Prefer to listen?

Stream our audio version

In part 1 of a 3-part blog series, Bob Bellis answers an important question about gas plant flexibility.

Why is flexibility so important now, and what advances are being made to make natural gas plants more flexible?

First, let me talk about how we’ve gotten to where we are now: What plants used to be like, and how we’ve been working to make them state-of-the-art in terms of flexibility to keep up with today’s demands.

Historically, combined cycle gas plants were designed for baseload operation. With the gas turbine bubble in North America in the early 2000s when power market deregulation first began, there was a rush to build power plants—and flexibility wasn’t part of the vision. Power plant operators just assumed that their gas turbines would be working in baseload operation for their whole 30+ year lifespan. Over the last 20 years, however, we’ve seen significant shifts in the power generation landscape driving the need to invest in software/hardware to enable more flexible operation.

What changed? Why do we need flexibility today?

The planning assumptions used when older plants were built are no longer valid. We thought gas would always be low cost and limitless, climate change wasn’t top of mind, and renewable solar and wind power were expensive and niche contributors. Fast forward, we’ve seen gas become contentious with supplies becoming more constrained, driving investment in shale gas over the last 10 or so years. Eventually the political landscape also started changing to recognize global warming as a major concern, which influenced willingness to invest money (like the Inflation Reduction Act) in technologies to slow down global warming.

Another driving factor for flexibility improvements is…Let’s be honest, power plants exist to make money. And today that’s becoming harder and harder to do because gas plants can’t always run economically at baseload as more and more renewable generation comes onto the grid. Grid operators still need dispatchable gas plants because of the intermittent nature of renewables, so they have opened new avenues to make money via changes in regional power market policy and structure. The way gas plants operate swings with the price of gas, so how do you keep your plant viable and stay ahead of your neighbor? A lot of our investment has been in ways to help plants remain economically viable and take advantage of the changing landscape. We have many ways to do that, including flexibility solutions to backstop the intermittent nature of renewables like wind and solar, allowing their increased use on the grid without sacrificing grid reliability. On top of that, there are now regulations on emissions and grid stability that are creating incentives for carbon reduction and reliability solutions, respectively.

We’re now in a dynamic, global landscape that’s driving big innovation and increased competition for economical livelihood. Gas plant operators are now looking to flexibility upgrades to maintain relevance. If you don’t invest, you’ll be irrelevant.

Flexibility is now a “must do”!

That’s why I’m so excited about our flexibility offerings, and we have plenty! Today I’m going to focus on two: The OpFlex product line and AFS.

OpFlex Solutions Suite:

Our OpFlex product line is made up of advanced controls technology that will help operators get the most out of their physical power plant equipment, expand the operating envelopes and enable operations to adapt to changing conditions. OpFlex solutions can help in four ways:

Startup Agility

The solutions in this category are aimed at making a combined cycle plant or a simple cycle turbine have the fastest, most reliable, most repeatable starts with the lowest emissions, lowest fuel burn, and lowest wear and tear.

Combustion Versatility

Combustion turbines of course operate using the combustion process. It’s the most challenged, constrained subsystem of the overall gas turbine system. The combustion system must operate robustly and reliably (i.e., with stable flame, low dynamics, and low emissions) as you face external changes in weather (e.g., temperature, humidity), fuel composition, and grid frequency variation. Leveraging model-based controls—essentially an on-board, real-time simulator of the Brayton thermodynamic cycle and combustion process—our goal is to expand fuel flexibility, ensure robust operation with fewer trips, ensure the hardware lasts multiple long service intervals with low dynamics, all while maintaining emissions compliance.

Load Flexibility

So now that the gas turbine has robust combustion control, what’s the best way to take advantage of that? The answer is via load range expansion, meaning higher highs, and lower lows, in emissions compliance, as well as how to optimize turbine operation for the best efficiency at all load levels, how to get the best responsiveness to survive grid events and respond to them, and how to customize plant operations to meet whatever the power landscape suggests is needed. So it’s higher highs in terms of output, and lower lows in terms of deeper turndown, and improved efficiency at all loads, all while being able to move between that bottom and top as quickly and reliably as possible, while remaining in emissions compliance.

System Reliability

These are enhancements to ensure that, as you change plant operation from baseload to cyclic duty, you maintain high reliability. How can we be more reliable on different fuels, at different load levels, and at different ambient conditions, and reduce trips to ensure least amount of downtime? And if you do go offline, how can you most effectively troubleshoot to get the plant back online quickly? A lot of this was developed leveraging what we’ve done in our newest turbine models, the HAs, which are clean sheet paper designs built based on the lessons-learned from thousands of GE Vernova turbines over decades of operation, and bringing those enhancements back to the older models, like the Bs and Es and Fs. So essentially modernizing the protection logic and permissive logic to the latest standards to keep the turbines up and running no matter how they’re operated.

So the overall solution suite is edge controls technology, meaning it’s software running inside the power plant, inside the unit controller that’s there, for all modes of power plant operation to help you adapt to a changing industry landscape. You can pick and choose from these solutions to develop a custom solution package to adapt your operation to the specific power generation landscape you’re facing now or expect to in the near future.

Axial Fuel Staging:

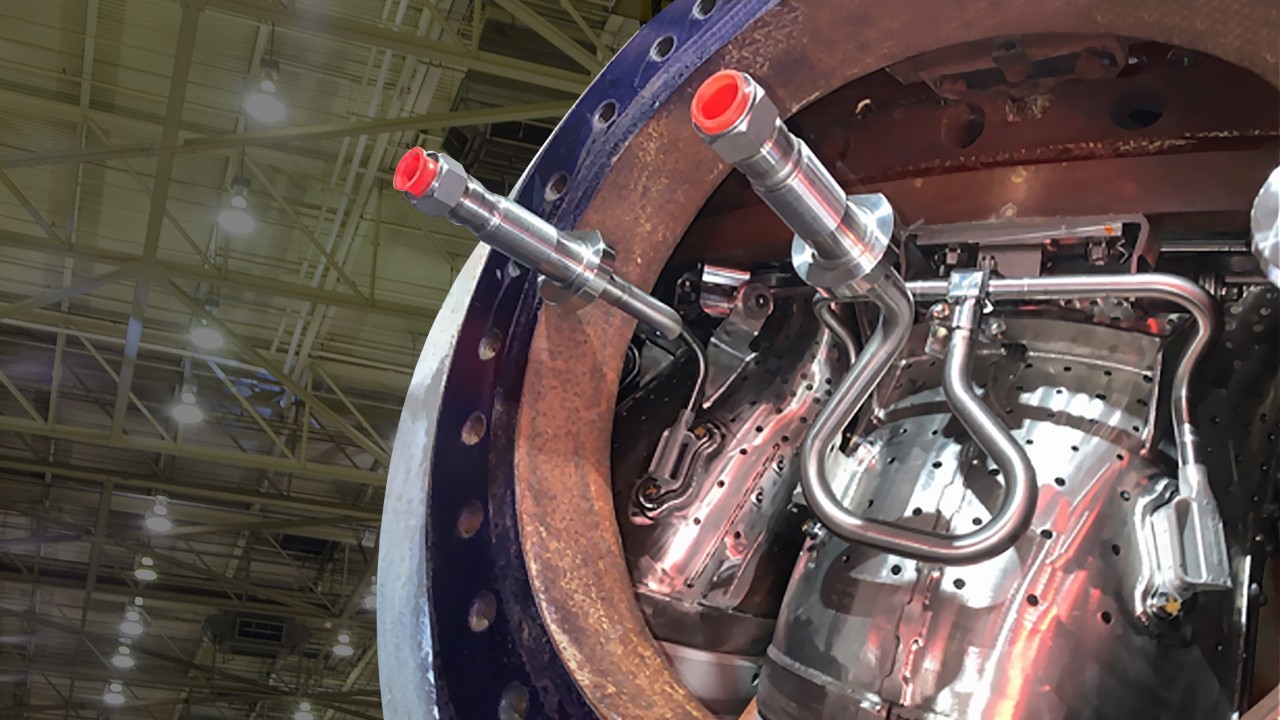

Axial Fuel Staging (AFS) is one way to future-proof your 7F power plant. AFS is a variant of the Dry Low NOx (DLN) 2.6+ combustion system that adds Axial Fuel Staging (AFS) technology to significantly extend turndown capability. So it can help you achieve lower turndown, with reduced emissions and reduced maintenance costs via improving the economics to stay online, and avoid the wear and tear of shutdown/startup cycling.

How does it work?

The AFS upgrade adds a new fifth fuel circuit that allows part of the total fuel and air mixture to be injected at a downstream stage in the combustion system, in the transition pieces. When the unit operates at baseload, a portion of the total fuel flow is injected through the AFS injector, with the overall total fuel flow unchanged to maintain the same level of baseload performance. As the unit unloads to go into extended turndown, the AFS injector is unfueled first, resulting in a high temperature being maintained in the primary combustor section to extend emissions compliance to lower load levels. Experience to date suggests emissions compliance down to as low as approximately ~25% gas turbine load, versus ~40% without AFS.

Bob Bellis

Principal Engineer, Controls Solution Architect, GE Vernova

Bob has 24 years of combined cycle power plant controls, digital product management, engineering management, and energy ISO/RTO experience. Prior to joining GE Vernova, Bob was an officer in U.S. Navy serving at the headquarters of the Naval Nuclear Propulsion program. Bob received the B.S. and M.S. degrees in mechanical engineering from MIT, and a Master of Engineering Administration from Virginia Tech.

Webinars

Hear from our experts

Plant flexibility: Adapting to stay relevant

Operators and plant managers are experiencing rapid change as the evolving energy landscape impacts their power plants' operating profiles. The ability to adapt and be flexible is key to remaining relevant.

Learn more7F DLN 2.6+ AFS: Turn up your plant profitability with improved turndown

Learn how to achieve lower turndown and reduce maintenance costs with GE Vernova's latest flexibility solution—a variant of the Dry Low NOx (DLN) 2.6+ combustion system that adds Axial Fuel Staging (AFS) technology for further turndown capability.

Learn moreContact us