How did you learn about GE Vernova’s aeroderivative gas turbines?

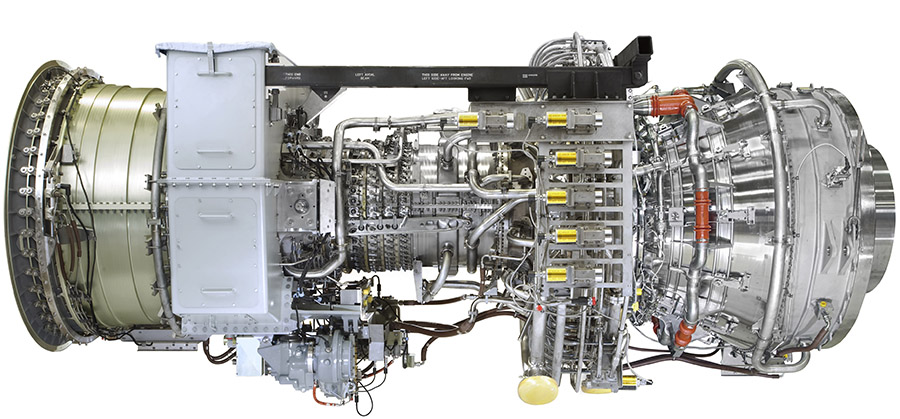

The aero business is very new for us, so we researched what technologies are on the market that are the right the size for the plant. We explored both aeros and heavy-duty gas turbines from GE Vernova and competitors, and at the end of the day, the Gas Power aero solution was the right choice for this plant.

Were you satisfied with the installation and commissioning of the gas turbines?

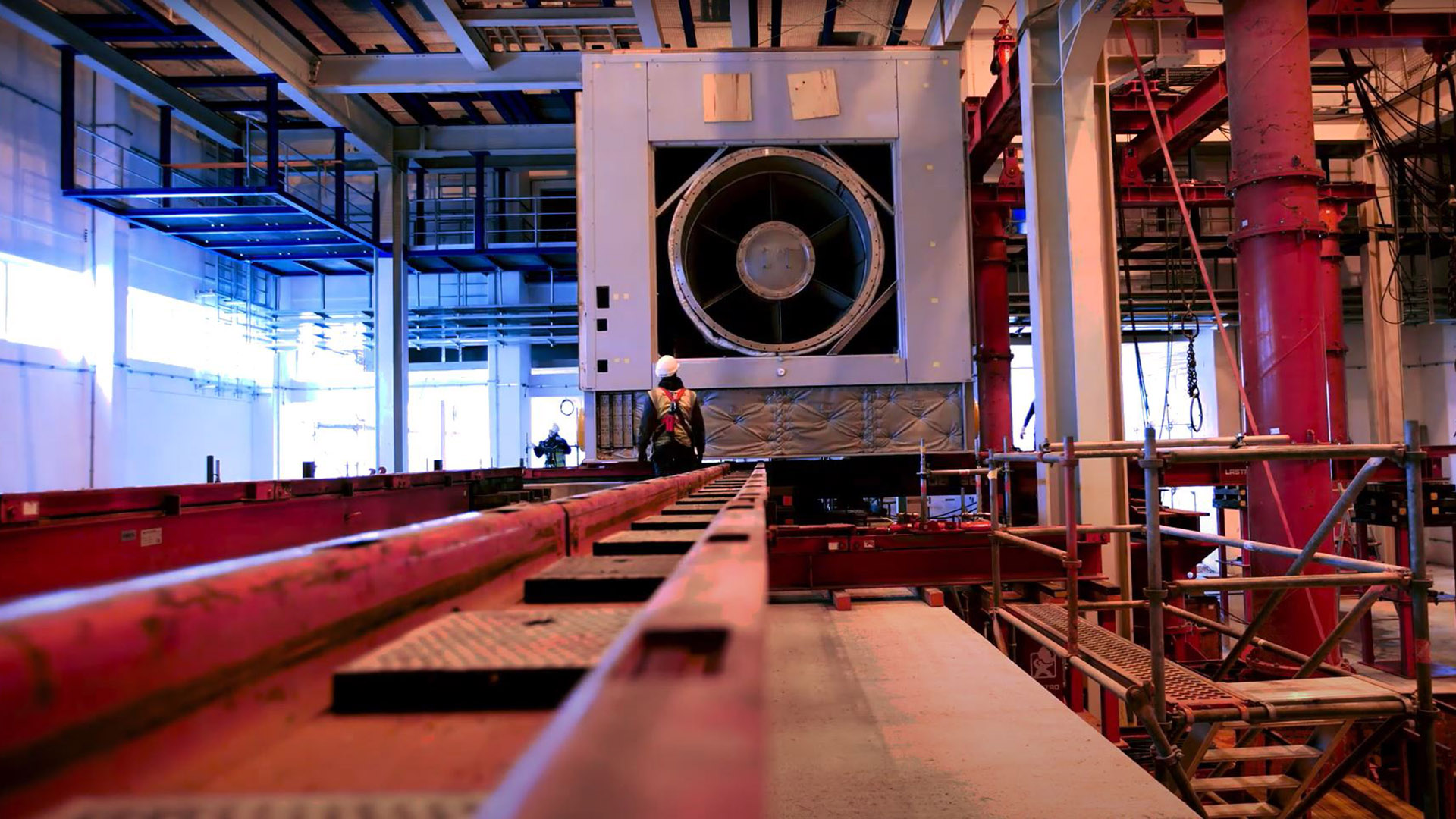

We did have some challenges with the installation and commissioning because it’s built within an existing plant, so we had to work around a certain set of boundaries that you wouldn’t need to with a brand-new plant. But through a very collaborative and creative project team on both the GE Vernova and SWM side, we were able to meet all our requirements and resolve all issues onsite.

During the installation it was good to have the GE Vernova specialists onsite because the LM6000 PF+ was a new engine uprate in 2018 and was commissioned at Freimann among a group of first projects worldwide. We had some specific issues during commissioning but having the Gas Power team there helped us solve problems fairly quickly and easily. It was also a good opportunity to learn a lot from the people who are responsible for the technology. And now during operation it’s good to know that the GE Vernova team can continue to advise.