MiCOM Agile P34x

Generator Protection Systems

GE Vernova's MiCOM Agile P34x generator protection relays provide flexible and reliable integration of protection, control, monitoring and measurement functions for a wide range of applications. The P34x relay platform is available in six models that cover most installations from small generators to sophisticated systems including generator-transformer applications and large variable speed double fed induction pumped storage machines.

MiCOM Agile P34x

Generator Protection Systems

GE Vernova's MiCOM Agile P34x generator protection relays provide flexible and reliable integration of protection, control, monitoring and measurement functions for a wide range of applications. The P34x relay platform is available in six models that cover most installations from small generators to sophisticated systems including generator-transformer applications and large variable speed double fed induction pumped storage machines.

What's New

The new software features:

- Enhanced power protection with 4 stages of single phase power/VAR (P341-6) and 4 stages of 3 phase power/VAR protection (P341-6)

- New minimum power setting reduced to 0.2%Pn for large generator reverse power applications

- Independent voltage dependent overcurrent (51V) and underimpedance (21) protection

- IEC 61850 Edition 2 support - with support for Ed 2 test modes for online testing.

- IEEE 1588 Precision Time Protocol - efficient time synchronizing direct from the substation LAN.

- Editable Logical Nodes/Devices - to customize the IEC 61850 modelling and maximize interoperability.

- Role based access control (RBAC) for centralized authentication.

- Authorization and account management via RADIUS, and directly on the relay.

- Security Event Management via Syslog.

- Duplicate GOOSE Rejection - Defense against incorrect publishing of out-of-sequence or duplicated GOOSE messages by other devices on the network.

- SNMP version 2c and cybersecure v3 - network management tools can monitor protection IEDs.

- New Ethernet Board - Improved traffic density handling, PRP, HSR and RSTP supported in the same order option for standardization.

Overview

GE Vernova's Agile P34x generator protection solutions provide extensive functionality to meet all generator and generator - transformer applications, including differential protection for fast and selective tripping of phase and earth faults. All generator protection, control, monitoring, recording and communications components are housed within one box, and the solutions are accompanied by a comprehensive library of hardware options, protection and control functions to meet system requirements.

Key benefits:

- Extensive condition based monitoring features for generators and transformers

- Graphical programmable scheme logic eases protection scheme creation and avoids the need for external logic controllers

- Range of different protocols (MODBUS, DNP3, IEC 60870-5-103 and IEC 61850) are available

- IEC 61850 / DNP3.0 redundant Ethernet, supporting self healing ring, RSTP, dual homing, PRP or HSR

- Programmable curves for easy protection customization

Main characteristics:

- Sensitive rotor earth fault protection using low frequency injection method

- Harsh Environment Option to protect against corrosive gases such as H2S or SO2

- Generator and transformer thermal overload, transformer loss of life and through fault monitoring

- Extensive protection for large machines such as pole slipping and 100% stator earth fault protection (3rd harmonic and low frequency injection method)

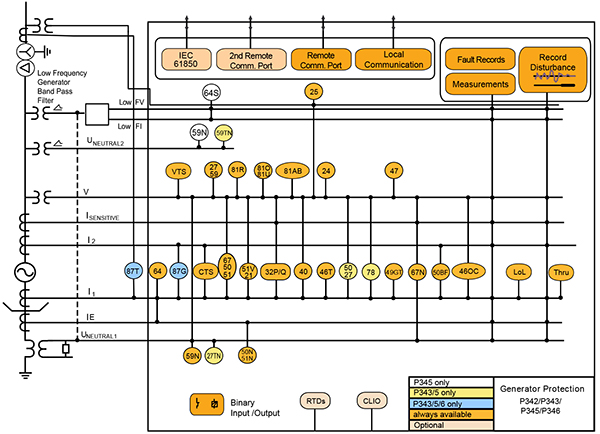

ANSI ® Device Numbers and Functions

| Device Number | Function |

|---|---|

| 87GT | Generator/transformer differential |

| 50DT | Interturn (Split Phase) |

| 50/51/67 | Directional/non directional, instantaneous/time delayed phase overcurrent |

| 50N/51N | Non directionnal, instantaneous/time delayed phase earth fault |

| 67N/67W | Sensitive directional ground fault / wattmetric ground fault |

| 64 | Restricted ground fault |

| 51V | Voltage dependent over current |

| 21 | Under impedance |

| 59N | Neutral voltage displacement/residual overvoltage, interturn -measured,derived |

| 27/59 | Under/Over voltage |

| Device Number | Function |

|---|---|

| 81U/81O/81R | Under/over frequency/rate of change of frequency |

| 81AB | Turbine abnormal frequency |

| 32P/Q | Forward/Reverse, under/over Power/Var |

| 40 | Loss of field |

| 46T | Negative phase sequence thermal |

| 46OC | Negative phase sequence overcurrent |

| 47 | Negative phase sequence overvoltage |

| 49G/T | Stator/Transformer thermal overload |

| 24 | Overfluxing |

| 78 | Pole slipping |

| 27TN/59TN | 100% stator ground fault (3rd harmonic neutral under/over voltage) |

| 64S | 100% Stator ground fault (low frequency injection) with GPM-S |

| Device Number | Function |

|---|---|

| 50/27 | Unintentional energization at standstill |

| 50BF | CB Fail |

| 25 | Check synchronizing |

| 64R | Rotor ground fault (available with CLIO option and P391) |

| RTD | RTD Measurement |

| CTS | CT Supervision |

| VTS | VT Supervision |

| PSL | Programmable Logic |

| TCS | Trip Circuit Supervision |

| Lol/Thru | Loss of life/Thru fault monitor |

Agile P34x Models

P342 Small Generator Management IED.

P343 Medium to Large Sized Generator Management IED

P345 Large Generator Management IED with 100% Stator Earth Fault

P346 Small Generator Management IED with Differential

P348 Variable Speed Double Fed Induction Machine protection IED

P391 Rotor Earth Fault Unit

GPM-S 100% stator earth fault unit (20Hz injection), used with the P345

Manufacturing for P342 has been discontinued. As an alternative, please refer to 889.

Manufacturing for P344 has been discontinued.

Manufacturing for P346 has been discontinued. As an alternative, please refer to P343, 889, G60 or G30.

Manufacturing for P348 has been discontinued. Please contact us to discuss alternatives.

MiCOM S1 Agile

Key benefits:

- Powerful, free of charge, PC toolsuite

- Optimum management of the installed base, structured as per the substation topology

- Intuitive and versatile interface with file management facilities

- Logical structure based on substation, voltage level and bay

- Version control and cross-checking facilities for IED settings

- Real-time measurement visualization – MiCOM S1 Agile extends to all MiCOM Agile IEDs - including P847 PMU and busbar schemes

Engineering Tool Suite

S1 Agile is the truly universal PC tool for MiCOM Agile relay, assemble all tools in a palette for simple entry, with intuitive navigation via fewer mouse-clicks. No-longer are separate tools required for redundant Ethernet configuration, phasor measurement unit commissioning, busbar scheme operational dashboards, programmable curve profiles or automatic disturbance record extraction – applications are embedded. MiCOM S1 Agile supports all existing MiCOM, K-Series and Modulex, including a utility for automatic conversion of setting files from previous generations of numerical relays like K-series and MiCOM P20 to the latest P40 Agile models.

To move to the future, with no loss of functionality, no loss of device support, and full compatibility with your installed base and system architecture – request a copy of S1 Agile with the contact form link below.

Key features in the MiCOM S1 family:

- GE Vernova’s integrated engineering tool that provides users with access to automation IED configuration and record data

- Integrated configuration and monitoring features

- Send and extract setting files

- Event and disturbance record extraction and analysis

MiCOM S1 Agile software request

To receive the MiCOM S1 Agile, please use our Contact form. This will also ensure that you are kept up-to-date with the latest enhancements, including updates and bug fixes.

Refurbishment Solutions

GE Vernova’s latest MiCOM P340 models offer a perfect functional match for LGPG relay from the heritage installed-base brands of GEC Measurements, GEC Alsthom, GE VERNOVA and Areva:

Refurbishment Solutions – “If It’s Blue Think to Renew”

GE Vernova’s latest MiCOM P340 series models P341 to P348 inclusive offer an ideal path to refurbish an older installed base of MiCOM P340 relays. Whether those older products were initially sold as GE VERNOVA or AREVA-branded products, newer models retain pin-pin refurbishment capability. Advantageously, users can benefit from the advancements made in protection, control, communications, hardware that have taken place in the intervening years. The new P40 retains form, fit and function compatibility but delivers the latest platform and software ready for today’s environment, and for future-proofed application for the decades ahead. Pin-Pin Upgrade Methodology:

- Take the order code (CORTEC) of the older relay being removed, typically a blue case relay

- Translate to today’s latest GE Vernova MiCOM model, adding Ethernet options if required

- Order the new P40 relay

- Extract settings and logic, use S1 Agile toolsuite to convert settings

- Detach the terminal blocks from old relay, leaving wiring attached / detach terminal blocks from the new.

- Carefully examine the terminal blocks to see that no physical damage has occurred since installation

- Mount new relay. Old relay blocks fit straight onto the new relay - safer, less wiring to reconnect.

- It is recommended to apply rated current and voltage to the relay CT/VT inputs during secondary injection testing to check the continuity of the CT/VT terminal block connections to the relay.

- Download converted files

- Test, return circuit to service with only minutes of downtime

Contact us for advice and support

Recommended Products & services

Multilin G60

Generator Protection Systems

Built on the industry-leading UR platform, the G60 offers superior protection for medium and large generators, including large steam and combustion turbines, combined cycle generators and multi-circuit hydro units. The G60 may also be used on pumped storage generators without the need to switch the CT secondary circuitry. The G60 provides advanced communication with an integrated, fully managed Ethernet switch reducing network installation costs while supporting industry standard communication protocols.

Multilin G60

Generator Protection Systems

Built on the industry-leading UR platform, the G60 offers superior protection for medium and large generators, including large steam and combustion turbines, combined cycle generators and multi-circuit hydro units. The G60 may also be used on pumped storage generators without the need to switch the CT secondary circuitry. The G60 provides advanced communication with an integrated, fully managed Ethernet switch reducing network installation costs while supporting industry standard communication protocols.

New and Enhanced Communication Capabilities

- New process bus module supports IEC 61869 sample values, PTP master capabilities and SV switching (FW 7.9x)

- New UR process bus modules supporting IEC61850-9-2LE Merging Units (FW 7.8x) Module Training available here

- Support switchable IEC 61850 Ed. 1 and Ed. 2 and redundant SNTP (FW 7.7x)

- New UR front panel with integrated 7” color, graphical display - providing operators with enhanced situational awareness (FW 7.6x)

- High density I/O module supporting up to 120 inputs or up to 72 contact outputs – eliminating the need for additional discrete devices (FW 7.6x)

Cyber Security - CyberSentry UR (FW v7.xx)

CyberSentryTM enables UR devices to deliver full cyber security features that help customers to comply with cyber security requirements (NERC CIP, IEEE 1686, IEC 62443, etc):

- Secured firmware upgrade: FW file includes hash code that enables authentication prior to being used for upgrading UR Relay (FW 7.9x)

Fully Compatible with IEC 61850-9-2LE or IEC61869 process bus schemes:

- Can connect to up to 8 merging units over -9-2LE or 61869

- Supports PRP, HSR, dual HSR and point-to-point process bus topology

- Provides support for GE Vernova’s IEC 61850 HardFiber Process Bus Solution

Extended Oscillography Records (FW v7.xx)

- Increased number of digital and analog channels (FW 7.90)

- Supports IEEE C37.111-1999/2013, IEC 60255-24 Ed 2.0 COMTRADE 2013 standard (FW v7.40)

- Configurable events allow for records of up to 45s at 64 samples per cycle

New and Enhanced Protection and Control Functionality

- New Inrush detection element (FW 8.0)

- Expanded Bay Controller Capabilities – providing a one box solution (FW 7.6x)

Key Features

- Generator stator differential

- 100% stator ground protection 3rd harmonic

- Field ground protection

- 100% stator ground fault protection using sub-harmonic injection

- Loss of excitation

- Power swing blocking and out-of-step tripping

- Backup distance

- Reverse/low forward power

- Restricted ground fault, thermal overload protection, directional, time, instantaneous, phase, neutral, negative sequence and ground overcurrent protection

- Restricted ground fault

- Overexcitation plus dedicated harmonic/inrush detection

- Overexcitation

- Generator unbalance

- Breaker failure protection

Protection & Control

The G60 generator protection system provides comprehensive protection for medium and large generators, including large steam and combustion turbines, combined-cycle generators and multi-circuit hydro units. The G60 includes advanced automation and communication capabilities, extensive I/O options, and powerful fault recording features that can simplify postmortem disturbance analysis and help minimize generator downtime. As part of the UR Family, the G60 provides superior protection and control.

Functional Block Diagram

ANSI® Device Numbers & Functions

| Device Number | Function |

|---|---|

| 21P | Phase Distance Backup |

| 24 | Volts Per Hertz |

| 25 | Synchrocheck |

| 27P | Phase Undervoltage |

| 27TN | Third Harmonic Neutral Undervoltage |

| 27X | Auxiliary Undervoltage |

| 32 | Sensitive Directional Power |

| 40 | Loss of Field Relay |

| 46 | Generator Unbalance |

| 49 | Thermal Overload |

| 50G | Ground Instantaneous Overcurrent |

| 50N | Neutral Instantaneous Overcurrent |

| Device Number | Function |

|---|---|

| 50P | Phase Instantaneous Overcurrent |

| 50SP | Split Phase Instantaneous Overcurrent |

| 50BF | Breaker Failure |

| 50/27 | Accidental Energization |

| 51G | Ground Time Overcurrent |

| 51PV | Phase Time Overcurrent with Voltage Restraint |

| 51N | Neutral Time Overcurrent |

| 59N | Phase Overvoltage |

| 59X | Auxiliary Overvoltage |

| 59_2 | Negative Sequence Overvoltage |

| 59X | Auxiliary Overvoltage |

| 64F | Field Ground Protection |

| Device Number | Function |

|---|---|

| 64S | Sub-Harmonic Stator Ground Protection |

| 64TN | 100% Stator Ground |

| 67_2 | Negative Sequence Directional Overcurrent |

| 67N | Neutral Directional Overcurrent |

| 67P | Phase Directional Overcurrent |

| 68 | Power Swing Blocking |

| 78 | Out-of-Step Protection |

| 81O | Overfrequency |

| 81R | Rate of Change of Frequency |

| 81U | Underfrequency |

| 87G | Restricted Ground Fault |

| 87S | Generator Stator Differential |

Key Features

- Metering - current, voltage, power, energy, frequency

- Oscillography – analog and digital parameters at 64 samples/cycle

- Event Recorder - 1024 time tagged events with 0.5ms scan of digital inputs

- Data Logger - 16 channels with sampling rate up to 1 sample / cycle

- Advanced relay health diagnostics

- P & M class synchrophasors of voltage, current and sequence components – 1 to 120 frames/sec

Monitoring & Diagnostics

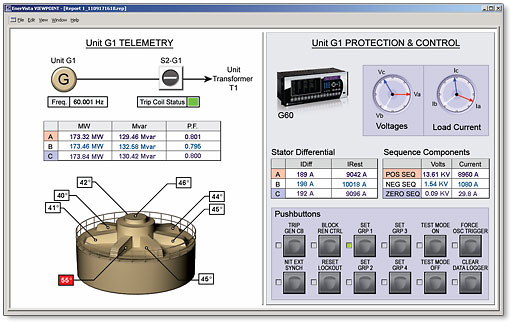

The G60 is the single point for protection, control, metering, and monitoring in one integrated device that can easily be connected directly into DCS or SCADA monitoring and control systems like Viewpoint Monitoring as shown.

The G60 is the single point for protection, control, metering, and monitoring in one integrated device that can easily be connected directly into DCS or SCADA monitoring and control systems like Viewpoint Monitoring as shown.

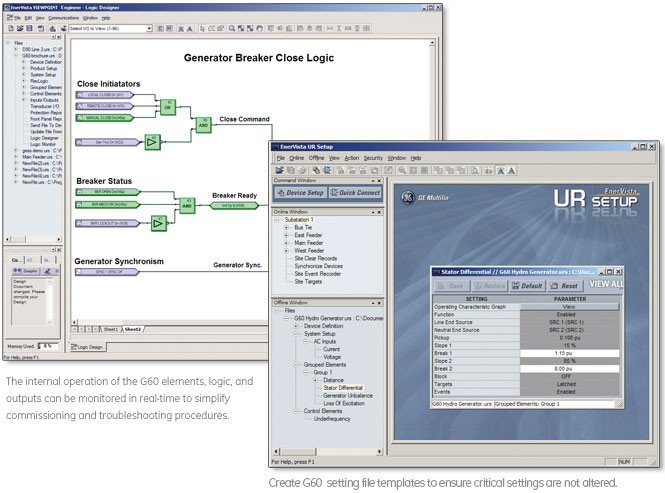

Advanced Automation

The G60 incorporates advanced automation features including powerful FlexLogic™ programmable logic, communication, and SCADA capabilities that far surpass what is found in the average generator relay. The G60 integrates seamlessly with other UR relays for complete system protection, including unit and auxiliary transformers, and balance of plant protection.

FlexLogic allows for the customization of the G60 outputs for most generator protection schemes and applications.

FlexLogic allows for the customization of the G60 outputs for most generator protection schemes and applications.

Key Features

Complete IEC 61850 Process Bus solution providing resource optimization and minimizing total P & C life cycle costs

- Three independent 100Mbps Ethernet ports enable purpose specific LAN support that eliminates latency effect of heavy traffic protocols on mission critical communication services

- Embedded IEEE 1588 time-synch protocol support eliminates dedicated IRIG-B wiring requirements for IEDs

- Direct I/O secures high-speed exchange of binary data between URs

- Increase network availability by reducing failover time to zero through IEC62439-3 PRP, HSR or dual HSR support

Advanced Communications

The G60 provides advanced communications technologies for remote data and engineering access, making it easy and flexible to use and integrate into new and existing infrastructures. Direct support for fiber optic Ethernet provides high-bandwidth communications allowing for low-latency controls and high-speed file transfers of relay fault and event record information. The available three independent and redundant Ethernet options provide the means to create fault tolerant communication architectures in an easy, cost-effective manner. The G60 supports the most popular industry standard protocols enabling easy, direct integration into DCS and SCADA systems.

- IEC 61850-9-2LE or IEC 61869 point-to-point or networked or IEC61850-9-2 Hardfiber process bus support

- DNP 3.0 (serial & TCP/IP)

- Ethernet Global Data (EGD)

- IEC 60870-5-103 and IEC 60870-5-104

- Modbus RTU, Modbus TCP/IP

- HTTP, TFTP, SFTP and MMS file transfer

- Redundant SNTP and IEEE 1588 for time synchronization

- PRP as per IEC 62439-3

- Supports Routable GOOSE (R-GOOSE)

Interoperability with Enbedded IEC 61850

Use the G60 with integrated IEC 61850 to lower costs associated with generator protection, control and automation. GE Vernova’s leadership in IEC 61850 comes from thousands of installed devices and follows on years of development experience with UCA 2.0.

The G60’s IEC 61850 Process Bus module is designed to interface with the Multilin HardFiber System, allowing bi-directional IEC 61850 fiber optic communications. The HardFiber System is designed to integrate seamlessly with existing Universal Relay applications, including protection functions, FlexLogic, metering and communications.

The G60 can also connect to GE Vernova MU320 or third-party merging units using standard IEC 61869 or IEC 61850-9-2LE communication protocols.

Cyber Security - CyberSentry™ UR (FW v7.4xx)

CyberSentry enables UR devices to deliver full cyber security features that help customers to comply with NERC CIP and NITIR 7628 cyber security requirements through supporting the following core features:

Secure FW upgrade

UR FW files v7.9 and up now include a hash code that allows for authentication prior to being used for upgrading UR devices.

Password Complexity

Supporting up to 20 alpha- numeric or special characters, UR passwords exceed NERC CIP requirements for password complexity. Individual passwords per role are available.

AAA Server Support (Radius)

Enables integration with centrally managed authentication and accounting of all user activities and uses modern industry best practices and standards that meet and exceed NERC CIP requirements for authentication and password management.

Role Based Access Control (RBAC)

Efficiently administrate users and roles within UR devices. The new and advanced access functions allow users to configure up to five roles for up to eight configurable users with independent passwords. The standard “Remote Authentication Dial In User Service” (Radius) is used for authentication.

Event Recorder (Syslog for SEM)

Capture all cyber security related events within a SOE element (login, logout, invalid password attempts, remote/local access, user in session, settings change, FW update, etc), and then serve and classify data by security level using standard Syslog data format. This enables UR devices integration with established SEM (Security Event Management) systems.

EnerVista™ Software

The EnerVista™ suite is an industry-leading set of software programs that simplifies every aspect of using the G60 relay. The EnerVista™ suite provides all the tools to monitor the status of the protected asset, maintain the relay, and integrate information measured by the G60 into DCS or SCADA monitoring systems. Convenient COMTRADE and Sequence of Events viewers are an integral part of the UR setup software included with every UR relay, to carry out postmortem event analysis and ensure proper protection system operation.

Recommended Products & services

Perception Fleet

Transformer Fleet Risk Management Software System

Continuing its legacy in providing innovative solutions, Perception™ Fleet is GE Vernova's Online Transformer Fleet Management Software System that provides a revolutionary and holistic approach for transformer fleet assessments for utilities and industrial customers around the globe.

Perception Fleet

Transformer Fleet Risk Management Software System

Continuing its legacy in providing innovative solutions, Perception™ Fleet is GE Vernova's Online Transformer Fleet Management Software System that provides a revolutionary and holistic approach for transformer fleet assessments for utilities and industrial customers around the globe.

Key Benefits

Transformer Fleet Replacement Strategy

- Provides a clear strategic view for asset replacement across the entire fleet

- Tracks the fleet risk index over time to show the improving overall condition of the fleet

- Allows for flexible and scalable transformer fleet risk management

Condition-Based Maintenance Program

- Provides the insight required to shift from costly time-based maintenance to cost effective and focused condition-based maintenance

- Reduces ambiguity and the need to speculate regarding budget requirements

- Reduces OPEX usage on assets to only as required

Automated Data Analysis

- Reduces time required to gather, amalgamate, analyze and interpret transformer diagnostic data

- Provides intelligent algorithms to determine each transformer's condition, and ranks the transformers in the fleet based on their risks

- Reduces reliance on transformer expertise that is rapidly being lost

A Smart Transformer Fleet Management System

Perception Fleet is a smart software solution designed to provide a comprehensive condition evaluation of a transformer fleet. Perception Fleet can analyze and interpret data in order to determine a transformers risk without the need for expert data analysis. Full technical analysis is also instantly available for transformer technical expert use.

This is accomplished by gathering, amalgamating, analyzing and interpreting the data held on transformers utilizing GE Vernova's online monitoring devices and offline data. The data is analyzed using intelligent algorithms for condition anomalies and characteristics to determine the transformers risk. Each transformer is then assigned a risk index, and they are ranked based on their criticality and risk of failure.

Utilising and evaluating data taken from GE Vernova's online multi gas, single gas and bushing monitoring equipment. Perception Fleet performs an automate risk analysis of transformers focusing on dissolved gas analysis (DGA) of insulation oil, tap changer insulation oil DGA, bushing capacitance, bushing power factor and partial discharge.

The transformer insulation oil properties and quality is also evaluated based on the results received from labs for manually sampled transformer oil. Perception Fleetx's specific offline oil algorithm uses oil analysis techniques outlined by standards, working groups, committees and industry experts to evaluate the condition of the transformer where online monitoring is not available.

Due to the increased and varied level of information provided in lab results Perception Fleet is capable of evaluating a wealth of information beyond pure DGA, as outlined in the brochure.

The automated import facility enables not only the users but their labs to seamlessly update Perception Fleet with the latest data for a manual oil sample analysis. Perception Fleet then performs an automated analysis and evaluation of the newly imported data without the need for any operator interaction.

As well as analysing manually sampled oil data, the offline algorithm can also perform an analysis of oil information from 3rd party online monitors or software applications. The algorithm determines the data available in the imported CSV file received from the 3rd party and performs an evaluation.

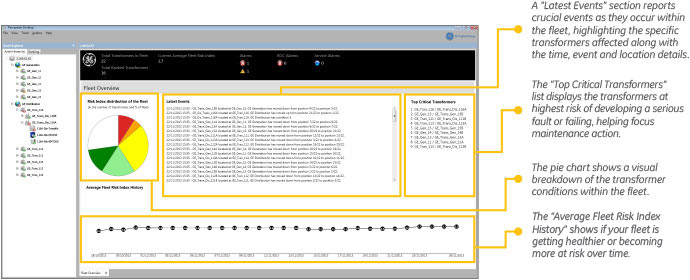

Simple Management with Dashboards and Diagnostics

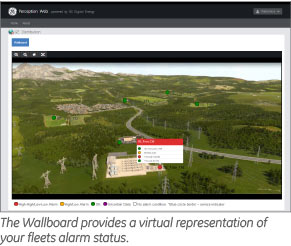

In a world of intelligent and powerful monitoring devices, customers face the problem of data overload making it hard for operators and other users to recognize changes, identify abnormal conditions and react quickly. Perception has used cognitive techniques to build its dashboards for rapid recognition of any change and with extensive use of the traffic light approach that empowers users with at-a-glance recognition of key indicators or important condition changes optimizing reaction time.

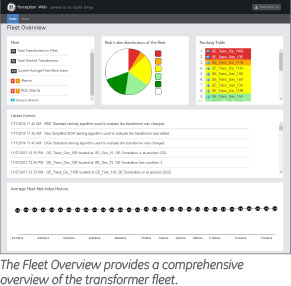

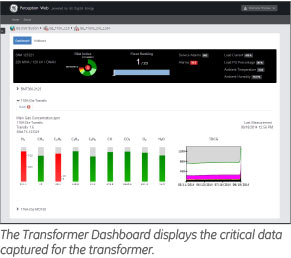

The fleet dashboard provides a comprehensive overview of the transformer fleet, highlighting which transformers are being monitored and risk assessed, how many monitoring devices are experiencing alarms, the overall fleet risk index history and the critical events occurring within the fleet. The device summary dashboard automatically self-configures to show, the most important data from all available online monitoring devices in a simple and concise design.

Standards-Based Management

Perception Fleet incorporates several internationally recognized standards for dissolved gas analysis. These standards are widely considered as the best in class and are attired to by transformer technical experts throughout the world.

The algorithms used in Perception Fleet automatically apply these standards along with best practice techniques against the dissolved gas data received by the GE Vernova online monitoring device. By combining these standards within the algorithms, the software is able to calculate the transformers risk index and score. The algorithm assigned to a transformer can also be weighted in terms of its importance and its sensitive to the parameters adjusted - these adjustments have a direct impact on the algorithm and affects the final risk index and risk score applied to each transformer. Perception Fleet's standards-based algorithms Include:

For a list of all that standards that Perception Fleet is certified to please view the brochure.

Web Interface

Perception Web is a web browser interface for Perception Fleet that provides critical fleet and transformers information via any modern web browser application running on any platform. By using a web browser to interface with Perception Fleet; Perception Web removes the need to install Perception Desktop thereby simplifying and speeding up the Perception Fleet deployment and roll-out process. The information provided via Perception Web is perfect for any user who is interested in viewing the critical fleet and transformer data.

As well as running on a desktop or laptop platform, Perception Web can also be viewed on any Smart Phone or Tablet. The data displays provided by Perception Web are designed to automatically adapt to suit the screen size of the device.

Perception Web can be configured to run as an Intranet or Internet service. The Internet configuration allows users to access and browse the Perception Web data from anywhere on a device with an Internet connection securely. When configured for Intranet access users must be connected to their organisations network infrastructure directly or via a VPN.

Perception Web provides access to the following critical data:

Fleet Overview

Asset Wallboards

Transformer Dashboards

Asset Hierarchy

- Visual representation of the network of areas, substations, transformers and online monitors as preconfigured in Perception Fleet via the Perception Desktop application.

- Click through on an Area or Substation asset to show associated Wallboard.

- Click through on transformer asset to show associated Wallboard or Transformer Dashboard.

Technical Specifications

Recommended Products & services

MS 3000

Transformer monitoring system

Benefiting from decades of transformer manufacturing experience and previous transformer monitoring systems (MS 2000), GE Vernova now offers the MS 3000 online condition monitoring and expert system.

The MS 3000 system provides a holistic approach that not only relies on a GE Vernova’s Dissolved Gas Analysis (DGA) monitor but expands the monitoring by connecting to the other existing transformer sensors and adding functionalities and measuring devices as per customer requirements.

MS 3000

Transformer monitoring system

Benefiting from decades of transformer manufacturing experience and previous transformer monitoring systems (MS 2000), GE Vernova now offers the MS 3000 online condition monitoring and expert system.

The MS 3000 system provides a holistic approach that not only relies on a GE Vernova’s Dissolved Gas Analysis (DGA) monitor but expands the monitoring by connecting to the other existing transformer sensors and adding functionalities and measuring devices as per customer requirements.

Recommended Products & services

Kelman BMT 430

An Essential Bushing and Partial Discharge Monitoring Solution

GE Vernova’s latest and advanced Kelman BMT 430 is on-line system that continuously monitors the condition of the bushings, which are constantly under high stress, and developing partial discharge (PD) activity in the transformer. It will immediately alert personnel of evolving fault conditions with the bushings and provide vital health information on the bushings and the transformer.

Kelman BMT 430

An Essential Bushing and Partial Discharge Monitoring Solution

GE Vernova’s latest and advanced Kelman BMT 430 is on-line system that continuously monitors the condition of the bushings, which are constantly under high stress, and developing partial discharge (PD) activity in the transformer. It will immediately alert personnel of evolving fault conditions with the bushings and provide vital health information on the bushings and the transformer.

Recommended Products & services

Hydran 201Ti

The Hydran 201Ti is a small on-line early warning transmitter. It is permanently mounted on the transformer and will provide personnel with a single reading in ppm of a composite value of various fault gases to alert them to a potential issue.

This value can be downloaded and alarms can be set at pre-determined levels to alert personnel and enable monitoring of the developing fault condition.

Hydran 201Ti

The Hydran 201Ti is a small on-line early warning transmitter. It is permanently mounted on the transformer and will provide personnel with a single reading in ppm of a composite value of various fault gases to alert them to a potential issue.

This value can be downloaded and alarms can be set at pre-determined levels to alert personnel and enable monitoring of the developing fault condition.

Recommended Products & services

Hydran M2-X

Enhanced Monitoring with Extended Sensor Life

The Hydran M2-X is the next generation of the field-proven family of Hydran DGA monitoring solutions, providing continuous monitoring of gas and moisture levels to alert users of developing faults and minimize the risk of unplanned outages. The M2-X builds on GE Vernova’s strong domain expertise to deliver an optimized, low maintenance monitoring device with extended sensor life.

The Hydran M2-X is also available in a UL certified, HazLoc version (part number: M2-X-HZ) for installation on transformers located in hazardous locations designated as Class I, Division 2

Hydran M2-X

Enhanced Monitoring with Extended Sensor Life

The Hydran M2-X is the next generation of the field-proven family of Hydran DGA monitoring solutions, providing continuous monitoring of gas and moisture levels to alert users of developing faults and minimize the risk of unplanned outages. The M2-X builds on GE Vernova’s strong domain expertise to deliver an optimized, low maintenance monitoring device with extended sensor life.

The Hydran M2-X is also available in a UL certified, HazLoc version (part number: M2-X-HZ) for installation on transformers located in hazardous locations designated as Class I, Division 2

Recommended Products & services

PDWatch

UHF PD Monitoring for GIS

Gas Insulated Substations have become more frequent sites due to their reduced footprint and high reliability of operation. But this reliability can be undermined by the presence of free moving metallic particles originating from breaker operations or mechanical vibrations. These particles can generate high electric fields locally initiating partial discharges (PD) within the insulation. Repeated partial discharges will eventually produce a flashover necessitating shutting down the GIS for repairs.

PDWatch

UHF PD Monitoring for GIS

Gas Insulated Substations have become more frequent sites due to their reduced footprint and high reliability of operation. But this reliability can be undermined by the presence of free moving metallic particles originating from breaker operations or mechanical vibrations. These particles can generate high electric fields locally initiating partial discharges (PD) within the insulation. Repeated partial discharges will eventually produce a flashover necessitating shutting down the GIS for repairs.

Recommended Products & services

BWatch

Integrated SF₆ and g³ Monitoring System and Internal arc localization for GIS

With worldwide scrutiny on SF₆ gas usage, increased environmental reporting requirements and even possible penalties, precise early detection of small gas leaks in Gas Insulated Substations that use so much SF6 is essential.

The BWatch uses the latest generation of EMC resistant digital gas sensors to continuously measure gas pressure and temperatures in order to track changes in density and detect gas leaks down to 0.1% per year.

BWatch

Integrated SF₆ and g³ Monitoring System and Internal arc localization for GIS

With worldwide scrutiny on SF₆ gas usage, increased environmental reporting requirements and even possible penalties, precise early detection of small gas leaks in Gas Insulated Substations that use so much SF6 is essential.

The BWatch uses the latest generation of EMC resistant digital gas sensors to continuously measure gas pressure and temperatures in order to track changes in density and detect gas leaks down to 0.1% per year.

Recommended Products & services

CBWatch

Intelligent monitoring for HV circuit breakers

GE Vernova’s CBWatch is a compact, modular, online monitoring solution suitable for high voltage circuit breaker. It records information using non-invasive sensors and performs local real time monitoring of operational parameters attached to key breaker functions. It looks for threshold breaches, warns of any significant change in operating performance and assembles an overall condition assessment of the breaker.

CBWatch

Intelligent monitoring for HV circuit breakers

GE Vernova’s CBWatch is a compact, modular, online monitoring solution suitable for high voltage circuit breaker. It records information using non-invasive sensors and performs local real time monitoring of operational parameters attached to key breaker functions. It looks for threshold breaches, warns of any significant change in operating performance and assembles an overall condition assessment of the breaker.