Boost performance and reliability with generator rotor wedge shimming

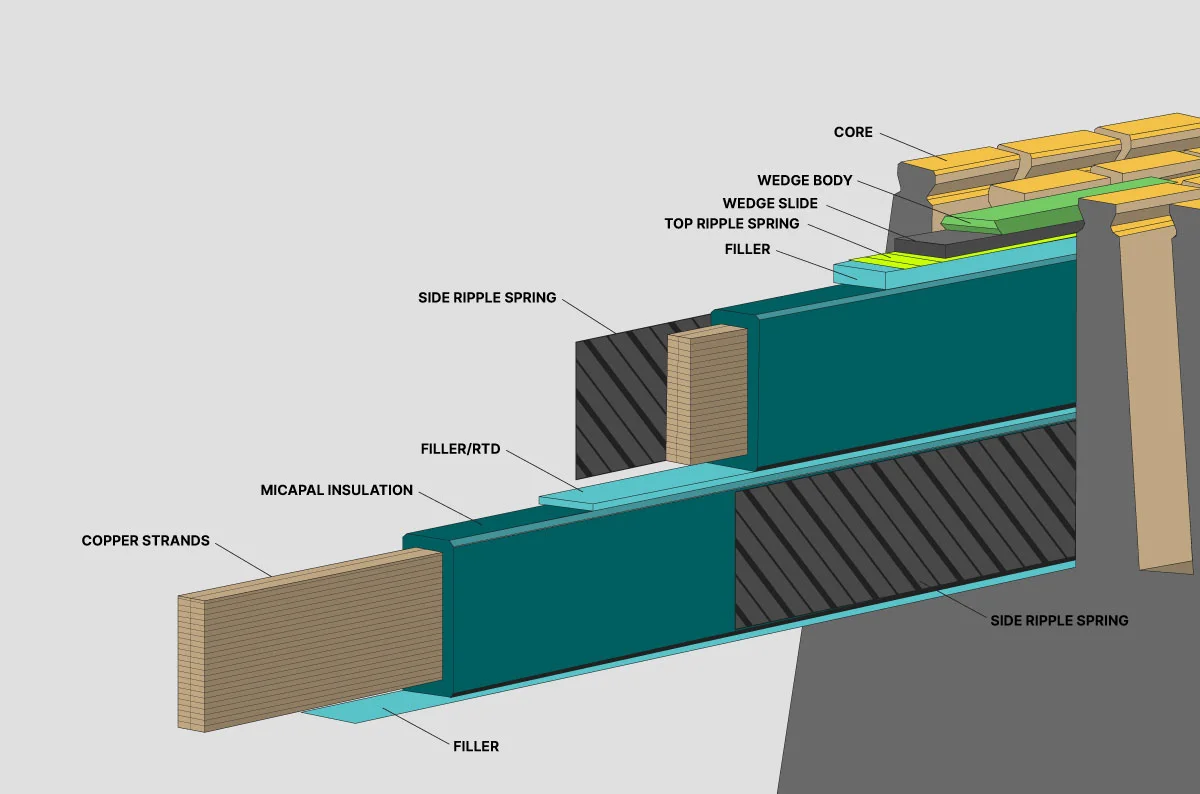

GE Vernova’s stator wedge shimming process for gas and steam turbine generator rotors offers a fast, effective, and non-invasive solution to address loose stator wedges in generators. By minimizing downtime and extending equipment life, this service helps customers maintain high performance and reliability while reducing maintenance costs.