Reliability and availability

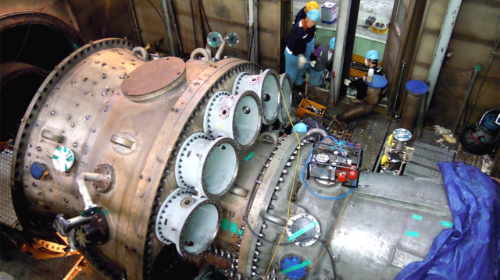

Heavy duty gas turbines require routine on-site maintenance stops, causing a plant stop for several weeks. In contrast, gas generator replacement of aeroderivative gas turbines for major maintenance work requires a plant stand-still of <3 days, guaranteeing a CHP plant availability of +98.7%.*

Benefits of a CHP system are easy to quantify. A plant with three aeroderivative units can offer 95% cumulative availability in a continuous operating application. A plant with 10 large reciprocating engines (single availability of 93%) can yield availability of <50%. To match the aero gas turbines, two more reciprocating units would be needed: 20% excess in plant size and CAPEX.

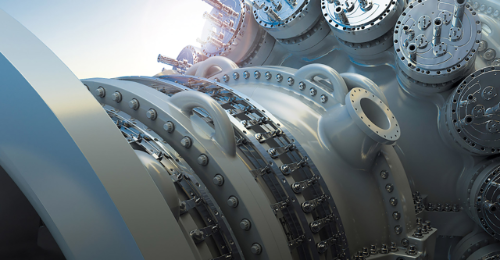

Aeroderivatives: more reliable and efficient

GE Vernova's aeroderivative turbines offer 99.9% operational reliability and +99% start reliability technology, per SPS ORAP data, another of many cogeneration plant benefits. This performance is the highest of any thermal power system. Aero gas turbines reliably go from cold start to maximum power delivered to the grid in as quickly as five minutes.