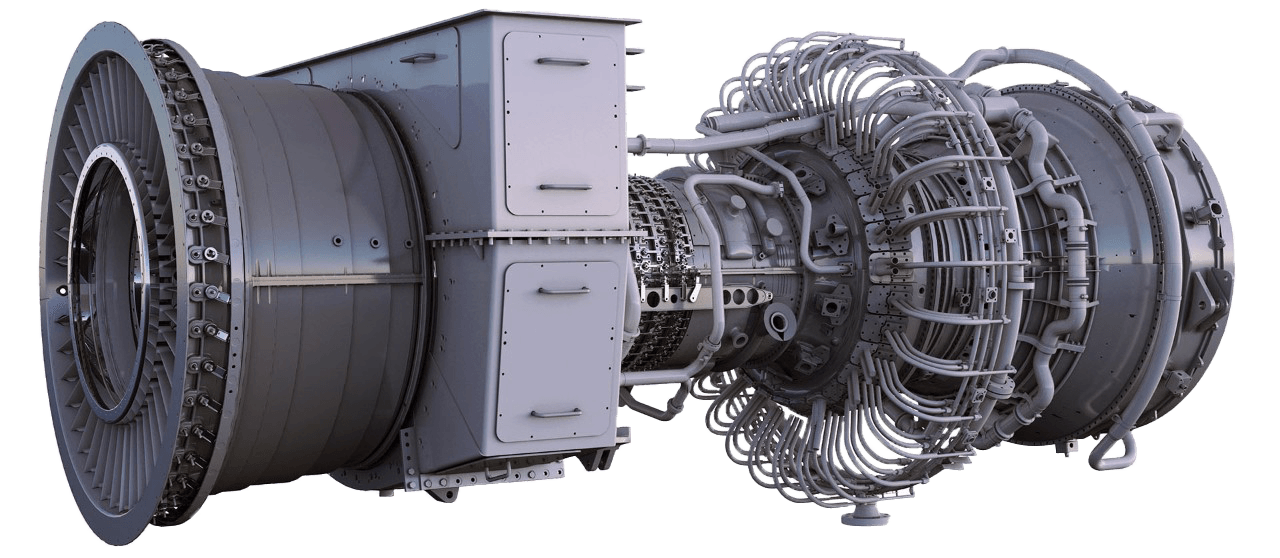

Explore GE Vernova's Aero Advantage for OEM aeroderivative services

Industry-backed aeroderivative (aero) solutions rooted in safety, quality control, and reliability.

A history of aero expertise

Behind every aero asset is a team of experts that continuously develops technology for improved performance. As an original equipment manufacturer (OEM) for gas turbines and aeroderivative turbine solutions with over 40 years and 180 million hours of proven expertise, GE Vernova stands by the construction, validation, and implementation of its products and systems.

Benefits

Sourcing individual parts, materials, and software from various manufacturers may lead to short-term cost savings, but the long-term effects could impact safety, reliability, support, and repair costs. Before turning to alternatives, consider the advantages of working with a trusted manufacturer;

Our engineers have clocked countless hours of product development, aiming to ensure that every piece of equipment that hits the field is built to a specific set of standards. As a company, we have spent millions of dollars on software development and validation testing on industrial aero gas turbines and turbine packages. And our installed base has a long history of increased asset productivity with our technologies.

Engineered for safety and longevity: The parts, engineering, algorithms, and software used are specific to aeros instead of general industry standards.

Thorough testing: Each piece of equipment undergoes full engine development testing prior to field release and must meet GE Vernova’s technical requirements.

Continuous improvement: GE Vernova continuously develops new solutions to improve the operational characteristics of its aeroderivative gas turbines. Examples include reliability improvements, upgrades to significantly increase output and efficiency, and lifecycle cost reductions.

Standardized testing: Each of the parts or software improvements are tested against gas turbine engineering models and include life impact analysis, risk analysis against engineering limits, and failure modes and effects analysis. Additionally, each of these improvements are tested and validated to very strict testing conditions, aiming to ensure that there are no interruptions in operations and the equipment receives the maximum benefit from each upgrade.

Updates and maintenance: Keeping your equipment within GE Vernova’s standards also guarantees access to the latest digital upgrades and offerings and access to world class analysis tools.

Non-OEM service providers often claim that they meet industry standards, but those standards may not allow for full optimization or long-term reliable operations

Though “meets OEM standards” is a common claim made in the industry by third-party suppliers, GE Vernova has limited knowledge of non-OEM materials and therefore has not analyzed the full potential impact on adjacent parts, like disks and thermal shields, that might be affected by non-OEM materials and repairs. However, GE Vernova and our authorized service providers (ASPs) are licensed to have full knowledge of the manuals’ instructions, which do not cover non-OEM materials installation needs and subsequent engine operating conditions.

Access to a dedicated support team for regular maintenance and troubleshooting can help fully realize the lifetime of your equipment.

Ongoing efforts to provide updated versions of the technical publications and manuals ensure that our documentation remains in line with GE Vernova’s OEM equipment understanding.

GE Vernova and GE Vernova ASPs are licensed to have full knowledge of the manuals’ instructions, which do not cover non-OEM materials installation needs and subsequent engine operating conditions.

By relying on GE Vernova and ASPs, your aero fleet’s repair history is documented and accessible in your customer portal, better understood by experts, and the parts used are genuine and meet OEM safety standards

Each authorized service provider can see an entire history of your product’s repairs to better understand and execute a personalized service and establish lifecycle limits on rotating hardware.

Because GE Vernova’s industrial aeroderivative OEM/GE Vernova-authorized hardware, software, and control solutions are specifically engineered to fit GE Vernova industrial aeroderivative gas turbines and to perform to factory specifications, using such software and solutions can support the reliable operation and lifetime of your equipment.

As noted in the product Operation and Maintenance manuals (O&M) and Industrial Repair Manual (IRM), utilizing used and/or refurbished aircraft engine parts in an industrial gas turbine is something GE Aerospace/GE Vernova specifically cautions to avoid.

Once equipment is serviced outside of the industrial aeroderivative OEM network, many technical publications are no longer applicable to that equipment, leaving customers in a potential gap for support.

By choosing a non-OEM, it is difficult to obtain any independent information on the actual performance, reliability/availability, or how the units are holding up and are expected to last before repairs are needed.

Turning to a third party to service your equipment voids your engine’s warranty and prevents it from receiving the authorized maintenance from an OEM.

Non-OEM service providers sometimes use secondhand or refurbished OEM parts and/or parts with different mission profiles, such as those from GE Aerospace. This use case is not backed by GE Aerospace or GE Vernova and does not take the life of the equipment into consideration. Using such parts may increase the likelihood of uncontained engine events increases.

Contact us

.jpg)