Essential transformer diagnostics for comprehensive protection

Optimize your capital expenditure, increase the life of your transformer, and improve reliably of service by implementing a preventative asset maintenance & management tool using the Multilin T60, T35 and 845 transformer protective relays

Essential transformer diagnostics for comprehensive protection

Optimize your capital expenditure, increase the life of your transformer, and improve reliably of service by implementing a preventative asset maintenance & management tool using the Multilin T60, T35 and 845 transformer protective relays

Transformer Protection Systems

Delivering fast, adaptive, sensitive and secure protection for small, medium and large power transformer applications. Multilin protection relays include advanced Health Diagnostics capabilities, coupled with advanced communications including IEC 61850 for remote data and engineering access to increase asset life and improve quality of service.

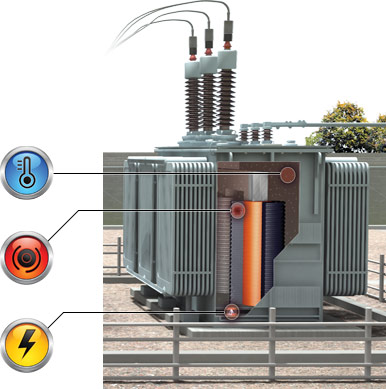

Top Oil Temperature

- Improve maintenance through oil temperature monitoring

- Detection of oil aging to avoid isolation faults

- Monitoring and alarming easily integrated with SCADA systems

Winding Hot Spots

- Advanced algorithm based on IEEE C57.91-1995 and C57.96-1989

- Constant, value-based monitoring of winding temperatures

- FlexLogic for control of cooling fans

Internal Short Circuit

- Fast tripping with unrestrained differential element

- Enhanced selectivity with double break point transition characteristic

- Sensitive ground current differential element

Increased equipment use, deferred capital expenditures and reduced maintenance expenses are challenges faced by most capital asset owners today. Therefore, managing critical electrical system assets such as large power transformers require a preventative maintenance plan that can screen device degradation and make intelligent device protection decisions.

Excessive heat and mechanical stress are major reasons for transformer damage. These factors can cause hot spots, breakdown of winding insulation, short circuits, and catastrophic failures. The good news, however, is that transformer failures are attributable to manageable problems and new technology in transformer protective relays enable Engineers to implement a diagnostic approach to assess the health of power transformers.

Measurable indicators of transformer health include electrical load, hottest-spot, ambient temperature, loss of life etc. Users who use protective relays to monitor these indicators, plan optimal transformer loading and maintenance, and thereby increase life of their asset and improve quality of their service.

The transformer top-oil temperature can be directly measured, or calculated from the ambient temperature, load current, and other transformer characteristics. The protective relays can be set to alarm or trip in cases where the computed hottest-spot temperature is above the pickup threshold for a user specified time (considered as transformer overheating).

Multilin relays use IEEE C57.91 compliant thermal models to calculate the winding hot-spot temperature, detect abnormal temperatures inside the transformer, and prevent loss of life of the winding insulation. The loss of life element detects the accumulated total consumed transformer life. This element can be set to issue an alarm or trip when the actual accumulated transformer life becomes larger than the user-specified loss of life pick up value.

The protective relay aging element detects the transformer aging in per unit normal insulation aging. This element can be set for alarm or trip whenever the computed aging factor is greater than the maximum permissible user-defined pickup setting under emergency loading conditions and maximum ambient temperature.

Return Procedures

Follow these 6 steps to return your product to us

1. Obtain "Return Materials Authorization" (RMA) Number

- Call this number to receive an RMA number:

1-800-547-8629, toll-free inside North America

or (905) 927-7070 outside North America - Fill in the Online Form

- Email us at: [email protected], or

Return Procedures

Follow these 6 steps to return your product to us

1. Obtain "Return Materials Authorization" (RMA) Number

- Call this number to receive an RMA number:

1-800-547-8629, toll-free inside North America

or (905) 927-7070 outside North America - Fill in the Online Form

- Email us at: [email protected], or

Real-Time Digital Simulator Lab Testing

The real-time digital simulator lab provides real-time dynamic simulation of system faults, sequence of events, and/or conditions such as power swings, open poles, out of step conditions and other fault and system conditions. Relay responses can then be observed in a real closed loop environment to prove the relay's performance within the customer's system.

Real-Time Digital Simulator Lab Testing

The real-time digital simulator lab provides real-time dynamic simulation of system faults, sequence of events, and/or conditions such as power swings, open poles, out of step conditions and other fault and system conditions. Relay responses can then be observed in a real closed loop environment to prove the relay's performance within the customer's system.

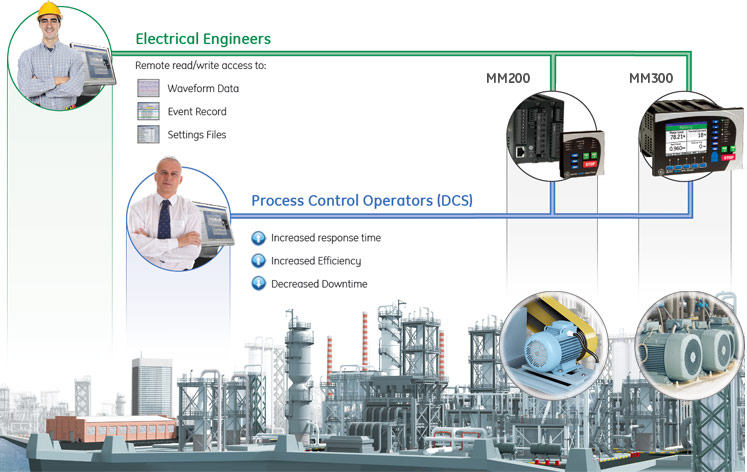

Advanced, flexible motor protection using simultanious communications

Ensure the transfer of critical process control data without jeopardizing system response time or stability utilizing simultaneous communications available in the Multilin MM300 and MM200

Advanced, flexible motor protection using simultanious communications

Ensure the transfer of critical process control data without jeopardizing system response time or stability utilizing simultaneous communications available in the Multilin MM300 and MM200

Dedicated industrial strength network

Industrial applications depend on a communications highway within the facility to ensure proper operation of both the process and electrical systems. In traditional industrial applications there are two different groups of people that are responsible to ensure the facility maintains continual operation, the Process Control Group, and the Electrical Engineering Group.

The Process and Control group is responsible for set-up and maintenance of the overall process of the facility. The Electrical Engineering group is responsible for troubleshooting problems, maintenance, and fixing the electrical equipment. Each group has their own management and control system, each with very different requirements.

Limited electrical information available to the Electrical Engineering group

In typical refinery applications, there is traditionally one communication network communicating data to both the Electrical Engineering and the Process and Control groups. Since this network is designed with the Process Control groups’ requirements in mind, limited electrical information is available to the Electrical Engineering group.

As a result, the Electrical Engineering group does not have the visibility and remote access to connected loads for essential operational information and statistics required for efficiency. Without remote access to this critical information, remote troubleshooting of electrical system problems are not possible, increasing system downtime.

The MM300 and MM200 provide dedicated communications

With the implementation of the GE Vernova Multilin MM300 or MM200 Low Voltage Motor Management Systems, dedicated individual networks for both the Process and Control group and the Electrical Engineering group, is possible.

By having individual networks at field level devices, the MM300 and MM200 provide dedicated communications to the Electrical Engineering Group. This allows full remote access to critical electrical operation information such as; event records, data log files, motor learned data, waveform captures, operational status, full settings files, and troubleshooting.

This also provides the Process and Control group a network designed specifically for the process application ensuring maximum system response and efficiency. With the Multilin MM300 and MM200 motor management systems, simultaneous high-speed communications allow critical information to be transmit remotely, ensuring a higher level of system stability and efficiency, without compromising data integrity.

Advanced generator protection and communication utilizing IEC 61850

Significantly reduce costs associated with installation and maintenance utilizing the Multilin G60 Generation Protection System and the Multilin HardFiber IEC 61850 Process Bus Solution

Advanced generator protection and communication utilizing IEC 61850

Significantly reduce costs associated with installation and maintenance utilizing the Multilin G60 Generation Protection System and the Multilin HardFiber IEC 61850 Process Bus Solution

HardFiber™ System

IEC 61850 Process Bus Solution

- Hardened switchyard interface to acquire all measurement and I/O signals

- Robust and secure communications via IEC 61850 over Fiber Optic cables

- Reliable operation provided by integrity and self-check monitoring tools

- Save up to 50% on Protection and Control Labor costs

Protection & Control

G60 Generator Protection System

- Streaming Synchronized Phasor Measurements

- Industry leading cyber security including Dual Permission Access Control

- Comprehensive support for IEC 61850 Process Bus with HardFiber System

- Pumped storage generator applications

- Advanced automation capabilities

Today’s critical generation systems require more sensitive, dependable protection. Coupled with the introduction of new regulatory requirements and a focus on infrastructure security, electrical system operators need real-time access to device status and metering value data from generating units and associated equipment, to effectively manage and maximize operational output and availability.

The Multilin G60 Generator Protection System sets a new standard in Generator protection and control with streaming synchrophasor measurements, advanced protection capabilities, cyber security features and tools and support for IEC 61850 communications.

The G60 Generator Protection System is designed for any size generator application and is well suited for applications where the generator is driven by turbines such as, steam, gas or hydraulic. The G60 Generator Protection System also provides protection and control for pumped storage applications where the generator is used as both the generator and the pumping motor.

As the first Intelligent Electronic Device to provide streaming synchronized phasor measurements according to the IEEE C37.118 standard, operators are able to maximize system availability with access to captured synchrophasor data to examine machine performance, including inter-unit oscillations, during power system disturbances.

Providing the latest in cyber security, the Multilin G60 Generator Protection System includes several layers of functions and tools to maintain secured device and system access including, Dual Permission Access Control, multiple passwords, and security event alarming and reporting.

With support for IEC 61850 communications, combine the Multilin G60 Generator Protection System with the Multilin IEC 61850 HardFiber System, to create a robust and secure Process Bus Solution. Eliminate the need for miles of long distance, point-to-point copper cabling that is traditionally required to obtain measurement and I/O signal data from generators and associated system devices that are interconnected over wide geographic areas. Utilities are able to gain significant reductions in costs and effort associated with the engineering, installation and commissioning of new and retrofit generation systems while maintaining and gaining real-time access to generator status and metering values.

Integrating the Multilin G60 Generator Protection System and the IEC 61850 HardFiber System, creating a robust process bus solution for any generator station application provides detailed diagnostic information, secure control capabilities while reducing initial project capital costs and future maintenance costs.

Distribution Feeder Spotlight- Early fault detection with comprehensive feeder protection

Major faults occurring in the distribution system such as arc flash, incipient cable splice fault, high impedance fault, etc. must be sensed quickly and isolated immediately to prevent hazards to the general public and personnel.

View 8 Series

Distribution Feeder Spotlight- Early fault detection with comprehensive feeder protection

Major faults occurring in the distribution system such as arc flash, incipient cable splice fault, high impedance fault, etc. must be sensed quickly and isolated immediately to prevent hazards to the general public and personnel.

View 8 Series

Electrical technicians are exposed to various hazardous conditions when they work live on a power system. Arc flash is the most devastating of these hazards as it can cause catastrophic damage, fire or injury. An arc flash is a voltage breakdown of air resistance, resulting in a flash over from one exposed live conductor to another conductor or to ground. The massive energy released during an arc flash fault sends concentrated radiant energy, hot gases and melting metal outward at 35,000 degrees Fahrenheit (F) or four times the temperature of the sun’s surface. In addition to the explosive blast, electrical workers caught in such a condition may suffer severe radiation burns, damaged eyesight from high-intensity flash, and hearing loss and brain damage from accompanying pressure waves. Three factors determine the arc flash intensity on line personnel- the available system fault current, the time for the arc flash to clear, and the individual’s distance from the arc. Various configuration choices can be made with leading edge protection and control products such as the Multilin 850, 350, 750, F60, F35, F650 and P14N protective relays to affect these factors and in turn reduce the arc flash hazard.

Arcing and downed distribution conductors pose personnel and property safety threats such as fires, injuries, and even fatalities. Since high impedance (Hi-Z) faults do not produce enough fault current to be detectable by conventional over-current relays, they are not detected by traditional protection devices. Hi-Z protection in GE Vernova’s Multilin F60 is a unique, field proven algorithm incorporating a signature-based expert pattern recognition system. Harmonic energy levels in the arcing current and a sophisticated expert system assures security and dependability for detection of Hi-Z faults. This algorithm has shown a 90% success rate in detecting downed conductors based on actual in-service utility data. While traditional protection is designed to protect the power system, Hi-Z protection focuses on people and property.

Moisture ingress due to defective terminations is one of the major cause of underground cable failures. When water gathers in a subversive cable splice, a momentary line-to-ground fault occurs. Although the fault is self-clearing, the repetitive cycle of water ingress causes the splice insulation to deteriorate and in due course fail. These underground cable faults last a very short duration, which makes the design of an incipient fault protection function quite challenging The basic Multilin incipient cable splice protection algorithm detects a single incipient fault pattern. GE Vernova’s Multilin F60 uniquely recognizes the criteria that could lead to these faults, providing sufficient notification ensuring system dependability and safety. Incipient fault detection can be used either to alarm or trip. Either option is reasonable, however the occurrence of a half-cycle event indicates the cable is failing, and a full fault is about to occur in the circuit.

Turnkey Substation

Grid designs and installs innovative turnkey substation from substation definition to delivery which include solution design, network analysis, engineering, procurement, civil works, installation, tests, commissioning, and asset management.

Turnkey Substation

Grid designs and installs innovative turnkey substation from substation definition to delivery which include solution design, network analysis, engineering, procurement, civil works, installation, tests, commissioning, and asset management.

Recommended Products & services

Retrofit Solutions

GE Vernova Grid Solution designs, manufactures and supplies high quality protection, control, recording and monitoring systems for grid utilities and industries. To meet customer requirements related to network stability and reliability, we provide a comprehensive range of support and services for:

- System and product availability

- Lifecycle management and obsolescence

- Modernisation, extension and evolution

- Cybersecurity implementation on new and existing substation automation systems

- Skills and performance development

Retrofit Solutions

GE Vernova Grid Solution designs, manufactures and supplies high quality protection, control, recording and monitoring systems for grid utilities and industries. To meet customer requirements related to network stability and reliability, we provide a comprehensive range of support and services for:

- System and product availability

- Lifecycle management and obsolescence

- Modernisation, extension and evolution

- Cybersecurity implementation on new and existing substation automation systems

- Skills and performance development

Recommended Products & services

BiTRONICS M871 - Legacy

Monitoring and Recording IED

GE Vernova’s Grid Solutions has discontinued sales of this product. As an alternative, please refer to DR60.

BiTRONICS M871 - Legacy

Monitoring and Recording IED

GE Vernova’s Grid Solutions has discontinued sales of this product. As an alternative, please refer to DR60.

Recommended Products & services

K Series - Legacy

Manufacturing for the K-Series has been discontinued – except for the items identified below:

K Series - Legacy

Manufacturing for the K-Series has been discontinued – except for the items identified below: