Keep your generator running with a rotor exchange from GE Vernova

When your generator rotor is due for servicing, GE Vernova’s rotor exchange program provides a fast, reliable, and cost-effective solution to reduce outage time and extend asset life.

Fast, tested, ready to install

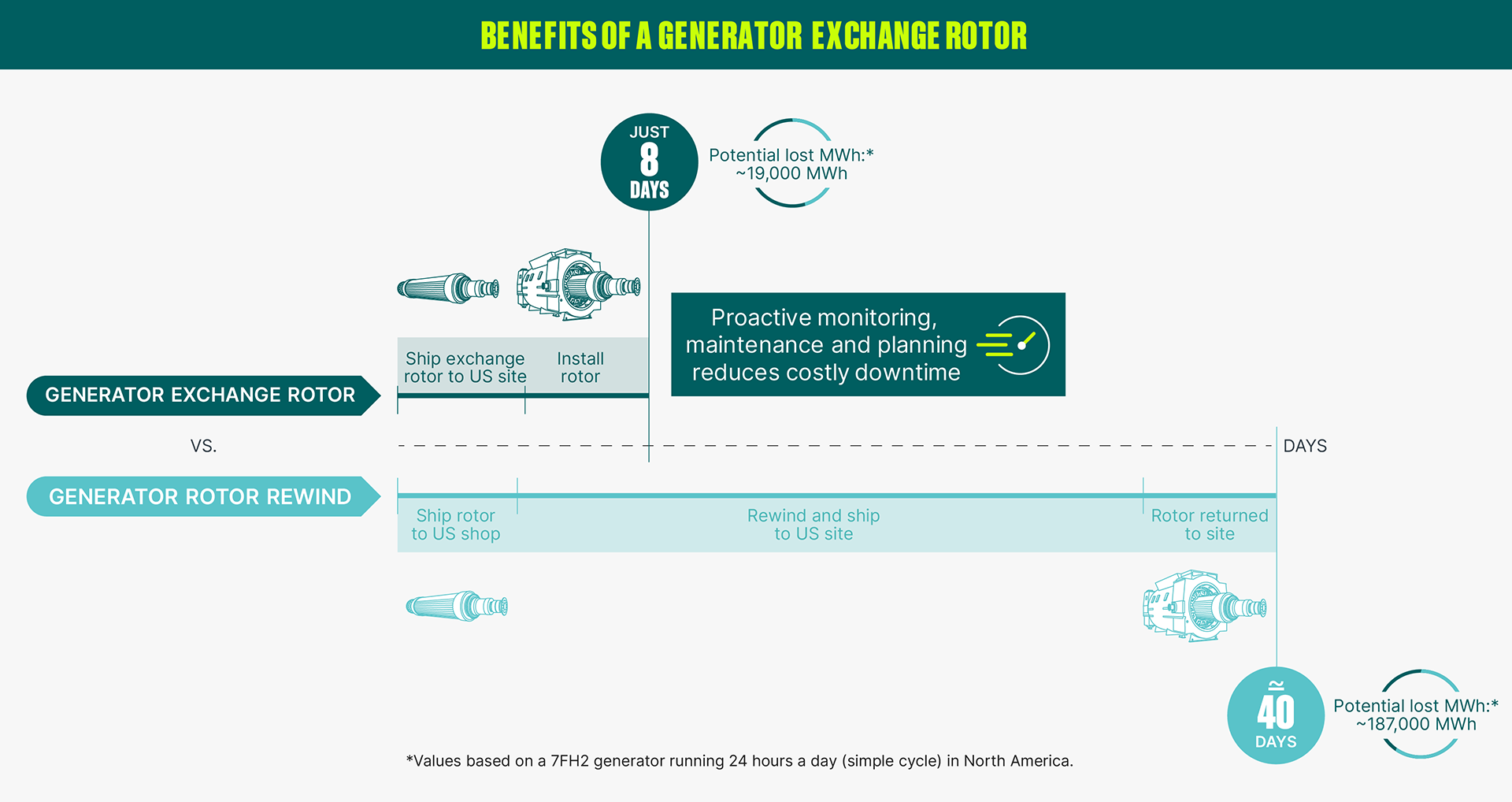

GE Vernova’s rotor exchange program allows you to replace a generator rotor needing maintenance or repairs with a fully refurbished, tested, and ready-to-install exchange rotor. For planned outages, these rotors can be delivered well in advance to help ensure a smooth and efficient outage schedule. With a rotor exchange, you’ll see removal and replacement in only 7 – 10 days—up to 40 days faster than an in-shop rotor rewind. On average, each day of reduced downtime translates to a savings* of $30,000 to $130,000, depending on the time of year the outage is performed.

*Average savings based on 100 to 175 MW units

Save time and money

Up to 40 days faster

Reduced uncertainity

Fully tested on delivery

Peace of mind

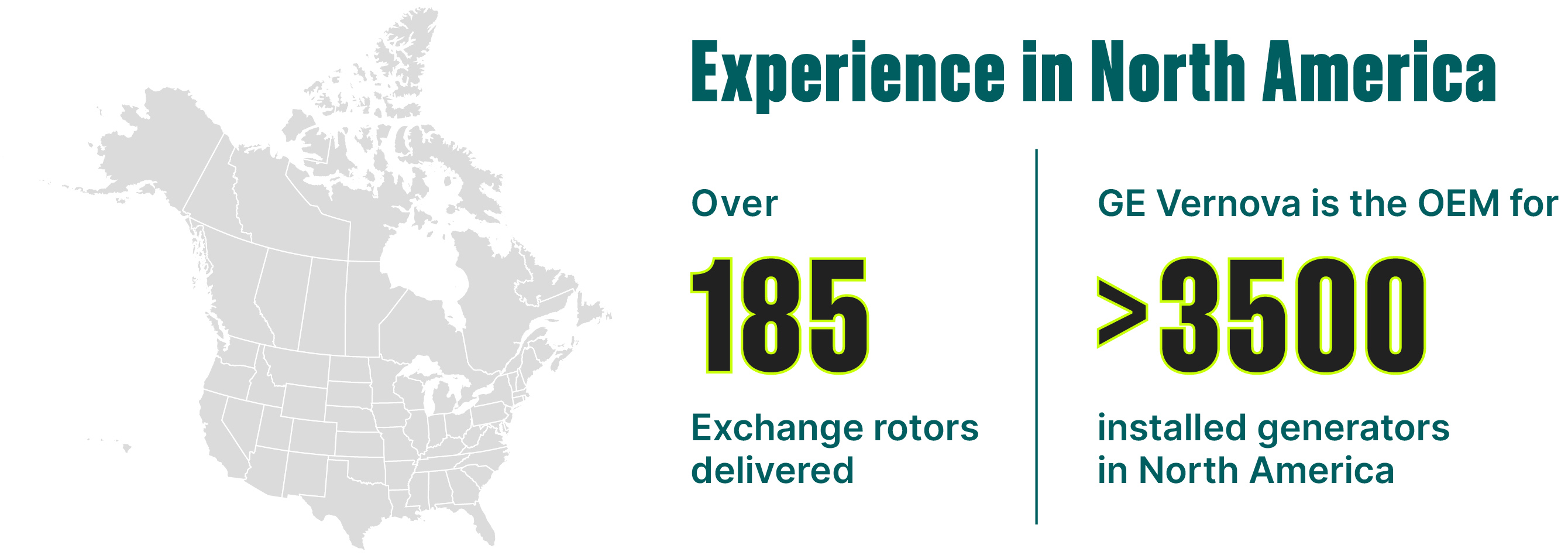

We know your generator equipment

250+ exchange rotors

delivered to customers globally

> 2 million

operating hours

Plan ahead

You can order a rotor exchange as far in advance as you need to, substantially reducing the risk of schedule extensions and execution challenges due to late rotor parts, winding delays, or test failures that are common with an on-site generator. Your generator's new replacement rotor will arrive:

Advanced technology and reliability

GE Vernova’s exchange rotors are engineered with upgraded materials, enhanced durability, and rigorous testing to help ensure seamless installation and long-term performance.

Latest insulation, blocking, and wedge configurations.

Modifications for cyclic duty, main terminal stud replacement, and amortisseur winding.

Ensuring full thermal and electrical reliability before installation.

A detailed assessment ensures compatibility with your generator.

A project manager will work with you to manage quality control throughout the process.

Faster turnaround, fewer lost MWh

When time is critical, a generator rotor exchange is the faster, more efficient alternative to a rotor rewind. Instead of waiting for lengthy repairs, our fully refurbished, high-speed balanced exchange rotors get you back online quickly, reducing downtime and avoiding lost MWh. With rapid installation and proven reliability, GE Vernova’s rotor exchange solution helps you maintain performance while keeping outage costs under control.

OEM expertise

Did you know that GE Vernova is the OEM for thousands of generators? That includes many sub-models that most other vendors don’t have experience servicing, so we can work with you to make sure your new rotor is interchangeable with your old one.

Available for the following models: 7FH2, 7FH2B, 7A6, 324, 7H2, 330H, BDAX 7-290ERJT, TRLI 115-36, TRLI 115-36, TRLI 115-52, 9A

Frequently asked questions

GE Vernova performs comprehensive assessments using electromagnetic testing, visual inspections, and material analysis to determine rotor condition and estimate remaining life. Our proven diagnostic methods provide high accuracy in evaluating stress levels, insulation degradation, and potential failure risks.

A rotor exchange typically takes 7 to 10 days, while a full in-shop rewind can take 30 days or more. The faster turnaround of an exchange helps reduce downtime and operational losses.

The repair timeline varies depending on the extent of work required. A full field rewind typically takes about 30 days, depending on the generator model and scope of work. However, some repairs can be completed in as little as 1-2 weeks. GE Vernova assesses each case individually to determine the fastest and most effective repair solution.

GE Vernova’s generator rotor exchange involves removing the existing rotor, installing a fully tested, high-speed balanced exchange rotor, and performing alignment and verification checks—all within 7 to 10 days to ensure minimal disruption.

A rotor exchange saves up to 30 days compared to an in-shop rewind. Less downtime translates to $30,000 to $130,000 in savings per day, depending on unit size and outage timing.

By eliminating extended outage time, rotor exchanges prevent lost revenue and reduce labor costs, making them a cost-effective alternative to rewinds.

GE Vernova works with customers to offer customized payment plans, financing solutions, and long-term service agreements to fit budgetary needs.

Yes! GE Vernova has extensive experience conducting interchangeability studies to ensure an exchange rotor will fit your unit. As the OEM, we have access to original unit records, repair history, and outage reports to verify compatibility.

In some cases, we may require additional information from the customer to supplement our records and ensure a precise match. Our team works closely with operators to confirm a seamless installation.

GE Vernova maintains a wide range of exchange rotors, but availability varies depending on the outage season and demand.

Common models included in our program are:

✔ 7FH2

✔ 324

✔ 7A6

✔ 330H

✔ 7FH2-B

✔ 9A5

For other models, including OOEM generators, our team can assess availability and explore solutions tailored to your unit’s needs.

Exchange rotors undergo extensive testing, including:

✔ Electrical testing for insulation integrity

✔ High-speed balancing for smooth operation

✔ Retaining ring inspections to detect stress corrosion cracks

✔ Dimensional checks to confirm precise fit

✔ Final certification to ensure compliance with OEM standards

Customers can return their removed rotor for refurbishment or reuse as a spare. GE Vernova also offers recommendations for repair or repurposing based on its condition.

GE Vernova leverages historical records, operational data, and advanced modeling tools to assess rotor condition and risk levels. While the exact process and data are proprietary, customers can contact their local sales account manager for further discussion and a detailed evaluation.

GE Vernova assesses the exchange rotor against your unit’s current configuration to determine if any additional components or modifications are required. While some units may not need any modifications, common replacements include:

✔ Oil deflectors

✔ Bearing liners

✔ Hydrogen seals

✔ Excitation system settings

Our experts ensure seamless integration by identifying necessary upgrades before installation, reducing the risk of unexpected issues during the outage.

Common indicators of rotor issues include:

✔ Shorted turns affecting electrical performance

✔ Increased vibration levels

✔ Higher excitation current needed to maintain output

✔ Excitation limitations causing an inability to maintain power output

These issues can often be detected while the rotor is still running. More severe conditions, such as a grounded field, can lead to a unit trip. Using GE Vernova’s Generator Health Monitoring enables continuous tracking and trending of potential rotor issues, helping operators take proactive maintenance actions.

Our exchange rotors incorporate advanced repair technologies, such as:

✔ Copper-finned ventilation ducts for better cooling

✔ Retaining ring material enhancements to resist cyclic stress

✔ Rotor FlexPack solutions to handle cyclic operations and prevent premature failures

Yes! Our rotors include design and material enhancements that improve cooling efficiency, reduce energy losses, and in some cases, increase power capacity.

Yes. GE Vernova offers performance upgrades, including:

✔ Advanced insulation materials for durability

✔ New end-winding blocking for enhanced mechanical stability

✔ Improved slot armor protection to prevent wear

GE Vernova provides end-to-end support, including:

✔ On-site technical advisors to oversee removal and installation

✔ Global logistics coordination for timely delivery

✔ Precision alignment and testing for optimal performance

GE Vernova maintains a global network of specialists and strategically placed inventory for rapid rotor deployment in emergent outage situations.

With strategically located warehouses and pre-positioned rotors, we can reduce lead times and help ensure quick response to both planned and unplanned outages.

GE Vernova provides comprehensive warranty coverage for workmanship and materials. Customers can also opt for extended service agreements, including periodic inspections and maintenance.

Absolutely! Customers can integrate rotor exchange with:

✔ Full generator inspections

✔ Stator rewinds and upgrades

✔ Onsite generator repairs

✔ Lifecycle management solutions

By combining services, customers can reduce future outages, optimize maintenance costs, and improve long-term reliability.

Consider your options

There are a number of things to consider when planning your outage, from the age and future operation mode of your generator to the best timing for an outage for your plant and customers. GE Vernova can perform a risk assessment to determine the condition of your rotors, identify the ones most at risk and the type of rotor, and any spare generator rotor parts you might need.

Services

Contact us