-

Products

-

Services

Equipment services and upgrades

Services overviewLifecycle services

-

Resources

Search Gas Power

What are you looking for?

Or start with a popular search:

Recommended resources

GT13E2 TAT probes improvement upgrade

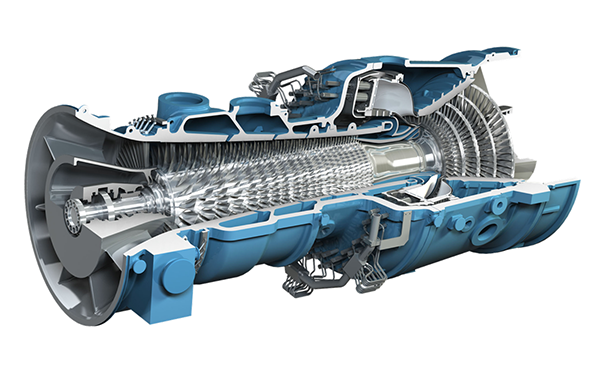

When it comes to controlling and protecting your GT13E2 gas turbine, proper measurement of the exhaust gas temperature (TAT) is crucial.

Benefits

What can upgrading do for you?

The TAT is measured with probes installed in flow direction behind the turbine, on the exhaust diffuser. With time and operation, the fixation of the TAT probes can become loose. This can lead to relative movement and accelerated wear of the probe tip, which usually requires repair or replacement of the TAT probe.

With a TAT probe improvement upgrade you will benefit from:

- An improved coupling fixation that helps prevent loosening of the multi-thermocouple and the need for maintenance work

- Reduction of TAT probes replacement rate due to mechanical wear

Related services

Structural parts maintainability

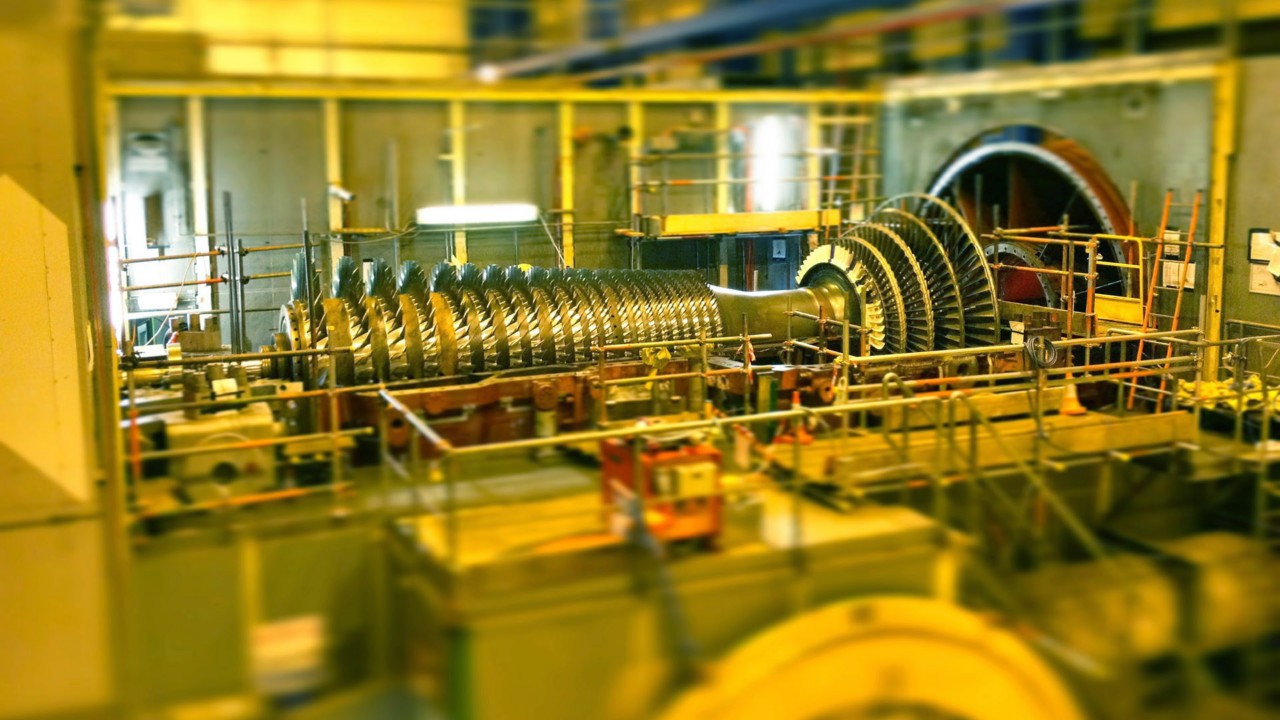

The GT13E2 gas turbine needs to periodically have its Radial Rotor Positioning (RRP) measured and potentially adjusted. In standard configuration, it’s only possible to perform the adjustments by opening the unit.

The GT13E2 gas turbine needs to periodically have its Radial Rotor Positioning (RRP) measured and potentially adjusted. In standard configuration, it’s only possible to perform the adjustments by opening the unit.

GT13E2 Cross-flange rework for leakage elimination

A cross-flange rework for leakage elimination can address a hot air leakage in the cross-flange area of your GT13E2 gas turbine.

A cross-flange rework for leakage elimination can address a hot air leakage in the cross-flange area of your GT13E2 gas turbine.

Exhaust casing spring support upgrade

An exhaust casing spring support upgrade from GE Vernova can reduce blade rubbing caused by exhaust gas housing (EGH) sagging, resulting in improved EGH stability and gas turbine efficiency.

An exhaust casing spring support upgrade from GE Vernova can reduce blade rubbing caused by exhaust gas housing (EGH) sagging, resulting in improved EGH stability and gas turbine efficiency.

Gas Power

Gas Power engineers cleaner, more accessible energy that communities depend on to power growth and prosperity.

Contact usEmpowering the data-driven world with reliable, cleaner energy

GE Vernova’s Gas Power business helps provide scalable efficient, infrastructure that supports the world’s energy demands, including those of hyperscale and colocation data centers. Explore our products, from fuel-flexible turbines to services that keep reliable power flowing worldwide.

Explore our Gas Power data centers solutions