Frequently asked questions

The importance of steam turbines in energy ecosystems

1) What are steam turbines?

Basically, steam turbines are engines that convert heat from pressurized steam into mechanical energy.

The turbine steam path converts thermal energy into mechanical energy through a series of stages that capture the momentum from the expanding steam. These impulses and reactions are used to drive the shaft, which is connected to the generator to produce electricity.

Factoid: Steam turbines were conceived of and developed by De Laval in the 1870s, but in 1884 Sir Charles Parsons was the first to use them specifically for electrical generation.

2) How do steam turbines keep things running?

Any heat source and water combo can generate steam. These machines are used to produce power in worldwide industries like oil and gas, paper, steel, and energy. Steam turbines can vary from a few kilowatts (kW) to several hundred megawatts (MW).

When a turbine is well-maintained and upgraded, its dependability in creating available power increases. Mechanically healthy turbines fight the enemy of electricity production—downtime.

Factoid: Steam itself is invisible, so what our eyes pick up is actually vapor.

3) How does a steam turbine work?

What’s the science behind it all? Like any other turbine, steam units convert thermal energy into the mechanical motion that creates electricity. As with steam locomotives of the 19th century, fuels are used to boil water for continuously expanding, superheated vapor—the resulting force behind mechanisms like flywheels, pistons, mechanical arms, apertures, and such into motion.

With greater inlet temperatures and pressures and lower exhaust temperatures and pressure higher efficiencies are achieved, and more useful work can be drawn from the turbine. The upper bound of temperatures we can achieve is limited by the materials of construction for the power plant and turbine.

Enthalpy: a thermodynamic quantity equivalent to the total heat content of a system. It is equal to the internal energy of the system plus the product of pressure and volume

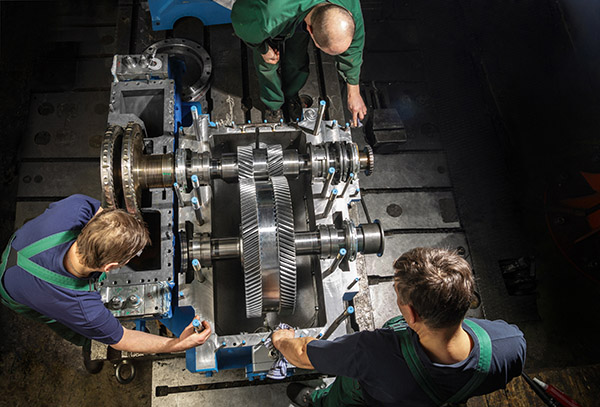

4) How do the different parts in a steam turbine ultimately function?

Imagine a high-velocity jet of pressurized steam moving through the machine. What is the system of parts? Steam turbine construction can be broken down into a few key components.

STEAM PATHS direct the energy of the steam and capture the energy of its expansion. The key parts to this are:

- stationary nozzles and diaphragms

- rotating vanes and buckets

- multiple stages throughout the turbine

ROTORS collect the energy from the steam path, converting it to rotational energy to drive the generator. The part behind this is called a shaft.

STATIONARY STRUCTURES contain the pressure of the steam, and also support the rotor. Key parts to this are:

- shells and casings

- pedestals

- bearings

In a combined-cycle power plant, the steam turbine utilizes steam generated by the heat recovery steam generator (HRSG) using waste heat from the exhaust of the gas turbine. In most modern plants, this dramatically increases plant efficiency from about 40% to 60%. This increased efficiency also lowers the carbon footprint of each MW generated compared to a conventional plant.

5) What are common steam turbine configurations?

Many builds of steam turbines exist, and each suits a different configuration of a power plant. But let’s break it down into just two—impulse turbines and reaction turbines.

Impulse turbines: Here, only the velocity of the water jet is used to rotate the turbine. This “impulse force” is pushed through a fixed nozzle, striking symmetrical blades. Its pressure remains constant.

Reaction turbines: Here, both kinetic energy as well as the velocity of the water jet is used. The water stream enters the casing, and after moving the rotors, the water exits. Its pressure changes throughout the cycle.

All machines in the industry today actually take from the spectrum two types; a sort of tailor-made combination for specific needs.

6) How does maintenance save the day?

Running constantly, steam turbines suffer wear and tear. They also accumulate damage from:

- an overage of startups

- variation in loading and steam conditions

- rubbing of rotating and stationary components

- chemical exposure

- erosion of solid particles or water

- water induction

That said, a thorough maintenance and monitoring program is essential for top performance and output. In order to maintain its efficiency, routine inspection and remediation of a turbine's key components helps promote turbine health.

The sustainability factor: Turbine efficiency equals plant efficiency, and that leads to less carbon output.

7) What kind of upgrades improve turbine capability?

While their many parts accumulate damage at different rates, steam turbines have a long useful life if well maintained. As technology evolves, important changes modernize hardware and software, making turbines more versatile, agile, and durable.

GE’s recommended upgrades include:

- steam turbine valve upgrades to improve reliability and increase intervals

- advanced steam paths to improve performance and extend the expected lifetime

- OpFlex ST Agility* to reduce start times and increase plant flexibility

*Trademark of General Electric Company

8) How can we connect the dots?

Upkept and upgraded combined steam turbines help power plants keep their uptime and efficiency, which in turn gives us the kind of reliable power we don’t think about, the kind we just trust is there.

With GE’s experts pushing technologies to new capability, our local maintenance and repair field services keep the turbines the world depends on in careful hands.

Explore

Learn more about our steam turbines and services

Contact us