OpFlex* Sliding Fuel Pressure Control

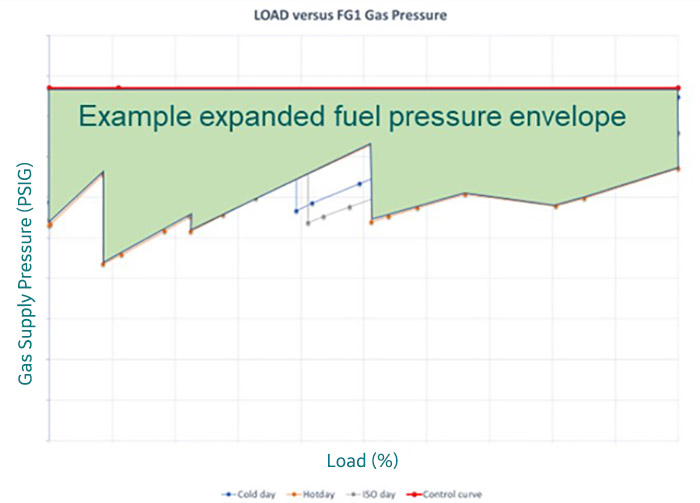

Reduce your gas fuel supply pressure requirements during start-up and operation and reduce the likelihood of trips or runbacks.

Nobody has time for trips or runbacks

Stable and reliable gas turbine operation with low emissions relies on the accurate and fast control of the fuel flow rate supplied to the combustion system. Sliding Fuel Pressure Control enables your turbine to accommodate low or fluctuating gas supply pressure, so you keep operating with confidence.

Webinar

With over 1.6 million starts across 1,350+ F-class gas turbines, GE Vernova has gained deep insight into reliability challenges. Join our webinar to learn how we can help you reduce trips and failed starts with proven solutions.

Mohamed Sayed

Customer Application Engineering, GE Vernova

Noora AlAmiri

Lead Upgrade Sales Manager for Gulf, GE Vernova

Houssem Zoghmar

Service Engineering Leader, GE Vernova

Contact us

*Trademark of GE Vernova and/or its affiliates.

**Features vary by turbine model