Insights

Understand the lifecycle of your control system platform, identify risks, and plan mitigations.

Readiness

Prepare your spare parts inventory to cover critical control system components and address immediate parts needs.

Planning

Build a roadmap for both hardware upgrades and software maintenance—to proactively manage lifecycles, stay secure, and be compliant with cybersecurity regulations.

Platform status

Why Lifecycle Reviews matter: Three key reasons

Lifecycle management

What is a Lifecycle Review?

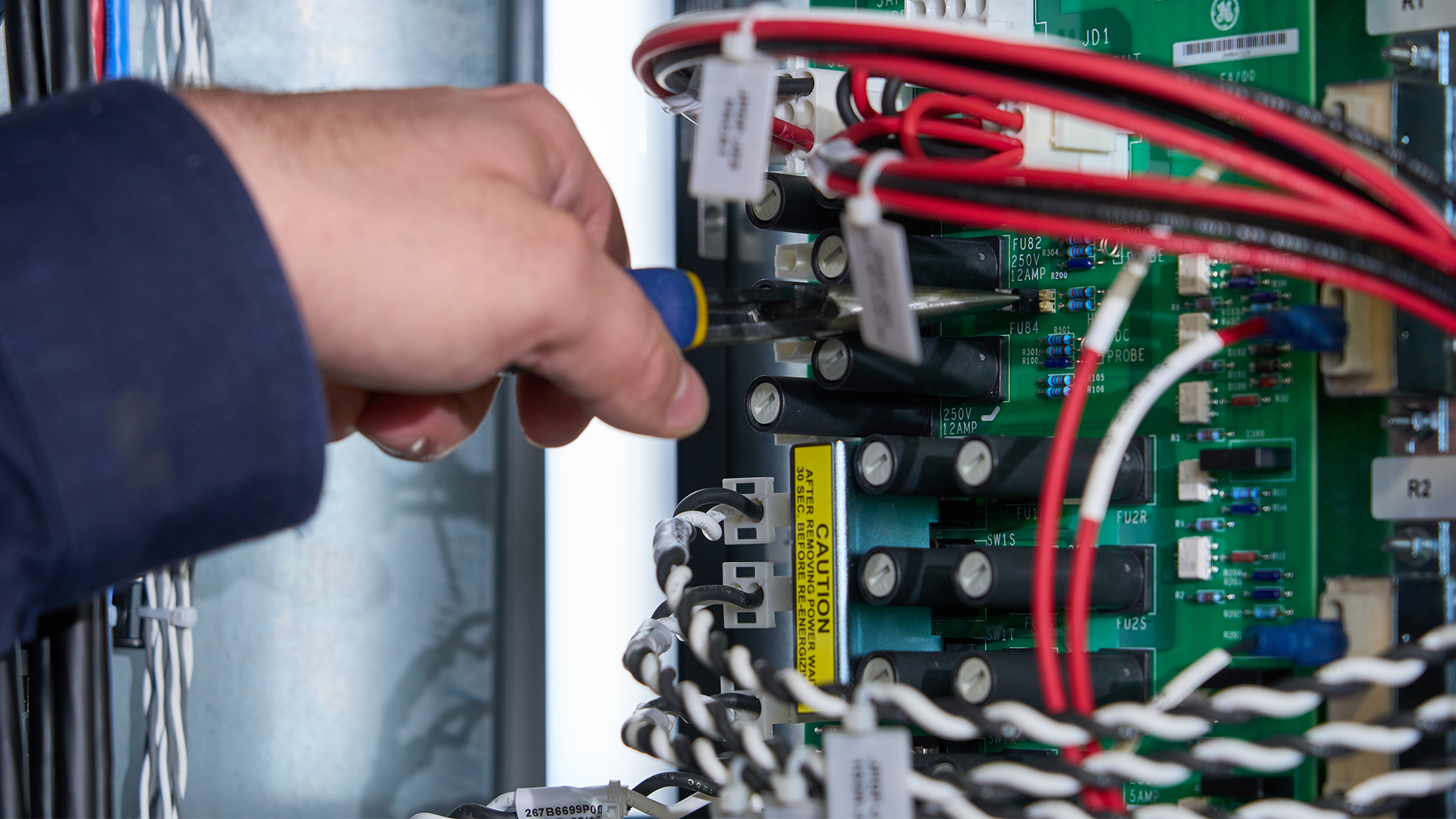

A Lifecycle Review evaluates your GE Vernova control systems, and network equipment. The resulting report post a lifecycle review provides a full breakdown of part numbers, minimum software requirements, and actionable recommendations to help ensure seamless alignment between hardware and software, including the following critical areas:

Hardware lifecycle status

Identifying components beyond their end-of-life dates to help ensure replacements and upgrades.

- Analysis of electronic hardware components inside the control cabinets to determine lifecycle status and the required replacement parts.

- Analysis of network equipment (switches, firewalls, and routers) and recommendation for upgrades as applicable.

- Recommendations for incremental spare parts based on your current inventory.

Software lifecycle status

Graphics Software (Cimplicity*), and Windows† operating system to plan for software maintenance.

- Analysis of HMIs, and OTArmor systems and recommendation for software maintenance as applicable.

Technical Information Letter (TIL)

Verifying TIL implementation status to understand gaps that could help improve your equipment reliability and reduce operational costs.

- Assessment of TILs applicable to the user site, review of current installation status, and provision of update recommendations.

Ongoing reliability

How GE Vernova supports your lifecycle management

Lifecycle Reviews are part of our broader Controls Lifecare Services (CLS) program, and provide ongoing lifecycle support tailored to your plant’s unique needs:

Videos

Mark VIe: A modular control system built to evolve

Your operations need reliability, adaptability—and longevity. The Mark VIe delivers solutions engineered to keep your plant performing for decades.

Mark VIe explained: Future-proof control system

Featuring insights from GE Vernova’s Jamie Butler and Chris Long, our latest video explores supporting a more reliable and sustainable energy future.

GE Vernova's Nexus Integration: Powering the future of controls solutions

Discover how GE Vernova is transforming control systems with the integration of Nexus Controls.

- Stay ahead of obsolescence

- Future-proof your controls systems

- Unlock operational excellence with Integrated Plant Controls

- In control: Maintaining your control system throughout its lifecycle

On-demand webinar

Stay ahead of obsolescence: Lifecycle Reviews for the Mark* VIe

Lifecycle Reviews can help you plan for obsolescence and maintenance, providing crucial insights for your strategy. Join our expert discussion to discover how modular upgrades can extend the service life of your Mark VIe, keeping it secure and efficient for the future.

Carla Lewis

Global Marketing Leader, GE Vernova

Brad Shochat

Global Aftermarket Parts Leader, GE Vernova

Brad Belina

Controls Lifecare Services Leader, GE Vernova

Thaha Nazeemudeen

Senior Product Manager Controls Services, GE Vernova

On-demand webinar

Future-proof your controls systems: Long-term Controls Lifecare agreements

Discover how you can address the challenges of both aging hardware and cybersecurity threats by proactively maintaining your controls systems with long-term Controls Lifecare agreements. Join our experts to learn more!

Thaha Nazeemudeen

Controls Lifecare Product Manager, GE Vernova

Marija Radicevic

Multi-year Agreement Senior Commercial Excellence Manager, GE Vernova

Ramesh Pai

Senior Product Development Engineer, GE Vernova

Matt Leipnik

Senior Industrial Cybersecurity Specialist, GE Vernova

On-demand webinar

Unlock operational excellence with Integrated Plant Controls

Discover the benefits of Integrated Plant Controls for your operations. These systems offer a unified control solution spanning your entire plant, encompassing power train equipment, electrical and mechanical distribution, processes, and BOP.

Nathaniel Martin

Senior Product Manager, GE Vernova

Gautam Chatterji

Plant Controls Customer Solution Architect, GE Vernova

Hiro Hardwani

EMEA Growth Leader, GE Vernova

On-demand webinar

In control: Maintaining your control system throughout its lifecycle

While every facet of your plant is crucial and needs to work seamlessly, one area that’s particularly vital is your turbomachinery control system. That’s why strategies for extended life, business continuity, and cybersecurity compliance of your controls are important.

Brad Shochat

Global Aftermarket Parts Leader, GE Vernova

Thaha Nazeemudeen

Senior Product Manager Controls Service Solutions, GE Vernova

Frequently asked questions

Which technologies are covered by GE Vernova's Lifecycle Review reports?

GE Vernova's lifecycle review reports cover Mark VIe, EX2100e, LS2100e, GE Vernova-provided HMIs, network switches, routers, and OTArmor cybersecurity systems. Lifecycle Reviews are also available for legacy Mark control systems but are limited to electronic control components only.

The reports do not include power conversion components, consumables, or third-party components such as power supplies and miscellaneous hardware.

What customer site data is required to conduct a Lifecycle Review?

To perform a Lifecycle Review, GE Vernova requires the following information:

- A copy of the as running software archive,e.g., site TCW file (if as running software is not available, then the analysis will be based on the latest GE Vernova records available).

- A copy of the as running network topology drawing (4108).

- The existing versions of ControlST and Cimplicity.

- Pictures of the nameplates of all Mark VIe, EX2100e and LS2100e panels.

- Current site inventory for all Mark VIe, EX2100e and LS2100e systems (if not available, analysis will provide a list of recommended spare parts as applicable).

- HMI/OTArmor workstation/server model number and operating system version (if not available, analysis will be based on the latest As-Shipped configurations available).

- Network switch model number (if not available, analysis will be based on the latest as As-shipped configurations available).

Please note that this analysis pertains to the shipped configuration, either as a new or upgraded system. If there are any changes made afterwards, the customer would need to supply updated drawings as follows:

- Layout drawing.

- Part number changes from as shipped configuration.

How can customers request a Lifecycle Review assessment?

Customers interested in scheduling a Lifecycle Review can contact their GE Vernova sales representative, reach out to the Parts Team at controlparts@gevernova.com, or connect with us via Controls Connect at controlsconnect@gevernova.com. Our team will guide you through the process and help tailor the assessment to your specific needs.

How do Lifecycle Review reports help identify system risks, help manage end-of-life support hardware, end of development software, as well as support inventory planning?

GE Vernova’s Lifecycle Review reports provide detailed insights into the status of installed hardware, software, and verification of Technical Information Letter (TIL) implementation status. They help customers uncover hidden risks such as outdated software that can impact system security status, system compatibility, and identify critical end-of-life and end-of-development dates for hardware and software.

These reports also include customized recommendations for onsite spare parts stocking levels. When customers share their inventory data, GE Vernova can identify gaps and suggest optimizations. Additionally, the vendor-managed inventory program, PartSmart, provides access to a large stock of new parts in Colorado, USA, aiming to ensure critical components are available when needed.

By addressing obsolescence and lifecycle risks early, Lifecycle Reviews help customers maintain secure, up-to-date, and more reliable operations.

Once a Lifecycle Review is completed, what actions should customers take based on the findings?

Actions depend on your report’s findings and your lifecycle strategy. We recommend contacting a GE Vernova representative, our Parts Team at controlparts@gevernova.com, or connect with us via Controls Connect at controlsconnect@gevernova.com.

We’re here to help you evaluate your report and build the right support plan.

How are Controls Lifecare Services (CLS) directly connected to the outcomes of Lifecycle Reviews?

To support implementation, GE Vernova offers Controls Lifecare Services (CLS) that are closely aligned with the outcomes of Lifecycle Reviews. CLS aims to help customers to manage their systems by providing parts coverage, hardware and software maintenance recommendations, including network switches firmware.

Available as long-term controls focused service agreements, CLS service packages allows customers to get a comprehensive lifecycle management plan based on their plant’s specific requirements, operational goals, and available resources—including the implementation of Lifecycle Reviews findings.

Customers are encouraged to contact a GE Vernova representative to help them evaluate the recommendations and implement a support plan that meets their needs.

Why choose GE Vernova?

With decades of experience in industrial control systems, GE Vernova can deliver unparalleled lifecycle management support throughout the lifecycle of your power plant.

We are committed to help you ensure that your Mark VIe control system continues to meet your operational goals, as industry demands evolve.

Contact us

Get started with a Lifecycle Review

Are you ready to enhance the performance and longevity of your Mark VIe control system? Schedule a Lifecycle Review with GE Vernova today and take the first step toward proactive, efficient controls platform lifecycle management.

*Trademark of GE Vernova and/or its affiliates.

†Trademark of Microsoft