Coverage beyond DGA to enhance transformer knowledge and protection.

Not finding the product that you’re looking for? View legacy enhanced transformer monitoring products.

Precise and comprehensive on-line diagnostics when the consequences of outages are significant.

Not finding the product that you’re looking for? View legacy multiple gas transformer products.

Not finding the product that you’re looking for? View legacy single gas transformer products.

High Voltage Capacitors

Increased durability and harmonic tolerance with ratings of 25 to 1,000 kVAR and 2.4 kV to 25 kV.

Active Filters

Highly versatile filters cancel problematic harmonics, reduce flicker, correct power factor and balance network currents

DC Capacitors

A broad range of capacitors for high current, power semiconductor and DC applications.

Fast Switching Capacitor Banks(Flicker Banks)

Harmonic filters provide broadband reduction of harmonics.

Fixed Motor & Pump PFC

Designed for fixed power factor correction at the motor. Harmonic filters are also available for harmonic rich environments.

Induction Heating Capacitors

Available as single- and three-phase, air cooled and water cooled AC and DC units up to 50 kHz.

Low Voltage Capacitor Banks

GE Vernova’s LV capacitor units help customers improve performance through energy savings and better power quality.

Low Voltage Capacitors

A broad array of devices that help improve the power quality of networks.

Reactors

Air- and iron-core reactors designed to be durable, maintenance free and environmentally friendly.

CapMD™

Capacitor Health Monitoring Solution

Comprehensive range up to 1,200 kV including Current Transformers, Magnetic Voltage Transformers, Combined Metering Units, Capacitor Voltage Transformer, GIS Voltage Transformers and Power Voltage Transformers.

Not finding the product that you’re looking for? View legacy high voltage instrument transformers products.

Line Traps

Line traps are a key component in power line carrier systems used for remote control signals, voice communication, remote metering & control.

GE Vernova provides a broad range of customizable instrument transformers supporting HV, MV and LV applications, along with a complete line of control and test switches.

Flexible and reliable layout configurations up to 1,200 kV supporting international standards such as IEEE, IEC and GB (China).

HVDC Disconnectors

GE Vernova offers disconnectors, earthing switches and valve hall earthing switches for HVDC projects up to 1,000 kV.

Power Connectors

Power connectors join two or more conductors for the purpose of providing a continuous electrical path. GE Vernova offers tap, terminal, splice and non current carrying connectors.

Railway Disconnectors and Load Switches

GE Vernova offers disonnectors and load switches for railway applications that are designed to meet the specifications of major railway companies worldwide.

Available in both single or three pole operated design and tested according to international standards, our live tank circuit breaker portfolio ranges from 36 kV up to 1,100 kV.

GE Vernova's dead tank circuit breakers are available for single or three pole operation, qualified to IEEE and IEC standards and available from 38 kV up to 550 kV.

Hybrid Switchgear

GE Vernova's HYpact is a hybrid, compact switchgear assembly designed for space and cost savings.

Compact Switchgear

GE Vernova’s modular compact switchgear system combines a circuit breaker, disconnector and other equipment on a common frame.

Flexible generator circuit breaker solutions for new and refurbished power plants up to 50,000 A and 1,500 MW.

HVDC Switches

GE Vernova's offers fast switches developed based on the highest standards of performance, ratings, user convenience and reliability for all HVDC applications up to 800 kV.

Alternative to SF6

g³ is GE Vernova’s environmentally friendly alternative to SF6 for high voltage applications above 66 kV.

GE Vernova provides a full range of SF₆ Gas-Insulated Substations (GIS) as well as SF₆-free g3 GIS at 145 kV and 420 kV for utilities and industries worldwide.

GE Vernova’s Gas-Insulated Lines (GIL) Dual Gas, available with SF₆ or SF₆-free with g3 gas, meet the challenges of electrical networks up to 800 kV.

GIS Services

Our local technical specialists provide customized services to fit your needs.

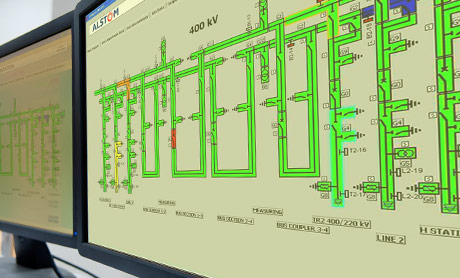

GIS Digital Solutions

Digital gas monitoring, partial discharge monitoring, controlled switching and low power instrument transformers up to 800 kV.

Hybrid gas-insulated switchgear

Hybrid Gas-Insulated Switchgear for networks up to 550 kV in generation, transmission and industrial applications.

Mobile Gas-Insulated Switchgear

Mobile Gas-Insulated Switchgear for temporary and emergency applications.

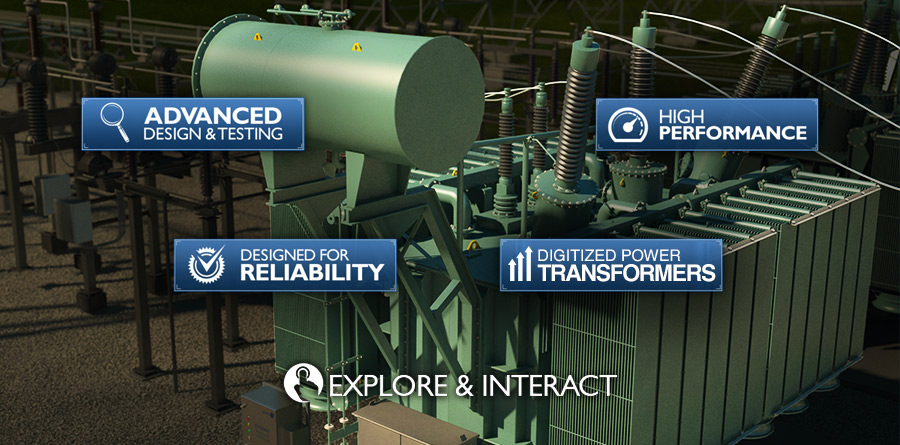

Power Transformers

Low maintenance, high performance, digital and environmental-friendly designs

GE Vernova’s comprehensive suite of power transformers support a wide range of voltage levels with applications in generation, transmission and distribution. GE Vernova offers a wide variety of power transformers from medium to ultra-high voltage (1200 kV AC and ±1100 kV DC) and from small (5 MVA) to very large power ratings (2750 MVA).

Power Transformers

Low maintenance, high performance, digital and environmental-friendly designs

GE Vernova’s comprehensive suite of power transformers support a wide range of voltage levels with applications in generation, transmission and distribution. GE Vernova offers a wide variety of power transformers from medium to ultra-high voltage (1200 kV AC and ±1100 kV DC) and from small (5 MVA) to very large power ratings (2750 MVA).

DIGITIZED POWER TRANSFORMERS

- Continuous & intelligent bushing monitoring

- Online gas analysis of up to 7 fault gases plus oxygen & moisture

- Constant temperature monitoring for winding hot spots

- Fast tripping with unrestrained differential element

HIGH PERFORMANCE

- High efficiency cooling system with speed controllable fans

- Minimizing losses & noise level

- Leakage flux control reduce stray losses & hot spots

DESIGNED FOR RELIABILITY

- Design verified with sophisticated validation & analysis software

- High short circuit withstand

- Wide range of options for HV/MV bushings

ADVANCED DESIGN & TESTING

- Extensive testing capabilities with in-house developed design rules & software

- Strong contribution to industry & standardization organizations (i.e: CIGRE & IEEE)

- State-of-the-art software & design analysis tools

Conventional Power Transformers

GE Vernova’s large, medium and small power transformers include equipment and solutions tailored to meet global customer’s needs. GE Vernova utilizes the latest in design, measurement and testing tools to ensure each transformer meets and exceeds the latest industry standards, as well as operational and customer specifications. Our design software includes sophisticated, in-house scientific calculation tools to perform advanced transformer analytics.

The power transformer design optimization, verification and analytical software supports consistent fulfillment of all specified requirements and efficiencies greater than required by 2020 EC Energy Directive, EN 50629 and EN 50588-1. Examples of high efficiency are found in optimized transformer cooling, low air forced cooler noise, advanced core design techniques that reduce no-load loss and no-load noise, and accurate design verification tools.

Key benefits

- Large power transformers up to 1200 kV AC and power ratings up to 1000 MVA

- Small and medium power transformers up to 245 kV and 120 MVA

- The design and rating of tertiary windings and coupling arrangements are adapted to customer’s requirements

- Autotransformers up to 1200 MVA and voltages up to 765 kV Learn more

- Generator step-up transformers up to 1000 MVA Learn more

Autotransformers

Compared with interconnection transformers of equivalent power flow, the autotransformer presents a lighter and more economically optimized solution which is possible whenever the voltage ratio is between 1 and 2. However, autotransformers have non-disconnected windings, meaning there is no galvanic insulation between the interconnected systems.

Characteristically for complex regulation arrangements, autotransformers impose a total mastership of dielectric phenomena. Designs for constant flux regulation at high voltages or booster schemes are part of GE Vernova’s mastery. For many years, GE Vernova been supplying very high rated autotransformers such as single phase up to 500 MVA and very high voltage up to 765 kV for networks all over the world.

Key features:

- Available up to 765 kV

- Designed for constant flux regulation at high voltages and booster schemes

- Advantages include compact footprint, lighter weight and lower losses

Generator Step up Transformers

GE Vernova’s generator step-up (GSU) transformers are designed and manufactured to stringent standards, providing superior performance and long life. They are suitable for nuclear, thermal and hydraulic applications from small to high voltages with power ratings from 5 MVA to 1000 MVA. The step-up transformers have delta-connected LV windings energized by the generator voltage, while star connected HV windings are connected to the transmission lines.

Constantly faced with voltage changes either due to load rejection or switching operations, followed by generator over excitation, the transformer must also maintain the ability to withstand over-loads. The high rated current involved requires absolute control of the magnetic field inside the tank to avoid localized overheating of associated metallic parts. All of these situations are taken into account by GE Vernova during the design process of individual units and are tested with state-of-the-art techniques.

Thanks to our specific know-how coupled with state-of-the-art modeling and design tools, GE Vernova is able to provide solutions that meet unique power requirements with every installation.

Special Power Transformers

Prolec GE taps into state-of-the-art technology and deep domain expertise in insulation structures, thermal requirements and magnetic field distribution applications, to provide power transformers with exceptional performance, quality and reliability.

PHASE-SHIFTING TRANSFORMERS

As high voltage network systems are connected with each other at several points, the necessity of controlling the flow of energy increases. Classical voltage regulation without phase shifting is no longer sufficient for these situations. GE Vernova’s phase-shifting transformers, rated up to 2750 MVA, are available as single core units with independent phase angle and voltage regulation, and as dual core for higher power and voltages. Quadrature boosters provide an economical solution when limited phase-shifting angles are required with voltage variations.

TRANSFORMERS FOR SVC

GE Vernova’s Static Var Compensator (SVC) systems can help grid operators to gain accurate control of reactive network power, maximize power transfer capability, improve steady-state and dynamic stability within the grid. GE Vernova’s SVC power transformers are custom designed and built to handle harmonic loading and a wide voltage variation. These can be configured as three phase units or a bank of single phase units. The function of the power transformers is to connect the medium voltage equipment to the high voltage transmission grid.

INDUSTRIAL TRANSFORMERS

GE Vernova’s industrial specialized transformers portfolio includes a wide range of rectifier transformers for the electrolysis process of metal or chemical industries, as well as AC or DC Electrical Arc Furnace (EAF) transformers. With expertise in products up to the highest ratings in the world, GE Vernova’s references include rectifier transformer combinations above 80 kA DC current ratings and EAF transformers up to 300 MVA.

LOW MAINTENANCE TRANSFORMERS

Hermetically sealed power transformers without oil conservator are GE Vernova’s field-proven answer to today’s needs. Thanks to the innovative design of the radiators, the oil expansion vessel is not needed and thus the oil is prevented from coming into contact with ambient humidity. Service life is also increased with the use of a vacuum-switch on-load tap-changer (OLTC) that eliminates contact erosion. With minimal oil and OLTC aging rate, the Hermetik does not require any particular maintenance or work over its service life, speeding up the return on your investment.

OIL-IMMERSED REACTORS

GE Vernova’s environmental-friendly, long-life, maintenance-free reactors enhance system performance and power quality from transmission and distribution to industrials, improving network operational efficiency. This results in considerable savings for customers and reduces the environmental impact of their operations.

HVDC CONVERTER TRANSFORMERS

GE Vernova offers a wide range of dedicated High Voltage Direct Current (HVDC) systems that enable efficient and reliable transmission of energy over long distances and interconnect networks with different characteristics and frequencies. GE Vernova is an expert in the design and manufacture of HVDC converter transformers with sophisticated insulation and thermal structure. Ratings include 500 MVA and voltage levels up to 800 kV.

Green Transformers

GE Vernova has developed a wide offering of green solutions for power transformers ranging from 10 to 500 MVA and ratings up to 550 kV. Our environmentally-friendly solutions are aimed at meeting the major energy challenges of today and tomorrow: energy efficiency, market efficiency, grid reliability, enhanced overload capability, low loss, low noise and environmental concerns.

GE Vernova’s green power transformers offer significant environmental benefits, including better product performance, across the phases of the product life cycle:

- Reduced consumption of natural resources during manufacturing

- Lower CO2 emissions, limitation of environmental risk, noise reduction, space savings and energy efficiency during operation

- Recycling capabilities of products at the end of their life

Key benefits

- Range of green eco-efficient power transformers, from 10 to 500 MVA and up to 550 kV

- Prevention of pollution and increased safety by using natural ester insulation liquid

- Innovative technologies to reduce acoustic energy transferred and optimized design of the active part

- Optimized low loss levels

- Innovative technology to reduce noise level

- Reduced maintenance cost, extended life time and increased overload with hermetically-sealed tank design, equipped with patented expandable radiators and vacuum type tap changer

- On-line condition monitoring system

- State-of-the-art factories around the world

VG-100 Fluid – Vegetable Oil for Electrical Transformers

VG-100® is a biodegradable dielectric fluid developed by Prolec GE, with patents granted for its application in electrical transformers. VG-100 has been satisfactorily used in more than 500 units since its introduction in 2009, and is an excellent alternative to mineral oil for use in new transformers and retrofill applications.

View the brochure

Recommended Products & services

Designed for diverse utility and industrial applications, GE Vernova’s distribution transformers are manufactured for high quality and compliance.

EPM 7000 Power Quality Meter

Power Quality and Energy Cost Management

The EPM 7000 provides continuous metering of three-phase systems with waveform and data logging. It performs energy measurements with 0.2% accuracy and supports optional Ethernet, relay, status, and analog output communication modules. This flexible meter can be used for a wide range of high accuracy applications including disturbance recording and power quality studies.

The EPM 7000T is a transducer configuration that comes without a display and has a DIN rail mount.

EPM 7000 Power Quality Meter

Power Quality and Energy Cost Management

The EPM 7000 provides continuous metering of three-phase systems with waveform and data logging. It performs energy measurements with 0.2% accuracy and supports optional Ethernet, relay, status, and analog output communication modules. This flexible meter can be used for a wide range of high accuracy applications including disturbance recording and power quality studies.

The EPM 7000T is a transducer configuration that comes without a display and has a DIN rail mount.

EPM 7000 FEATURES

The EPM 7000 meter provides revenue class (0.2%) three phase power metering with optional Ethernet, relay, status, and analog output communication modules. This flexible meter can be used for a wide range of high accuracy applications including disturbance recording and power quality studies.

EPM 7000 can easily be mounted in a panel for generator monitoring, substation automation, power quality studies, data recording and more. The meter can also provide data to RTUs, PLCs and other control devices.

The EPM 7000 is a highly accurate meter providing 0.1% accuracy for Voltage and Current. The unit’s real-time clock provides time stamping of all logs as they are created. Up to 2 MB of data can be logged for analysis of historical trends, limit alarms, I/O changes and sequence of events.

Advanced Logging Capability

(With Software option B and higher)

Historical Logs:

- 3 Assignable Historical Logs

- Independently Program Trending

- Up to 64 Parameters per Log

System Events Log:

- Demand Resets

- Password Requests

- System Startup

- Energy Resets

- Log Resets

- Log Reads

- Programmable Settings Changes

I/O Change Log:

- Times Stamped Log of any Relay Output

- Time Stamped Log of Input Status Changes

- 2048 possible events

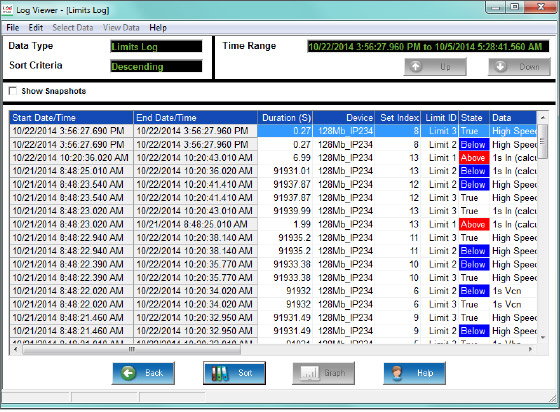

Limit/Alarm Log:

- Provides Magnitude and Duration of an Event

- Time Stamp and Alarm Value provided

- 2048 possible events

Limits Alarms and Control Capability

(Option D and higher)

- Any measured parameter

- Up to 16 limits can be selected

- Voltage Imbalance

- Current Imbalance

- Based on percentage full scale settings

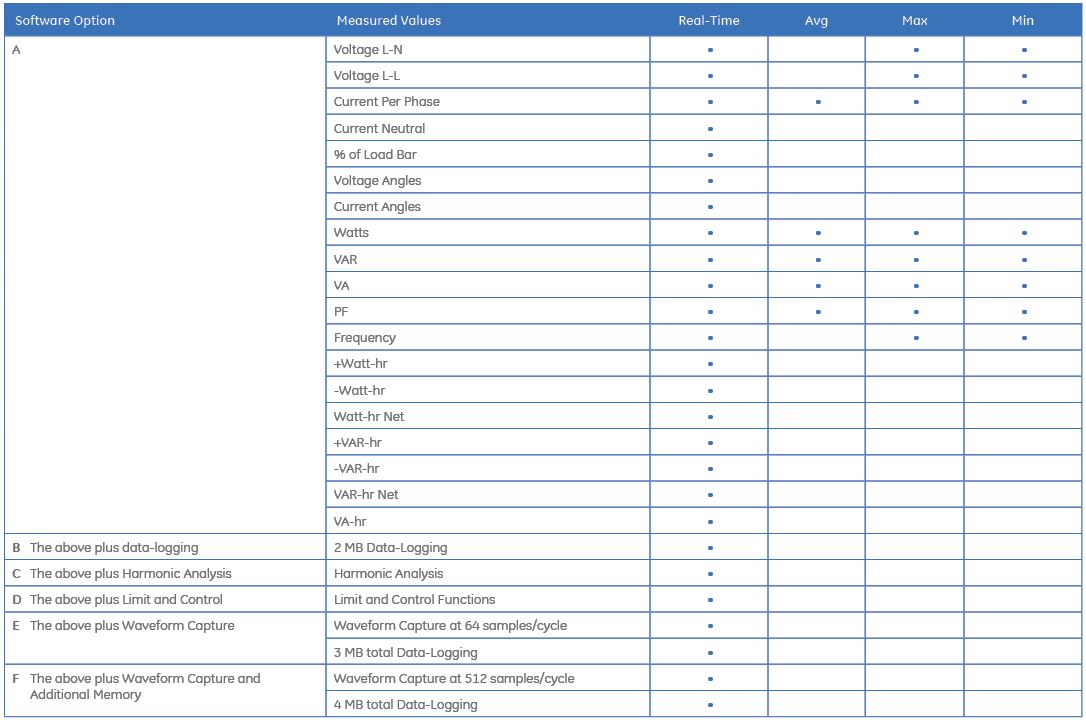

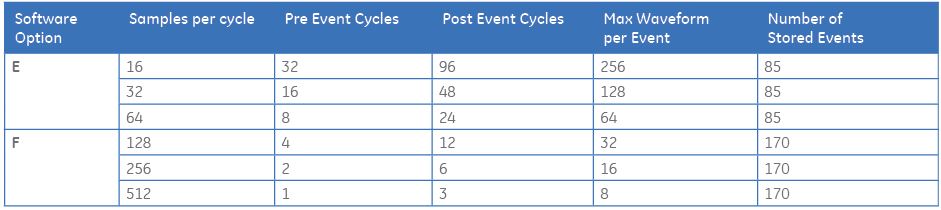

Power Quality Analysis

(Options E and F)

The EPM7000 can record voltage sag, swell, and current fault events. It records up to 512 samples per cycle, when events occur the meter will record pre and post event activity at a programmable sampling rate. Up to 4MB of storage is available allowing for a maximum of 170 events to be stored. Waveform data is stored in a circular buffer, this means that the meter is always recording.

The data sampled can be viewed as a real-time waveform, giving the user the ability to use the meter in an oscilloscope fashion. Harmonics can also be viewed in real time up to the 40th order, and stored waveforms may be viewed up to the 255th order.

INSTALLATION

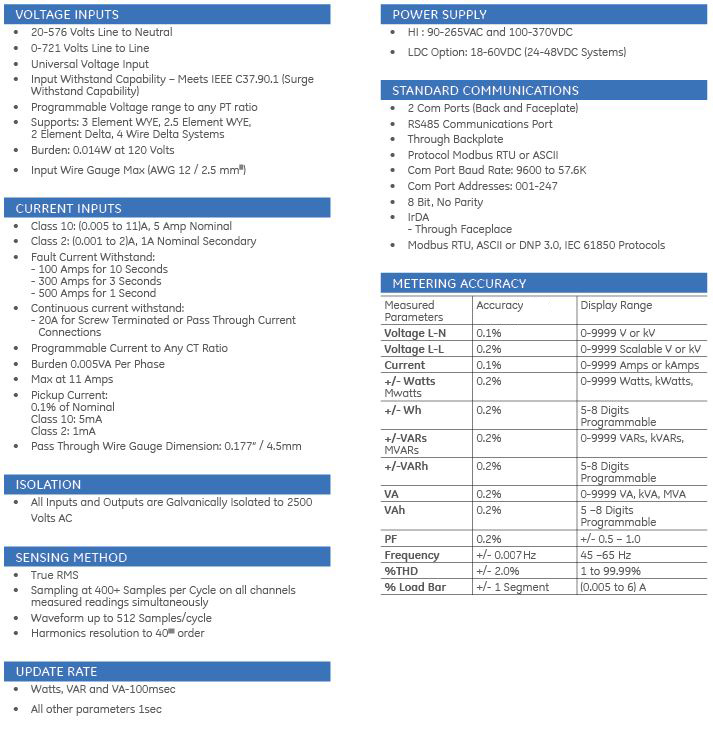

Universal Voltage and Current Inputs

This meter allows voltage input measurements 20 Volts to 576 Volts Line to Neutral and up to 721 Volts Line to Line. This ensures proper meter safety when wiring directly to high voltage systems. The unit will perform to specification on 69 Volt, 120 Volt, 230 Volt, 277 Volt and 347 Volt power systems.

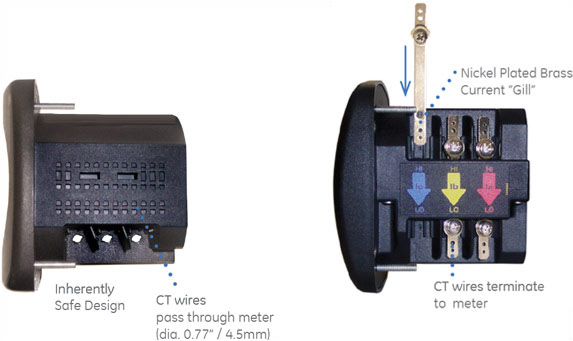

Unique Current Input Connections

EPM 7000 meter uses two current input wiring methods.

Method One - CT pass through. Directly pass the CT through the meter without any physical termination on the meter. This insures that the meter cannot be a point of failure on the CT circuit. This is preferable to utility users when sharing relay class CTs. No Burden is added to the secondary CT circuit.

Method Two - Current “Gills.” The meter additionally provides ultra-rugged termination pass through bars allowing the CT leads to be terminated on the meter. This also eliminates any possible point of failure at the meter. This method is also a preferred technique for ensuring relay class CT integrity does not get compromised. No terminal blocks are required and this stud based design ensures that CTs will not open under a fault condition.

Through an optional high speed Modbus communications interface, the meter can also provide data to RTUs, PLCs and other control devices at Baud rates ranging from 9600 baud to 57.6 kbaud.

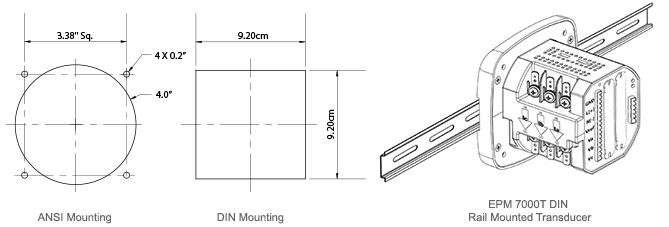

Solid Construction with Mounting Versatility

The EPM 7000 has a rugged design for harsh environment. This is especially important in power generation, utility substation, and critical user applications. The structural and electrical design of this meter was developed based on the recommendations and approvals of many of our utility customers.

EPM 7000 can easily be mounted in a panel for generator monitoring, substation automation and more. The unique dual design combines ANSI and DIN mounting structure and allows easy installation for both new metering applications and retrofit of existing analog meters.

The unit mounts directly in an ANSI C39.1 (4” Round form) or an IEC 92 mm DIN square form.

SOFTWARE OPTIONS

The EPM 7000 is equipped with a virtual firmware based switch that allows feature upgrades through communications even after installation. This allows you to optimize your metering investment. Begin with a standard meter and upgrade it with more functionality as new features are needed, such as data logging, waveform capture or more memory. The tables below describe the feature sets of each of the software and waveform options.

WAVEFORM OPTIONS

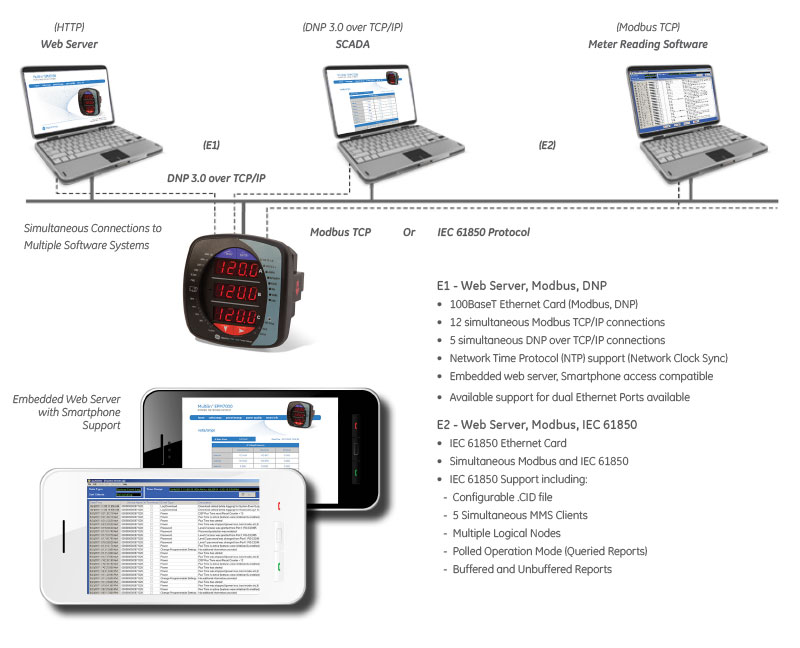

COMMUNICATIONS OPTIONS

Front Mounted IrDA

All EPM 7000 meters come equipped with Front Mounted IrDA Communications port. This eliminates the need for a communications cable when the technician has an IrDA-equipped PC or a PDA with COPILOT EXT software. The meter can be set-up and programmed through the IrDA connection.

Rear Mounted Serial Port with KYZ Pulse

The RS485 serial interface supports Modbus, and DNP 3.0 at baud rates ranging from 9600 to 57.6K. Also supported are KYZ pulse outputs that are mapped to absolute energy.

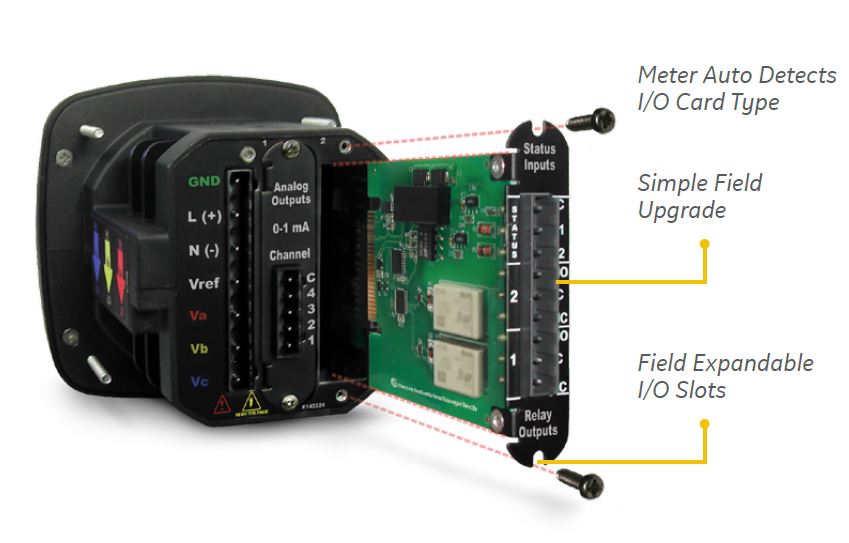

Expandable I/O and Communications Capabilities

EPM 7000 meters have two expansion slots used to accept new I/O cards. These slots can be equipped at the factory or in the field. The meter auto-detects installed I/O cards. Up to two cards of any type may be used per meter.

E1:

- 100BaseT Ethernet Card (Modbus, DNP)

- 12 simultaneous Modbus TCP/IP connections

- 5 simultaneous DNP over TCP/IP connections

- Network Time Protocol (NTP) support (Network Clock Sync)

- Embedded web server, Smartphone access compatible

- Available support for dual Ethernet Ports available

RS1:

- Two Output Relays/ Two Status Inputs

- 250VAC/30VDC – 5A Relays, Form C

- Trigger on user set alarms

- Set delays and reset delays

- Status Inputs – Wet/Dry Auto Detect (Up to 150VDC)

- Requires Software Option D or higher for limit based alarms and control

E2:

- IEC 61850 Ethernet Card

- Simultaneous Modbus and IEC 61850

- IEC 61850 Support including:

- Configurable .CID file

- 5 Simultaneous MMS Clients

- Multiple Logical Nodes

- Polled Operation Mode (Queried Reports)

- Buffered and Unbuffered Reports

PS1:

- Four Pulse Outputs / Four Status Inputs

- Programmable to any energy parameter and pulse value

- Normally Open Contacts, Form A

- 120mA continuous load current

- Status Inputs – Wet/Dry Auto Detect (Up to 150VDC)

- Can function for manual relay control and limit based control

- Requires Software options D or higher for limit based alarms and control

C1:

- Four Channel Bi-directional 0-1mA Outputs

- Assignable to any parameter

- 0.1% of Full Scale

- 0 to 10KΩ

- Range ±1.20mA

F1:

- Fiber Optic Interface with ST terminations

- Daisy Chain switchable built-in logic mimics RS485 half duplex bus.

- ST terminated

- Modbus and DNP 3.0 Protocols available

C20:

- Four Channel 4-20mA Outputs

- Assignable to any parameter

- 0.1% of full scale

- 0 – 500Ω, no accuracy losses

- Loop Powered up to 24VDC

F2:

- Fiber Optic Interface with Versatile terminations

- Daisy Chain switchable built-in logic mimics RS485 half duplex bus.

- Versatile terminated

- Modbus and DNP 3.0 Protocols available

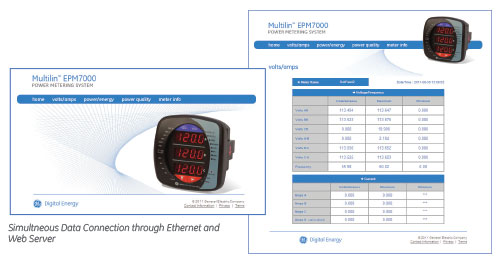

EMBEDDED WEB

The EPM 7000 with Ethernet (E1,E2 options) includes a secure web server that is viewable from a variety of web browsers. The web server supports multiple simultaneous connections to view the following information:

- Voltage and Current Reading

- Power and Energy Readings

- Power Quantity Information

- General Meter Information

Simultaneous Data Connections

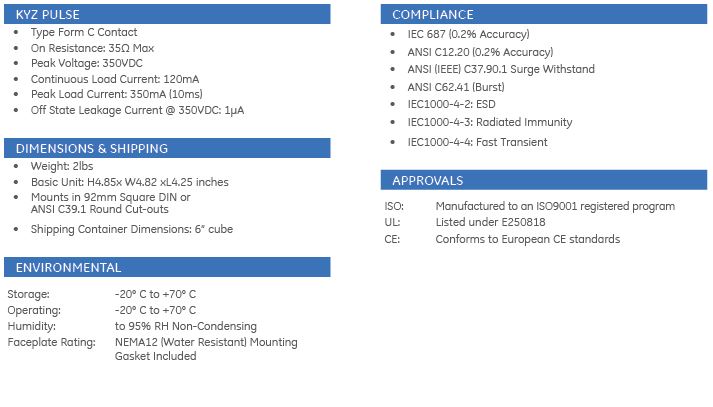

SPECIFICATIONS

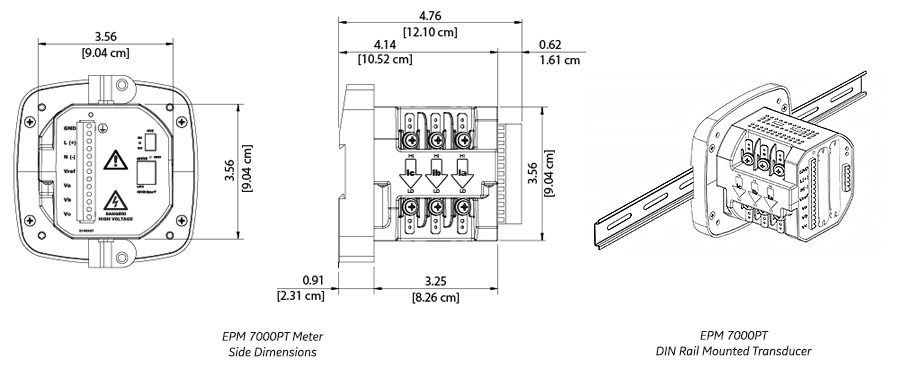

EPM 7000T TRANSDUCER OPTION

GE Vernova’s Grid Solutions has discontinued sales of EPM 7000T. As an alternative, please refer to the EPM7000PT .

The transducer configuration comes without a display and has a DIN rail mount. It’s ideal for use in switchgear retrofit applications where access to the meter face and display is not necessary, and where budgets are a large consideration.

Features

- EPM 7000 Power Meter without display, DIN mount

- Mounts directly in ANSI C39.1 (4” round form) or and IEC 92mm DIN square form

- Uses minimal panel space with 4.25” panel depth

- 0.2% Watt-Hour Accuracy and waveform capture at up to 512 samples/cycle

- Up to 4MB of data logging

- Field Replaceable I/O modules

Mounting

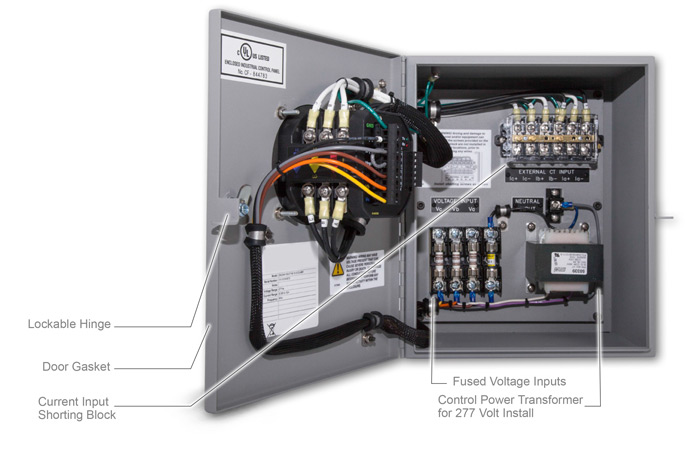

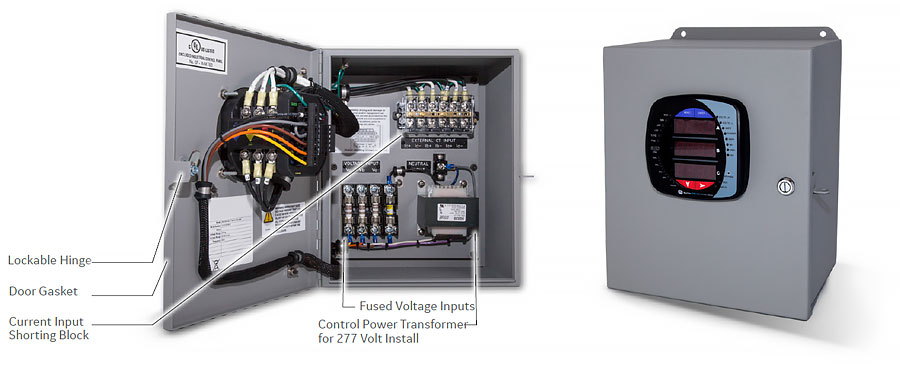

MULTILIN METER ENCLOSURE

Expanding existing switchgear or installing new metering capability can be challenging due to space limitations, downtime and installation and equipment costs. GE Vernova's Multilin Meter Enclosure is a pre-wired configured, economical solution for both retrofit expansions and small scale meter installations that allows the expansion of existing switchgear capability without expensive and time-consuming design.

When ordered as a meter option the enclosure provides a factory pre-wired, installation-ready metering solution that further drives energy cost savings, by enabling the measurement of key energy usage information along multiple metering points for new or existing systems.

Ordering the enclosure is simple when selected as an option during meter configuration, ensuring correct pre-wired meter-compatible delivery.

Pre-Wired, Configured and Economical Solution for Retrofit and Small Metering Systems

Easy and Rapid Installation

- Factory pre-wired, installation-ready GE Vernova metering solution eliminates wiring and associated errors for rapid installation

- Extend metering capability with new systems and existing switchgear without system installation downtime

Cost-Effective Retrofit Solution

- Save up to 200% versus the addition of a new switchgear cabinet

- Compact footprint makes effective use of existing allocated space

- Allows new installations or the expansion of existing switchgear capability without expensive, time-consuming designs, eliminating system downtime

Reliable and Compatible

- Backed by a 10 year warranty

- Simple meter option ordering ensures compatibility with GE Vernova EPM 2000/6010/6000/7000 meters

- Comprehensive factory testing of both meter and enclosure together

- NEMA1 tested and UL/CUL certified

Applications (New and Retrofit installations)

- Industrial Multi-Tenant Monitoring

- Commercial/Residential Buildings

- Healthcare Institutions

- Government Buildings

- Manufacturing

- Educational Campuses

Assembly

Diagram

Recommended Products & services

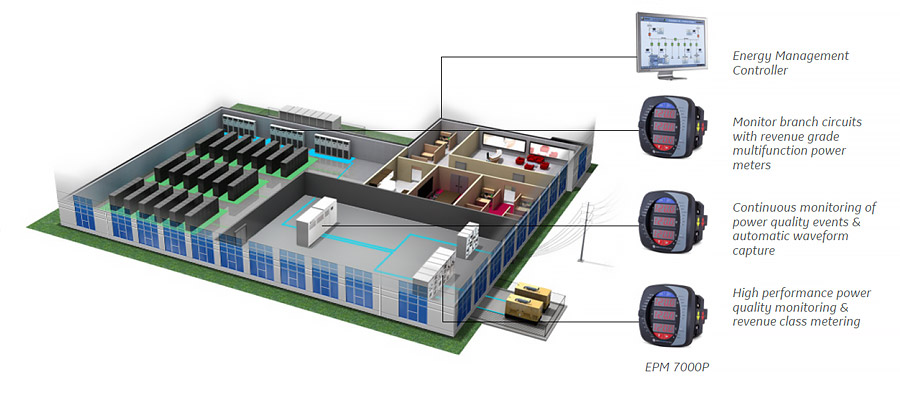

EPM 7000P

Versatile Power Quality Metering with Logging and Flexible Communications

The Multilin™ EPM 7000P is a versatile power quality meter offering that can be used for a wide range of high accuracy revenue and power quality applications for both Utility and Industrial customers.

EPM 7000P

Versatile Power Quality Metering with Logging and Flexible Communications

The Multilin™ EPM 7000P is a versatile power quality meter offering that can be used for a wide range of high accuracy revenue and power quality applications for both Utility and Industrial customers.

Key Features

- High resolution waveform recording (up to 512 samples/cycle) and high accuracy ANSI C12.20 Class 0.1% accuracy energy metering

- Easy system integration with support for Modbus (RTU, TCP/IP), DNP 3.0, IEC 61850 Protocols

- Field upgradeable functionality for future requirements with communications and I/O cards as well as software option functionality upgrades and logging memory (up to 128MB) to log years of captured data

- Flexible installation mounting with standard ANSI cutout as well as available optional meter enclosures for retrofit applications and no display transducer version (EPM 7000T) for DIN rail mounting

Applications

- New or retrofit (available enclosures) revenue energy billing or reconciliation (demand, time of use) for utility or industrial applications

- Power quality studies/alarming/event capture for utility or industrial event investigation/reconciliation, ensuring uptime and predictive maintenance for critical power quality sensitive assets (Utility substation, Data Centers, Manufacturing, Hospitals)

- Energy metering or power quality monitoring for harsh environments with standard conformal coating

Enhanced Revenue and Power Quality Metering

The EPM 7000P has been designed with features to satisfy both revenue and power quality metering for utility substation and industrial applications.

Accurate Revenue Energy Metering

The EPM 7000P provides several features to support accurate Revenue Energy metering including: an Energy Test Pulse; ANSI C12.20 0.1% and IEC 62053-22 CL 0.2S Accuracy Class certification; Time of Use; CT/PT Compensation.

This allows the EPM 7000P the flexibility and capability to be installed either as a utility or industrial device to ensure accurate readings and assist with reconciliation of energy consumption.

Multifunction Metering & Power Quality Monitoring

The EPM 7000P can provide a total picture usage and power quality as different points within a power distribution network on critical infrastructure such as data centers, allowing users to make power related decisions quickly and effectively.

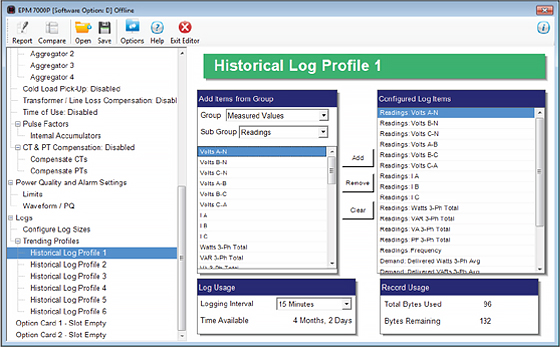

Configure up to 6 Historical Logs Limit log

Configure up to 6 Historical Logs Limit log

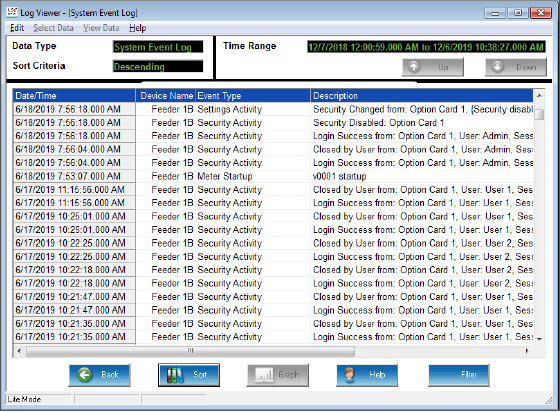

View System Events

View System Events

Limit log viewer

Limit log viewer

Extensive Logging Capability

The EPM 7000P provides up to 128MB of memory for logging.

Through upgradeable Software Options, the memory can be upgraded as requirements change from a multifunction meter with no logging to a logging capability up to 128MB.

The logging capability of the EPM 7000P provides:

- Detailed information for analysis during Power Quality and/or Load studies

- Logged data for Historical Logs; Meter System Events; I/O Changes; and Limits/Alarms

Historical Logs

- Configure logging values with up to 6 assignable historical logs

- Independently programmed trending profiles

- Up to 64 parameters per log

System Events Log

To protect critical information captured by the EPM 7000P, the meter records and logs the following System Events with a time stamp to log and track:

- System startup

- Programmable settings changes

- Password requests/sealing switch changes

- Demand resets

- Energy resets

- Log resets

- Critical data repairs

Input/Output (I/O) Change Log

- Provides a time stamped log of meter I/O relay outputs; input status changes

- Ability to capture up to 2048 events

Limit/Alarm Log

- Provides magnitude and duration of an event

- Includes time stamps and alarm value

- Ability to capture up to 2048 events

- Capability to send Alarm Email with E1 Ethernet card option

Limit Alarms and Control Capability

- Ability to set up to 16 Limit Alarms on measured parameters

- Monitor Voltage/Current unbalance

- Set Alarms based on % of full scale settings

Extensive Communications and I/O Cards

The EPM 7000P provides two universal option slots for communications and/or I/O. The unit can be easily configured to accept new I/O cards even after installation by auto-detecting installed I/O option cards. Up to 2 cards of can be used for communications and or I/O per meter providing a range of integration possibilities.

Along with I/O expandability the EPM 7000P can integrate with many different systems, using multiple standardized protocols such as Modbus RTU/ASCII/TCP, Level 2 DNP3 and IEC 61850. Expandable communications cards allows customization for system requirements at time of purchase as well as in the future if requirements change.

E1: 100BaseT Ethernet Card (Modbus,DNP3)

- 12 simultaneous Modbus TCP/IP connections

- 5 simultaneous Level 2 DNP3 over TCP/IP connections

- Network Time Protocol (NTP) support for high accuracy network time sync

- Embedded web server

- Available support for dual Ethernet Ports

E2: 100BaseT Ethernet with IEC 61850 Protocol

- Simultaneous Modbus TCP/IP and IEC 61850

- IEC 61850 Support including:

- Configurable .CID file

- 5 Simultaneous MMS Clients

- Multiple Logical Nodes

C1: Four Channel Bi-directional 0-1mA Outputs

- Assignable to any parameter

- 0.1% of Full Scale

- Max Load Impedance 0 to 10KΩ

C2: Four Channel Bi-directional 4-20mA Outputs

- Assignable to any parameter

- 0.1% of full scale

- 850Ω, at 24VDC

- Loop powered using up to 24VDC

RS: Two Output Relays/ Two Status Inputs

- 250VAC/30VDC – 5A Relays, Form C

- Trigger on user set alarms

- Set delays and reset delays

PS: Four Pulse Outputs / Four Status Inputs

- Programmable to any energy parameter or pulse value

- Form A: Normally Open Contacts

- Can function for manual relay control and limit based control

F1: Fiber Optic Interface with ST Termination

- Daisy Chain switchable built-in logic mimics RS485 half duplex bus to support daisy chain for lower installation cost/ effort

- ST terminated

- Modbus and Level 2 DNP3 Protocols available

F2: Fiber Optic interface with Versatile Link Termination

- Daisy Chain switchable built-in logic mimics RS485 half duplex bus to support daisy chain for lower installation cost/ effort

- Versatile terminated

- Modbus and Level 2 DNP3 Protocols available

S1: Serial RS232/RS485 Communications

- Programmable RS485 or RS232 Port

- Adds up to 2 ports per meter in addition to the standard Serial RS485 port

- Supports one session at a time of DNP3 serial communication per meter

Comprehensive, Upgradeable Features

Along with basic standard features (Software Option A) the EPM 7000P provides field upgradeable, post installation Software Options. An unlock key for the higher Software Option can be entered in the GE Vernova Communicator Setup software providing more functionality with the same installed unit in the future. The following table illustrates the available features and upgrades.

| GE VERNOVA EPM 7000P/PT FEATURES | SOFTWARE OPTION A | SOFTWARE OPTION B | SOFTWARE OPTION C | SOFTWARE OPTION D |

|---|---|---|---|---|

| BASIC MEASUREMENTS | ||||

| Multifunction Measurement (Voltage, Current) | • | • | • | • |

| Time of Use | • | • | • | • |

| CT/PT Compensation | • | • | • | • |

| Transformer/Line Compensation | • | • | • | • |

| POWER QUALITY MEASUREMENTS | ||||

| THD and Harmonics | • | • | • | • |

| Waveform Recording Sampling Rate | 128 Samples/Cycle | 512 Samples/Cycle | ||

| STORAGE | ||||

| Memory for logging | 2 MB | 10MB | 128MB | |

| System Events |

| • | • | • |

| Waveform Log |

|

| • | • |

| Limit Log | • | • | • | • |

| Input Status Change | • | • | • | • |

| COMMUNICATION | ||||

| Modbus | • | • | • | • |

| DNP 3.0 Level 2 | • | • | • | • |

| IEC 61850 (E2 Option) |

| • | • | • |

Waveform Recording Options

| Software Option | Samples per Cycle | Pre Event Cycles | Post Event Cycles | Max Waveform per Event |

|---|---|---|---|---|

| C | 16 | 32 | 96 | 256 |

| 32 | 16 | 48 | 128 | |

| 64 | 8 | 24 | 64 | |

| 128 | 4 | 12 | 32 | |

| D | 256 | 2 | 6 | 16 |

| 512 | 1 | 3 | 8 |

Technical Specifications

| VOLTAGE INPUT RANGE |

|---|

|

| ISOLATION |

|---|

| Voltage Inputs galvanically isolated to 2500V AC |

| CURRENT INPUT RANGE |

|---|

|

| CURRENT INPUT WITHSTAND CAPABILITY (AT 23 °C) |

|---|

|

| BURDEN |

|---|

|

| FREQUENCY RANGE |

|---|

| 45 to 65 Hz |

| MEASUREMENT METHOD |

|---|

|

| ACCURACY RATINGS |

|---|

|

| UPDATE RATE |

|---|

|

| UPDATE RATE |

|---|

|

| CONTROL POWER REQUIREMENTS |

|---|

|

| COMMUNICATION |

|---|

Standard Communications

|

| KYZ PULSE |

|---|

|

| ENVIRONMENTAL |

|---|

|

| SHIPPING |

|---|

|

| COMPLIANCE |

|---|

|

EPM 7000PT Transducer Option

The EPM 7000P is available in a Transducer Option (EPM 7000PT). The EPM 7000PT is ideal for use in applications where a meter display or front port is not required and/or there are mounting/installation constraints in terms size or location within a switchgear cabinet or enclosure. The EPM 7000PT Transducer option also provides a more economical alternative to the EPM 7000P when a display is not required and there are only communications requirements.

Features

- Similar Configuration, Software, Communication options as the EPM 7000P

- Easy installation supporting International Standards DIN 46277/3

- Field replaceable I/O modules

Mounting

Multilin Meter Enclosure

Expanding existing switchgear or installing new metering capability can be challenging due to space limitations, downtime and installation and equipment costs. GE Vernova's Multilin Meter Enclosure is a pre-wired configured, economical solution for both retrofit expansions and small scale meter installations that allows the expansion of existing switchgear capability without expensive and time-consuming design.

When ordered as a meter option the enclosure provides a factory pre-wired, installation-ready metering solution that further drives energy cost savings, by enabling the measurement of key energy usage information along multiple metering points for new or existing systems.

Ordering the enclosure is simple when selected as an option during meter configuration, ensuring correct pre-wired meter-compatible delivery.

Pre-Wired, Configured and Economical Solution for Retrofit and Small Metering Systems

Easy and Rapid Installation

- Factory pre-wired, installation-ready GE Vernova metering solution eliminates wiring and associated errors for rapid installation

- Extend metering capability with new systems and existing switchgear without system installation downtime

Cost-Effective Retrofit Solution

- Save up to 200% versus the addition of a new switchgear cabinet

- Compact footprint makes effective use of existing allocated space

- Allows new installations or the expansion of existing switchgear capability without expensive, time-consuming designs, eliminating system downtime

Reliable and Compatible

- Backed by a 10 year warranty

- Simple meter option ordering ensures compatibility with GE Vernova EPM 2000/6010/6000/7000 meters

- Comprehensive factory testing of both meter and enclosure together

- NEMA1 tested and UL/CUL certified

Applications (New and Retrofit installations)

- Industrial Multi-Tenant Monitoring

- Commercial/Residential Buildings

- Healthcare Institutions

- Government Buildings

- Manufacturing

- Educational Campuses

Assembly

Diagram