Benefits

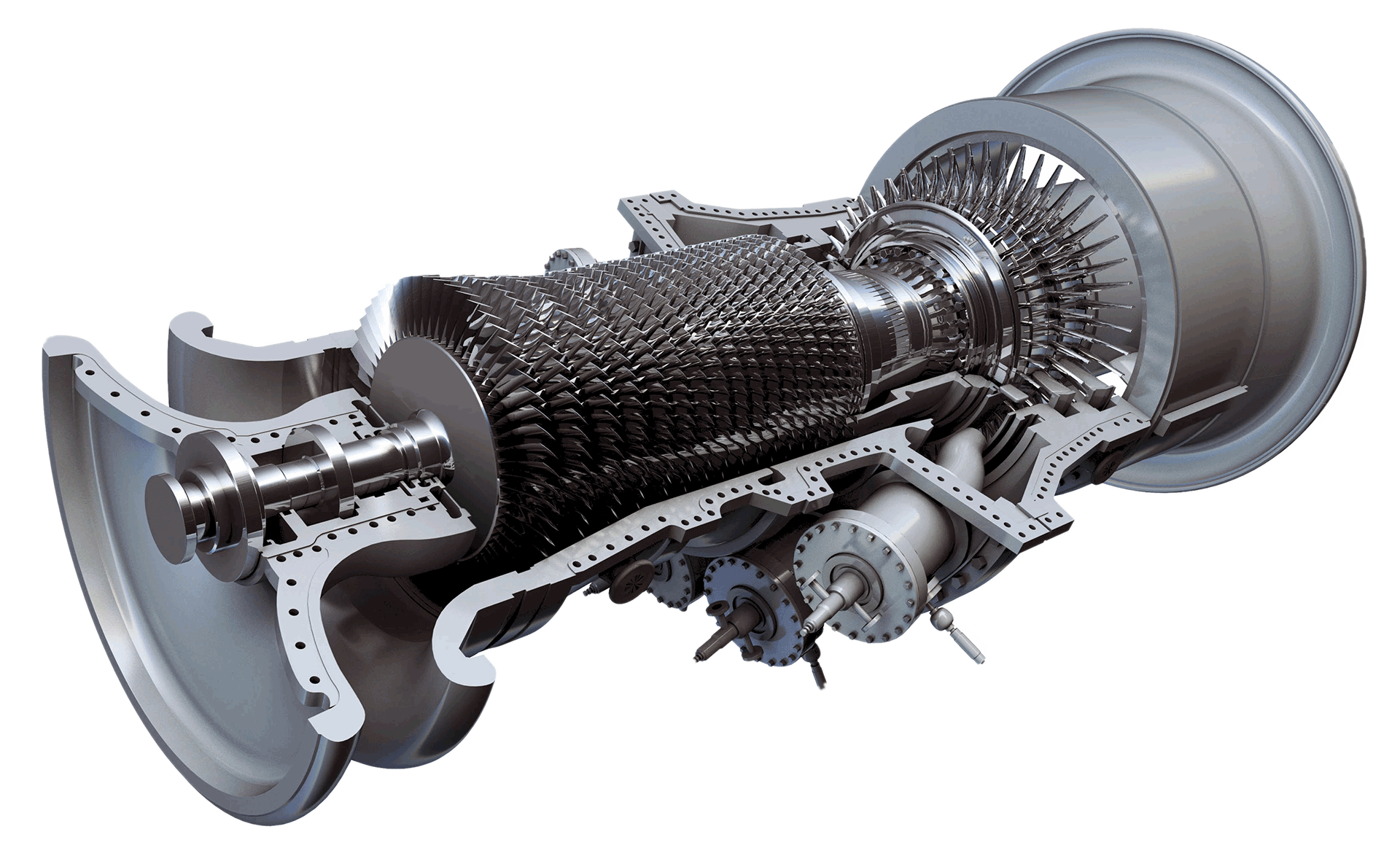

What can an AGP upgrade do for your 6B gas turbine?

The 6B AGP builds on the proven rugged reliability the fleet has demonstrated for over 40 years while allowing customers to remain competitive.

This upgrade utilizes proven E, F, and H-class developments to increase firing temperature. The 6B AGP enables higher output and exhaust energy, lowers fuel consumption, and increases maintenance inspection intervals.

The AGP can improve power output by 4%-16% depending on the plant's configuration. This option also results in an exhaust energy increase of 2%-9%.

6B AGP can improve heat rate by up to 4% depending on the plant's configuration.

When packaged with the 6B Advanced Extendor combustion technology, the AGP allows for synchronized combustion and hot gas path inspection intervals up to 32,000 Factor Fired Hours.

Key features and requirements

6B AGP: Key Features

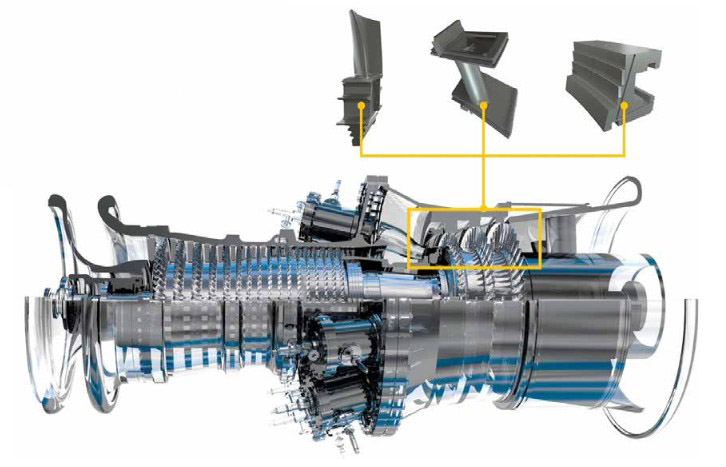

The AGP upgrade involves 9 new HGP capitals. Key highlights of the upgrade include:

- Laminate sealings and sealing geometry redesign for improved heat rate

- Advanced blade tip shroud configurations for improved cooling and sealing efficiencies

- Advanced coating for improved durability

- Cooling airflow changes for improved efficiency

6B AGP: Requirements

- Requires a Mark* IV control system or newer

- Compatible with a wide rnage of gaseous and liquid fuels

- Applicable to PG6541 or newer models

- Requires compressor stage 17 protection mitigation

Advanced Mark VIe controls

GE Vernova’s Mark* VIe control system is the foundation for unlocking the full potentional of OpFlex* advanced control software, which further enables full performance benefits from 6B gas turbine upgrades. Integrating gas turbine hardware upgrades with a modern control system and advanced software can deliver improved performance, flexibility, and adaptability to help power plants stay ahead in today’s rapidly evolving power generation landscape.

Further Reading

Learn More

Other AGP upgrades

Related services

- 6B gas turbine enhanced reliability upgrade

- 7Extend upgrade package

- Dry Low NOx 2.6+ Combustion Solution

- OpFlex advanced controls solutions

Downloads

Customer stories

-

Saudi Arabia

-

Saudi Arabia

Saudi Arabia

Saudi Cement orders the first 6B AGP technology for the cement industry

In a historic deal that marks the first time GE Vernova’s Advanced Gas Path (AGP) solution will strengthen power generation productivity for the cement industry globally, Saudi Cement will upgrade three GE Vernova 6B gas turbines at its Hofuf plant to increase capacity by 25 megawatts and efficiency by up to 3.3% per turbine.

Contact us

Want to learn more about our AGP upgrade for 6B gas turbines?

*Trademark of GE Vernova and/or its affiliates.