A bolt of lightning crackles through the air. An instant later there’s a flash, followed by an ominous sizzle: the lightning struck a powerline. Normally, you’d run inside and call the electric company. But overhead, where you might expect to see a wall of clouds darkening a summer sky, instead a white ceiling arches above a thicket of space-age structures: 60-foot poles encircled by gleaming metal rings; a cylinder rising almost to the rafters, capped by a spherical mesh of metal discs, like a disco ball reimagined by Stanley Kubrick.

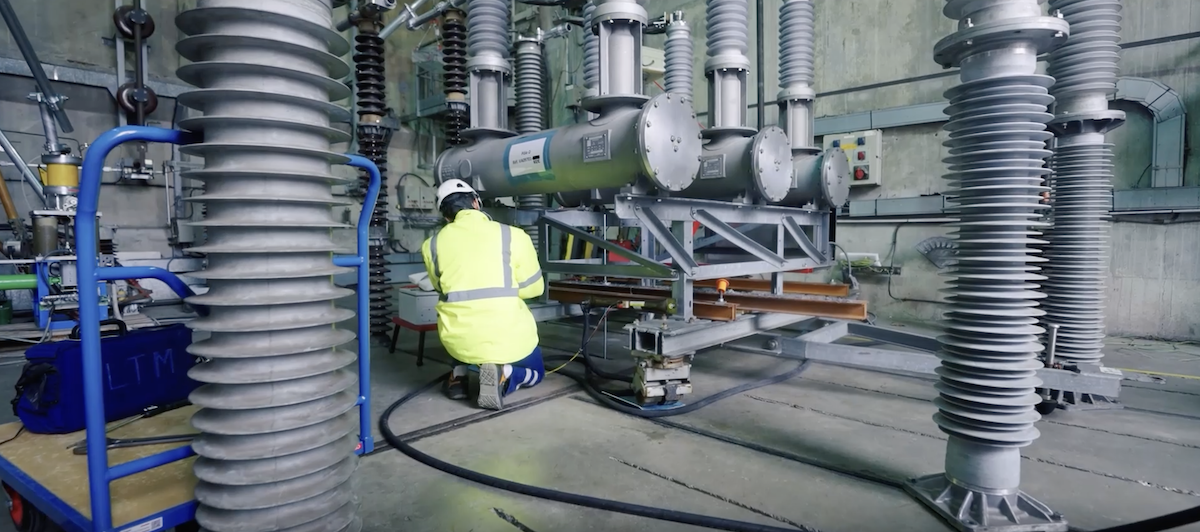

This is one of the testing labs inside GE Vernova’s Research Center for High Voltage Technology in Villeurbanne, France, a world-class research facility specializing in high-voltage (HV) grid equipment. Down the hall, a team of engineers and scientists designs the future of HV substation components; the products then get put through their paces in the lab. You might find a circuit breaker in a deep freeze, bristling with spikes of ice, or operating in a chamber heated to 60 degrees Celsius (140 F), to make sure they can stand up to Mother Nature’s rough conditions.

As climate change breeds stronger storms and intense heat waves, we can expect our power infrastructure to take these sorts of beatings more often. To try to put the brakes on global warming, the International Energy Agency has recommended the rapid deployment of sustainable energy technologies. Meanwhile, power demand continues to surge; it jumped by 15% worldwide between 2013 and 2023 and is projected to nearly double by 2050.

There are two ways to meet this demand: install new power lines or boost the power carried by existing lines. Both require equipment upgrades. Existing systems will need greater breaking capacity to mitigate an uptick in short circuits caused by the increased current, while new lines must be equipped with switchgear that can handle the higher voltages that help transport power more efficiently.

To help address the need to both decarbonize the grid and accelerate the electrification of the world, the Research Center assembled four teams to work on new technologies and product design. One of these is the eco-design team, which works with the R&D team to reduce the environmental impact of high-voltage equipment without sacrificing reliability or cost efficiency. The teams collaborate on projects ranging from microamperes to hundreds of kiloamperes. Their innovations are at the heart of GE Vernova’s GRiDEA portfolio of decarbonization solutions aimed at reducing grid emissions and raw material use.

“We continuously investigate new materials and technologies to lighten the impact on the environment,” says Yannick Kieffel, chief technology officer for the Power Transmission business line at GE Vernova and former leader of the eco-design team. “We’re trying to prioritize the planet as we develop the technology of the future.”

A Broader Perspective on Product Development

The eco-design team’s mission is to make HV equipment as sustainable as the energy it transmits. The first step in the design process for every project at Villeurbanne is a life-cycle assessment. To stitch together an understanding of a product’s overall environmental effect, they model the impact of every phase of its existence, including manufacturing, shipping, deployment, and end-of-life disposal.

“We look at a product from cradle to grave, so that when we improve one piece of equipment, we don’t transfer the environmental impact somewhere else,” Kieffel says.

Life-cycle assessments serve as a compass for the team’s eco-design approach, ensuring that their choices are guided by measurable outcomes. Their goal is to do more with less — by creating compact, efficient products and incorporating recycled components whenever possible to minimize the harvest of virgin materials.

The team applies these principles to the development of power transformers, investigating the benefits of incorporating recycled copper in the windings, using recycled mineral oil for insulation, and extending the product’s life through improved monitoring and timely maintenance.

In addition to supporting grid decarbonization, the Research Center helps accelerate electrification. For example, R&D engineers are working on products for the North American market and higher performances, which requires them to develop testing methods and devices that comply with American standards. The team also aims to produce cost-efficient, competitively priced products.

Because it can help extend the life of systems in the field, digitization is an important part of that mindset. Digital switching devices contain fewer mechanical parts that can wear out, making them more reliable. In addition, intelligent, sensor-monitored upgrades allow for continuous health monitoring and alert maintenance teams to early signs of equipment damage before they worsen.

Last August, at the 2024 conference of the International Council on Large Electric Systems (CIGRE), the Research Center team’s paper on eco-design considerations for power transformers and switchgear was selected as one of the best of the 1,100 submissions. For Kieffel and his team, it was a moment of pride — and even more motivation to keep pushing.

“Decarbonization isn’t just a buzzword for us,” Kieffel says. “It’s what we do, and it just makes sense. We know exactly why we come to the office every day.”

This article contains forward-looking statements, which provide current expectations based on certain assumptions. Except as required by law, we disclaim any obligation to update these statements.