Stay agile in a changing energy landscape

The value of being ready—whatever the industry demands

What works today might not work tomorrow. One day, your plant may need to ramp up quickly to meet peak demand; the next, new emissions rules or fuel costs could redefine what success looks like.

GE Vernova’s portfolio of technologies empowers plants to adapt seamlessly to these shifting priorities—delivering faster starts, improved capacity, and lower minimum loads. These aren’t just technical upgrades—they’re strategic levers that drive long-term operational and economic performance.

Flexibility package

Plant flexibility and integration matter more than ever

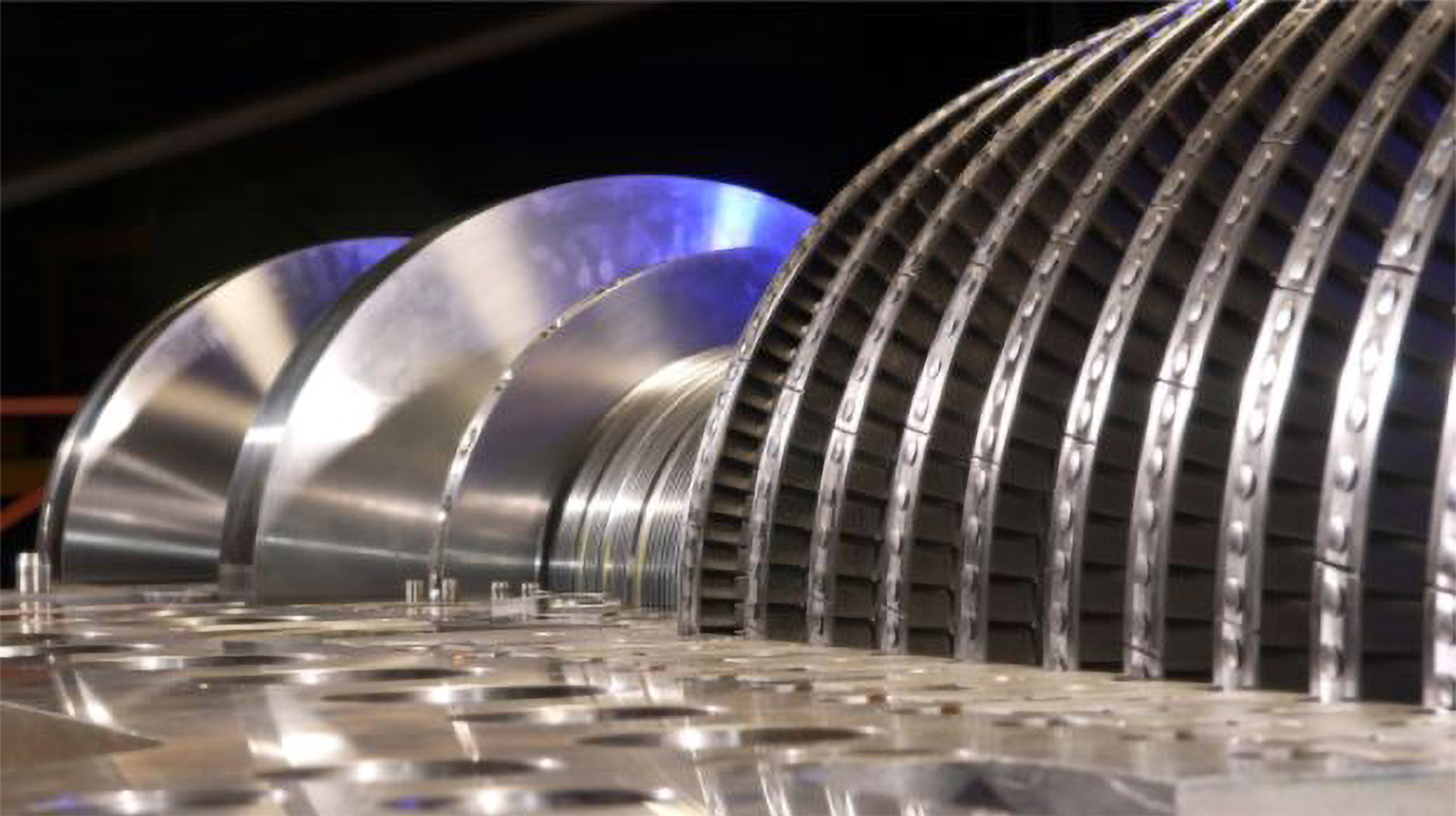

Today’s power markets demand flexibility. GE Vernova boosts responsiveness by pairing OpFlex™ advanced controls with targeted hardware upgrades—improving ramp rates, minimum loads, and start-up times. We break the silos between gas turbine, steam turbine, and control systems to optimize the entire plant, tailored to your goals.

Whether you’re targeting energy market participation, emissions compliance, or balancing intermittent renewables, we’ll help you build the right flexibility roadmap.

Boosting flexibility

Three ways to build a more flexible plant

Fast, consistent starts help you respond to real-time price signals and secure new revenue. With OpFlex™ Fast Start and Purge Credit on the gas side, turbines are ready to operate sooner—up to 15 minutes faster in many cases. On the steam side, tools like OpFlex Steam Turbine Agility, steam path warming, and heating blankets can reduce waiting times, enable reduced start up fuel consumption and emissions, and lower wear and tear through reduced stresses on equipment.

GE Vernova offers upgrades across gas turbines, steam turbines, and HRSG systems to deliver more output from existing assets. This is especially valuable for plants built 15–20 years ago that now face the decision to retire or reinvest. Capacity improvements extend useful life and adapt plants to growing demand without full system replacement.

Frequent starts increase emissions, fuel use, and wear—driving up O&M costs. GE Vernova’s integrated solutions help combined cycle plants stay online at lower, emissions-compliant turndown loads, improving economics and readiness for next-day dispatch. Solutions like OpFlex Turndown software and Axial Fuel Staging hardware for the 7F DLN2.6+ combustor expand the emissions-compliant load range, enhancing flexibility to balance renewable power in real time.

Flexibility blog series

Explore our blog series with GE Vernova’s Bob Bellis, who answers important questions about gas plant flexibility

*Trademark of GE Vernova and/or its affiliates.

Contact Us