In part 2 of a 3-part blog series, Bob Bellis answers important questions about gas plant flexibility.

What have you learned from other markets with high penetration of renewables?

First, let’s step back and look at where North America markets stand in relation to the rest of the world. Europe is generally much farther ahead than North America when it comes to adapting to the changing energy landscape with higher penetration of renewable generation, so it's a good leading indicator for future trends.

Ten years ago, many older power plants in Europe were in an “adapt or die” mode. This was driven by a combination of high gas prices and smaller grids with relatively high penetration of low/zero cost renewable power generation. For some plants, there were only a few hours a day where power prices supported profitable operation (i.e., the spark spread was positive, spark spread = power price minus fuel cost). So it became crucial for those thermal power producers to change how they operated to catch that few-hour window to be profitable—which meant a shift to cyclic operation with fast, repeatable, predictable and consistent starts.

Looking forward, as zero fuel cost renewable power generation continues to be rapidly added to grids worldwide, one could envision a future landscape, perhaps in less than 20 years, where most thermal plants will be in cycling mode.

This means many combined cycle plants--which historically have run baseload operation with high capacity factors--may see their capacity factors move lower and lower, potentially to the point where they essentially become peakers, operating only to fill the gaps and maintain grid reliability when renewables are not available.

The challenge, however, is that most of these combined cycle plants were not initially designed and built for cyclic operation. They need solutions that help optimize starts, since they will be doing lots of them. That means solutions to reduce start time, cost, fuel burn, and emissions, all without excessively increasing wear and tear and maintenance costs. And when online, plants need the flexibility to operate in emissions compliance over as large a load range possible with as fast a ramp rate as possible (up or down in load), to better balance intermittent renewables.

What do you see as potential options for flexible technologies in the future as we move towards a decarbonized power grid?

There are essentially three key types of flexibility to focus on:

1. Startup: The ideal scenario would be for thermal plants to operate like a light switch: Turn on and off, nearly instantaneously. Realistically, the idea is to get combined cycle plants to have nearly the same flexibility as simple cycle power plants, which can have startup times as quick as 10 minutes. So while a combined cycle plant may not be able to deliver 100% output in 10 minutes, it can be upgraded to provide at least some fraction of load within 10 minutes and be more fully automated to provide consistent, repeatable start times.

2. Dispatchable Load Range: Once a plant is online, synchronized to the grid, it needs to have an emissions-compliant operating load range that is as large as possible, expanded with a combination of higher highs and lower lows (AGP and AFS are two GE Vernova offerings that can help with this). The larger this dispatchable load range is, the better it enables increased integration of non-dispatchable renewable generation onto the grid, by providing maximum power when renewables are not available (to ensure grid reliability) and minimum power when they are available (to reduce renewable curtailment).

3. Ramp Rate: Last, a plant needs to be able to move between those two load limits as fast as possible, quickly traversing that load range from highest to lowest and vice versa. Ramp rate is key to quickly balancing both rapidly varying solar and wind power generation, and swings in system load demand. Many independent system operators (ISOs) are now incentivizing such regulation up and regulation down services via ancillary service markets.

OpFlex: Focus on faster start solutions

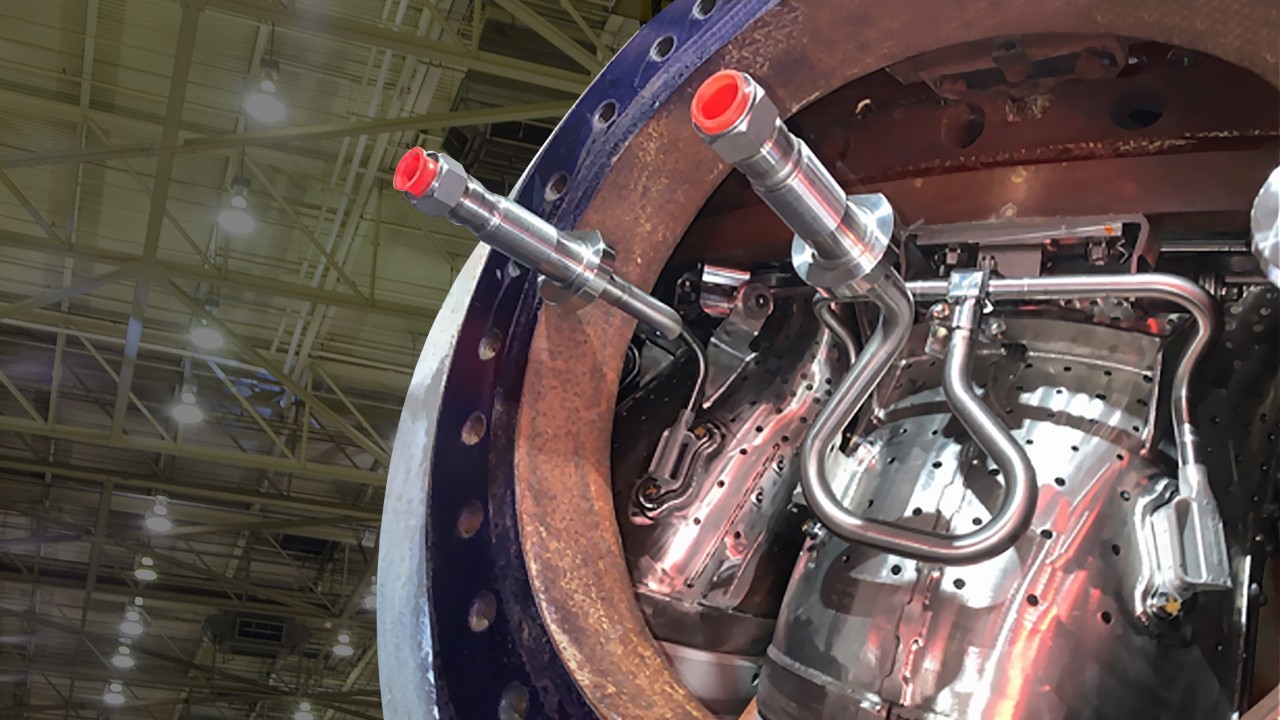

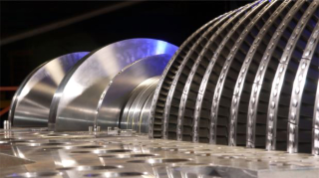

When it comes to startup, you have to look beyond the gas turbine—and consider the entire combined cycle (CC) plant. While the gas turbine is inherently very flexible, the steam turbine and HRSG are much less flexible. And while there are some flexibility solutions specifically for these, we’ve found that we can leverage the flexibility of the gas turbine to further accommodate the steam turbine and HRSG limitations, such that the net result is better flexibility of the overall combined cycle plant.

Most plants are combined cycle because it's much more efficient: 55-65% combined cycle efficiency versus ~30-40% simple cycle efficiency). But the tradeoff you get with a combined cycle block is less flexibility: For example, a much more complicated and longer start process because combined cycle plant start times are measured in hours versus minutes for simple cycle plants.

GE Vernova can help at the plant level. We have a whole suite of solutions for achieving start times that are closer to that of a simple cycle unit—including Purge Credit, Variable Load Path, Steam Turbine AGILITY, and HRSG Advanced Attemperation Control. Note that you don’t necessarily need big upgrades for startup improvements; rather, it’s more about re-engineering your plant’s start process with a focus on removing unnecessary holds, improved automation, and better visibility to tradeoffs between wear and tear, and start time, emissions, and fuel burn. Given many older plants weren’t designed with optimized start processes, there’s often a lot of simple changes that can be made which provide significant improvement. The end result is start capability that is more attractive to grid operators, keeping the plant relevant in a very dynamic power generation industry. That’s what was happening with our customers in the EU: gas prices were high and plant owners wanted to permanently shut the plants down since they struggled to be profitable. So we helped them drastically improve their start times so they could quickly get online to run during that 3-4 hour period per day where spark spreads were positive, and thus remain economically viable.

So as global efforts to decarbonize the power grid accelerate, we can expect that zero fuel cost renewable power generation will no doubt continue to be rapidly added to grids worldwide, which in turn will accelerate the need for flexible, dispatchable thermal generation.

While the pace at which gas plants will need to adopt flexible technologies will differ by market, really most all thermal plants should at least begin planning for it now.

GE Vernova sees those trends, and we have solutions to help!