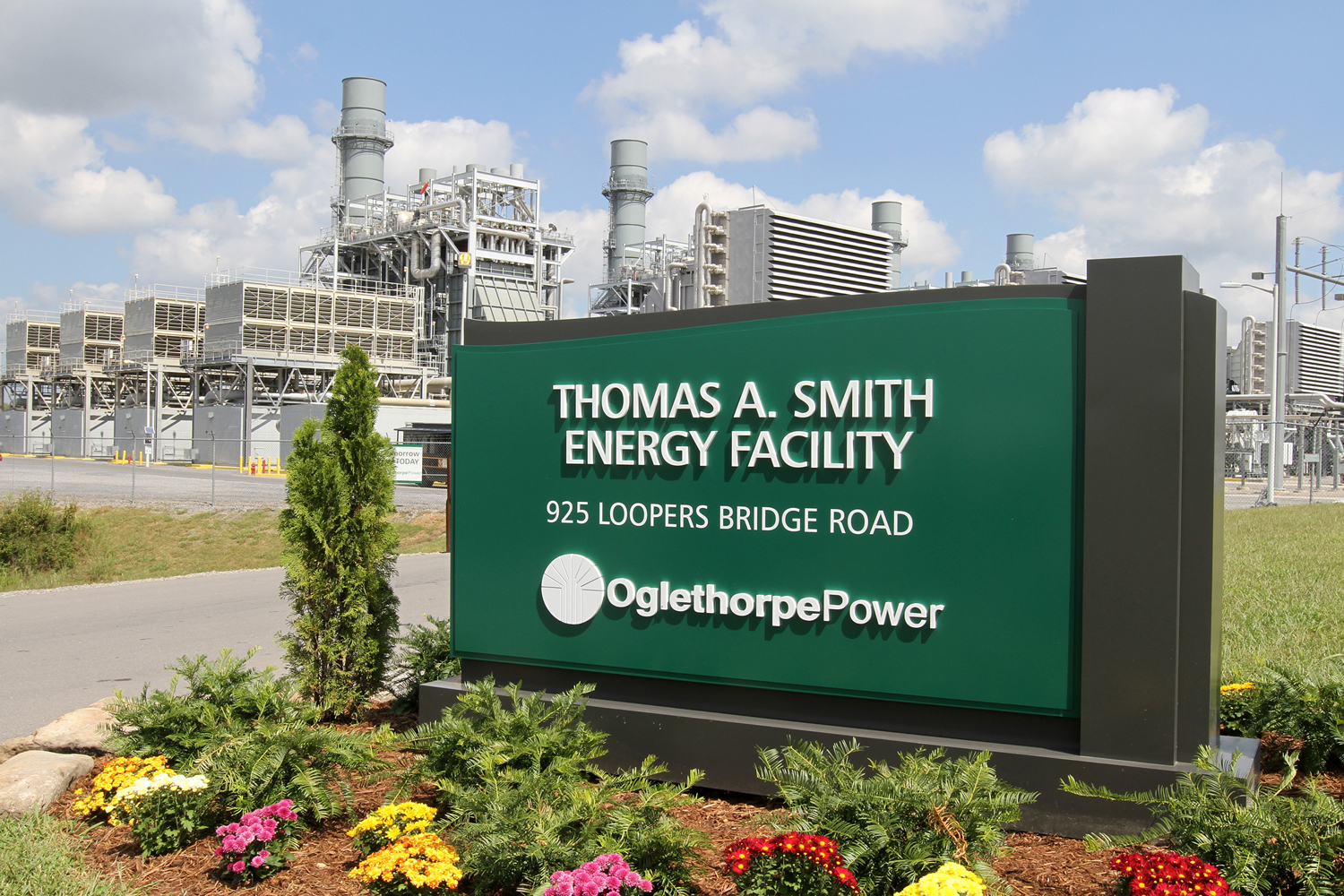

After realizing the positive outcomes of the AFS technology at the Thomas A. Smith Energy Facility, Oglethorpe Power subsequently purchased the AFS solution for a recently acquired plant.

Oglethorpe Power is among the nation’s largest power supply cooperatives and one of the largest energy producers in Georgia. With more than $16 billion in assets, Oglethorpe Power owns and operates a diverse portfolio of resources to provide reliable, affordable, safe, and environmentally responsible energy to 38 consumer-owned, not-for-profit Electric Membership Cooperatives (EMCs) that provide retail electricity to approximately 4.7 million Georgians.

For not-for-profit cooperatives like Oglethorpe Power, cost savings and reliability are key operating goals. Lower operating costs enable the company to reinvest in its fleet to improve operational flexibility. With fuel being one of the highest operational costs, AFS was the ideal solution to help Oglethorpe Power lower its fuel costs. AFS allows gas turbines to achieve lower turndown—essentially “idling” when renewable power is supplying most power needs and then ramping up quickly to provide power when renewables start to decline.

GE Vernova had previously installed the Dry Low NOx (DLN) 2.6+ combustion system upgrade on all four of the Thomas A. Smith units, which helped lower emissions, increased flexibility, and brought the gas turbine minimum emissions-compliant load down from 100 MW each to ~70 MW. With the addition of AFS, all four units are now averaging 43 MW in emissions compliance.