safety, quality, cost and delivery.

APS brings together a wide range of best practices and standards in seven domains such as Basics, Environmental, Health & Safety (EHS), Supply Chain, Project Delivery, Manufacturing, and Quality & Leadership to create and sustain world class manufacturing excellence.

Rigorous Testing

All dead tank circuit breakers are type tested in world class laboratories such as KEMA, CESI and CERDA, in full compliance with international standards such as IEEE, IEC, GOST and DL standards. Specific homologation processes (additional tests, specific reports) are provided as per customer requirements.

Following tests are performed according to the latest standards:

- Seismic performance

- Dielectric performance including BIL, SIL, RIV, AC withstand and partial discharge

- Mechanical endurance

- Power testing including short circuit, short time withstand, capacitance switching and reactor switching

- Temperature rise continuous current test

- Environmental testing

GE Vernova's Center of Excellence for dead tank circuit breakers located in Charleroi, PA, USA

GE Vernova's Center of Excellence for dead tank circuit breakers located in Charleroi, PA, USA

Value Added Services - Optimizing Asset Reliability, Up-Time and Performance

Dedicated project teams are located in all regions throughout the world. These on the ground teams provide support and expertise to assist customers during different project phases. Local field service teams are also available worldwide, providing immediate support, training and supervision.

As part of optimizing the maintenance and asset replacement strategies, GE Vernova employs stress assessment analysis, SF₆ monitoring and online condition monitoring to allow comprehensive centralized asset management.

Maximizing the life cycle performance of circuit breakers through the right maintenance strategy, strategic spare parts stock and toll-free 24/7 hotline.

GE Vernova has the technical expertise to deliver customized engineered solutions to extend the life of ageing equipment. Our Service Teams are experienced in solving obsolescence issues and overhauling substation equipment as required.

GE Vernova provides on site technical training such as modular and competence development training as well as e-learning and educational partnerships. These skills not only enhance team knowledge, but increase productivity.