GE Vernova's dead tank circuit breakers are available for single or three pole operation, qualified to IEEE and IEC standards and available from 38 kV up to 550 kV.

GE Vernova's dead tank circuit breakers are available for single or three pole operation, qualified to IEEE and IEC standards and available from 38 kV up to 550 kV.

The SF₆-free DT1-145g rated for 63 kA represents the latest dead tank circuit breaker technology. The DT1-145g-63 is suitable for application up to nameplate ratings, including definite-purpose switching. It meets the challenges of networks up to 145 kV for power generation, transmission and energy-intensive industry applications.

The SF₆-free DT1-145g rated for 63 kA represents the latest dead tank circuit breaker technology. The DT1-145g-63 is suitable for application up to nameplate ratings, including definite-purpose switching. It meets the challenges of networks up to 145 kV for power generation, transmission and energy-intensive industry applications.

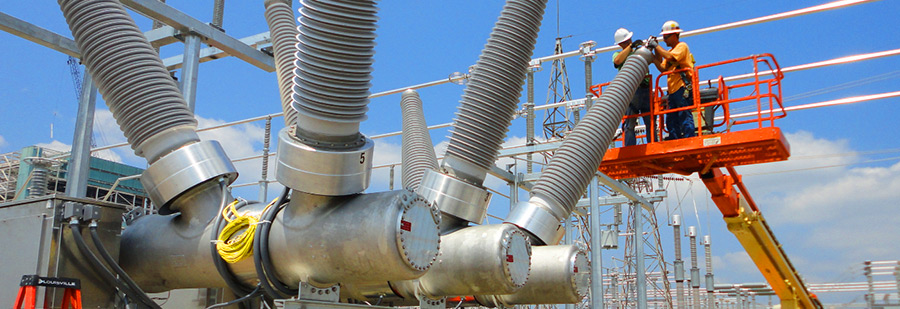

Grid Solutions, a GE Vernova business, offers a comprehensive range of dead tank circuit breakers that support a voltage rating up to 550 kV, and are capable of carrying a continuous current up to 5,000 A. Our circuit breakers meet or exceed the latest IEEE/ANSI and IEC standards, including C2 and M2. They can be gang operated up to 245 kV, and Independent Pole Operation (IPO) is available at all voltage levels.

Grid Solutions, a GE Vernova business, offers a comprehensive range of dead tank circuit breakers that support a voltage rating up to 550 kV, and are capable of carrying a continuous current up to 5,000 A. Our circuit breakers meet or exceed the latest IEEE/ANSI and IEC standards, including C2 and M2. They can be gang operated up to 245 kV, and Independent Pole Operation (IPO) is available at all voltage levels.

Utilities are heavily struggling with the decentralization of power generation and especially with the integration of renewable energy sources into the grid. Integration can conflict with existing modernization and optimization plans. Issues of reliability, safety, power quality and economics have to be taken into account when planning substations and choosing the right switchgear.

Additionally, power systems are already interconnected, highly complex networks that are susceptible to instability. Utilities face several challenges in managing and maintaining today‘s complex grid, including:

Overall, utilities are under intense scrutiny, by both regulatory agencies and the public, to prevent power system failures today, and in the future.

GE Vernova offers utilities very reliable high voltage circuit breakers with advanced switchgear technology to improve grid stability and increase the efficiency of the transmission system infrastructure. The role of circuit breakers is to protect electrical equipment and system infrastructure, by fulfilling critical operational and safety functions. In normal operation, they carry nominal load currents, and depending on the installation, switch various equipment such as lines or transformers.

GE Vernova's dead tank circuit breakers are developed based on the highest standards for performance, ratings, user convenience and reliability. Every circuit breaker model is thoroughly tested to meet or exceed the latest IEEE and IEC standards including Class C2, Class M2, fast TRV and high asymmetry.

Unique and Superior Design Provides Optimal Performance and Lower Total Cost of Ownership

Manufacturing Excellence to Ensure Highest Quality Standards

Extensive Research, Testing and Proven Field Experience Resulting in Enhanced Reliability

Optional Features for Enhanced System Compatibility, Digital Integration and In-House Expertise

GE Vernova's Dead Tank Circuit Breakers, the DT Series, supports system voltages from 38 kV to 550 kV and are designed for reliable performance, maximized safety and lower cost of ownership. The DT Series is designed to operate within extreme environmental conditions including high elevation, very low and high temperatures (-60 °C to +60 °C ), seismic zones, polluted areas and corrosive atmospheres.

DT1-38

Dead Tank Circuit Breaker for 38 kV / 40 kA

DT1-72.5

Dead Tank Circuit Breaker for 72.5 kV / 40 kA

DT1-145g 63

SF6-Free Dead Tank Circuit Breaker for 145 kV / 63 kA

DT1-145 and DT1-170

Dead Tank Circuit Breakers for 123 kV, 145 kV and

170 kV / 40 kA

DT1-145 63

Dead Tank Circuit Breaker for 123 kV and 145 kV / 63 kA

DT1-245P

Dead Tank Circuit Breaker for 245 kV / 40 kA

DT1-245P 63

Dead Tank Circuit Breaker for 245 kV / 63 kA

DT1-362

Dead Tank Circuit Breaker for 362 kV / 63 kA

DT2-550

Dead Tank Circuit Breaker for 550 kV / 63 kA

DT1-145R-40

Dead Tank Circuit Breaker with Pre-Insertion Resistors

GE Vernova's DT Series is characterized by advanced self-blast interrupters, leak resistant cast aluminum enclosures and durable low energy mechanisms.

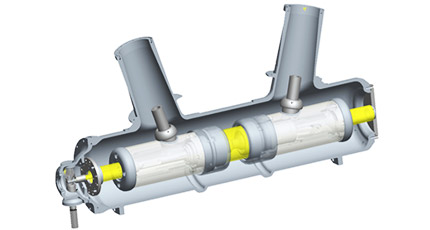

Interrupting Chamber

GE Vernovacircuit breakers use a proven innovative interrupter design with self-blast technology that significantly reduces the mechanical energy required to clear short-circuit currents. The interrupter design uses the arc energy to generate gas compression for efficient quenching of the arc itself.

As a member of the puffer family, the interrupter has two gas volumes within the chamber, one mechanical and one thermal. The design of the interrupter ensures that the circuit breaker will interrupt short-circuit fault current from low level faults to the full nameplate rating.

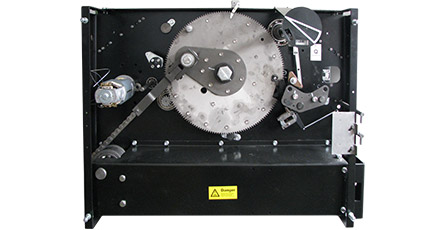

Spring-Spring-Operated Mechanism

GE Vernova has been developing and manufacturing spring-spring-operated mechanisms since 1938. The most recent state-of-the art evolution for these mechanisms is the FK3 range, which is used for all GE Vernova high voltage switchgear applications including dead tank, live tank, generator circuit breakers, GIS and hybrid solutions. Over 300,000 FK3 mechanisms are in operation worldwide.

The FK3 low energy spring-spring mechanism provides the highest level of reliability with Class M2 performance for 10,000 no-load close-open operations without the need for routine maintenance. With a spring-spring-operated mechanism there are no pneumatics or hydraulics, ensuring safe, reliable and maintenance-free operation for the normal circuit breaker service life of 50 years or more.

CBWatch3 is a universal and compact device suitable for any kind of high voltage circuit breaker.

GE Vernova's investments in Research and Development (R&D) are significant, allowing utilities and grid operators to benefit from the latest technologies and innovations. The Center of Excellence for dead tank circuit breakers is located in Charleroi, PA (USA), where dead tank circuit breakers up to 550 kV and live tank circuit breakers up to 800 kV are assembled.

The production lines feature high degree of domestic content which can help to facilitate compliance with national requirements. In addition, the complete wiring and assembling of low voltage control cabinets and mechanism cabinets is done locally, resulting in greater flexibility to respond to utility needs.

Research and Development (R&D), manufacturing and commercial units are fully certified according to ISO 9001. This means that during the entire production process, all employees, all equipment and all of the company's operations are dedicated to the highest quality standards and permanent improvement.

The Advanced Production System (APS) is the framework for contemporary manufacturing excellence in all Grid Solutions sites. It is based on lean tools for continuous improvement of safety, quality, cost and delivery.

APS brings together a wide range of best practices and standards in seven domains such as Basics, Environmental, Health & Safety (EHS), Supply Chain, Project Delivery, Manufacturing, and Quality & Leadership to create and sustain world class manufacturing excellence.

All dead tank circuit breakers are type tested in world class laboratories such as KEMA, CESI and CERDA, in full compliance with international standards such as IEEE, IEC, GOST and DL standards. Specific homologation processes (additional tests, specific reports) are provided as per customer requirements.

Following tests are performed according to the latest standards:

GE Vernova's Center of Excellence for dead tank circuit breakers located in Charleroi, PA, USA

GE Vernova's Center of Excellence for dead tank circuit breakers located in Charleroi, PA, USA

Dedicated project teams are located in all regions throughout the world. These on the ground teams provide support and expertise to assist customers during different project phases. Local field service teams are also available worldwide, providing immediate support, training and supervision.

As part of optimizing the maintenance and asset replacement strategies, GE Vernova employs stress assessment analysis, SF₆ monitoring and online condition monitoring to allow comprehensive centralized asset management.

Maximizing the life cycle performance of circuit breakers through the right maintenance strategy, strategic spare parts stock and toll-free 24/7 hotline.

GE Vernova has the technical expertise to deliver customized engineered solutions to extend the life of ageing equipment. Our Service Teams are experienced in solving obsolescence issues and overhauling substation equipment as required.

GE Vernova provides on site technical training such as modular and competence development training as well as e-learning and educational partnerships. These skills not only enhance team knowledge, but increase productivity.

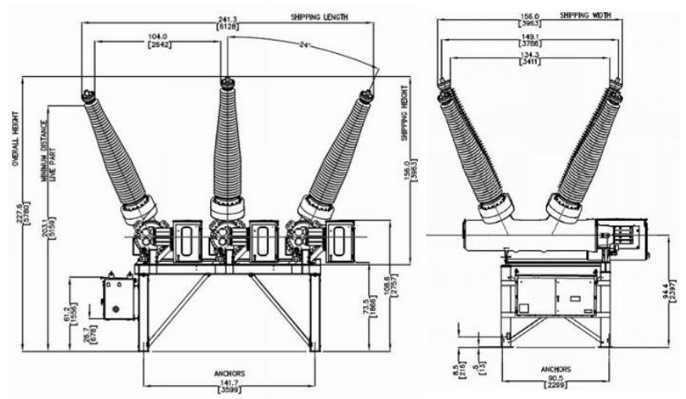

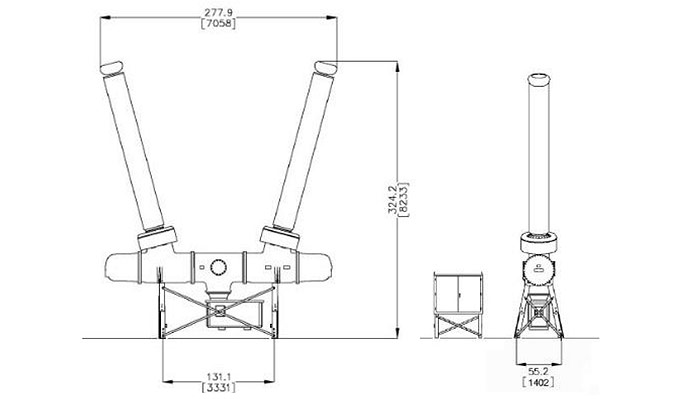

The DT2-550 is ideal for applications at 550 kV levels and below, including 420 kV transmission systems. It is specifically designed and tested for general or definite purpose applications and for severe environmental conditions, including low temperatures, highly active seismic areas, regions with high pollution levels and corrosive atmospheres.

The DT2-550 is ideal for applications at 550 kV levels and below, including 420 kV transmission systems. It is specifically designed and tested for general or definite purpose applications and for severe environmental conditions, including low temperatures, highly active seismic areas, regions with high pollution levels and corrosive atmospheres.

The DT2-550 is suitable for applications up to nameplate ratings, including definite purpose ratings for capacitor bank switching. Extensive mechanical operation design testing (in excess of 10,000 operation), assures trouble-free operation for the lifetime of the circuit breaker. Intensive production leak testing assures superior in-service SF₆ performance. All external surfaces are corrosion resistant, without the need for maintenance-intensive paint.

The DT2-550 is available with design options and ratings to best fit your needs. Designed with a footprint that minimizes foundation costs, the DT2-550 adapts to retrofit live tank or dead tank foundations.

The DT2-550 is an independent pole operation (IPO) circuit breaker provided with one mechanism per pole. The DT2-500 circuit breaker can be supplied with the Point on Wave controller for synchronous closing in capacitor bank and line switching applications, or synchronous opening in reactor switching applications.

The DT2-550 is available with design options and ratings to best fit your needs. Designed with a footprint that minimizes foundation costs, the DT2-550 adapts to retrofit live tank or dead tank foundations.

The DT2-550 can be provided with reliable spring-operated mechanisms for 2.5 cycle operation or a compact, low-pressure hydraulic mechanism for 2 cycle operation.

The DT2-550 can also be supplied with many customized options such as closing resistors, electronic density monitors and composite bushings. The generous enclosure allows space for up to three current transformers per bushing to accommodate complex measurement and protection schemes.

The DT2-550 is factory tested, adjusted and prepared for shipment with the bushings disassembled. On-site installation requires only a few simple steps. Thanks to the low energy spring mechanisms and low pressure hydraulic mechanisms, the DT2-550 is considered virtually maintenance free.

| IEEE/ANSI | IEC | Value | Units |

|---|---|---|---|

| Rated maximum voltage | Rated voltage | 550 | kV |

| Rated power frequency | Rated frequency | 50/60 | Hz |

| Dry withstand | At power frequency,dry | 860 | kV |

| Rated lightning impulse withstand voltage | At lightning impulse | 1,800 | kV |

| Rated chopped wave impulse voltage 2us | 2,070 | kV | |

| Rated switching impulse withstand voltage terminal to terminal | Rated switching impulse withstand voltage terminal to terminal | 1,300 | kV |

| Rated continuous current | Rated normal current | 3,000/4,000/5,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 40/50/60 | kA |

| Rated closing,latching and short time carrying | 164 | kA | |

| Rated short-circuit making current | 163 | kA | |

| Rated capacitance switching* | |||

| Rated break time (spring/hydraulic) | 500 | A | |

| Rated interrupting time (spring/hydraulic) | 2.5/2.0 | cycles | |

| Rated break time (spring/hydraulic) | 42/33 | ms | |

| Rated standard operating duty | O-CO-15s-CO O-0.3s-CO-180s-CO | ||

| *Rating available upoon request. **Please contact Grid Solutions for special purpose, high TRV, high X/R or other ratings requirements | |||

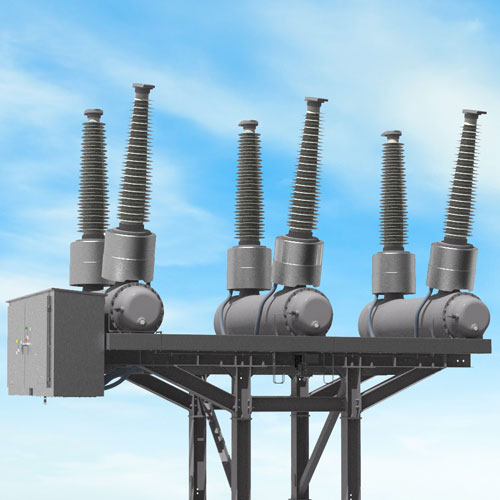

GE Vernova’s DT series of dead tank circuit breakers are characterized by advanced self-blast interrupters, leak-resistant, cast aluminum enclosures and durable, low-energy spring-spring-operated mechanisms. More than 100,000 circuit breakers with self-blast interrupters and FK spring-spring-operated mechanisms have been in service since 1989.

GE Vernova’s DT series of dead tank circuit breakers are characterized by advanced self-blast interrupters, leak-resistant, cast aluminum enclosures and durable, low-energy spring-spring-operated mechanisms. More than 100,000 circuit breakers with self-blast interrupters and FK spring-spring-operated mechanisms have been in service since 1989.

The circuit breaker design is optimized for quick and easy installation at site. Where truck shipments are possible, individual poles are shipped with bushings and the operating mechanism assembled. In this case, site work involves installing the poles on the supporting frame and making the necessary low voltage electrical connections. Each phase is factory set to the proper position, eliminating the need for complex rigging at site.

Every DT1-362 breaker produced by GE Vernova is subjected to a rigorous SF6 tightness testing protocol. Our state-of-the-art testing system validates the gas integrity of every circuit breaker in the as shipped condition. This proprietary system provides quantifiable evidence of our <0.5% guaranteed leak rate in the exact configuration in which the breaker is delivered.

The DT1-362 is suitable for applications up to nameplate ratings, including definite purpose ratings and is uniquely qualified under the latest ANSI IEC standards as C2 class for capacitance switching including back-to-back (very low restrike probability) and for reactor switching applications. Extensive mechanical operation design testing ensures trouble-free operation for the lifetime of the circuit breaker. Intensive production leak testing ensures superior in-service SF6 performance.

GE Vernova designs, manufactures, tests and delivers its circuit breakers in accordance with the latest IEEE/ANSI and IEC standards, maintaining a quality assurance system according to ISO-9011 and ISO-14001 certifications. The center of excellence for dead tank circuit breakers is located in Charleroi, PA (USA).

| IEEE/ANSI | IEC | Value | Units |

|---|---|---|---|

| Rated maximum voltage* | Rated voltage* | 362 | kV |

| Rated power frequency | Rated frequency | 50/60 | Hz |

| Rated dielectric withstand capability: - dry withstand | Rated insulation level - at power frequency,dry | 555 | kV |

| Rated lightning impulse withstand voltage | - at lightning impulse | 1,300 | kV |

| Rated chopped wave impulse voltage 2us | 1,680 | kV | |

| Rated switching impulse | 900 | kV | |

| Rated continuous current | Rated normal current | 3,000/4,000/5,000 | A |

| Rated short-circuit current | Rated short-circuit breaking current | 40/50/63 | kA |

| Rated closing,latching and short time carrying | 170 | kA | |

| Rated short-circuit making current | 170 | kA | |

| Rated capacitance switching* | 500 | A | |

| Rated single capacitor bank breaking current | 500 | A | |

| Rated interrupting time | 2 | cycles | |

| Rated break time | 33 | ms | |

| Rated standard operating duty | Rated operating sequence | O-CO-15s-CO O-0.3s-CO-180s-CO | |

| *Rating available upoon request **Contact GE Vernova for special purpose, operating voltage, generator synchronizing,high TRV, high X/R or other ratings requirements. | |||