Inside the Griñón Level-2 service center

Juan Antonio Castilla

December 19, 2025

8-minute read

Work experience

I began with GE Vernova’s aero division in 2003 when it was still under Global Turbine Services (GTSI). Initially, we mostly provided labor services without engineering support, which is now incorporated into One Field Services (OFS).

From 2003 to 2004, I worked exclusively with aero. Then, from 2005 – 2007, I transitioned to working full time for Packaging and General Services (PGS) before being promoted to Mechanical Supervisor. I then accepted the role of Aero Tooling Coordinator in 2009 for all of southern Europe. The business continued to expand, and in 2011, we moved the tooling department to Griñon, where we manage aero, PGS, Jenbacher, and the wind business.

In January 2024, we integrated all generator services across Europe and nearby countries like Kazakhstan and Uzbekistan into Griñón’s tooling center’s scope.

Site history

The center was established in 2011, with key involvement from Conor Goonan, who now serves as Director of Middle East services. It started small but has steadily grown and expanded its capabilities.

We’ve always focused on servicing the aero units in southwestern Europe and recently took on all of Europe’s generator tooling. We also provide significant support to Latin America, Africa and, to a lesser extent, Asia.

We currently have a total of 20 employees, and 11 are technicians and tooling experts.

We’ve always focused on servicing the aero units in southwestern Europe and recently took on all of Europe’s generator tooling.

L-2 service center advantage

The biggest advantage offered by our service center is specialized equipment, which is not typically found on-site. For example, a crane bridge is a critical tool that most clients don’t have due to its size and complexity.

Also, our on-site crane bridge offers precise control when handling components unlike external cranes with operators who may not be familiar with a particular turbine. Our technicians can make fine adjustments, lifting by millimeters rather than centimeters, to prevent damage and improve safety.

This precise handling capability is a major benefit of working with an OEM tooling center like Griñón.

Critical repairs and night shifts

Our night shifts are reserved for clients or project managers with urgent requests or needs; otherwise, most of our work is during the day. When we have tight deadlines—like a leasing that must be finished within a week—we set up night shifts alongside day shifts. These shifts typically involve tasks such as engine swaps or hot exchanges.

Our technicians can make fine adjustments, lifting by millimeters rather than centimeters, to prevent damage and improve safety.

Standardized tooling

Tooling itself is the same globally, but having immediate access to replacements is a big plus for the Griñón L2 service center.

If a tool breaks or a component bends, we can swap it out in minutes, avoiding delays that could impact plant schedules.

We don’t formally collaborate at the global level. However, we often coordinate with other Level 2 facilities to help ensure there is no interference with operations.

Quality assurance

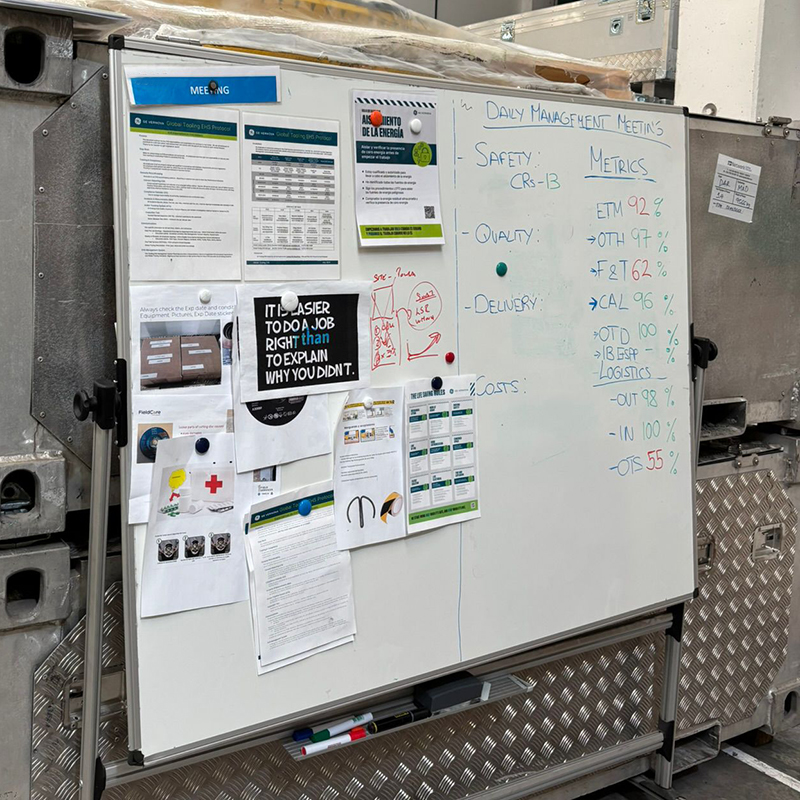

We have strict quality procedures for everything, including tool check-ins and lifting operations, all of which are standardized globally to help ensure consistency across repairs.

This also helps to ensure that all sites meet the same high standards regardless of location. In addition, each piece of equipment undergoes identical quality checks and is marked with a green tag and certification number, indicating that it is ready to be transferred to the next person.

Having standardized training and consistency helps address labor continuity. When a technician falls ill or is unavailable, another trained tech can step in and offer the same consistent work quality. This rigorous approach to quality control is fundamental to our daily operations and helps achieve high-quality results worldwide

This rigorous approach to quality control is fundamental to our daily operations and encourages excellent results worldwide.

A commitment to safety

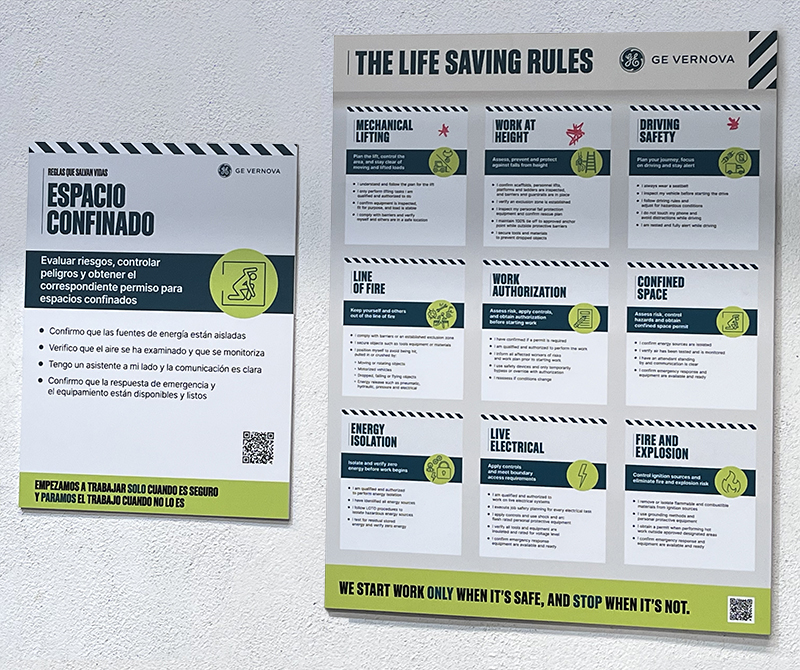

Absolutely. Our commitment to environment, health, and safety (EHS) standards goes beyond what legislation requires. For example, there’s no law mandating the use of harnesses, yet we enforce it because safety is a core value at Griñón.

We also implement internal audits that encourage strict adherence to quality and safety protocols. External auditors are often impressed when conducting site inspections. During our ISO 45001 audit in March of 2025, the auditor said there was no need to even discuss safety, because our commitment to it was evident at first glance.

Throughout all my roles at GE Vernova, I have remained impressed by the continued level of commitment to safety across all operations.

Continuous training

Our Learning Center supports continuous training across all locations and includes regular refreshers for work-at-height protocols, lockout/tagout (LOTO) procedures, and other critical safety practices. This keeps everyone up-to-date and reinforces quality and safety.

Training impact

Ongoing training is essential. Although our workshop operates independently, we closely support work done in the field.

This training helps ensure technicians are skilled and ready, which directly contributes to repair quality and safety.

L2 versus L4 repairs

The key benefits are speed, safety, and cleanliness. Clients usually prioritize speed, but safety is also crucial. If an accident happens, it’s isolated to our site and does not affect their plant operations.

Cleanliness is also paramount, especially when working on compressors or hot sections. Even a tiny particle entering the compressor could potentially cause months of downtime or serious damage. For instance, we only use specific markers for blade marking to avoid residue that could harm the turbine when heated.

Clients also appreciate that our workers are trained GE Vernova employees, which are familiar with our processes and understand our values. Because of our employee-only policy, quality control and quality assurance are maintained.

Clients also appreciate that our workers are trained GE Vernova employees, which are familiar with our processes and understand our values.

Common customer concerns

One common concern is insurance. Some clients worry about coverage during the repair, but we clarify that GE Vernova is responsible under existing contracts.

Another factor is emotional. Aero clients often feel a personal attachment to their engines, which can make them wary about sending their turbine outside their facilities.

Transportation

Transport isn’t usually a major point because turbines require transportation whether it’s a machine swap or a repair.

Some clients have concerns about lack of visibility into the repair process, but our facilities are open, and visitors are welcomed.

Also, many clients have warehouses or facilities that cost more in rent and crane usage than transportation itself. For example, crane rental can cost several thousand euros per day, far more than shipping costs.

Most common repairs

We mostly service hot sections and high-pressure compressors (HPC), but sometimes we work on HPCs in conjunction with low-pressure compressors (LPC), just not as frequently.

Turbine models

We often see LM2500 and LM6000 engines.

LMS100 turbines have yet to arrive for service, in part because we don’t have any units in Spain; the closest are in Italy.

Turnaround times

Our target turnaround time for engine repairs is 7-10 days unless parts are unavailable or delayed. The facility is always fully prepared to deploy quick turnarounds.

2025 repairs

We have successfully completed three turbine repairs in our service center this year. The goal is to handle more repairs in Europe, splitting work between Griñón and Livorno. Historically, we do about two or three per year, and most are unscheduled emergency repairs.

Industries that rely on us

Our clients are across various industries such as oil & gas, mining, paper and pulp, and manufacturing. In particular, clients who operate within the oil and paper mill industries risk residues interfering with repairs. They really appreciate the controlled, clean environment that we provide at Griñón.

Customer surveys

After every job, clients receive a satisfaction survey through their CPM, like Nuno Benedito (now CSL), who recently visited us. Clients appreciate the quality of GE Vernova’s work, and the feedback we get is consistently very positive.

A thorough approach

Many clients are not fully aware of our processes and tend to have doubts. But once they truly understood how carefully and thoroughly we work, they are more confident bringing their engines to us.even more so than keeping them onsite. Once an engine leaves the package, it often loses its clean environment. At Griñón and all our L2 shops, we maintain strict protocols on cleanliness, safety, and quality that help ensure their turbine is well cared for.

A history or success

Typically, when the engines are still under warranty, clients who bring their turbines here are very satisfied with the repairs.

Understandably, clients are usually upset when they send their engines to Griñón since their machine is down and operations are halted. But when they leave happy, that’s the best kind of feedback. We’ve even handled two repairs simultaneously, and completed both on time in under 20 days, which was a first for us. Everyone was pleased, including our technicians.

Local advantage

Sending a turbine to Houston from Europe or another overseas location typically takes much longer because most engines are transported by ship. This can take around 15 days, not including customs. Here, we can drastically reduce downtime. Clients often say they wish they had not waited to bring their machine to us.

Clients often say they wish they had not waited to bring their machine to us.

Customer locations

Most of our clients are European, with the majority coming from right here in Spain. Some customers in Italy, for example, usually send theirs to Livorno, and others in Northern Europe might prefer L4 shops instead. However, a French client recently brought their turbine here for repairs and left quite impressed.

There isn’t a strong culture of bringing machines for L2 repairs, but that is changing. Once clients see our facility and the procedural controls that we follow, their trust is quickly built. We are committed to providing quality service to every client that comes to Griñón.

Improvement projects

Yes! If we ramp up to four or more repairs a year, with more LM6000 engines, one key improvement will be adding a second hook to our crane bridge. This is particularly important for turning the low-pressure turbine (LPT), a complex and risky operation in the field.

With two hooks, we can perform the task simultaneously and much faster, reducing what currently takes an hour or more to about ten minutes. Although it is a significant investment, it will greatly enhance safety and efficiency.

Expanding our facilities

The contract is signed, and we’ll soon receive the keys. This expansion, mainly for power services generator technology, will give us an additional 350 square meters for the workshop, with 200 more for flexible use. This will enhance aero services by freeing up space in the existing buildings for hot sections, dollies, and other equipment.

Success at Griñón

I’m very proud that in the past four years, only two non-conformity reports (NCRs) with escape have occurred. That translates to only one NCR during a single repair—where we had two escapes—in a six-year period. This shows our commitment to quality and minimizing downtime. That’s quite impressive in our industry.

Continuous improvement

Absolutely. We’re always looking for ways to improve processes, safety, and quality. Everyone here at Griñón understands the importance of their work, especially when delays can be costly. It’s essential for the team to see the impact of their efforts firsthand.

Contact us