Gas generator stator rewinds

GE Vernova offers a portfolio of stator rewind solutions engineered to help extend asset life, improve availability, and manage outage duration across a wide range of legacy GE Vernova generators.

Benefits

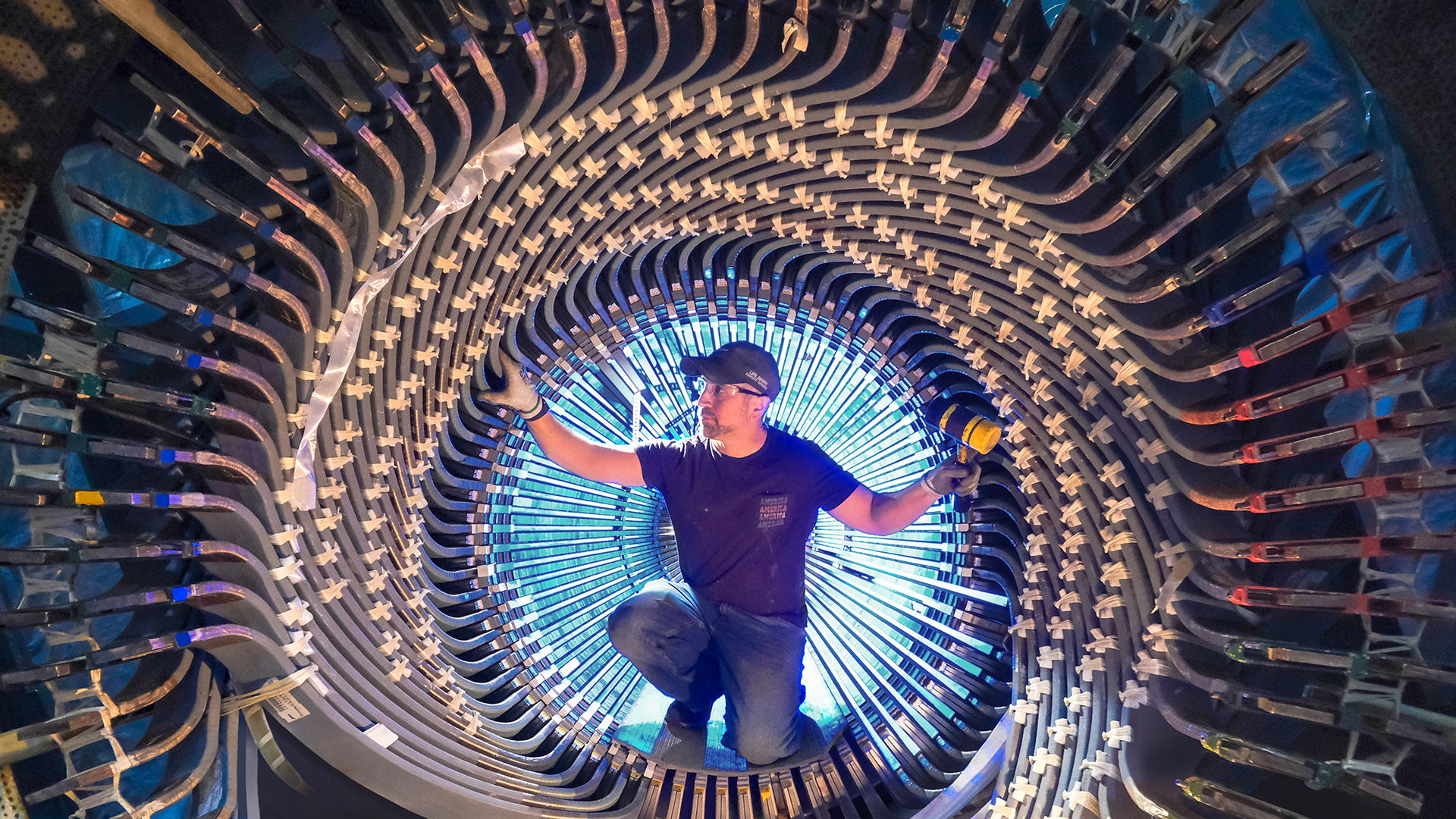

Gas turbine generators face intense thermal demands and frequent cycling that can degrade insulation, create hot spots, and accelerate component wear, increasing the likelihood of unplanned outages. Stator rewinding is a proven solution to counter these effects. GE Vernova’s stator rewinds and upgrades incorporate advanced insulation systems, improved end‑winding support, and validated manufacturing processes to extend stator life, enhance reliability, and increase output while preserving long‑term asset value.

Benefits of GE Vernova's stator solutions:

Core offering

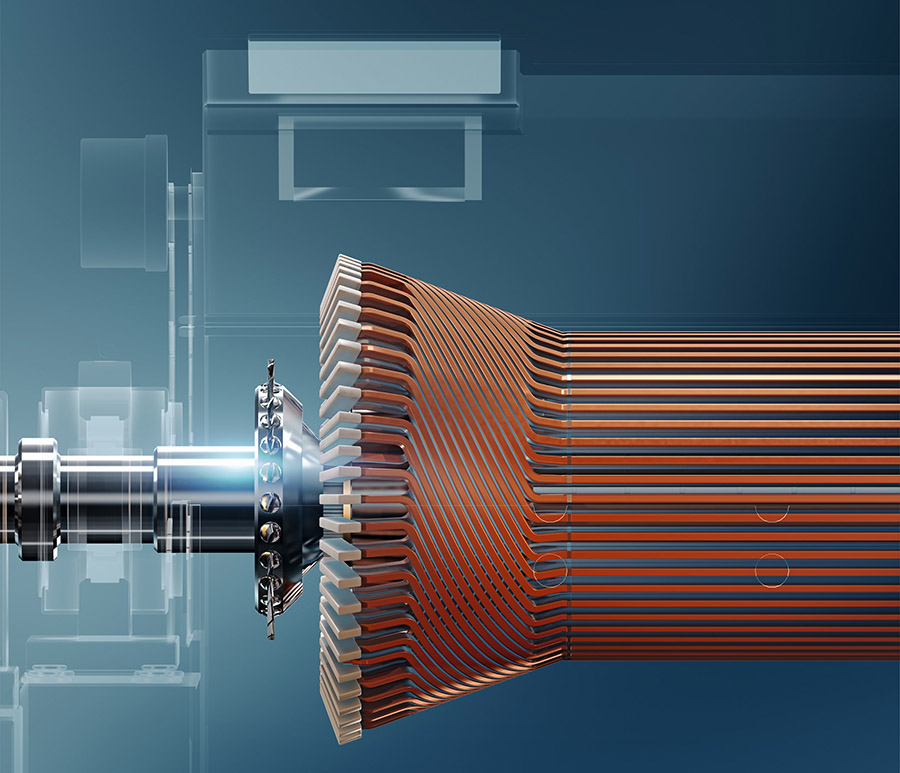

Our approach starts with a core, conventional stator rewind offering as the base scope for most legacy GE Vernova generators. It is a configurable, field-proven solution that restores the stator winding system and associated components to support long-term reliability.

While the exact scope is tailored to each unit, a typical conventional rewind service includes:

NEW STATOR BARS AND INSULATION

SLOT AND END-WINDING SUPPORT SYSTEM

CORE AND INSTRUMENTATION

CONNECTIONS AND TERMINALS

ONSITE SERVICES AND TESTING

Flex Pack

As an optional enhancement to a conventional stator rewind, GE Vernova’s Flex Pack is configured to support today’s increasingly cyclic operating profiles by reducing thermal and mechanical stresses in the stator end‑winding system. It helps lower the risk of forced outages and premature rewinds by supporting critical components to accommodate axial movement during operation.

The Flex Pack enhances flexibility and durability through:

By supporting controlled movement rather than constraint, the Flex Package improves stator resilience and reliability under cyclic duty.

A longer stator lifetime that works well for modern operating conditions.

Up to 5,000 start-stop cycles with legacy copper.

Up to 10,000 cycles with advanced copper.

Additional offerings

GE Vernova offers additional solutions for scenarios where traditional rewinds may not be appropriate. Whether you opt for fast stator rewinds or replacement stator, these flexible pathways maintain our advantage of standardization, quality, and reliability while supporting operators to match solutions to their specific needs.

Fast stator rewind (FSR) is GE Vernova’s standardized stator rewind solution for indirectly cooled generators up to 300 Megavolt-ampere (MVA). It replaces one-off rewinds with a repeatable “one technology, one process” approach, cutting typical on-site rewind activities from as long as 120 days down to about 35 days on average.

Benefits include:

When outage windows are too tight for a conventional rewind, or a rewind is not recommended due to the particularities of a unit's engineering, another effective solution is to replace the entire stator assembly. With GE Vernova, replacement stators can be manufactured in parallel with ongoing plant operations, which supports undisrupted generation and reduced downtime.

Benefits include: