The technology

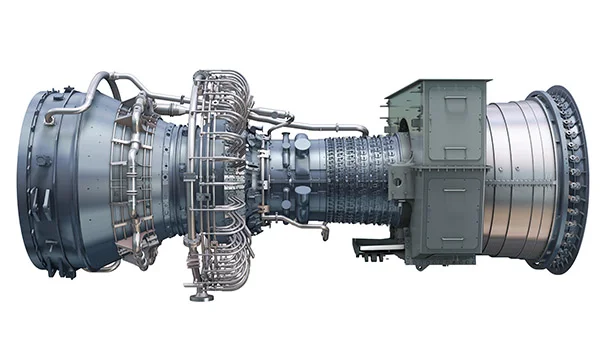

GE Vernova has introduced the first LM6000VELOX DLE aeroderivative gas turbine package, slated to be installed at Tennessee Valley Authority's (TVA) Johnsonville Aeroderivative Plant in Middle Tennessee.

The advantage

The new LM6000VELOX package aims to reduce the installation and commissioning schedule of LM6000 aeroderivative gas turbines by up to 40%, while reducing installation time and total installed costs. TVA chose the DLE option of the LM6000VELOX package solution for its dual fuel capability, high cyclic life and fast start time.