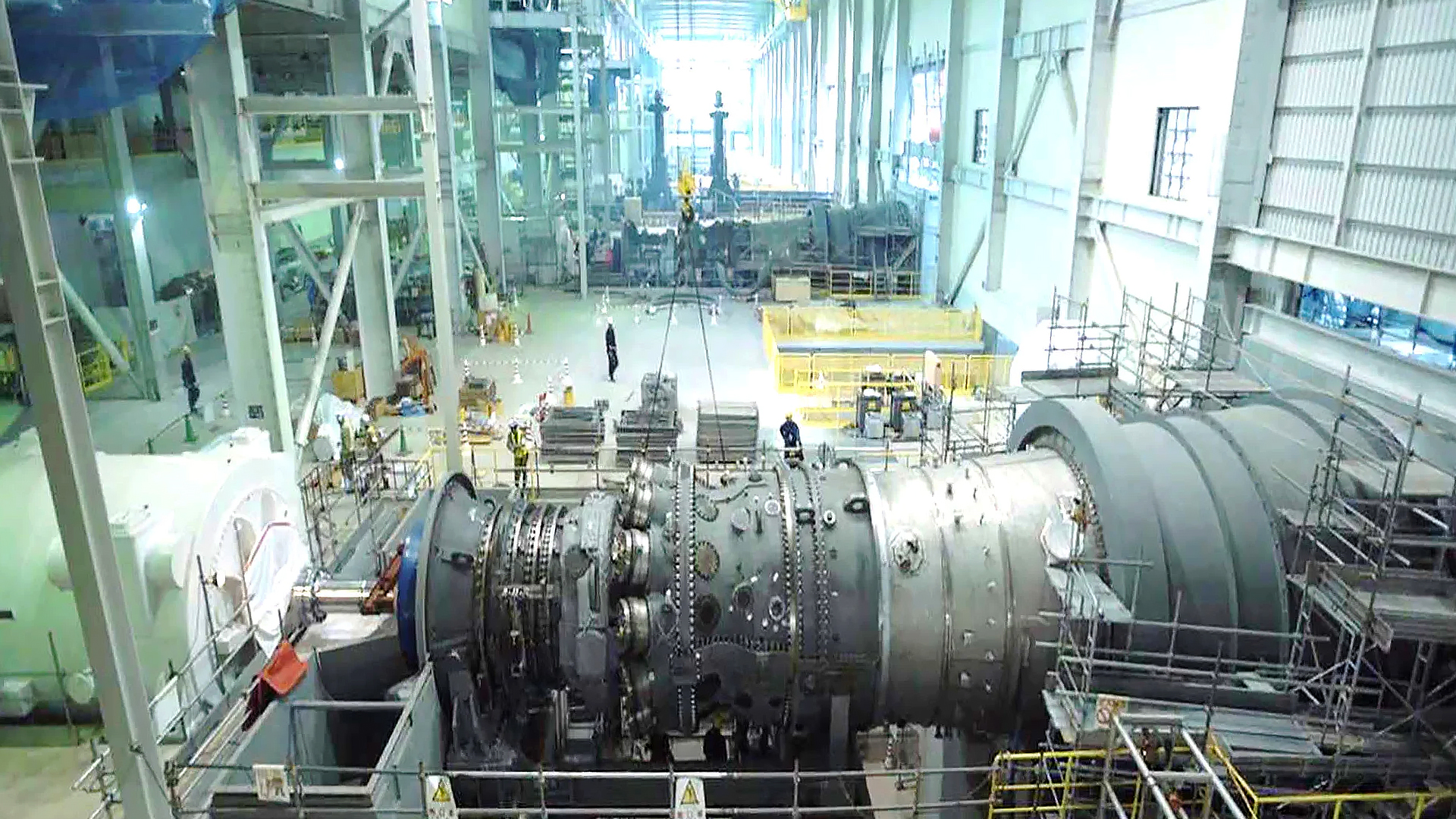

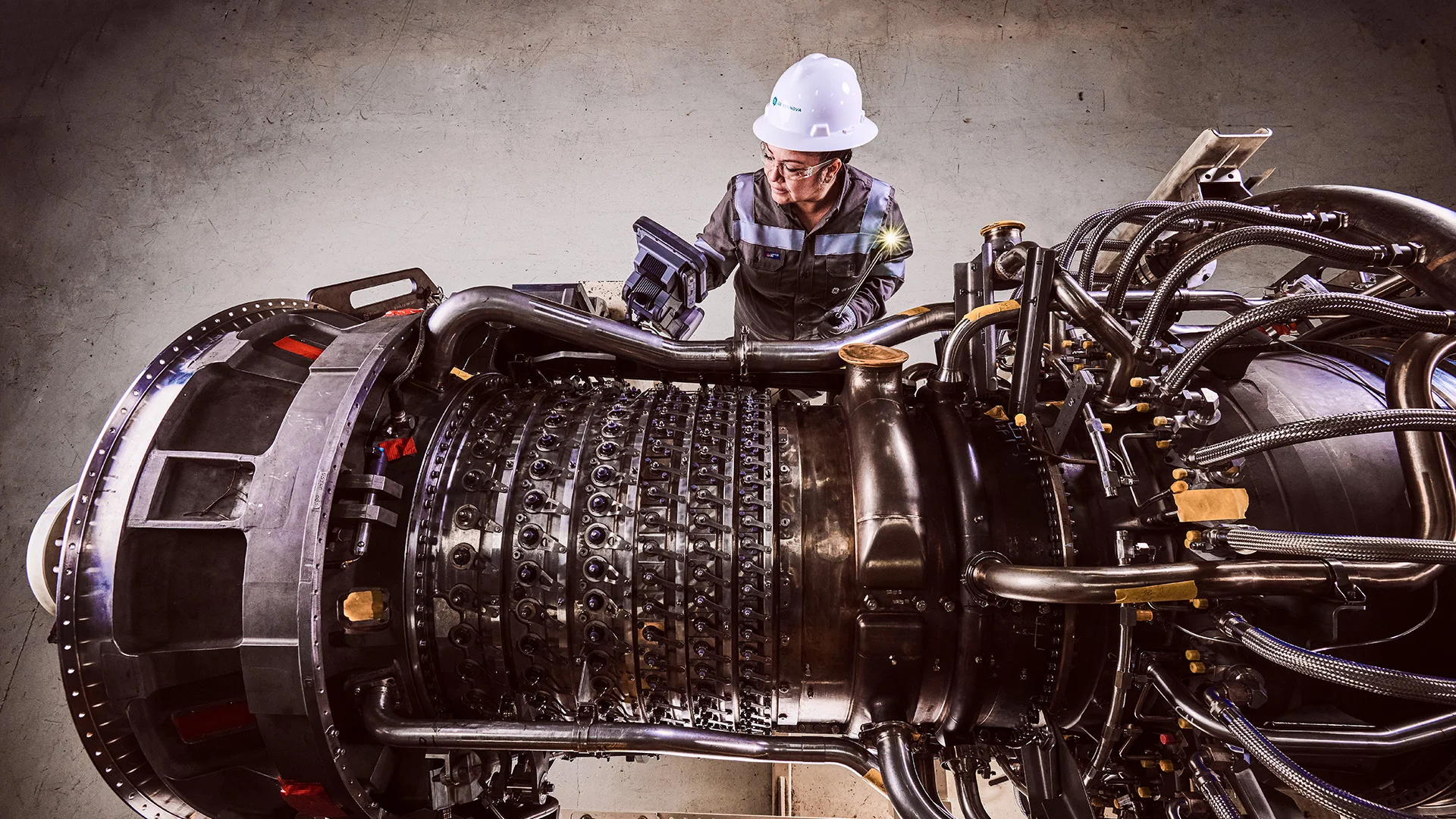

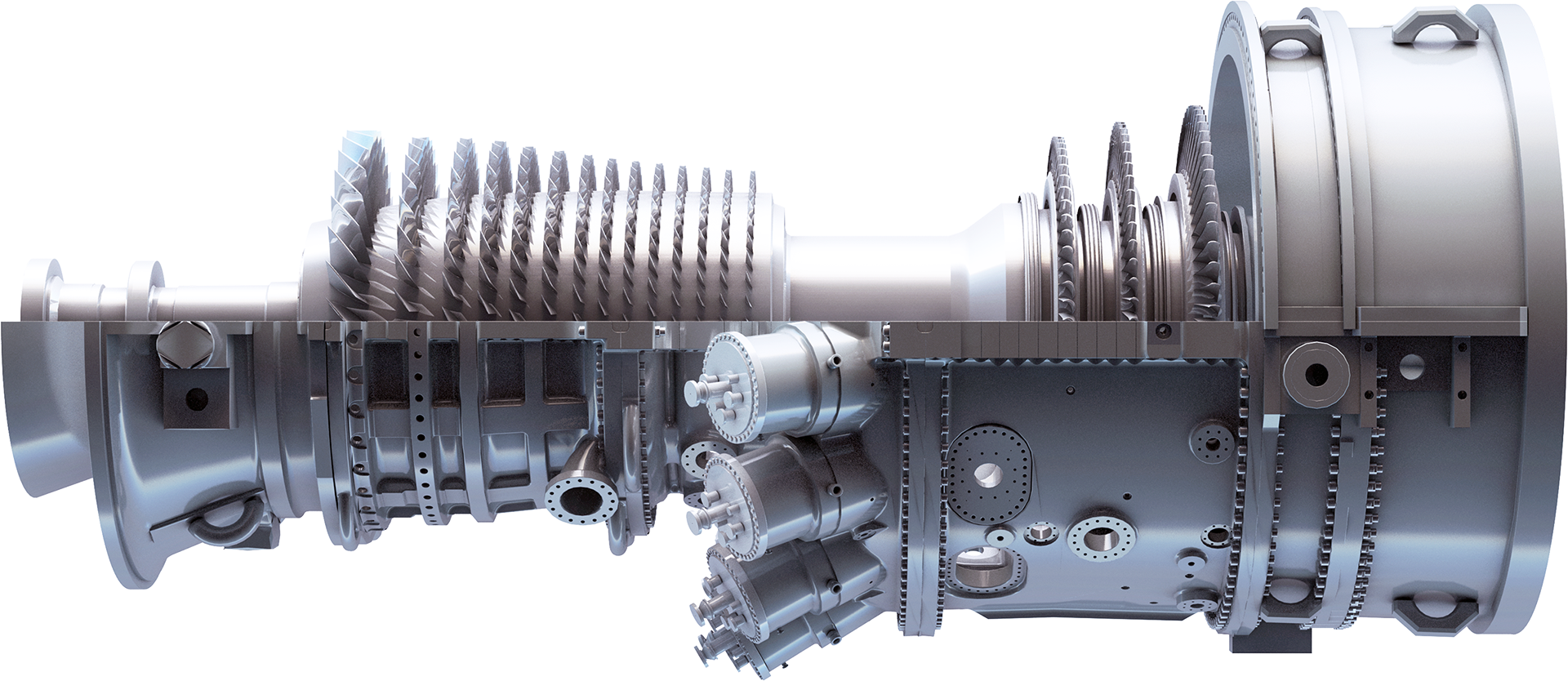

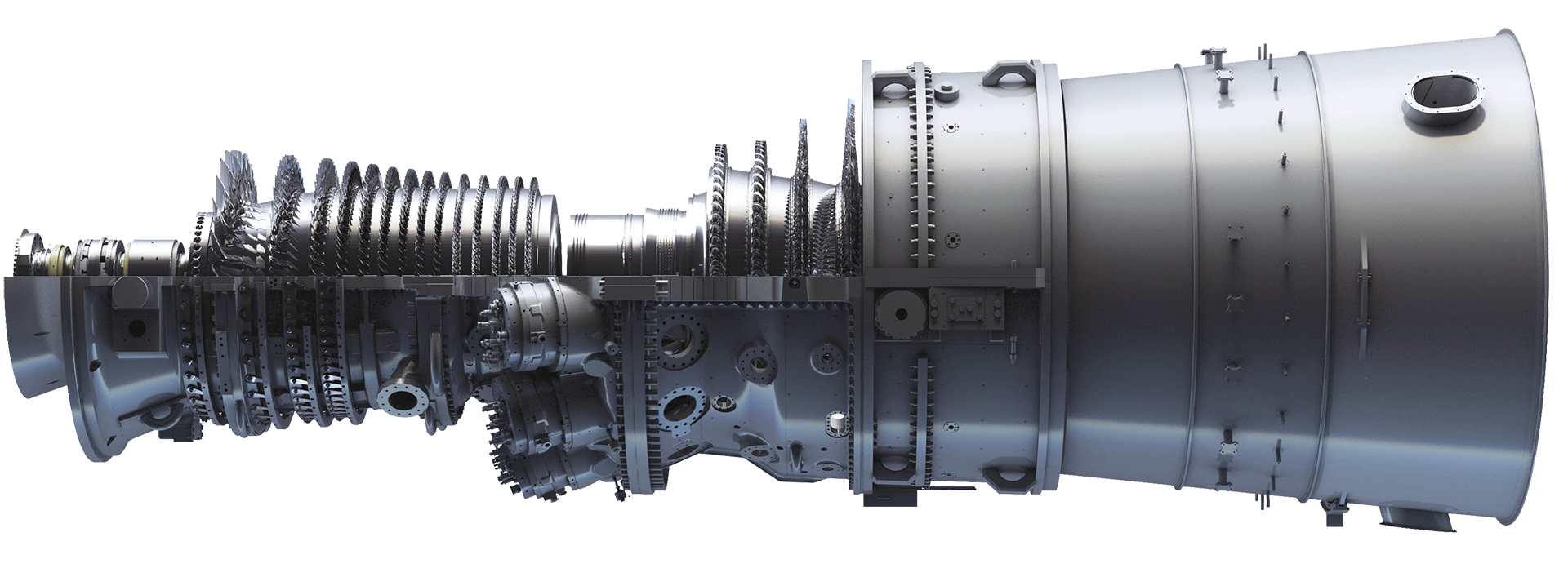

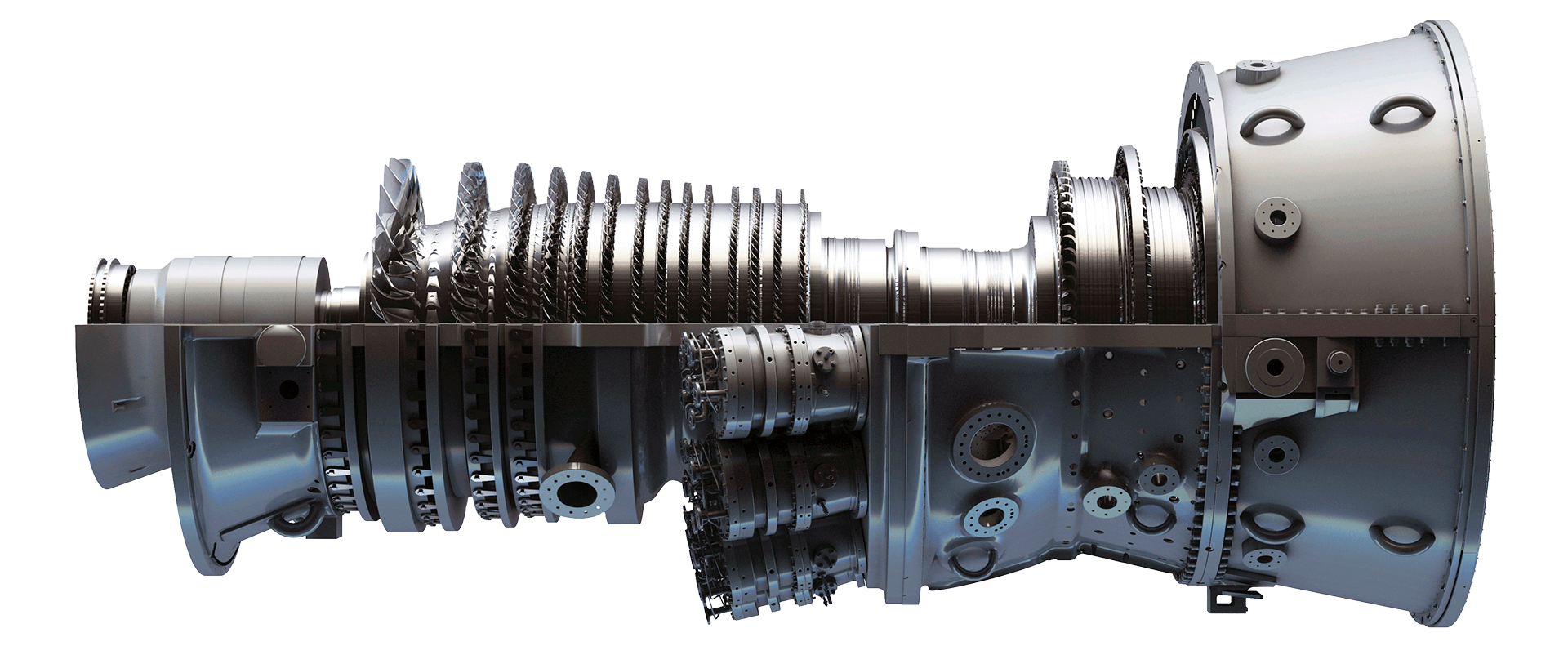

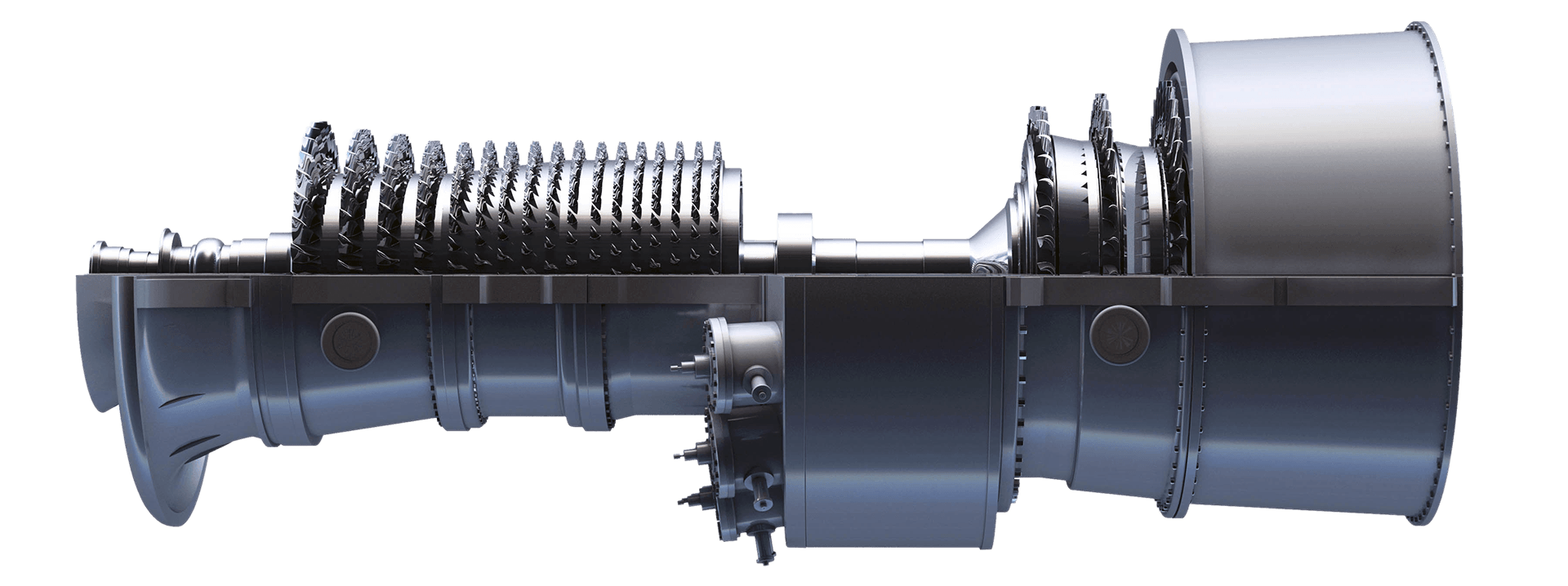

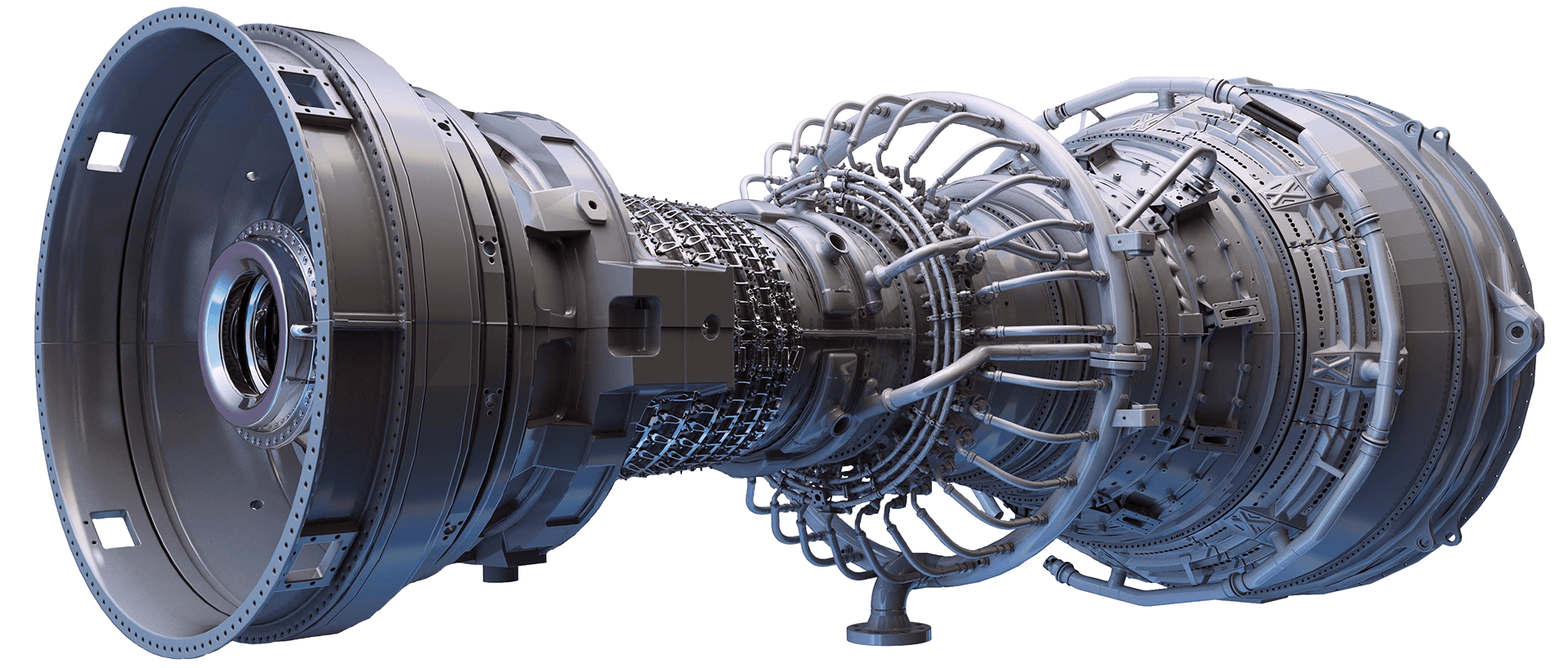

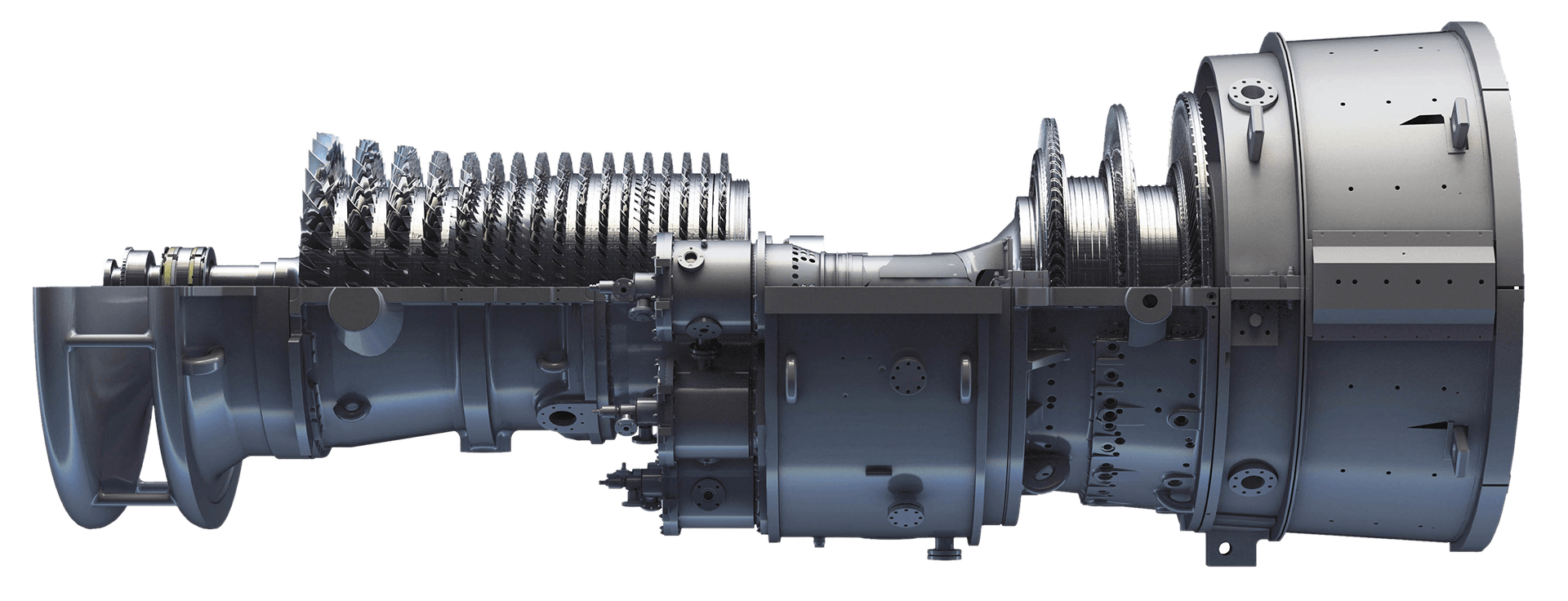

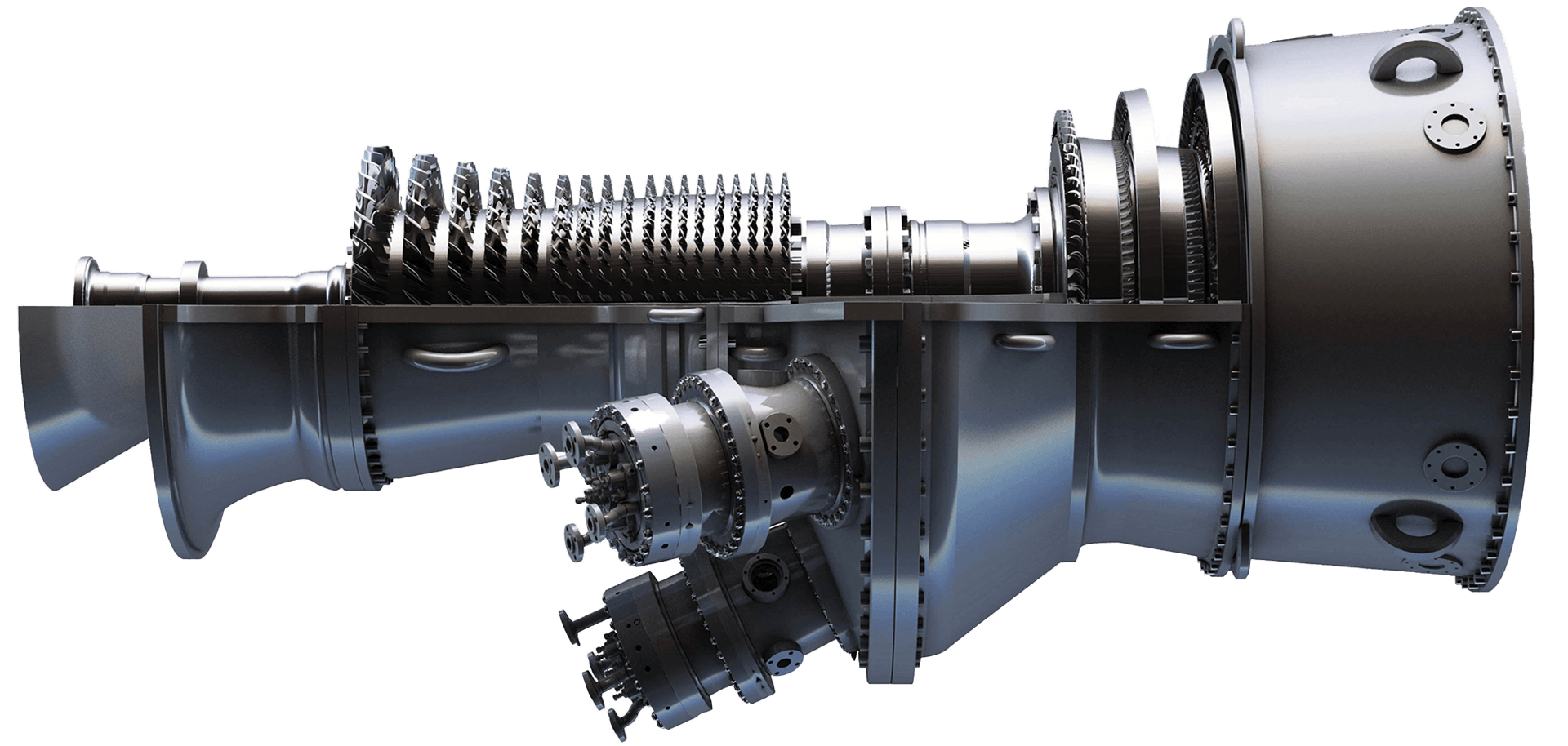

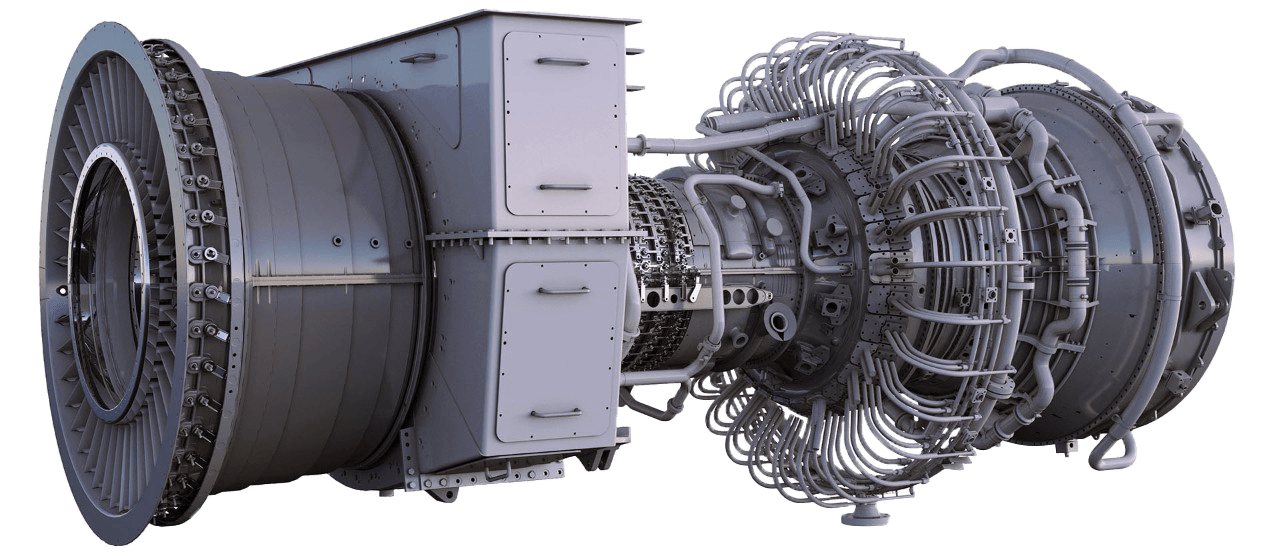

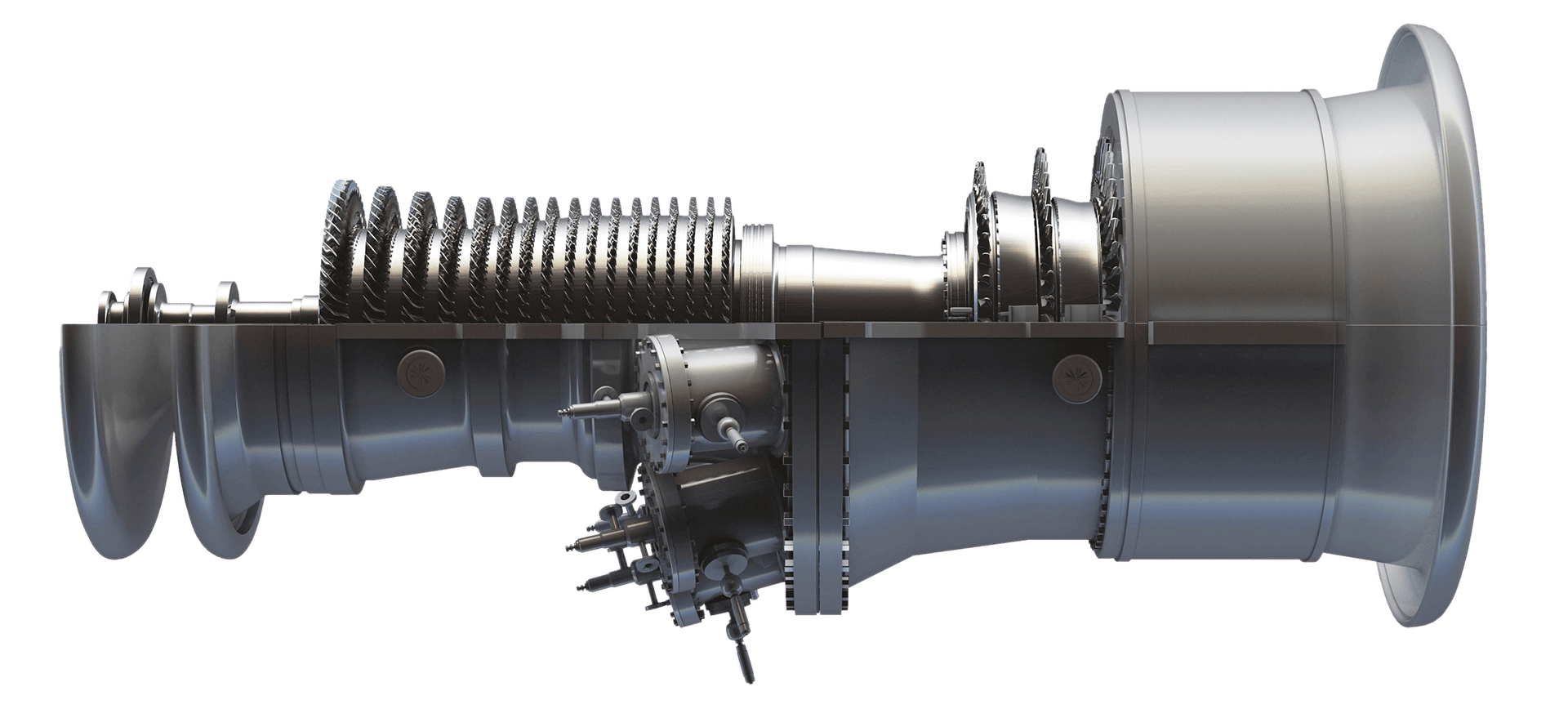

H-class gas turbines

GE Vernova's HA portfolio is the world's fastest-growing fleet in its class with more than 200 gas turbines ordered by 55+ customers across more than 25 countries. Our HA technology has accumulated over 3M operating hours (as of February 2025) at more than 50 customer sites globally.