Transformer oil analysis:

The cost-effective solution for efficient preventive maintenance.

Transformer failures in the energy industry account for 50% of operating losses according to Allianz Group. Unexpected interruptions can severely impact production, profitability, and customer relations.

Through preventative maintenance, you can reduce these risks and increase potential damage coverage by your insurance in case of an incident.

Conduct transformer oil analysis to strengthen your approach to preventing failures.

From vigilance to protection:

oil analysis preserves your transformer.

Detect defects and emerging phenomena

Dielectric oil analysis helps detect early signs of malfunction or aging in your transformer before they become problematic. By anticipating these emerging faults, you can plan specific maintenance operations and avoid operational losses due to untimely shutdowns.

Opt for an economical prevention solution

Oil analysis is an economical preventive solution for detecting defects before they become costly. By anticipating issues, avoid unexpected costs and preserve the profitability of your business.

Meet your insurer's requirements

Depending on the power and age of the transformer, insurers require analyses to be conducted from its commissioning and throughout its operation. Emphasis is placed on the APSAD D91 standard to prevent degradation and production interruptions by detecting anomalies as soon as they appear.

With transformer oil analysis, ensure your coverage in the event of a claim.

Monitor the health status of your transformer

Oil analysis provides a comprehensive diagnosis of the health of your transformer. They establish a first point of reference as well as a comparison framework for subsequent monitoring.

Transformer oil analysis, step-by-step:

1

Send the kit

2

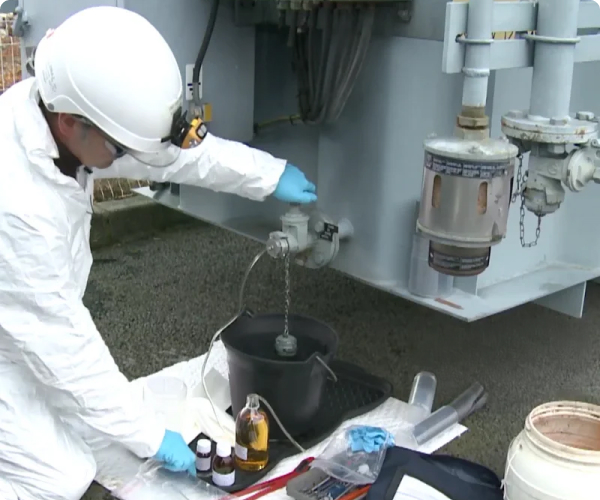

Sampling

(Any type of device)

3

Receipt of samples

4

Analysis in laboratory

5

Sending of report

In case of emergency, receive your report within 8 hours.

What analyzes to detect which defect?

THE IMPORTANCE OF OIL ANALYSIS

PRESENCE OF WATER IN THE TRANSFORMER

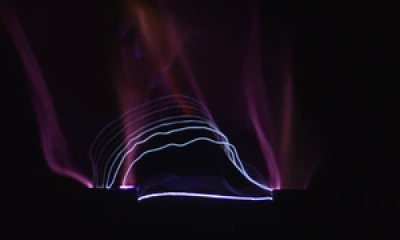

THERMAL OR ELECTRICAL FAULT

AGING OF TRANSFORMER PAPERS

TRANSFORMER PCB ANALYSIS

Meet your insurer's requirements

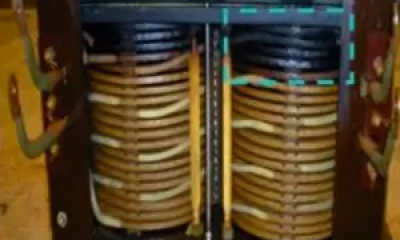

Actives parts

Chromatography: analyzing the dissolved gases in a transformer contributes to the detection of thermal and/or electrical faults related to the active parts.

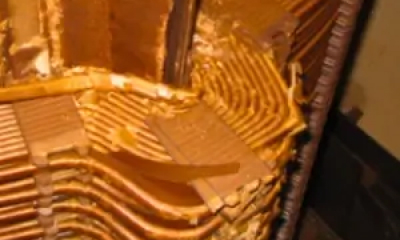

Dielectric fluid

Analysis of the dielectric strength of the oil, water content, and acidity index to assess the insulating and heat-transfer capacities of the fluid, as well as its quality.

Insulating papers

Analysis of furan derivatives and methanol to assess the condition of insulating papers and estimate the residual life of the transformer.

Pollution / PCB

Research and quantification of PCBs to verify compliance with regulations.

How often should transformer oil analysis be performed?

Is transformer oil analysis subject to regulation?

How do I take a sample of oil from my transformer?

Should oil be added to my transformer after sampling?