Industrial Communications Training

A wide variety of classroom,virtual & e-learning courses at your fingertips

GE Vernova’s Industrial Communications training is offered in a wide variety of platforms and topics to provide flexibility in time, location and skill level. From attendance in on-site classroom courses to virtual course attendance, self-paced e-learning videos and customized courses, GE Vernova’s training provides customers with high-quality knowledge to be safe, efficient and successful in industrial wireless communications.

Industrial Communications Training

A wide variety of classroom,virtual & e-learning courses at your fingertips

GE Vernova’s Industrial Communications training is offered in a wide variety of platforms and topics to provide flexibility in time, location and skill level. From attendance in on-site classroom courses to virtual course attendance, self-paced e-learning videos and customized courses, GE Vernova’s training provides customers with high-quality knowledge to be safe, efficient and successful in industrial wireless communications.

Recommended Products & services

Product Environment Profiles

For GE Vernova’s high voltage products

Product Environmental Profile (PEP), also known as Environmental Product declaration (EPD), is a document communicating the environmental impact and performance of the product based on Life Cycle Assessment (LCA).

A PEP includes:

Product Environment Profiles

For GE Vernova’s high voltage products

Product Environmental Profile (PEP), also known as Environmental Product declaration (EPD), is a document communicating the environmental impact and performance of the product based on Life Cycle Assessment (LCA).

A PEP includes:

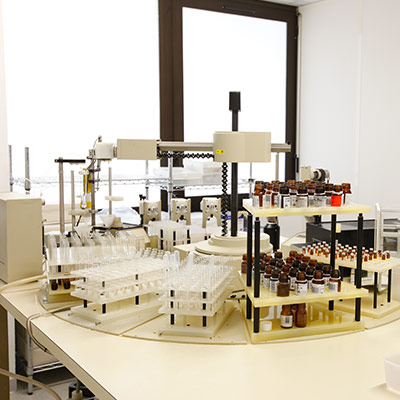

Oil Test and Analysis

The analysis of dielectric materials and the preventive maintenance programs of oil-insulated equipment can reduce the risk of unscheduled outages, ensuring asset performance and durability. Transformer active part and cellulosic insulation immersed in oil generate markers during their lifecycle. With analysis, oil variations can be detected at an early stage before failure occurs. Oil analysis provides critical information on asset health status, including electrical properties and ageing.

Oil Test and Analysis

The analysis of dielectric materials and the preventive maintenance programs of oil-insulated equipment can reduce the risk of unscheduled outages, ensuring asset performance and durability. Transformer active part and cellulosic insulation immersed in oil generate markers during their lifecycle. With analysis, oil variations can be detected at an early stage before failure occurs. Oil analysis provides critical information on asset health status, including electrical properties and ageing.

France – Laboratory of Oil Services

Parc technologique du canal

8 rue Giotto

31520 Ramonville-St-Agne

Phone: +33 (0)562 190 560

Email: [email protected]

Web: LOS

Certified ISO 9001, ISO 14001, OHSAS 18001, Accredited COFRAC based on ISO 17025

Australia - Transformer Oil Testing Laboratory

Unit4B/29-41 Lysaght Street Acacia Ridge,

QLD 4110

Australia

Phone: +61 408 885 801

Email: Email Contact

Certified ISO 9001, ISO 14001, OHSAS 18001, Accredited National Association of Testing Authorities (NATA)

Turkey - Transformer Oil Testing Laboratory

Baris Mah. Guney Yanyol Cad. No:320 Gebze

41410 Kocaeli

Turkey

Phone: +90 (0) 262 648 3300 Ext 3373-3390

Email: Email Contact

Certified ISO 9001, ISO 14001, OHSAS 18001, Accredited Turkish Accreditation Agency TS EN ISO/IEC 17025

Recommended Products & services

Modular Training Courses

Focused on technical knowledge and hands-on experience, trainees learn both theory and practical skills on the “why” and the “how-to.”

Explore our portfolio of courses below.

Modular Training Courses

Focused on technical knowledge and hands-on experience, trainees learn both theory and practical skills on the “why” and the “how-to.”

Explore our portfolio of courses below.

- Electrical safety for managers - Qualification levels overview (F1001)

- Electrical safety for non-electricians (F1010)

- Electrical safety for non-electricians - Retraining (F1011)

- Electrical safety for electricians working at low voltage (F1020)

- Electrical safety for electricians working at low voltage - Retraining (F1021)

- Electrical safety for electricians working at low, medium and high voltage (F1030)

- Electrical safety for electricians working at low, medium and high voltage - Retraining (F1031)

- SF₆ gas recovery regulation EC 517-2014 - For inexperienced personnel (V0032)

- SF₆ gas recovery regulation EC 517-2014 - For experienced personnel (V0033)

- SF₆ gas recovery regulation EC 517-2014 - Evaluation and certification (V0039)

- Handling procedures for SF₆ and its mixtures according to IEC 62271-4 standard (V0010)

- Generator circuit breakers - Fundamentals (A9103)

- Generator circuit breaker FKG1 - Maintenance and breakdown repair (V9542)

- Generator circuit breaker FKG2 - Maintenance and breakdown repair (V9442)

- Introduction to high voltage circuit breakers (T002)

- Circuit breaker GL type up to 250 kV - Operation & maintenance or erection & commissioning (V5442)

- Circuit breaker GL type above 250 kV - Operation & maintenance or erection & commissioning (V5642)

- Dead tank circuit breakers - Operation & maintenance or erection & commissioning (P003)

- Circuit breakers HGF-FX-FXT-S1 type - Operation and maintenance (P002)

- Hybrid compact switchgear assembly – HYpact – Erection and Commissioning (TIR059)

- Introduction to instrument transformers (A5312)

- Instrument transformers – Maintenance (C5342)

- Courses On Demand

- Distribution transformers - Operation and maintenance (C4312)

- Introduction to power transformers (A4201)

- Power transformers - Definition and operational constraints (A4212)

- Power transformers - Fundamentals for specialists (A4213)

- Power transformers - Operation and maintenance (C4242)

- Power transformers - Design and specification (A4214)

- Power transformers - OLTC - Operation and maintenance (C4532)

- Power transformers - Oil sampling and analysis (C4233)

- Courses On Demand

- Introduction to gas-insulated substation (T003)

- Gas-insulated substation B105 type - Maintenance (X4442)

- Gas-insulated substation T type - Operation and maintenance (X6142)

- Gas-insulated substation F35-3/4/5 type - Maintenance (TIOE002)

- Gas-insulated substation B65 type - Maintenance (TIOE003)

- Gas-insulated substation B95/212 type - Maintenance (TIOE004)

- g3 Fundamentals (V0051)

- Courses On Demand

Recommended Products & services

High Voltage Disconnector

Operation and maintenance Ref. V7131

GOALS

- Understand the different types of disconnectors in our catalog

- General presentation

| Duration | Method | ||

|---|---|---|---|

| 1 day |  | ||

High Voltage Disconnector

Operation and maintenance Ref. V7131

GOALS

- Understand the different types of disconnectors in our catalog

- General presentation

| Duration | Method | ||

|---|---|---|---|

| 1 day |  | ||

Place

TIA, Aix-les-Bains

Disability or specific need

For anyone with a disability or any specific need, please contact us at +33 4 79 34 78 00

Intra-Training

Do you want in-house or tailor-made training? The dates are planned to match everyone's availability and to be agreed 3 months before the start of the session.

Inter Training

Do you want to participate in a training course planned with several other companies in our training centers? Our training calendar allows you to register your employees from two weeks to one year before the training.

Qualiopi-Certified process

The quality certification was issued under the following category of actions: training actions.

Key figures in 2023

Key Metrics in 2023

77% of our trainees are satisfied

94 trainees trained

Recommended Products & services

Safety in explosive atmosphere – Theory Electrical and mechanical - Level 2 (F5030)

| Duration |

|---|

| 4 days |

| Who should attend? |

|---|

| Person technically responsible for an installation in an explosive atmosphere area: engineer, project and design manager, supervisor responsible for workers in an explosive area. |

Safety in explosive atmosphere – Theory Electrical and mechanical - Level 2 (F5030)

| Duration |

|---|

| 4 days |

| Who should attend? |

|---|

| Person technically responsible for an installation in an explosive atmosphere area: engineer, project and design manager, supervisor responsible for workers in an explosive area. |

Recommended Products & services

Electrical Safety Awareness Suite of 3 modules (ELES123)

What will I learn from this course?

Provide the necessary knowledge and “know-how” which will enable you to adhere and comply with GE Vernova requirements for the protection of supervisors and their colleagues working on electrical systems.

Topics

Basic Electrical Safety Awareness Module

Electrical Safety Awareness Suite of 3 modules (ELES123)

What will I learn from this course?

Provide the necessary knowledge and “know-how” which will enable you to adhere and comply with GE Vernova requirements for the protection of supervisors and their colleagues working on electrical systems.

Topics

Basic Electrical Safety Awareness Module

Recommended Products & services

Handling of SF₆ and CF4 gases according to IEC 62271-4 technical report (V0010)

What will I learn from this course?

- Understand the general characteristics of SF₆ & CF4 gases

- Master near impact on our environment

- Know how to recover, drain the SF₆ to vacuum, their refill a compartment under SF₆ gas

- Apply the specific safety rules during the gas recovery operations

| Duration |

|---|

| 3.5 days |

Handling of SF₆ and CF4 gases according to IEC 62271-4 technical report (V0010)

What will I learn from this course?

- Understand the general characteristics of SF₆ & CF4 gases

- Master near impact on our environment

- Know how to recover, drain the SF₆ to vacuum, their refill a compartment under SF₆ gas

- Apply the specific safety rules during the gas recovery operations

| Duration |

|---|

| 3.5 days |

Recommended Products & services

GIS F35-145 kV Operation & Maintenance

Suite of 2 modules (ELF3512)

GIS F35-145 kV Operation & Maintenance

Suite of 2 modules (ELF3512)

Recommended Products & services

Generator circuit breakers Fundamentals (A9103)

What will I learn from this course?

Become conversant in the fundamentals of the main equipment operating with a generator circuit breaker

Topics

Generator Circuit breakers

Synchronous Generators |

Generator circuit breakers Fundamentals (A9103)

What will I learn from this course?

Become conversant in the fundamentals of the main equipment operating with a generator circuit breaker

Topics

Generator Circuit breakers

Synchronous Generators |