GE Vernova’s substation automation systems offer a seamless and scalable solution for automating and providing visibility to power system networks.

GE Vernova’s substation automation systems offer a seamless and scalable solution for automating and providing visibility to power system networks.

Network operators/owners are seeing more opportunities for monitoring and management of substation asset data as part of their overall asset management and optimization strategies. Where implemented, new training regimes are leading to a significant reduction in user costs.ing performance, at the lowest total cost of ownership, while also providing both communications network integration and data security.

Network operators/owners are seeing more opportunities for monitoring and management of substation asset data as part of their overall asset management and optimization strategies. Where implemented, new training regimes are leading to a significant reduction in user costs.ing performance, at the lowest total cost of ownership, while also providing both communications network integration and data security.

|

|

Manufacturing for this product has been discontinued

Comprehensive view and control of the substation to increase operator efficiency

Manufacturing for this product has been discontinued

Comprehensive view and control of the substation to increase operator efficiency

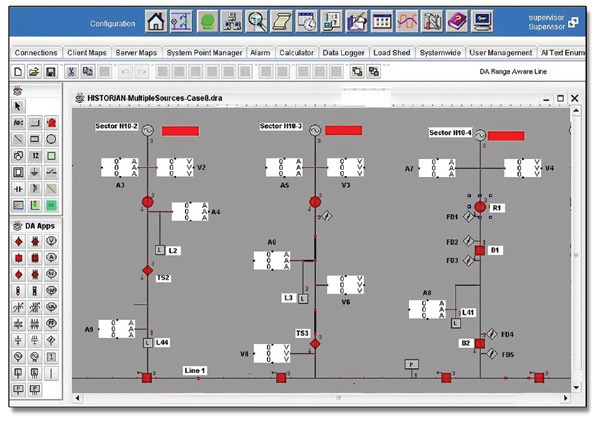

One-line screens for monitoring status, control and tagging

One-line screens for monitoring status, control and tagging

PLA aggregates from gateways and field devices and intelligently presents relevant near real-time and historical data in an easy to understand, customizable graphical format with features such as alarm and dynamic text displays to increase operator efficiency.

Dynamic trending to clearly visualize substation activity

Dynamic trending to clearly visualize substation activity

PLA provides aggregates trending data from substation devices and presents them in a clear visual format that is fully customizable to facilitate quick identification of potential issues or to assist in problem analysis.

Redundancy ensures system availability in the event of a hardware failure. PowerLink Advantage can be configured with redundancy so that a secondary system is ready to take over operations automatically should the primary system fail. During a failure, all main PowerLink Advantage functions are transferred to ensure that critical data acquisition, alarming, logging and security operations continue.

PLA server redundancy to ensure continuous uptime.

Multiple Viewer Stations provide client-server connectivity from additional computers on the LAN.

Remote Desktop (Terminal Services) licenses provide access from remote computers (requires Windows® Server operating system).

System Sentry improves system availability by constantly providing real-time information about the health of the PowerLink Advantage system. It provides detailed performance data at any given moment for every resource ranging from available hard drive space to CPU usage. System Sentry also provides configurable, automated alerts for problem conditions and the tools for problem determination to restore system functionality.

Digital Fault Recording Display and Analysis is a tool within DirectView providing advanced waveform viewing through capabilities to set multiple cursors and markers; waveform superimposition and waveform comparison functions. It also provides functionality to visualize harmonic spectrum and perform zero sequence current calculations. IEEE® COMTRADE file compatible.

Alarm Cast provides integration of PowerLink Advantage alarms for remote notification through a variety of channels such as Internet, mobile and PC media including pagers, SMS, e-mail, ODBC, UCP and more. The notification can contain key operational information and conditions.

PLA makes it easy to generate the reports based on a timed or event basis. The report viewer allows quick, convenient access to any report.

Power Quality Event Viewer provides sag, swell and interruption plots.

DirectView provides a Digital Fault Recording (DFR) COMTRADE file viewer and analysis application. DFR COMTRADE files are automatically retrieved from compatible field devices connected via Ethernet LAN.

Action Calendar provides the ability to create, maintain and execute a calendar schedule of system events.

GE Vernova Automation Projects deliver a complete solution for utilities and Industrial customers to address challenges in managing all aspects of increasingly complex substation automation systems:

GE Vernova delivers a complete modern substation automation solution based on deep knowledge and expertise, best in class products, configuration tools and industry standards with the following offerings:

Complete end-to-end system solutions including hardware, software and resources from initial evaluation to ongoing maintenance and support.

Manufacturing for this product has been discontinued.

Manufacturing for this product has been discontinued.

Comprehensive view and control of the substation to increase operator efficiency

Comprehensive view and control of the substation to increase operator efficiency

PLA aggregates from gateways and field devices and intelligently presents relevant near real-time and historical data in an easy to understand, customizable graphical format with features such as alarm and dynamic text displays to increase operator efficiency.

One-line screens for monitoring status, control and tagging

One-line screens for monitoring status, control and tagging

PLA provides aggregates trending data from substation devices and presents them in a clear visual format that is fully customizable to facilitate quick identification of potential issues or to assist in problem analysis.

Dynamic trending to clearly visualize substation activity

Dynamic trending to clearly visualize substation activity

Redundancy ensures system availability in the event of a hardware failure. PowerLink Advantage can be configured with redundancy so that a secondary system is ready to take over operations automatically should the primary system fail. During a failure, all main PowerLink Advantage functions are transferred to ensure that critical data acquisition, alarming, logging and security operations continue.

PLA server redundancy to ensure continuous uptime.

PLA server redundancy to ensure continuous uptime.

Multiple Viewer Stations

Multiple Viewer Stations provide client-server connectivity from additional computers on the LAN.

Remote Desktop (Terminal Services)

Remote Desktop (Terminal Services) licenses provide access from remote computers (requires Windows® Server operating system).

System Sentry

System Sentry improves system availability by constantly providing real-time information about the health of the PowerLink Advantage system. It provides detailed performance data at any given moment for every resource ranging from available hard drive space to CPU usage. System Sentry also provides configurable, automated alerts for problem conditions and the tools for problem determination to restore system functionality.

Digital Fault Recording Display and Analysis

Digital Fault Recording Display and Analysis is a tool within DirectView providing advanced waveform viewing through capabilities to set multiple cursors and markers; waveform superimposition and waveform comparison functions. It also provides functionality to visualize harmonic spectrum and perform zero sequence current calculations. IEEE® COMTRADE file compatible.

Alarm Cast

Alarm Cast provides integration of PowerLink Advantage alarms for remote notification through a variety of channels such as Internet, mobile and PC media including pagers, SMS, e-mail, ODBC, UCP and more. The notification can contain key operational information and conditions.

Reporting

PLA makes it easy to generate the reports based on a timed or event basis. The report viewer allows quick, convenient access to any report.

Power Quality Event Viewer

Power Quality Event Viewer provides sag, swell and interruption plots.

DirectView

DirectView provides a Digital Fault Recording (DFR) COMTRADE file viewer and analysis application. DFR COMTRADE files are automatically retrieved from compatible field devices connected via Ethernet LAN.

Action Calendar

Action Calendar provides the ability to create, maintain and execute a calendar schedule of system events.

| GE Vernova Automation Projects deliver a complete solution for utilities and Industrial customers to address challenges in managing all aspects of increasingly complex substation automation systems: | |

|

|

GE Vernova delivers a complete modern substation automation solution based on deep knowledge and expertise, best in class products, configuration tools and industry standards with the following offerings:

Automation Projects – Managed Solutions

Complete end-to-end system solutions including hardware, software and resources from initial evaluation to ongoing maintenance and support.

Automation Projects – Technical Services

Manufacturing for this product has been discontinued. Please contact us to discuss alternatives

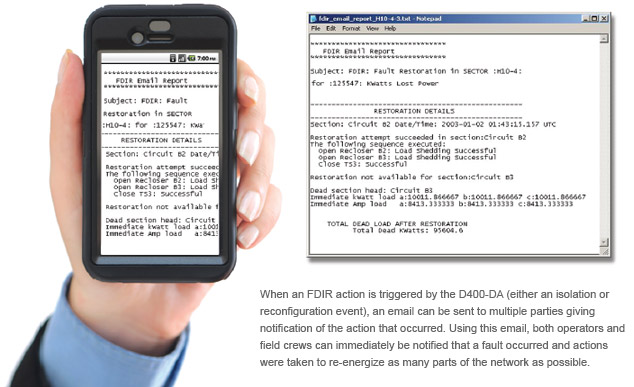

The D400-DA is a substation based Fault Detection, Isolation, and Restoration system, designed for improving the reliability of distribution utility networks. With the ability to monitor and control reclosers and switches, the D400-DA can restore unfaulted sections of network thereby improving utility reliability indices and customer satisfaction.

Manufacturing for this product has been discontinued. Please contact us to discuss alternatives

The D400-DA is a substation based Fault Detection, Isolation, and Restoration system, designed for improving the reliability of distribution utility networks. With the ability to monitor and control reclosers and switches, the D400-DA can restore unfaulted sections of network thereby improving utility reliability indices and customer satisfaction.

When faults occur on the distribution network, utility protection and control schemes normally shut down power on the feeder thus disrupting service to many customers. The size of area affected by the outage will directly translate into the number of consumers inconvenienced and some degree of economic loss.

Many distribution utilities are measured as to how well they are serving their customers and may be subjected to regulatory penalties if the regulators feel their performance is not as good as it should be. There are several different measurement indices that are used to gauge utility reliability effectiveness including:

Fault Detection, Isolation and Restoration (FDIR) schemes, also known as Fault Location Isolation and Supply Restoration

(FLISR) or Circuit Reconfiguration Schemes, will greatly enhance distribution grid reliability by quickly restoring power to as many customers as possible. By quickly isolating faults and rerouting power from alternate sources to customers on

healthy parts of the network, utilities can greatly reduce the number of customers affected by outages thus reducing their measurement indices and any penalties that may be associated with them.

Utilizes a system wide Distribution Management Systems (DMS) that analyzes the entire network to identify the best way to reconfigure the feeders to restore power after a fault.

Analyze smaller sections of the network and does not require information about the larger distribution network to reconfigure local sections of the grid that are experiencing outages due to faults.

Through implementing a D400-DA substation based FDIR scheme, communications needed for monitoring or reconfiguring the network only need to extend from the field recloser and switch controllers to the substation where the D400-DA is located. While communications can be sent back to a Control Center for SCADA management, the complete reconfiguration of the network can be done without a backhaul communications infrastructure. When large scale events occur that can cause multiple utility wide problems, the D400-DA substation based FDIR solution will continue to operate and reconfigure the network even if backhaul communications are lost.

The D400-DA substation based FDIR solution can automate both Looped and Multi-Ended feeder network configurations. The D400-DA can typically restore power to unfaulted sections less than 1 minute after a fault occurs, fast enough to prevent the outage affecting SAIDI and SAIFI indices.

This D400-DA solution provides a scalable solution for automating from as few as two and as many as twenty circuits or feeders with a single D400-DA. With this scalability, utilities have a cost effective solution that can be incrementally rolled out feeder by feeder or just installed on circuits that are causing the most reliability problems. One D400-DA can automate these twenty circuits whether or not they are emanating from one substation or from multiple substations, as long as the D400-DA can communicate to the controllers in the field.

Each D400-DA can monitor and automate up to twenty feeder sectors. Each sector is defined as a feeder that begins at a breaker and ends at a normally open tie point. The D400-DA that is monitoring a particular sector will be responsible for isolating that sector in the event a fault has occurred on it. This same D400-DA will also be responsible for controlling the tie switches to other sectors in the event that more load will be added to it to restore adjoining dead sectors.

Each D400-DA can communicate with and control up to 100 devices found within the sectors it is monitoring. Devices interfaced with it may include protection relays, recloser controllers, switch controllers and fault circuit indicators.

The D400-DA has two main modes of operation for isolating and reconfiguring distribution networks: Automatic Reconfiguration and Operator Assisted Reconfiguration.

– In Automatic Reconfiguration mode, the D400-DA will identify outages on its monitored sectors and take action to restore power to the maximum number of customers as possible. It performs the actions without any interaction required from system operators.

– In Operator Assisted Reconfiguration mode, the D400-DA will require confirmation that system operators agree with the recommended action before these actions are carried out. This mode of operation is often used by utilities for an initial trial period of time to have their operators get comfortable with the D400-DA recommendation before going into full Automatic Reconfiguration mode.

While the D400-DA is monitoring its feeders, there are several sequences that will initiate a reconfiguration action:

The D400-DA system configuration software is an easy-to-use online tool that allows for system modeling and FDIR sector configuration. When being used in Operator Assisted Mode, this tool can be the operator interface for acknowledging or rejecting reconfiguration scenarios proposed by the D400-DA FDIR system.

When a reconfiguration action has been triggered, the first course of action the D400-DA will take is to isolate any faulted sections on the line. Isolation actions will attempt to minimize the number of customers falling within an isolated section. When the D400-DA is in Operator Assisted Mode, it will give a recommendation to the operators on the best course of action to take to isolate the fault. If the operator does not agree with the recommended action, the D400-DA will calculate the next optimal scenario and propose that to the operators.

When a fault occurs on a sector of the line, the D400-DA will open all of the available switches to completely isolate the fault. On radial feeders or laterals, if additional switches are located downstream of the fault, the D400-DA will also open those switches to prevent any other sources such as distributed generation that may back-feed the fault.

Once the D400-DA has ensured any faults are isolated, it will attempt reconfigure the network to restore power to as many customers as possible. When operating in Operator Assisted Mode, the D400-DA will first ask for confirmation from the operator before taking any action. If the operator does not agree with the recommended action, the D400-DA will calculate the next optimal scenario and propose that to the operator.

To ensure that the source being used to re-energize a sector of the feeder can support the additional load, the D400-DA calculates the short term power requirements based on a 15 minute sliding peak demand window with 1 minute resolution. The D400-DA also identifies the long term load requirements using a 30 days sliding window with a 1 day resolution and a 15 minute averaging period.

Before reconfiguring the network, the D400-DA will verify that the voltage on the dead sector has dropped below configurable thresholds to ensure that the line is still not energized due to any residual distributed generation sources.

Before reenergizing a line, the D400-DA will alter the setting groups on any recloser or switch controllers on the line so that the protection functions will be coordinated for the new loads and direction of power flow.

The D400-DA collects data from substation protection, control, monitoring, RTU, and intelligent devices, pre-processes the data and moves it up to EMS and DMS SCADA systems providing centralized substation management.

The D400-DA provides the computing platform necessary to automate substation procedures, such that intricate processes are carried out safely and efficiently by creating custom automation programs using IEC 61131 compliant tools, and perform basic math functions on data points using the built-in Calculator tool.

Using pass-through connections, users can extract valuable non-operational data such as digital fault recording (DFR) records and event files. The user can also access the historical log files and upload the archived data for trending and analysis.

The D400-DA allows maintenance and relay engineers to securely access substation devices, locally or remotely, through advanced visualizations and communication tools, increasing productivity.

The D400-DA is built on a flexible, high performance, expandable disk-less and fan-less platform that is powered by a 1.0Ghz processor.

Two Ethernet networks are supported with separate multiport switches. An IRIG-B format time protocol input/distribution module is also supported. Isolated serial port media is selected for each pair of ports.

The D400-DA has dual redundant, hot swappable power supplies, ensuring continuous uptime. Each power supply can be connected to a different source. As an example Power supply 1 can be connected to Mains, while power supply 2 is connected to the battery system. Power Supply Health Monitoring raises a SCADA point alarm when either power supply fails. This allows an alarm to be transmitted to the EMS /OMS or DMS system, where a field personnel can be dispatched to replace the failed supply, all without service disruption.

The D400-DA has extensive support for various time sync methodologies and will accept time sync signals from SNTP/NTP Servers, IRIG-B (un-modulated/modulated), and SCADA protocols. The D400-DA can also distribute this time sync information through its built-in IRIG-B distribution interface, SCADA protocols, and/or through the RS232 ports directly.

DS Agile, GE Vernova’s Digital Control System, includes customer-inspired evolutions and combines advanced hardware, cutting-edge software and communications capabilities to provide advanced and secured protection, control and automation solutions in digital substations. DS Agile provides features such as integrated condition monitoring for online substation situational awareness, IEC 61850 Ed 2, Parallel Redundant Protocol (PRP) and High Availability Seamless Redundancy (HSR) architecture and full integration with control room network management and smart grid applications.

DS Agile, GE Vernova’s Digital Control System, includes customer-inspired evolutions and combines advanced hardware, cutting-edge software and communications capabilities to provide advanced and secured protection, control and automation solutions in digital substations. DS Agile provides features such as integrated condition monitoring for online substation situational awareness, IEC 61850 Ed 2, Parallel Redundant Protocol (PRP) and High Availability Seamless Redundancy (HSR) architecture and full integration with control room network management and smart grid applications.

GE Vernova’s DS Agile Substation Gateway substation gateways perform the communication interface between the electrical substation and the area dispatch centers (SCADA), allowing SCADA operators to remotely control and monitor the substation in coherence with the operation of the whole area of the electrical grid.

GE Vernova’s DS Agile Substation Gateway substation gateways perform the communication interface between the electrical substation and the area dispatch centers (SCADA), allowing SCADA operators to remotely control and monitor the substation in coherence with the operation of the whole area of the electrical grid.