CHP and cogeneration, and district heating

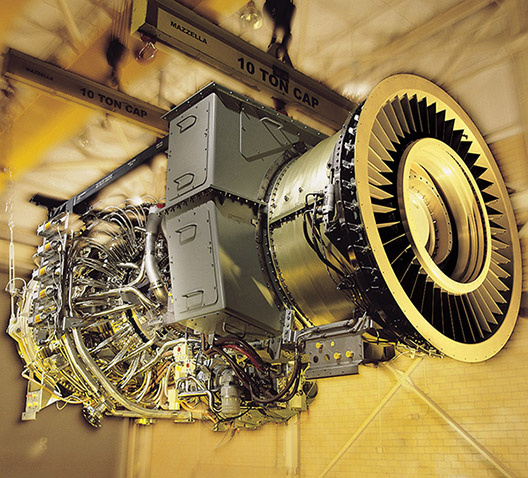

Manufacturers, municipalities, commercial buildings, and institutions including colleges, hospitals, and military bases use CHP to reduce energy costs, increase power reliability, and decrease carbon footprint. With the broadest gas turbine product portfolio in the industry, GE Vernova is uniquely positioned to provide its customers with the right products to provide the required ratio of power to heat for their CHP and cogeneration systems.

District heating service simplifies building operations, giving customers precise control over heating and providing flexibility to adapt as occupant needs change or building efficiency improves. The critical advantage of district heating is that connecting multiple buildings to a district system creates economies of scale that enable the deployment of more efficient, resilient local energy resources. This scale also enables integration of cleaner options like CHP, waste to energy, biomass, geothermal, and other renewables, which significantly reduce emissions to a level that would be unachievable on a building-by-building basis.