PowerNode: Motor Health Management

Electrical machines play a vital role for the modern industrial world. The impact of unplanned downtime due to breakage of these electrical motors is estimated to be more than $30 billion USD1 each year.

With more than 100 years of engineering experience with motors, generators, and control equipment, GE Vernova brings physics-based analytics and advanced machine learning algorithms to detect evolving faults within electrical motors and helps identify future issues to support customers with avoiding failures and resolving faults in advance.

PowerNode: Motor Health Management

Electrical machines play a vital role for the modern industrial world. The impact of unplanned downtime due to breakage of these electrical motors is estimated to be more than $30 billion USD1 each year.

With more than 100 years of engineering experience with motors, generators, and control equipment, GE Vernova brings physics-based analytics and advanced machine learning algorithms to detect evolving faults within electrical motors and helps identify future issues to support customers with avoiding failures and resolving faults in advance.

Facility Challenges

Unexpected motor failures decrease plant throughput, increase plant downtime, and can decrease production quality. Current solutions involving scheduled preventive maintenance or sensor-based condition monitoring are expensive.

PowerNode: Motor Health Management

GE Vernova’s Motor Health Management increases uptime and reduces OPEX by implementing prognostics-based equipment insights based on data provided by existing protection relays and meters. No additional sensors are needed.

Our on-site and cloud-based monitoring elements monitor equipment and provide an Equipment Health Dashboard with the remote connectivity and accessibility that enables this connection.

Motor Health Management Managed Services provides detailed insights into alarms and anomalies. Our team of experienced data analysts, subject matter experts and service engineers will provide recommendations for action when an incipient motor fault is detected.

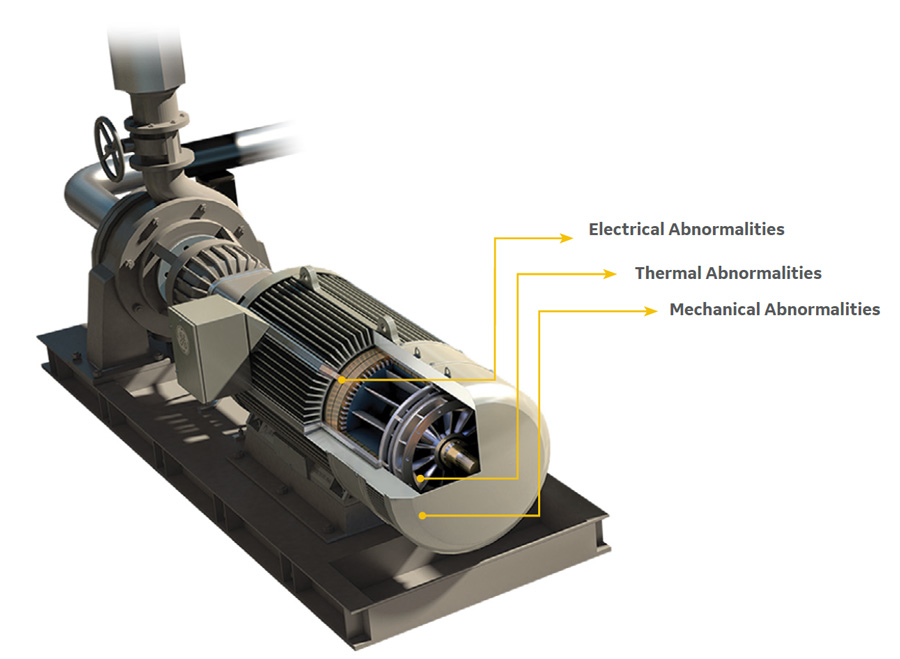

PowerNode: Motor Health Management uses Electrical Signature Analysis (ESA) and machine learning (ML) to predict failures.

PowerNode: Motor Health Management

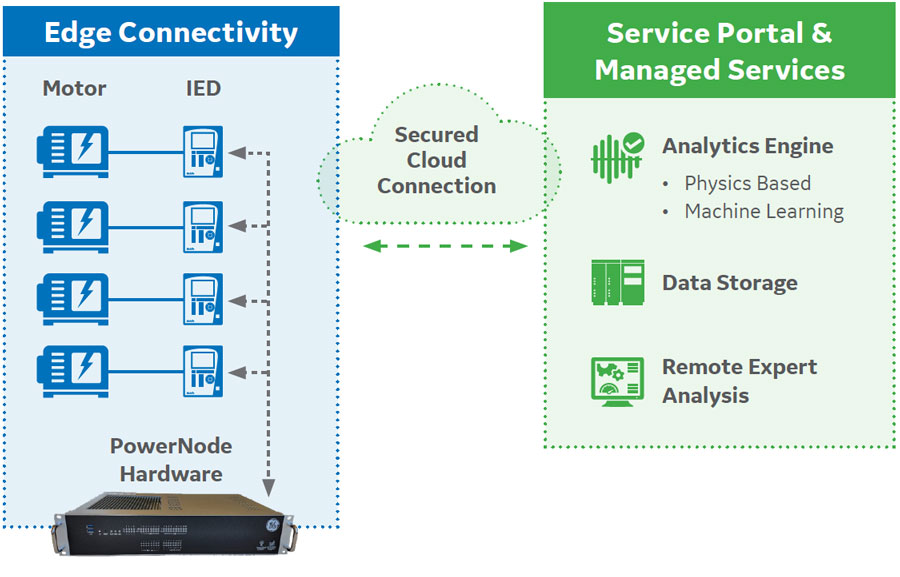

Architecture is as follows:

Edge Connectivity

The GPG Controller located at the industrial premises automatically triggers periodic oscillographies in the motor IEDs if the motor is running. Additional data (temperatures, vibration, electrical data) can also be automatically retrieved if available.

Oscillographies are transferred to the Service Portal through a secure remote connection.

PowerNode: Motor Health Management supports GE Vernova and non-GE Vernova IEDs. For non-GE Vernova IEDs, an evaluation will need to be carried out.

Service Portal

Motor data received from the industrial site is processed and stored in the Service Portal infrastructure.

When a potential fault is detected, the analytics engine automatically opens a case to be reviewed by our managed services team.

The Service Portal also provides a web interface to customers and the managed services team where they can see the asset status overview and details for each monitored asset.

Managed Services

The managed services center receives all potential failures detected by the service portal. A team of experts validates the data, provides recommendations to address the detected problem(s), and supports the site maintenance team.

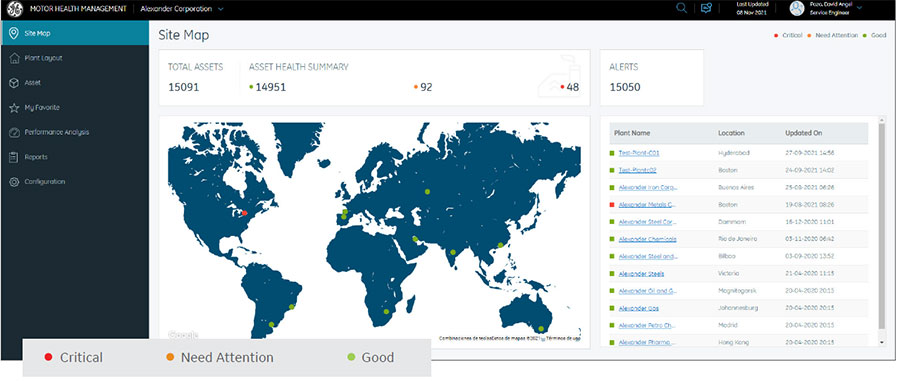

PowerNode: MHM Service Portal Web Interface

GE Vernova’s PowerNode Motor Health Management uses a cloud-based application to store and display data for analytics and monitoring.

Site Map

Overview of the location of all monitored sites and assets of a company. Locations of an asset with potential issues will be highlighted in orange or red.

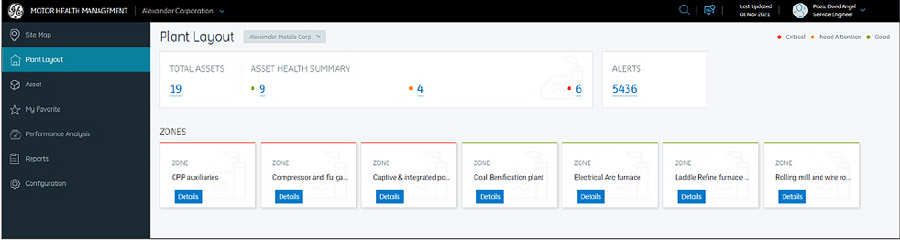

Plant Layout

View the status of an asset by navigating to a specific zone. Assets can be organized into four hierarchical levels for easy access.

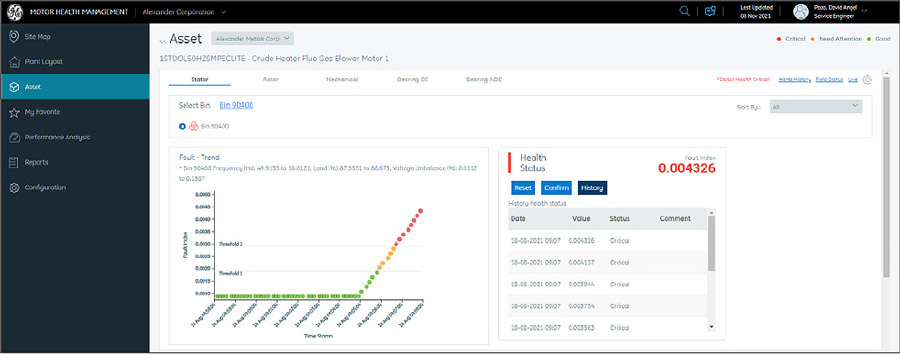

Asset Details

View current and historical data for each asset and failure type to validate a potential motor failure.

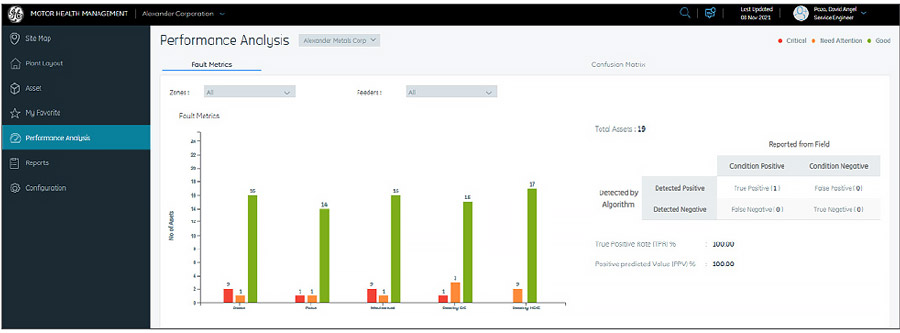

Performance Analytics

Monitor the performance of your assets with a set of dashboards that display the status of the assets by failure type, and a confusion matrix that displays the failure detection accuracy.

List of Failure Modes

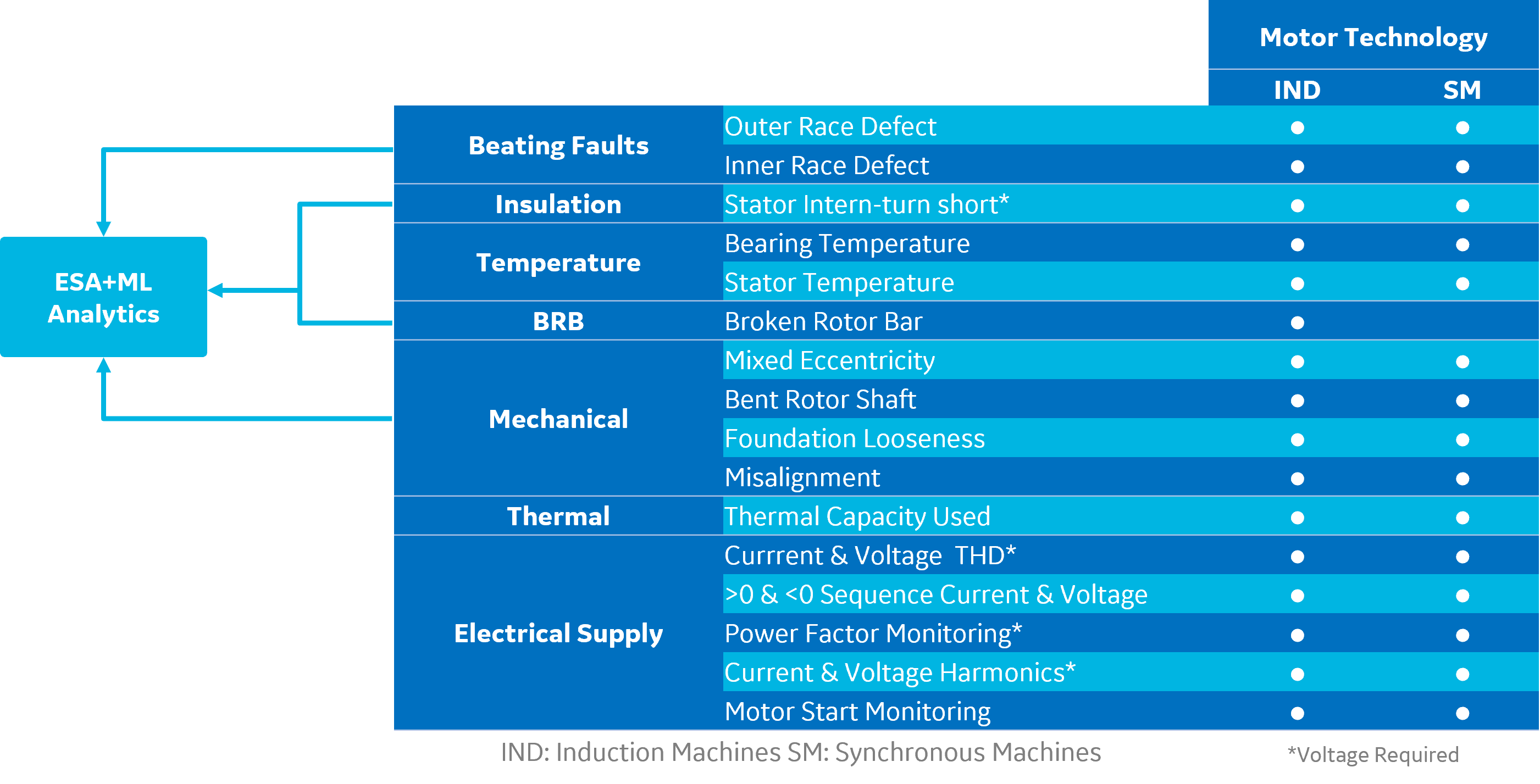

Electrical Signature Analysis (ESA)

- Used to detect various failure modes in a rotating machine by analyzing stator current and voltage signals.

- ESA systems rely upon Fast Fourier Transformer (FFT) analysis, much like vibration analysis.

- ESA fault detection algorithm uses FFT computation of the current signal to detect fault conditions at vibration frequencies related to the corresponding fault condition and computes peak magnitudes with respect to the baseline peak magnitudes (healthy mode of the motor without misalignment).

Machine Learning (ML)

Being part of artificial intelligence, ML algorithms can improve automatically through experience and using data.

GE Vernova’s ML algorithms can automatically detect and classify healthy and unhealthy motor operating conditions (unsupervised clustering).

The algorithms consider multiple parameters derived from the current and voltage readings (frequency, power, speed, rate-of-change, etc.) to increase accuracy of pure ESA analytics.

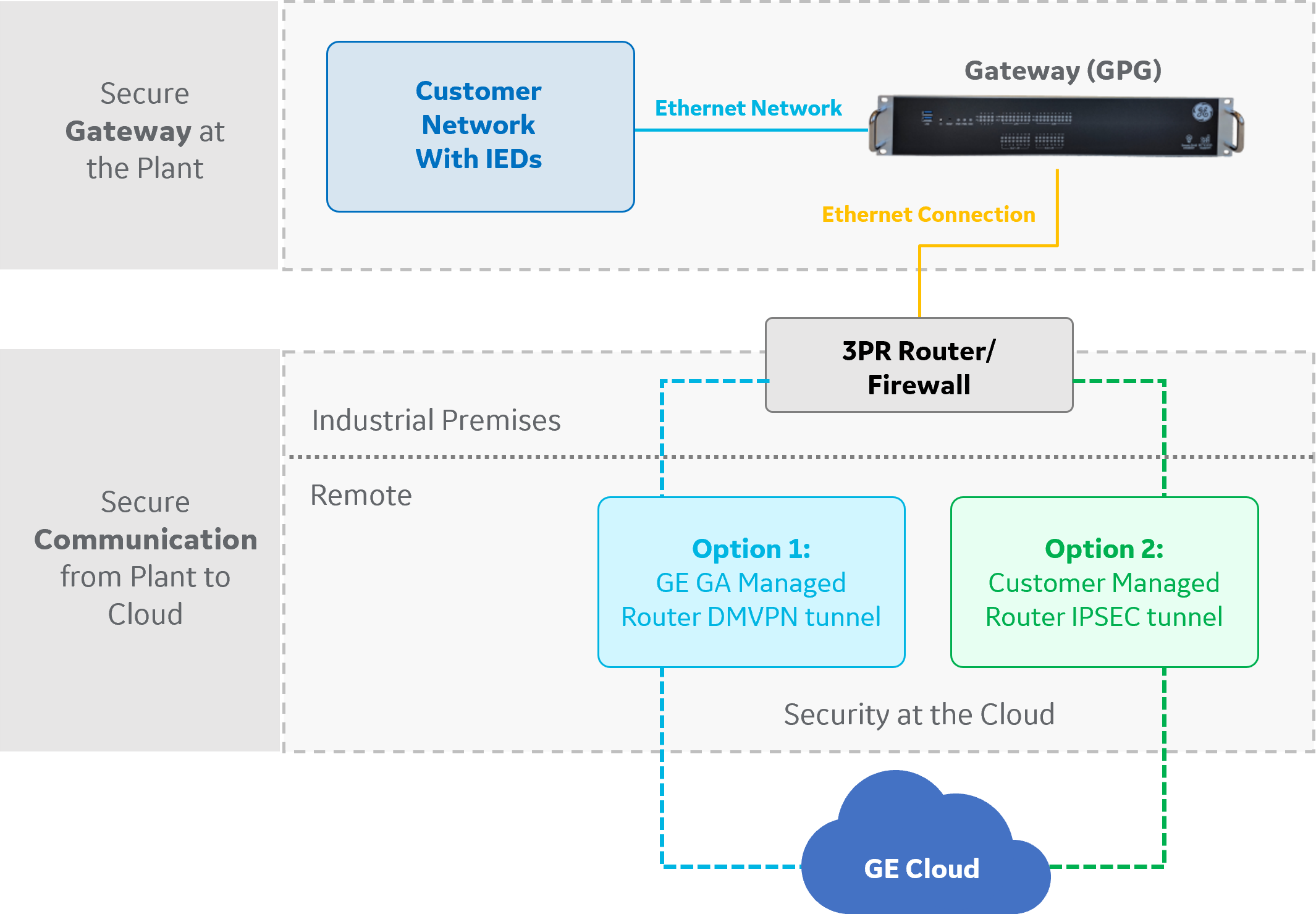

Secure Gateway at the Plant

- Secured data transfer between IEDs and gateway through standard communication protocols

- Malware protection software, white-listing, and hardening are all implemented

Secure Communication from Plant to Cloud using 3rd Party Rail (3PR)

- All external communications between the WAN router and the GE Vernova data repository are secured using encrypted tunnels. No control system or management ports will be exposed on the outside interface of the WAN router.

- Strong encryption standards to protect the privacy of the communication between the plant and GE Vernova over public networks.

- Inspect inbound/outbound traffic at the edge of the GE Vernova network.

Security at the Cloud

- All the endpoints of the cloud are secured by proper authentications and firewall implementations.

- The data files that are uploaded from the GPG are stored in a folder that is exclusively assigned to a customer. Access to this folder is given only to designated users through appropriate authentication.

Managed Services

The managed services provided by GE Vernova are the core value of Motor Health Management. These services save the customer the unnecessary pain of being exposed to the analytic algorithms while they are still in the process of being fine-tuned, thus avoiding unnecessary mis-operations. They also provide recommendations with regards to the detected failures in the form of prescriptive analytics.

The Managed Services team performs three main actions:

- Service 1:Review and validate the incipient failure of the motor. Prepare and send recommendations of actions to be taken by the site maintenance team to address the problem.

- Service 2:Support the site maintenance team to investigate and correct the problem.

- Service 3:If failures are missed or incorrectly detected, the managed services team performs an investigation and performs modifications of asset parameters and/or performs enhancements to the failure detection algorithms to increase failure detectability.

Electrical motors operate under different load conditions depending on the application. A continuous improvement process can adapt failure detection to your specific operating conditions.

Reduce unplanned downtime

PowerNode: Motor Health Management solution uses advanced diagnostics and prognostics to ensure you can plan your actions before the asset fails, avoid unplanned downtime, and reduce O&M costs.

Make the most of your IEDs

No additional sensors are required. The system uses protection and control relay data and existing communication infrastructure to minimize cost of deployment and installation impact.

Leverage GE Vernova's managed services

Our managed services team will accurately interpret the results and guide you in making the right decisions.

Recommended Products & services

PowerNode Load Shedding

Industrial load shedding enables facility electrical system stability in critical situations such as a sudden loss of available power, to balance load power consumption due to grid power restrictions (Demand Response) or to limit power consumption during peak hours (Peak Shaving).

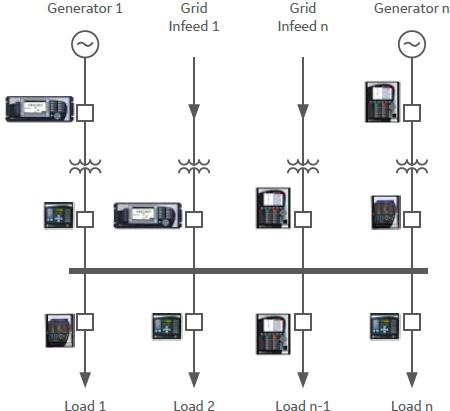

PowerNode offers a variety of applications that can be adapted to existing or new installations including:

PowerNode Load Shedding

Industrial load shedding enables facility electrical system stability in critical situations such as a sudden loss of available power, to balance load power consumption due to grid power restrictions (Demand Response) or to limit power consumption during peak hours (Peak Shaving).

PowerNode offers a variety of applications that can be adapted to existing or new installations including:

Facility Challenges

Industrial facilities often have multiple sources of power to support their operational needs which can include on site generation as well as power being supplied by the utility. When a plant experiences a loss of one of these power sources, the remaining power generation may not be able to support the existing plant loading and result in an unplanned shutdown. These unplanned shutdowns can have a very significant impact in the plant’s productivity and availability, causing significant losses in revenue when they occur.

Additionally, economical and/or grid compliance can require a facility to shed loads. Participating in Demand Response scenarios or limiting the Peak energy consumption of a facility can greatly impact the financial impact of plant operations.

GE Vernova’s PowerNode: Load Shedding Solution

GE Vernova’s PowerNode: Load Shedding (LS) solution provides a platform with real-time operation capabilities to combine all load shedding functions together with advanced monitoring and control.

Fast Load Shedding:

Subcycle (<15ms) remedial action scheme that prevents the electrical system from collapsing when there is a lack of available power due to a sudden loss of power sources in the industrial facility.

Industrial Facility Load Shedding Solution

Electrical Stability Load Shedding:

Customized load shedding solutions based on power, frequency or voltage moving out of acceptable limits. Scenarios executed by the Load Shedding controller can operate with times from 100ms to several seconds after the power instability was detected by the protection relays.

Demand Response:

Due to the increasing instability of the grid caused by renewable integration, grid operators are increasing the pressure on industrial consumers to participate in load demand control scenarios. Demand Response solutions can help facilities generate revenue through market participation as well as comply with grid requirements.

Peak Shaving:

Focuses on intelligently limiting utility peak power consumption to reduce a facilities electricity bill.

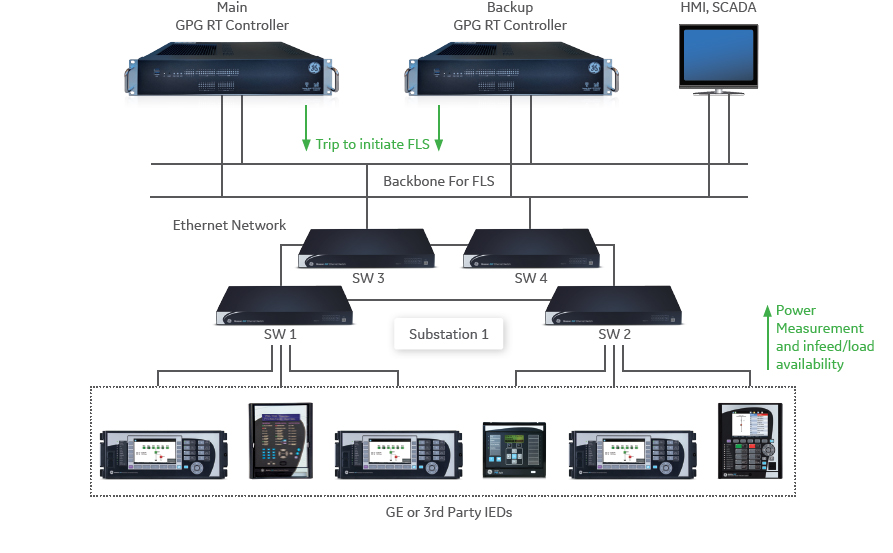

GPG RT Controller

GPG RT Controller

P&C relays send load/infeed power measurements and their availability to the Load Shedding controller using IEC 61850 GOOSE messages or other legacy protocols.

GE Vernova’s Load Shedding controller receives notification of a loss of an infeed from the P&C relays using IEC 61850 GOOSE messages.

Based on the priorities set by the operator, the FLS algorithms will dynamically shed only the loads groups needed to match the amount of generation lost.

GE Vernova’s proven algorithms have been verified and validated to operate in under 15ms from the time the loss of infeed has been detected.

For additional reliability, redundant Load Shedding controllers can be used.

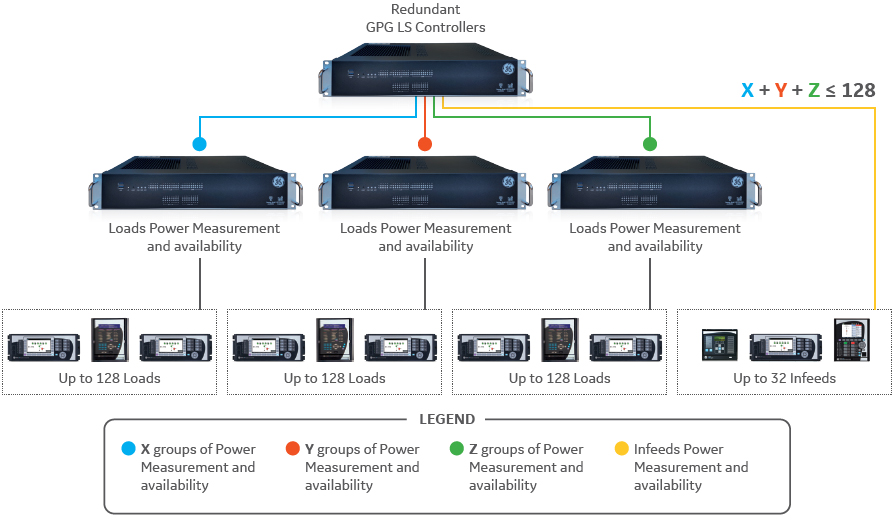

GE Vernova’s Load Shedding solution supports:

- 128 Load Priorities

- 32 Infeeds

- 128 Load Groups

- 1000+ Loads

Aggregator IEDs are used to group Loads when more than 128 loads are present in the installation.

Aggregator IEDs receive availability and power measures from multiple loads and group them in one of the 128 Load Groups.

The GPG RT Controller is a real-time controller that hosts GE Vernova’s Load Shedding solution and other power system control applications. The GPG RT Controller has been designed to be compliant with IEC 61850-3, which is an international hardware standard for communication networks and systems in power substations. Supporting international cybersecurity standard, the GPG RT Controller is the backbone of GE Vernova’s industrial power solutions that ensure reliable and secure operation for improving the reliability of industrial power networks.

Hardware Specifications

- Certification: IEC 61850-3, IEEE 1613, CE, FCC Class A, UL, CCC

- -20 to 70 degree Celsius operating temperature

- Mounting: 2U/19” Rack mount

- System Design: Fan-less, with no internal cabling

- OS Support: RTOS VxWorks and Windows Embedded.

- Power Supply: Redundant 100 ~ 240 VAC (47 ~ 63 Hz) DC: 100 ~ 240 VDC DC: 48VDC

- PRP & HSR Ethernet redundancy.

- Two expansion slots to increase serial and Ethernet port types and quantity.

Redundancy

GPG RT Controller offers multiple redundancy modes to align with customer requirements. The GPG redundancy can be set up in one of two different modes:

- Hot-Standby: GPGs arranged in a master and slave configuration

- Hot-Hot: Both GPGs working in parallel

PRP and HSR Ethernet redundancy options are available to support fault tolerant communication architectures.

GPG RT Controller

GPG RT Controller

Supported Protocols

- IEC 61850 Server Ed.1 and Ed.2

- IEC 61850 Client Ed.1 and Ed.2. KEMA Certified

- IEC 61850 GOOSE

- C37.118 and IEC61850-90-5 Synchrophasor Protocol

- IEC 60870-5-101/104 Server/Client. KEMA Certified

- DNP3 Master/Slave RTU and TCP

- SNMP Client

- MQTT

- NTP client. With Redundancy

- Modbus RTU/TCP Master/Slave

- IEC 6070-5-103 Master

- SPA-Bus Master

- OPC DA & AE Server/Client

- OPC UA Server

- EGD Producer

Reduces unplanned downtime impact

- Cost of materials lost in process

- Cost of lost production

- Cost of potential equipment damage

- Cost of environmental impact

Best in class performance

- The fastest operation time in the market: <15ms

Integrates with P&C

- Analog load and generation data transferred through IEC 61850 GOOSE messaging

- Integrates with existing protective relays

- Uses existing Ethernet network

Scalable and flexible

- Can expand from one to thousands of loads

- Dynamic load shed based on plant conditions

- Changes to the load priorities set in seconds from operator’s HMI system

Easy Future Expansions

- Updates / expansion made through device configuration, no additional wiring

Vendor Agnostic

- Can integrate GE Vernova and non-GE Vernova IEDs

Recommended Products & services

Wide Area Monitoring Protection & Control Solutions

The complexity of modern electrical power systems is steadily increasing with the penetration of massive amount of asynchronously connected renewable generation. This generation that is connected through inverters reduces the inertia of the Grid and significantly changes how today’s power system operates. These characteristics require shortened power system response time and strategies for dealing with the grid’s reduced Inertia and weakened system strengths.

Wide Area Monitoring Protection & Control Solutions

The complexity of modern electrical power systems is steadily increasing with the penetration of massive amount of asynchronously connected renewable generation. This generation that is connected through inverters reduces the inertia of the Grid and significantly changes how today’s power system operates. These characteristics require shortened power system response time and strategies for dealing with the grid’s reduced Inertia and weakened system strengths.

Solution Overview

System Oscillation Damping

Detecting and actioning on multiple signal oscillation types

- Inter-area Oscillations

- Forced Oscillations

Mitigating Reduced Inertia

Fast and coordinated frequency response using real time measurement of phasors

- Large local rate of change of frequency

- Large frequency exhursions

- Network phase angle divergence

Managing weak System Strength

Providing support for renewable energy generators with power electronic which creates weaker system strength

- Voltage stability issues

- Control stability issues

- Power electronic inter-oscillations

What GE Vernova can offer

Complete end to end solution

From plant measurement to control room monitoring & centralized control – range of solutions available from analysing, visualization, monitoring, protection, and control.

Application domain knowledge

Applying our knowledge and perspective to resolve limits and risks in the power systems combining experience of substation protection and control, telecommunication, and centralised power systems management.

Global center of excellence & regional capability

- Engineering, project management and execution capabilities of CoE and regional teams to manage and execute projects from small to large scale.

- Many years of installed base experience of projects covering end to end providing operational efficiency, reliability, and security for the power systems.