Derived from aviation technology, GE Vernova’s aeroderivative portfolio features turbines that provide cheaper power, a better-quality grid, and cleaner power with lower emissions, when compared to reciprocating engines.

Proven performance

Our turbine legacy

From higher efficiency and lower costs to faster, cleaner, higher quality power generation, aeroderivative gas turbines have many advantages over reciprocating engines.

50 years and counting

The aero advantage over reciprocating engines

GE Vernova has been in the aeroderivatives business for 50 years, with more than 150 million operating hours and more than 3,000 units in operation.

Aeroderivative turbines can be installed quickly—in as little as a few weeks—to help alleviate frequent outages, making them especially well-suited for utility and industrial applications.

Measure the difference

Aeroderivatives vs. reciprocating engines

The perks of aeroderivative turbines compared to reciprocating engines are many. Here are just a few that independent power providers like you can benefit from.

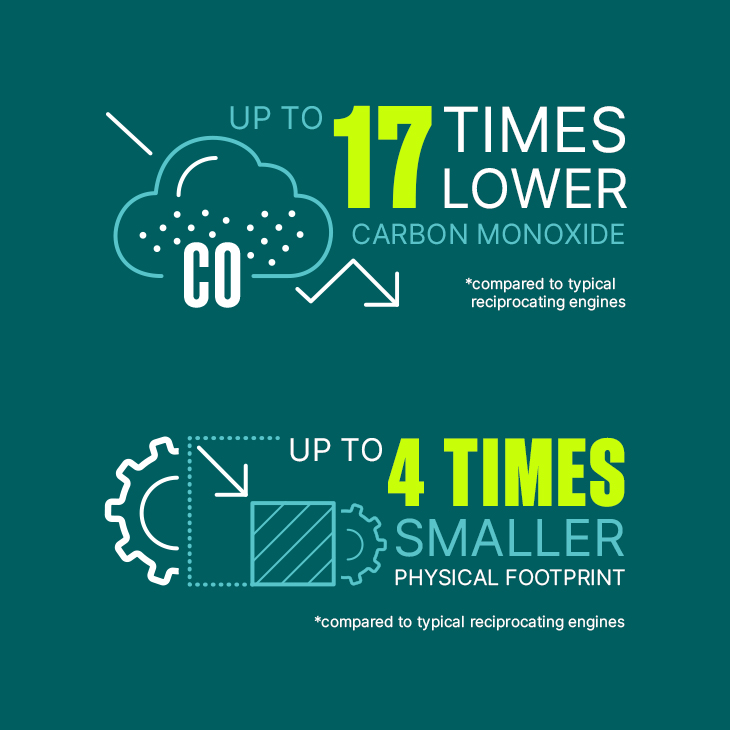

Environmental friendliness: Low emissions help with footprint reduction along your decarbonization journey.

Fast installation: Small and modular, they can be installed in as little as three months—and take up less floor space.

Fast response rate: They accept loads quickly with the ability to split or share them, yet still maintain fuel efficiency.

Diverse fuel options: Being able to switch between natural gas, LPG, isopentane, ethanol, diesel, and more significantly reduces OpEx.

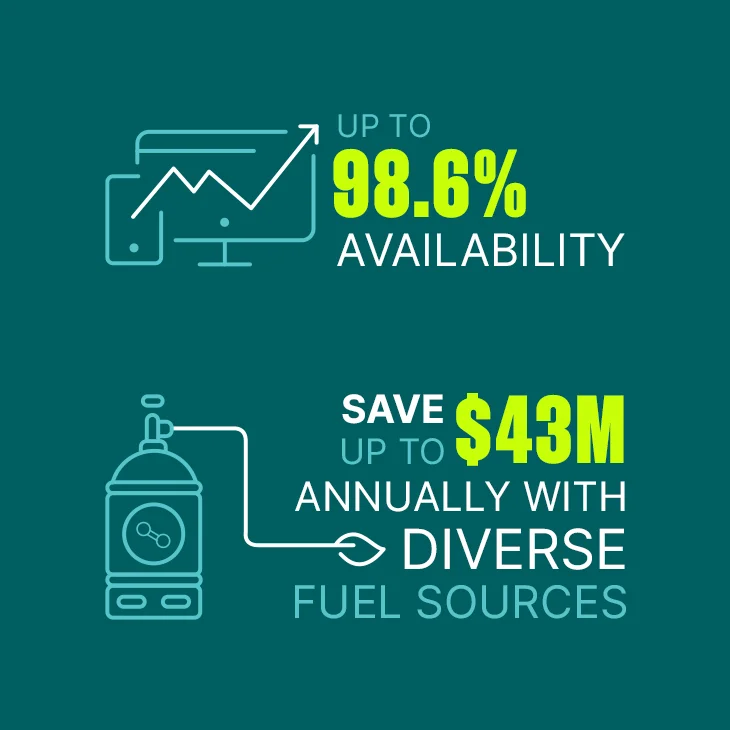

High availability: With the highest availability of any thermal power technology, you’ll see 98+%, where reciprocating engines average 93%.

Less maintenance: They require no offline maintenance in the first 10 years for peaking applications.

Start-up efficacy: They have faster start-up times with little or no cyclic life penalty and a modular construction.

Easy mobilization: They’re “footprint friendly” for quicker installment, removal, replacement, and reallocation.

Operational flexibility: They accept loads faster with the ability to split or share them, yet still maintain fuel efficiency.

Lightweight frame: With a small energy footprint, they utilize advanced materials half the weight and take up 30% less floor space.

Annual maintenance: They require maintenance just once a year, saving some 13,000 man-hours.

Aeroderivatives vs. reciprocating: power savings

Higher efficiency leads to lower costs

Lower lube oil costs

A highly efficient aeroderivative gas turbine in combined cycle like the LM2500 consumes only about 2 mL/MWh of lube oil per year—200 times less than a reciprocating engine. That can translate to a savings of more than $1 million per year for a 100 MW aeroderivative power plant.

Less maintenance

Aeroderivative gas turbines need maintenance only once a year, or when they have been in operation for 4,000 hours. Compared to high-speed reciprocating engines—which require 50 times more maintenance events per year—aeroderivative engines save more than 13,000 man-hours over a 3-year maintenance cycle.

Gas turbines yield higher quality power

Plant availability and fuel flexibility

High availability

Aeroderivative gas turbines have the highest availability of any thermal power technology. An aeroderivative gas turbine can be replaced in a power plant, such as a utility or power plant, within a few days for a major inspection, which translates to higher availability—98.2% as compared to power generated by reciprocating engines, which average 93% availability.

Diverse fuel options

Capable of burning many different fuels, including hydrogen, aeroderivative gas turbines can allow power customers to switch between fuels to save money, all without stopping, and without a reduction in power. Using diverse fuel sources doesn’t just increase reliability, it also results in significant fuel savings—from $12 million up to $43 million per year—as compared to the fuel costs of a high-speed reciprocating engine.*

*Fuel savings range based on a natural gas price of $1 – 4/MMBTU and a diesel gas price of $6 – 12/MMBTU.

Gas turbines create faster power

Getting power to the grid, wherever it’s needed

Fast installation

Because they are small and modular, aeroderivative engines can be transported, installed and commissioned in as little as 3 months, as compared to 12 – 18 months for reciprocating engines. They can be installed outdoors with minimal foundation requirements, making them an advantageous energy solution for any region that needs fast, clean, reliable power.

Fast response rate

GE Vernova’s aeroderivative gas turbines feature a power turbine and high-pressure shaft that work together to respond quickly to grid frequency fluctuations, helping create a more stable and reliable grid than that of reciprocating engines.

Aeroderivatives yield cleaner power

Smaller and more stable

Lower emissions

Equipped with best-in-class combustion systems, aeroderivative gas turbines can offer 15 or 25 ppm NOx without needing SCRs (selective catalytic reduction) or the use of ammonia.

Enabling renewables

Aeroderivative gas turbines allow renewables to operate when needed, saving fuel and maintenance—and maintaining a stable grid to allow the integration of more renewables in the future.

Smaller footprint

Because they have about 22 times more power output per unit than comparable high-speed diesel reciprocating engines, GE Vernova’s aeroderivative gas power plants take up less space—a real advantage where real estate is expensive. *

*Comparison based on a 3x1 cc LM2500 and a 115 MW reciprocating plant

Crunch the numbers

Methane slip calculator

Did you know that reciprocating gas engines can release unburned methane at a rate that’s almost 150 times that of a gas turbine? This is known as “methane slip”, and it’s something you should know about. Our new calculator can help you determine your plant’s potential greenhouse gas savings and reduction in NOx and particulate matter.

Featured video

See aeroderivative gas turbines in action

Curious to learn more about how aeros compare to reciprocating engines? Check out our video to see them go head-to-head.

Contact us