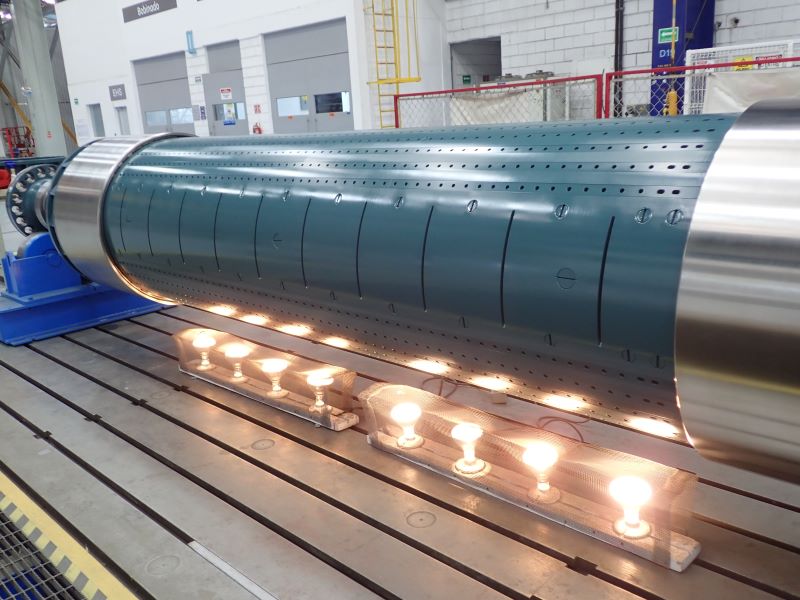

Generator rotor high-speed balancing

By identifying and correcting imbalances at operational speeds, we can help ensure that rotors continue to operate more smoothly and efficiently, reducing vibration, preventing wear, and extending your generator’s lifespan.