Heat Recovery Steam Generator (HRSG) services

GE Vernova offers a one-stop HRSG shop, with a portfolio of services that includes inspections, repairs, cleanings, life management solutions and lifetime extension upgrades.

HRSG OEM expertise

GE Vernova has extensive HRSG expertise, with nearly 1,300 HRSGs in operation—the single largest global installed OEM fleet. Our boiler design dates back to the early 1900s, and our primary GE Vernova shop has been fabricating HRSGs since the 1970s.

Stronger HRSG performance starts here

Today’s turbines are pushed harder than ever—rapid starts, frequent shutdowns, relentless part-load operation. Cycling takes its toll, shortening HRSG pressure-part life and driving up failures and O&M costs.

But you don’t have to accept that. No matter who built your HRSG, we deliver targeted service solutions that can restore reliability, boost performance, and get every ounce of potential out of your plant.

Unlock enhanced performance with tailored, site-specific engineered solutions from GE Vernova. Our seasoned HRSG engineers can provide holistic assessments, flexibility upgrades, and bespoke retrofits that can boost reliability, extend life and prime your plant for tomorrow’s demands.

Your questions answered

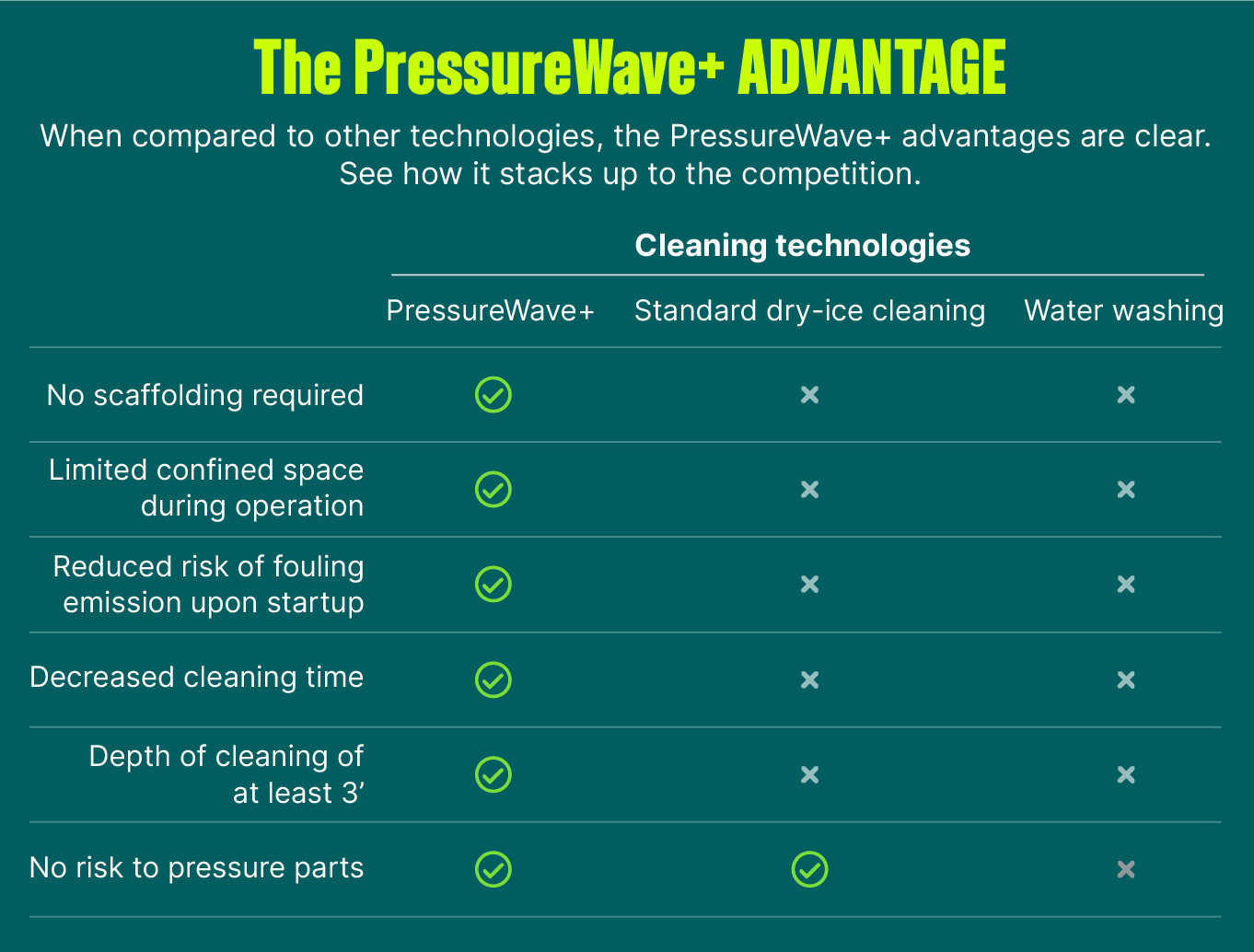

How does a PressureWave+ cleaning differ from other cleaning techniques?

PressureWave+ is an enhanced cleaning method in HRSG cleaning, offering distinct advantages over traditional methods. It precisely recalibrates backpressure to the manufacturer’s original specifications, boosting performance with an improved gas turbine output and combined cycle heat rate.

Additionally, unlike conventional cleaning techniques, PressureWave+ requires no scaffolding. The cleaning crew operates safely from outside the HRSG, lowering risks, making it one of the fastest and most secure methods for HRSG cleaning.

Flexible HRSG solutions and performance to meet the demand of a flexible, renewable-driven grid.

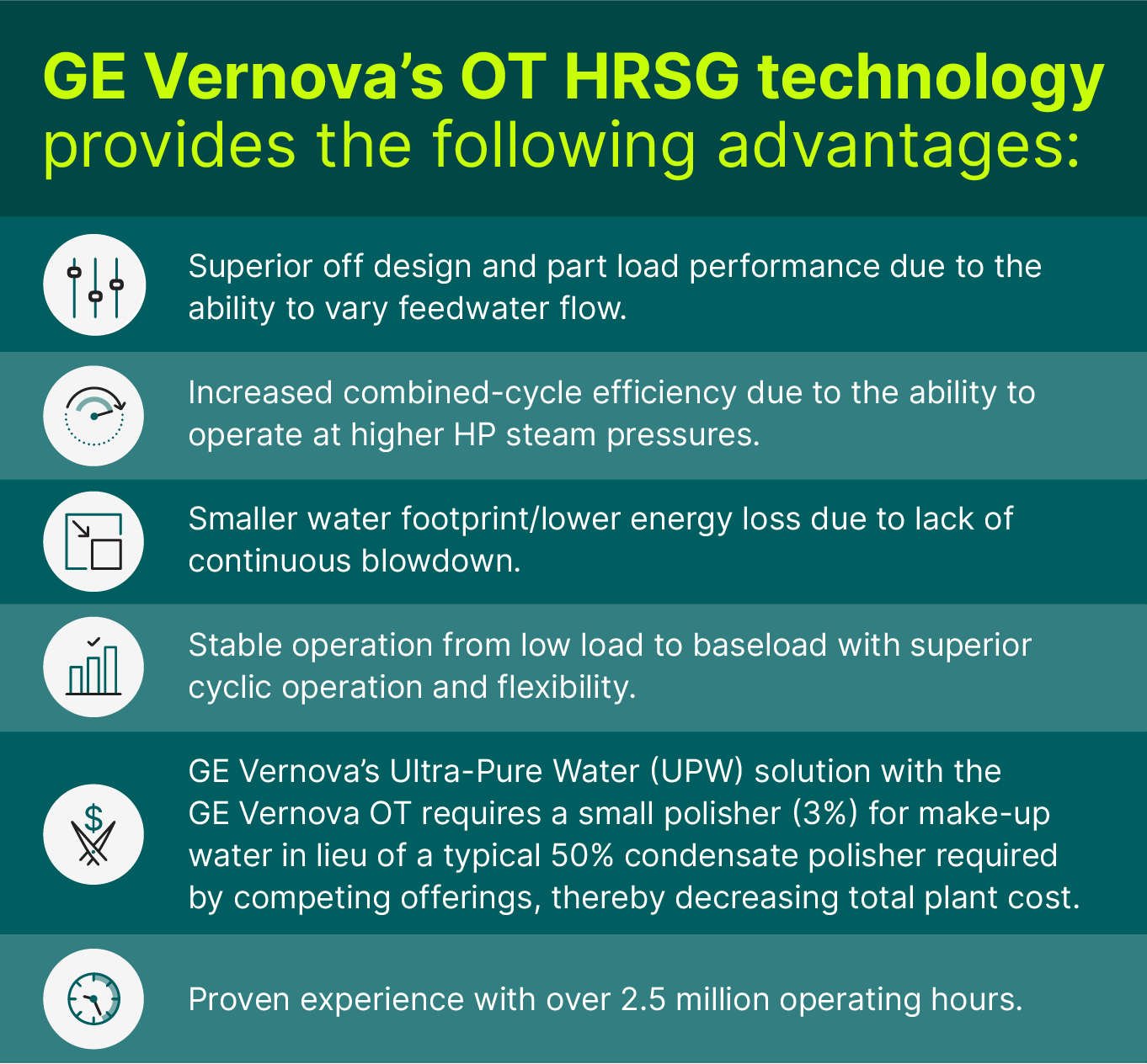

GE Vernova offers a variety of engineered solutions that are tailored to meet customers’ operating flexibility and performance requirements. One of these solutions is our proven in-house Once Through (OT) HRSG technology, which is a key enabler in advanced water-steam cycles, providing higher combined-cycle efficiency with high cyclic capability.

In general, higher efficiency comes at a higher price, so our efficiency solution starts with a project-specific economic evaluation to help ensure that we’re balancing performance and capex. To achieve high efficiency, we try to extract as much of the exhaust gas energy as possible. With tighter pinches in the evaporators and a reduction in the subcool leaving the economizers, we are able to achieve an ideal feedwater temperature, as well as higher steam temperatures and pressures.

This whole system approach is possible because GE Vernova’s portfolio of products and services includes the engineering and manufacturing of all the major components of a CCPP in-house, a natural result of which is improved combined-cycle efficiency.

To perform a lifetime assessment, we typically calculate the number of hot/cold/warm starts of the unit from the beginning of commercial operation. We also investigate the number of hours operated at base load and part load every year and compare those to the original specifications of the unit. Finally, we calculate the stresses on the most critical components (such as the superheater and reheater headers), and evaluate the theoretical lifetime consumed.

In order to reduce boiler startup times while mitigating the effects of fatigue damage to the critical components, it's necessary to reduce the strain range between startups. This can be accomplished by increasing the initial boundary conditions at startup (for instance, changing "cold starts" into "warm starts") and/or by controlling the temperature ramp rate and peak temperature of the gas turbine. For new units, we can also supply manifolds that are enhanced for fatigue life.

Browse common questions around HRSG maintenance.

Amines are often used to lower corrosion in the water or wet steam phase of the water steam cycles by forming a hydrophobic and pH buffering layer on top of the steel surfaces. A part of the dosed amines will be flushed with feedwater into the evaporator sections, where they are thermally cracked into organic acids and carbon dioxide. These organic acids could result in elevated cation conductivity of the steam, rendering the control of steam purity difficult. These acids might also result in lowering the pH and could increase potential for corrosion, especially at locations where the organic acids are accumulated. In GE Vernova’s experience, film forming amines should only be used in plants that are equipped with a condensate polishing system.

For users experiencing FAC, our typical recommendation is to upgrade certain sections with FAC-resistant alloys (such as P11 or P22). For units that are experiencing creep and fatigue-related damage, we would consider recommending geometry modifications to reduce stresses in the most critical areas.

Some users have an HRSG life monitor system installed, through which we are able to collect valuable information regarding remaining lifetime of critical components. We can use that information to provide pertinent recommendations about the most cost-effective upgrade.

In principle, cycling GT operation can result in accelerated lifetime consumption of pressure parts, control valves and desuperheaters.

The most common problems we see on HRSGs behind cycling gas turbines are:

See how the transformation of the energy landscape will impact HRSGs.

GE Vernova has carried out numerous carbon capture readiness studies for its fleet. The impact of a retrofit post carbon capture plant on the performance of the HRSG and the broader combined cycle plant depends on multiple parameters, including the preferred carbon capture technology, full capture or partial capture, CO2 capture rate, the size of the PCC plant and the ratio between natural gas versus hydrogen or any other biofuel used in the GT.

With the evolving market, there’s a need for the combined-cycle plant to operate in a more flexible manner—meaning faster ramp up, improved turndown, and potentially using different fuels ranging from natural gas to hydrogen and other biofuels.

On the gas turbine side, we can balance the “black box” of operability, maintaining our dynamics, emissions, and flame stability. However, the gas turbine increased turndown capability needs to be evaluated against the potential increase of thermal gradients and fatigue in the HRSG. Changes in the GT operating regime could drive increased unreliability and O&M costs for the HRSG.

Webinar

In this session, GE Vernova experts will show how to pinpoint where your generator, steam turbine, and HRSG systems can capture more power, regain lost performance, and extend asset life.

Matt Foreman

Steam Turbine and HRSG Platform Leader, GE Vernova

Joe D'Amato

Services and Operations Leader, Steam Turbine & Generator, GE Vernova

Jason Bowers

Steam Turbine and HRSG Upgrades Global Sales Leader, GE Vernova

Contact us

* Trademark of Bang&Clean GmbH