Recommended Resources

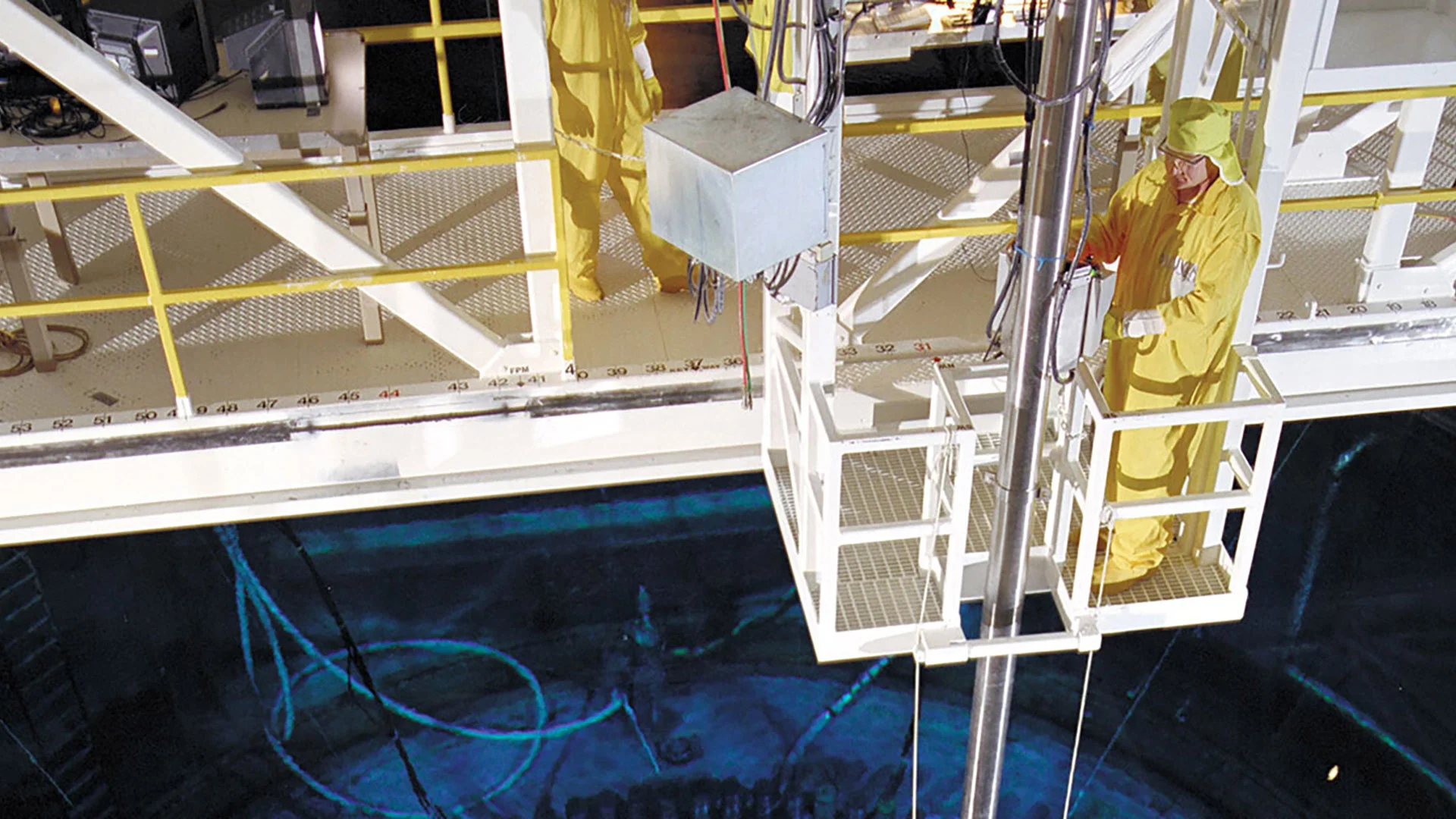

Steam separators and steam dryer services

With options ranging from repairs to complete unit replacement, GVH can help with steam dryer and steam separator fabrication and manufacturing as well as welding, machining, material processing, and NDE inspections.

Frequently asked questions

Information about GVH steam separators/dryers

How does a steam separator/dryer work?

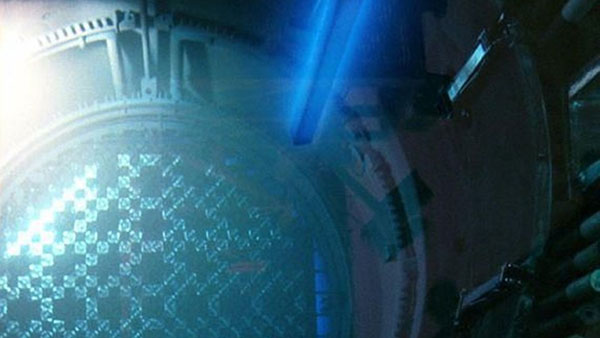

A steam separator/dryer is part of the reactor vessel. It is an inverted V-shaped structure (aka a chevron) through which water-saturated (“wet”) steam created in the reactor vessel passes. Water droplets collect in the chevron structure and ultimately return to the reactor vessel via a downcomer pipe, where they combine with the feedwater flow.

The separated “dry” steam enters the main steam line which directs it to the power plant’s main turbine. This action causes the turbine to rotate which, in turn, activates the electrical generator, producing electricity.

Why use GE Vernova Hitachi’s replacement steam dryers?

Analyzed using a highly predictive plant-based load evaluation (PBLE) methodology, GVH’s replacement steam dryer design exceeds ASME’s reduced maximum alternating stress ratio (MASR). This helps ensure that dryer components have the safety margin necessary for operating conditions up to extended power uprate (EPU).

The US Nuclear Regulatory Commission (NRC) has accepted GVH’s PBLE methodology which, to date, has predicted a minimum 2.0 MASR—well below the ASME limit—for each steam dryer component at EPU conditions. GVH steam dryers are currently operating at 10 US plants at EPU power levels.

Related services

Advanced tooling

Equipment servicing incorporating industry lessons learned with targets of dose reduction, schedule enhancement, and increased operational margin.

Equipment servicing incorporating industry lessons learned with targets of dose reduction, schedule enhancement, and increased operational margin.

Non-destructive examinations

With numerous tools and services available, you can be sure that your inspections will be completed on time and under budget while maintaining plant safety for both operating personnel and the public.

With numerous tools and services available, you can be sure that your inspections will be completed on time and under budget while maintaining plant safety for both operating personnel and the public.

GE Vernova Hitachi Nuclear Energy is a world-leading provider of advanced reactor technology, fuel and nuclear services.

Contact us