Soo Shing Tan had removed her hard hat and was leaving the Sultan Ibrahim (Track 4A) Power Plant in Pasir Gudang, in Johor, Malaysia, in the spring of 2024 when she realized something that made her smile. Tan is tooling director for the Asia region at One Field Services (OFS), part of GE Vernova’s Gas Power business.

GE Vernova completes acquisition of gas turbine combustion parts business from Woodward, Inc.

-

Acquisition supports crucial supply chain capacity during time of unprecedented growth

GREENVILLE, S.C. (March 3, 2025) – GE Vernova, Inc. (NYSE: GEV) announced today that it has completed its acquisition of Woodward, Inc.’s heavy duty gas turbine combustion parts business based in Greenville, S.C. This acquisition plays an important role in GE Vernova's strategy to invest in U.S. manufacturing and employment, while also strengthening its domestic supply chain.

“The completion of this acquisition adds resilience to our supply chain, aiming to deliver greater value to our customers and the energy sector,” said Eric Gray, President & CEO, GE Vernova’s Gas Power business. “I’m excited to now officially welcome these experts to the GE Vernova team and integrate them into our business.”

Combustion parts like those manufactured by these experts play an integral role in GE Vernova’s industry-leading gas turbines, supporting customers’ ability to meet growing energy demands from load growth, data centers and other areas.

The close of this acquisition is in addition to the Company’s previously announced plans to invest more than $160 million and hire more than 650 new employees at its Greenville facility which has had a strong presence in South Carolina for more than 50 years.

The team will be led by Shane Long, Global Supply Chain Leader, GE Vernova’s Gas Power business. GE Vernova acquired all assets related to Woodward, Inc.’s Greenville site, and the financial terms of the acquisition are not being disclosed.

end

GE Vernova’s Gas Power business engineers advanced, efficient natural gas-powered technologies and services, along with decarbonization solutions that aim to help electrify a lower carbon future. It is a global leader in gas turbines and power plant technologies and services with the industry’s largest installed base.

Forward-Looking Statements

This document contains forward-looking statements – that is, statements related to future events that by their nature address matters that are, to different degrees, uncertain. These forward-looking statements often address GE Vernova’s expected future business and financial performance and financial condition, and the expected performance of its products, the impact of its services and the results they may generate or produce, and often contain words such as “expect,” “anticipate,” “intend,” “plan,” “believe,” “seek,” “see,” “will,” “would,” “estimate,” “forecast,” “target,” “preliminary,” or “range.” Forward-looking statements by their nature address matters that are, to different degrees, uncertain, such as statements about planned and potential transactions, investments or projects and their expected results and the impacts of macroeconomic and market conditions and volatility on the Company’s business operations, financial results and financial position and on the global supply chain and world economy.

© 2025 GE Vernova and/or its affiliates. All rights reserved.

GE and the GE Monogram are trademarks of General Electric Company used under trademark license.

Press Resources

Investor inquiries

Media inquiries

NRG Energy, GE Vernova and Kiewit accelerating new generation capacity to support demand growth

HOUSTON (February 26, 2025) - NRG today joined GE Vernova and TIC, a subsidiary of Kiewit, in announcing a new venture aimed at rapidly bringing new electricity generation capacity to market in response to growing demand for computing power and generative AI (GenAI).

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20250225753165/en/

end

GE Vernova’s Gas Power business engineers advanced, efficient natural gas-powered technologies and services, along with decarbonization solutions that aim to help electrify a lower carbon future. It is a global leader in gas turbines and power plant technologies and services with the industry’s largest installed base.

Forward-Looking Statements

This document contains forward-looking statements – that is, statements related to future events that by their nature address matters that are, to different degrees, uncertain. These forward-looking statements often address GE Vernova’s expected future business and financial performance and financial condition, and the expected performance of its products, the impact of its services and the results they may generate or produce, and often contain words such as “expect,” “anticipate,” “intend,” “plan,” “believe,” “seek,” “see,” “will,” “would,” “estimate,” “forecast,” “target,” “preliminary,” or “range.” Forward-looking statements by their nature address matters that are, to different degrees, uncertain, such as statements about planned and potential transactions, investments or projects and their expected results and the impacts of macroeconomic and market conditions and volatility on the Company’s business operations, financial results and financial position and on the global supply chain and world economy.

© 2025 GE Vernova and/or its affiliates. All rights reserved.

GE and the GE Monogram are trademarks of General Electric Company used under trademark license.

Press Resources

Investor inquiries

Media inquiries

Super Creative Thinking: Meet the Plant Managers Who Engineer Success

In January, GE Vernova announced that it will invest nearly $600 million in its U.S. manufacturing facilities over the next two years to expand capacity to meet increasing energy demands — relying on an especially dynamic group of engineers: the executive site leaders steering operations at GE Vernova’s more than 115 manufacturing facilities.

What’s on Your Plate? These Brilliant, Hungry Young Engineers Are Tackling the Energy Transition

At 6 a.m. on the dot, Magnus Wamble whizzes up a spinach, kale, and carrot smoothie and spreads a gluten-free bagel with peanut butter and banana. Wamble, a Schenectady, New York–based new unit gas turbine project engineer at GE Vernova, washes the superfoods down with L-theanine and vitamin B supplements and a single shot of caffeine.

GE Vernova announces first commercial operation of its LM6000VELOX* package at Dominion Energy’s Bushy Park facility in South Carolina

-

Dominion Energy South Carolina’s Bushy Park Combustion Turbine facility is home to GE Vernova’s first LM6000VELOX* package in commercial operation globally

-

Advanced aeroderivative solution replaced older generation peaking units to help enable a more reliable, flexible, and efficient power supply

-

LM6000VELOX, including an LM6000* aeroderivative gas turbine and a generator, is factory assembled into simplified modules for a faster and easier site installation and commissioning

ATLANTA, GA (February 13, 2025) – GE Vernova Inc. (NYSE: GEV) announced today Dominion Energy’s Bushy Park Combustion Turbine (Bushy Park CT) facility achieved the start of commercial operation in Berkeley County, South Carolina, USA on November 1, 2024. The 52 megawatt** (MW) Bushy Park CT #1, powered by a GE Vernova LM6000VELOX* package solution including an LM6000* gas turbine and generator, marked the first LM6000VELOX package plant solution in operation globally.

GE Vernova introduced the LM6000VELOX package in 2023 aiming to reduce the installation and commissioning schedule of LM6000 aeroderivative gas turbines by up to 40%, thereby reducing installation time and costs. The enhancements incorporated in the new package aim to also reduce site construction delays for power generation utilities, EPCs, and other industry stakeholders.

The new LM6000VELOX, along with two other units ordered for Dominion Energy’s Parr facility in Fairfield County, South Carolina that are currently under construction, replaced older peaking generation units which help the company meet demands during peak energy usage. In addition to supporting peak usage periods, these fully dispatchable units complement solar generation on days when sunshine is limited or intermittent throughout the day. The Bushy Park and future Parr units incorporate an array of operational flexibility capabilities including dual-fuel capabilities, fast-starting, synchronous condensing, and black start. GE Vernova’s scope of supply included selective catalytic reduction and oxidation catalyst systems, which coupled with dry low exhaust combustion, enable best-in-class air emissions performance without the need for water injection.

“Achieving commercial operation of the Bushy Park project demonstrates our continued commitment to providing safe, reliable, affordable, and increasingly clean energy in the communities we serve,” said Keller Kissam, President of Dominion Energy South Carolina. “Investments in flexible, efficient units are critical to meet growing loads in one of the fastest growing states in the country and complement the large amounts of intermittent solar on our grid.”

“This project marks the first time this solution is in operation globally and we are delighted to celebrate this milestone with Dominion Energy“ said Dave Ross, President and CEO for GE Vernova's Gas Power business in the Americas. “This aeroderivative solution can provide dispatchable and lower carbon-emitting power compared to older units, and also important black-start capability necessary for restoring power after a blackout.”

GE Vernova is a leading supplier to Dominion Energy, which contributes to meeting the electricity needs of approximately 3.6 million customers in Virginia, South Carolina and North Carolina.

With over 40 million operating hours and more than 1,300 units shipped, the LM6000 aeroderivative gas turbine is a leader in the +40 MW space. In addition to the two LM6000VELOX packages currently being installed at Dominion Energy’s Parr facility, there are ten LM6000VELOX packages being installed at Tennessee Valley Authority’s Johnsonville Aeroderivative Power Plant in the Middle of Tennessee with an expected start of operation in 2025. Recently, GE Vernova also announced the first LM6000VELOX packaged solution that is expected to start operation on 100 percent hydrogen at Whyalla hydrogen power plant in Australia in 2026.

###

Notes to editors

*Trademark of GE Vernova and/or its affiliates

**Rating is based on baseload with natural gas fuel at ISO conditions

Forward Looking Statements:

This document contains forward-looking statements – that is, statements related to future events that by their nature address matters that are, to different degrees, uncertain. These forward-looking statements often address GE Vernova’s expected future business and financial performance and financial condition, and the expected performance of its products, the impact of its services and the results they may generate or produce, and often contain words such as “expect,” “anticipate,” “intend,” “plan,” “believe,” “seek,” “see,” “will,” “would,” “estimate,” “forecast,” “target,” “preliminary,” or “range.” Forward-looking statements by their nature address matters that are, to different degrees, uncertain, such as statements about planned and potential transactions, investments or projects and their expected results and the impacts of macroeconomic and market conditions and volatility on the Company’s business operations, financial results and financial position and on the global supply chain and world economy.

end

GE Vernova’s Gas Power business engineers advanced, efficient natural gas-powered technologies and services, along with decarbonization solutions that aim to help electrify a lower carbon future. It is a global leader in gas turbines and power plant technologies and services with the industry’s largest installed base.

© 2025 GE Vernova and/or its affiliates. All rights reserved.

GE and the GE Monogram are trademarks of General Electric Company used under trademark license.

Press Resources

Media inquiries

No Higher Calling: Powering Türkiye’s Transition to More Sustainable Energy

In Türkiye, demand for electricity is surging. With a growing — and urbanizing — population, the country ranks 15th in the world in annual energy production, outpacing several nations with much larger populations.

GE Vernova and Iraq's Ministry of Electricity propel key projects forward

-

Modernization project for 46 GE Vernova gas turbines powering 12 power plants is expected to add over 500 megawatts (MW) to the national grid within the summer of 2025

-

GE Vernova’s Advanced Gas Path (AGP) upgrades installed at Al Mansouriya, Al-Quds and Dhiqar power plants increased their power capacity by 6 percent

-

GE Vernova also completed comprehensive maintenance projects across multiple power plants with a total capacity of 3.7 gigawatts as part of services and upgrade agreements

Baghdad, Iraq (February 5, 2025) — In a major boost to Iraq's electricity infrastructure, the Ministry of Electricity (MoE) and GE Vernova Inc. (NYSE: GEV) have announced the successful completion of upgrades at several key power plants, significantly enhancing the performance and output of existing GE Vernova generating units. The new upgrades are part of a broader effort by the Ministry to modernize the power generation infrastructure to enhance grid stability and capacity, while meeting the growing energy demand in Iraq in alignment with the country’s energy transition efforts.

The broader upgrade project regards 46 gas turbines across 12 power plants, on the way to adding up to 500 megawatts (MW) to the national grid before the summer of 2025. This modernization is expected to improve operational flexibility and boost output, efficiency, and availability of the power generation assets. Some of the power plants included in this project - Ninawa, Al Diwaniyah, Hilla, Karbala, Shat Al Basra, Najibiya, Samawa, Dhiqar, Al Khairat and Al Haidariya– already transitioned from heavy fuel oil (HFO) to natural gas, with a capacity increase of approximately 260 MW. The other plants are expected to be modernized within the summer of 2025, with an expected additional increase in capacity of approximately 250 MW.

In addition, GE Vernova announced the successful installation of its Advanced Gas Path (AGP) upgrades on several 9.E gas turbines powering Al-Quds, and Dhiqar power plants, and MXLII upgrades on 13E2 gas turbines powering Al Mansouriya power plant. The expected output increases of up to 6% for each of these power plants will enable Iraq's Ministry of Electricity (MoE) to generate more electricity using the same amount of fuel.

In addition, as part of services and upgrade agreement announced in 2024 with MoE to enhance the availability of power plants across the country, GE Vernova completed comprehensive maintenance projects across several of these power plants corresponding to a total capacity of 3.7 gigawatts, including Qayyarah, Diwaniyah, Al-Haydariyah, and Baghdad South. These initiatives aim to enhance the long-term reliability and stability of Iraq's power sector.

Eng. Ziyad Ali Fadhil, Iraq’s Minister of Electricity, said: “These diverse and comprehensive projects significantly advance our goals of expanding electricity generation and enhancing energy reliability, particularly during peak demand periods. The projects also focus on improving power plant efficiency and increasing output without increased fuel consumption, leading to less carbon emissions per amount of fuel consumed. Collaborating with reputed international companies like GE Vernova is critical to achieving the Ministry's objectives and bolstering the nation's power sector.”

Joseph Anis, President & CEO, Europe, Middle East & Africa, Gas Power at GE Vernova, said: "We are proud of this ongoing collaboration to support the Ministry of Electricity’s strategic objectives of enhancing power generation efficiency across Iraq and accelerating the nation’s energy transition efforts. The timely completion of these projects is integral to GE Vernova's commitment to modernize Iraq's energy infrastructure and support the delivery of more efficient and more sustainable energy solutions.”

In October 2024, GE Vernova announced the early completion and commissioning of five critical 132-kilovolt substations across Iraq. Additionally, a sixth substation, Al Rasafa Center, was successfully energized on November 18, 2024, more than two months ahead of schedule.

In April 2024, GE Vernova also signed a Memorandum of Understanding (MoU) with the Iraqi government in Washington, D.C., during the visit of the Iraqi Prime Minister Mohammed Shia’ Al-Sudani to the United States. The MoU was signed under the patronage and in the presence of Prime Minister Al-Sudani, Deputy Prime Minister for Energy Affairs and Minister of Oil Hayan Abdul Ghani Al-Swad, and Roger Martella, Chief Corporate Officer, Chief Sustainability Officer, and Head of Government Affairs at GE Vernova.

Over the past decade, GE Vernova has significantly contributed to the development of Iraq's energy infrastructure, adding up to 19,000 megawatts of power to the national grid. The company has also constructed 30 substations and completed the first phase of the crucial electricity grid interconnection with Jordan. In addition, GE Vernova has facilitated access to over USD 3 billion in financing for energy projects in Iraq and remains committed to empowering local talent development and workforce training programs.

-ENDS

Forward Looking Statements:

This document contains forward-looking statements – that is, statements related to future events that by their nature address matters that are, to different degrees, uncertain. These forward-looking statements often address GE Vernova’s expected future business and financial performance and financial condition, and the expected performance of its products, the impact of its services and the results they may generate or produce, and often contain words such as “expect,” “anticipate,” “intend,” “plan,” “believe,” “seek,” “see,” “will,” “would,” “estimate,” “forecast,” “target,” “preliminary,” or “range.” Forward-looking statements by their nature address matters that are, to different degrees, uncertain, such as statements about planned and potential transactions, investments or projects and their expected results and the impacts of macroeconomic and market conditions and volatility on the Company’s business operations, financial results and financial position and on the global supply chain and world economy.

end

GE Vernova’s Gas Power business engineers advanced, efficient natural gas-powered technologies and services, along with decarbonization solutions that aim to help electrify a lower carbon future. It is a global leader in gas turbines and power plant technologies and services with the industry’s largest installed base.

© 2025 GE Vernova and/or its affiliates. All rights reserved.

GE and the GE Monogram are trademarks of General Electric Company used under trademark license.

Press Resources

GE Vernova's Services team at Ninawa Power Plant with the Live Outage kit

Image credit: GE Vernova

GE Vernova's Services team at Ninawa Power Plant, Iraq

Image credit: GE Vernova

Media inquiries

GE Vernova’s nuclear business accelerates UK Small Modular Reactor deployment with MoUs

LONDON, UK (February 4, 2025) - GE Vernova’s nuclear business, GE Hitachi Nuclear Energy (GEH), has signed another series of Memorandum of Understanding (MoUs) with two major UK nuclear engineering firms - Boccard and Cavendish Nuclear.

These MoUs signal GEH’s intent to work more closely with suppliers in the UK, leveraging their industry-leading expertise in the construction and delivery of nuclear power plants in order to advance the development and operation of GEH’s BWRX-300 Small Modular Reactor (SMR) as it continues to progress through Great British Nuclear’s (GBN) ongoing SMR selection competition. This builds on GEH’s previously announced MoU collaborations with Aecon, AtkinsRéalis, Jacobs and Laing O’Rourke.

Andy Champ, GE Hitachi UK Country Lead, said: “These MoUs with Boccard and Cavendish Nuclear strengthen our commitment to working with the UK nuclear supply chain to deliver our BWRX-300 SMR technology in the UK. We are proud to be working alongside these industry-leading companies, demonstrating our dedication to providing the UK with scalable, cost-effective clean energy solutions.

“By combining their expertise with our extensive experience working in partnership with Ontario Power Generation (OPG) on the Darlington project in Canada, we're well positioned to reliably deliver this technology for the best value for money. We look forward to continuing our work with both the supply chain and GBN to make nuclear energy a key enabler of Britain's clean energy future.”

Douglas McQueen, Managing Director, Boccard UK, said: “Boccard UK welcome the announcement regarding to the signing of this MOU with GE Vernova. Our state-of-the-art UK fully digitalised nuclear manufacturing facility in North Wales supported by our engineering and project management teams will bring exceptional levels of quality and value to the Nuclear New Build program. Our Digital Manufacturing controls delivered via our bespoke software “BocTrack ®”, will deliver a faster route to commercial market, not only SMRs, but also GW Generating stations which are pivotal to the UK’s major decarbonising program. We look forward to the ongoing collaboration with GE Vernova at this exiting time in the energy sector.”

Mick Gornall, Cavendish Nuclear Managing Director, said: “Cavendish Nuclear is delighted to continue to deepen our relationship with GEH; building on our current manufacturing studies to underpin credible UK supply chain options for the Reactor Pressure Vessel and other key components.”

The MoU with Cavendish Nuclear, a wholly-owned subsidiary of Babcock International, will build upon work on advanced manufacturing and operational readiness being delivered under the UK Government’s Future Nuclear Enabling Fund while also building on the existing relationship GEH has with Cavendish Nuclear in support of the regulatory approval of the BWRX-300 through the Generic Design Assessment (GDA) process.

GEH and OPG are developing the first BWRX-300 at OPG’s Darlington site near Toronto which is anticipated to be the first commercial SMR in the G7. Early site preparation work has been completed, with construction of the first unit expected to start later this year, pending regulatory approval, and commercial operation expected to commence by the end of 2029. A total of four 300 MW units are planned for the Darlington site.

Building on a long and deep history in the UK, GE Vernova has a significant local footprint with four manufacturing facilities and more than 30 percent of the country’s electricity currently powered by its technology. GEH is committed to developing a robust UK supply chain for its BWRX-300 deployment having held a SMR supply chain conference in Sheffield in April 2024, which was attended by over 150 UK businesses.

Separately, in January 2024 GEH received a £33.6 million Future Nuclear Enabling Fund (FNEF) grant from the UK Department for Energy Security & Net Zero (DESNZ). In conjunction with the awarding of this grant, GEH entered the Generic Design Assessment (GDA) process for the BWRX-300.

###

About GE Vernova

GE Vernova (NYSE: GEV) is purpose-built global energy company that includes Power, Wind, and Electrification segments and is supported by its accelerator businesses. Building on over 130 years of experience tackling the world’s challenges, GE Vernova is uniquely positioned to help lead the energy transition by continuing to electrify the world while simultaneously working to decarbonize it. GE Vernova helps customers power economies and deliver electricity that is vital to health, safety, security, and improved quality of life. GE Vernova is headquartered in Cambridge, Massachusetts, U.S., with approximately 75,000 employees across 100+ countries around the world. Supported by the Company’s purpose, The Energy to Change the World, GE Vernova technology helps deliver a more affordable, reliable, sustainable, and secure energy future.

GE Vernova’s Nuclear energy business, through its global alliance with Hitachi, is a world-leading provider of nuclear fuel bundles, services, and advanced nuclear reactor designs. Technologies include boiling water reactors and small modular reactors, such as the BWRX-300, which is one of the simplest, yet most innovative boiling water reactor designs. GE Vernova’s Nuclear fuel business, Global Nuclear Fuel (GNF), is a world-leading supplier of boiling water reactor fuel and fuel-related engineering services. GNF is a GE Vernova-led joint venture with Hitachi, Ltd. and operates primarily through Global Nuclear Fuel-Americas, LLC in Wilmington, N.C., and Global Nuclear Fuel-Japan Co., Ltd. in Kurihama, Japan.

GE Vernova’s mission is embedded in its name – it retains its legacy, “GE,” as an enduring and hard-earned badge of quality and ingenuity. “Ver” / “verde” signal Earth’s verdant and lush ecosystems. “Nova,” from the Latin “novus,” nods to a new, innovative era of lower carbon energy. Learn more: GE Vernova and LinkedIn.

Forward-Looking Statements

This document contains forward-looking statements – that is, statements related to future events that by their nature address matters that are, to different degrees, uncertain. These forward-looking statements often address GE Vernova’s expected future business and financial performance and financial condition, and the expected performance of its products, the impact of its services and the results they may generate or produce, and often contain words such as “expect,” “anticipate,” “intend,” “plan,” “believe,” “seek,” “see,” “will,” “would,” “estimate,” “forecast,” “target,” “preliminary,” or “range.” Forward-looking statements by their nature address matters that are, to different degrees, uncertain, such as statements about memoranda of understanding and the expected impact of the relationships created thereunder, contract and project proposals, bidding processes, government review processes and competitions, investments or projects and their expected results and the impacts of macroeconomic and market conditions and volatility on the Company’s business operations, financial results and financial position and on the global supply chain and world economy.

end

© 2025 GE Vernova and/or its affiliates. All rights reserved.

GE and the GE Monogram are trademarks of General Electric Company used under trademark license.

Press Resources

Media inquiries

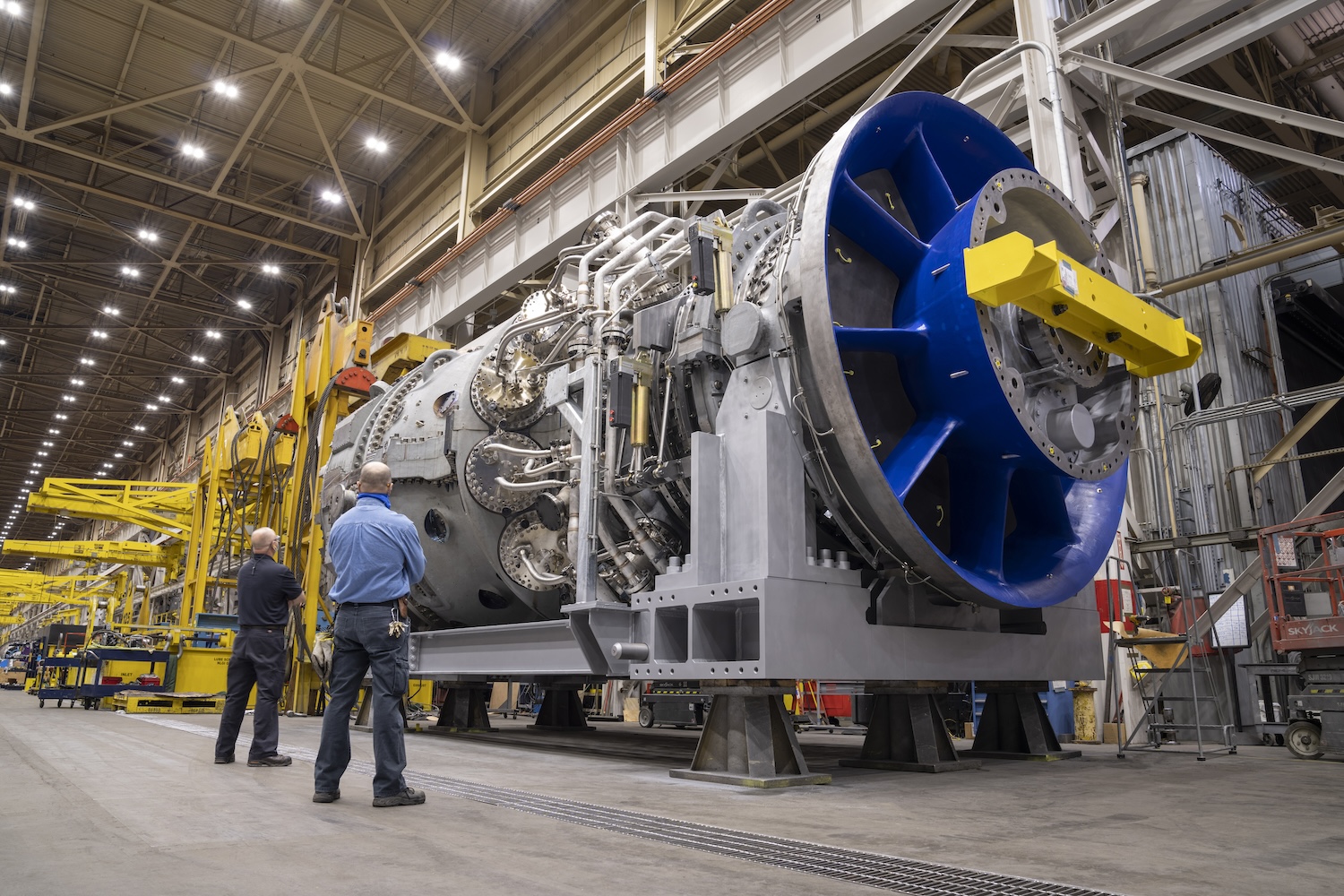

GE Vernova announces more than $160 million investment in Greenville facility

-

America’s leading energy manufacturer expected to create more than 650 new factory and engineering jobs in the Upstate

-

Expansion at company’s Greenville factory will help meet surging customer demand for electricity equipment at home and abroad

-

Investments to support capacity growth, quality, industrialization and delivery efforts, and new testing capabilities with hydrogen fuel

GREENVILLE, SC (January 29, 2025) – With global energy needs forecasted to double, GE Vernova Inc. (NYSE:GEV), America’s leading energy manufacturing company, announced plans today to invest more than $160 million and hire more than 650 new employees at its Greenville facility.

The substantial investments – the largest since the company’s spinoff in April – will help meet soaring customer demand, strengthen domestic supply chains, and continue developing cutting-edge American technology that helps power the world. The investments will also help enable U.S. energy affordability, security, resilience, and competitiveness while enabling the American manufacturing footprint to support global exports.

“These investments will have a significant impact on the Upstate today and for years to come,” said Shane Long, Supply Chain Leader, GE Vernova’s Gas Power business. “Beyond the immediate jobs additions and capacity expansion, this investment will allow Greenville to maintain and strengthen its position as the world’s center of gas turbine manufacturing.”

The investments in Greenville are part of a larger nearly $600 million planned investment across the U.S. the company announced earlier today and are the first part of a larger $9 billion cumulative global capital and R&D investment plan through 2028 across the company’s facilities in the U.S.

Currently GE Vernova has more than 2,500 workers in the state. This includes manufacturing, engineering and many other specialties. The factory has produced gas turbines for markets across the U.S. and globally since 1968.

Last year, Scott Strazik, CEO of GE Vernova, announced plans to increase global capacity of heavy duty gas turbines more than 25% to meet robust demand. Today’s announcement is in addition to the $35 million the company invested in the facility last year.

For those interested in pursuing opportunities with GE Vernova in the Greenville area, we have developed a Web site with information on the application process: https://careers.gevernova.com/greenville.

###

About GE Vernova

GE Vernova is a purpose-built global energy company that includes Power, Wind, and Electrification segments and is supported by its accelerator businesses. Building on over 130 years of experience tackling the world’s challenges, GE Vernova is uniquely positioned to help lead the energy transition by continuing to electrify the world while simultaneously working to decarbonize it. GE Vernova helps customers power economies and deliver electricity that is vital to health, safety, security, and improved quality of life. GE Vernova is headquartered in Cambridge, Massachusetts, U.S., with approximately 75,000 employees across 100+ countries around the world.

GE Vernova’s mission is embedded in its name – it retains its legacy, “GE,” as an enduring and hard-earned badge of quality and ingenuity. “Ver” / “verde” signal Earth’s verdant and lush ecosystems. “Nova,” from the Latin “novus,” nods to a new, innovative era of lower carbon energy. Supported by the Company purpose, The Energy to Change the World, GE Vernova will help deliver a more affordable, reliable, sustainable, and secure energy future. Learn more: GE Vernova’s website and LinkedIn.

Forward-Looking Statements

This document contains forward-looking statements – that is, statements related to future events that by their nature address matters that are, to different degrees, uncertain. These forward-looking statements often address GE Vernova’s expected future business and financial performance and financial condition, and the expected performance of its products, the impact of its services and the results they may generate or produce, and often contain words such as “expect,” “anticipate,” “intend,” “plan,” “believe,” “seek,” “see,” “will,” “would,” “estimate,” “forecast,” “target,” “preliminary,” or “range.” Forward-looking statements by their nature address matters that are, to different degrees, uncertain, such as statements about memoranda of understanding and the expected impact of the relationships created thereunder, contract and project proposals, bidding processes, government review processes and competitions, investments or projects and their expected results and the impacts of macroeconomic and market conditions and volatility on the Company’s business operations, financial results and financial position and on the global supply chain and world economy.

end

© 2025 GE Vernova and/or its affiliates. All rights reserved.

GE and the GE Monogram are trademarks of General Electric Company used under trademark license.

Press Resources

Media inquiries

- Previous page

- Page 7

- Next page