Cooperative Energy is a generation and transmission cooperative, powering approximately 437,000 homes and businesses across Mississippi. One of its turbines gave off CO2 at the ceiling of what was permitted. The unit was underfired and derated for compliance, but permanent measures were needed—not only to lower NOx, but to boost availability in the face of upcoming summer heat.

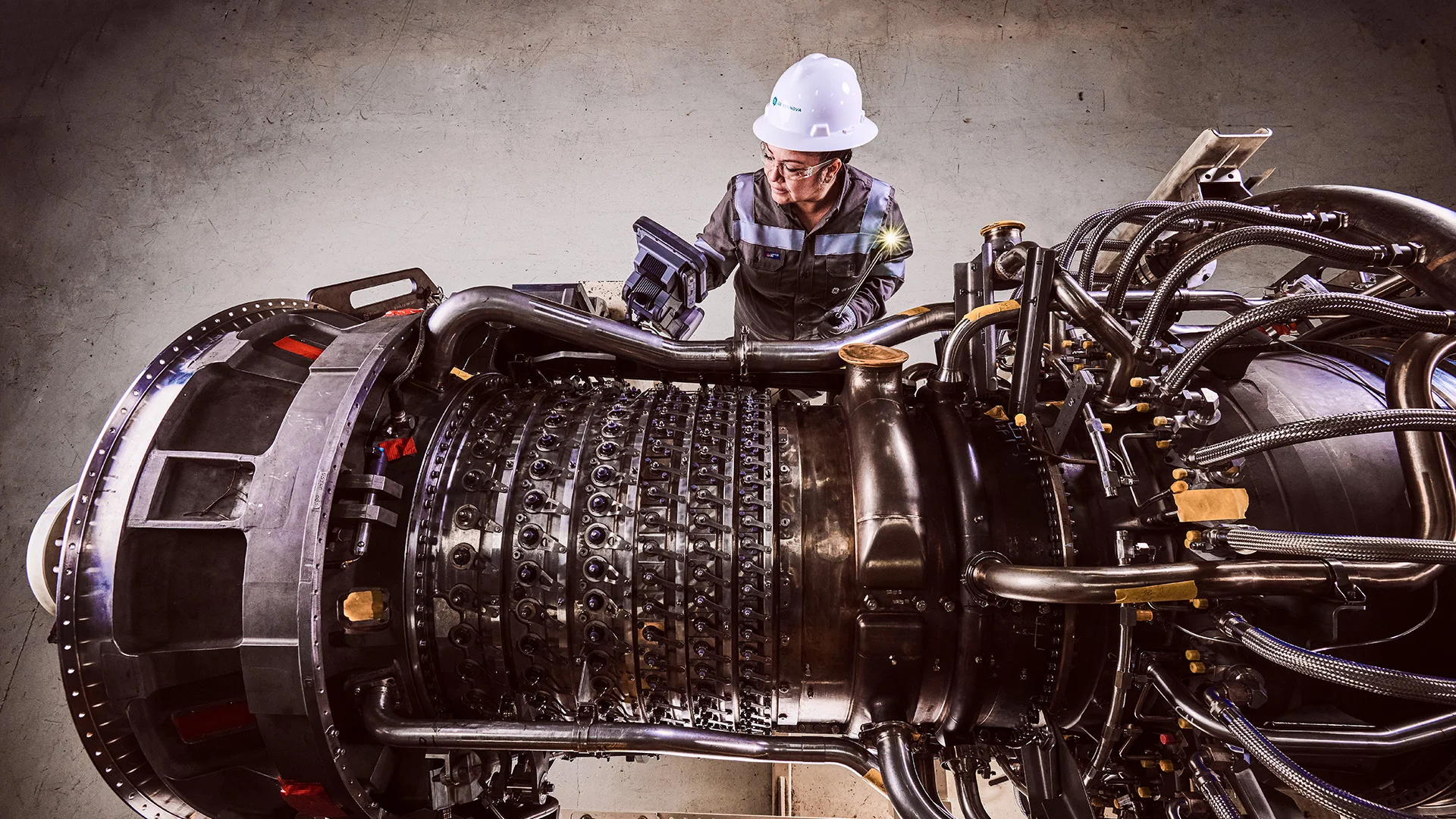

GE Vernova upgraded the 107EA combined cycle gas turbine, raising its DLN to 2.6+. But for long-lasting emission curbing, GE Vernova installed its newly configured advanced secondary fuel nozzle (AFSN), dropping Cooperative Energy’s NOx by a marked 37%. Now, the upgraded unit can overfire at +55° with NOx emissions at only 9 ppm.

Bothersome to start and stop overnight, a second 107EA turbine was addressed, and tuned for maximum turndown, it showed 45% load while meeting emissions compliance. Seeing the additional 15 MW of turndown and knowing this would support future renewables, Cooperative Energy asked that the first unit be tuned the same way.

With every upgrade done in four months, and far more cost-effective than an advanced gas path solution, GE Vernova’s 3D-printed fuel nozzle also helped add 4 MW to Cooperative Energy’s power profile. With that, it became GE Vernova’s ASFN launch customer, having since signed on for a multi-year maintenance program and a continued partnership.