Overview

High Voltage Direct Current (HVDC) systems enable utilities to move more power further, efficiently integrate renewables, interconnect grids, and improve network performance. HVDC systems utilize power electronics technology to convert AC and DC voltage and are ideal for supporting existing systems or building new power highways.

ELECTRIFICATION BUSINESSES

Overview

GE Vernova provides solutions that offer grid operators the ability to provide reactive power support, enhance controllability, improve stability and increase power transfer capability of AC transmission systems.

Product Categories

Overview

Substation and Electrical Infrastructure Projects for Utility and Industrial Customers.

Overview

GE Vernova offers solutions for a variety of substation projects and applications, including Modular Substation Automation Systems, utility and industrial substation projects, as well as DC substation solutions.

Product Categories

Overview

The energy landscape today is changing, this is being led by the current industry trends of Decarbonization, Digitization, Decentralization and Electrification. Discover how GE Vernova is working with utility, consumer and industrial customers to design and deploy tailored Microgrid and Distributed Energy Resource (DER) Management solutions.

Product Categories

Overview

Innovations to Decarbonize the Electrical Grid. GRiDEA is our portfolio of decarbonization solutions that empower grid operators to address their net-zero objectives.

Product Categories

- SF₆-free Solutions

- Reduced Raw Material Impact

Overview

GE Vernova offers a wide range of transformer solutions for the utility, industrial, commercial, residential and energy markets. These solutions feature flexible, reliable and robust designs to support a wide range of applications. With units operating in some of the most demanding electrical environments around the world, We design and delivers transformer solutions that provide among the highest level of performance and reliability to meet rigorous operating requirements.

Product Categories

- Power Transformers

- Distribution Transformers

Overview

GE Vernova provides GIS solutions from 50 kV to 800 kV, along with secondary products to maximize switchgear and network operation. The portfolio includes a full range of SF6 GIS as well as g3 (SF6-free) GIS at 145 kV and 420 kV voltage levels for utilities and industries worldwide.

Overview

GE Vernova is one of the top circuit breaker suppliers in the world. Our products include a range of live tank circuit breakers (up to 800 kV), dead tank circuit breakers (up to 550 kV), as well as hybrid and compact switchgear assemblies. We also provide solutions for power generation applications with our generator circuit breakers for installations up to 1,500 MW.

Overview

GE Vernova is a global market leader for disconnectors (disconnect switches) since 1960, with 8 product facilities in 7 countries and hundreds of thousands installations in more than 130 countries around the world. The portfolio includes disconnectors for AC applications (up to 1,200 kV), for DC applications (up to 1,000 kV) and for railway applications. We also offer power connectors to connect two or more conductors for a continuous electrical path.

Product Categories

Overview

GE Vernova is an industry leader in the design and manufacturing of high, medium and low voltage instrument transformers. With more than 100 years of experience, We offer a broad array of standard and high accuracy models for revenue metering and system protection applications. The portfolio of instrument transformers ranges from low voltage at 600 V suitable for industrial and high accuracy revenue metering, all the way up to high voltage at 1,200 kV. The portfolio also includes line traps and digital instrument transformers.

Product Categories

- High Voltage Instrument Transformers

- LV/MV Instrument Transformers

- Line Traps

Overview

For a century, utilities have relied on us to deliver electrical products and services to meet their quality, durability and performance needs. Our capacitor and reactor product lines are an integral part of our portfolio. GE Vernova provides power capacitors that meet ANSI, IEEE and IEC standards, and our low voltage capacitors are UL listed. Ratings range from 1 kvar to 500 MVAR, and from 240 volts to 500 KV.

Overview

GE Vernova provides a broad range of bushings and surge arresters to help protect electrical assets. The bushings portfolio includes AC and DC solutions that enable long life, high reliability and installation flexibility. GE’s Tranquell surge arresters are ideal for distribution and EHV applications up to 612kV, and are available as polymer and porcelain station and intermediate class IEEE/ANSI C62.11.

Product Categories

Overview

Our SF₆-free switchgear range features the same ratings and same dimensional footprint as the state-of-the-art SF₆ equipment, with a drastically reduced carbon footprint.

Product Categories

- Gas-Insulated Solutions

- Live Tank Circuit-Breakers

Overview

The collection of required asset condition data from the field on a large scale for GE Vernova and 3rd party electrical equipment is a key step in building a robust Asset Performance Management strategy. Grid Services specialists are constantly evaluating and implementing new innovative inspection technologies applying strict processes and methods. The digital inspections methods are designed to improve the efficiency of data collection, oil analysis and online monitoring. All new approaches to capture data are integrated into the EnergyAPM ecosystem for automatic data transfer.

Overview

Energy costs are significant expenses for utilities and industries at large, particularly those that are energy-intensive or operate heavy machinery. Between 5% and 25%* of the expenses in these organizations are allocated to energy payments, with up to 15%** of this energy consumption being wasted during operations.

Overview

GE Vernova offers a wide range of solutions to monitor and manage critical assets on the electrical grid, detect and diagnose issues and provide expert information and services to customers. Our asset monitoring and diagnostics portfolio includes solutions for single- and multi-gas transformer DGA, enhanced transformer solutions and switchgear monitoring, as well as software and services.

Product Categories

General

Overview

GE Vernova's Grid Solutions business electrifies the world with advanced grid technologies and systems, enabling power transmission and distribution from the grid to homes, businesses, and industries effieciently and reliably.

Product Categories

- Generator Protection

- Transformer Protection

- Line Protection

- Bus Protection

- Feeder Protection

- Motor Protection

- Single Function

- Auxiliary Relays

- Accessories

- Controllers

- Gateways & RTUs

- Merging Units

- Fault Recorders & PMUs

- Metering

Overview

GridBeats™ is a portfolio of software-defined automation solutions for grid digitalization. The portfolio is designed to enable utilities and industrial customers to ensure a stable, efficient energy supply amidst the growing integration of renewable energy sources and aging infrastructure.

Product Categories

Overview

GE Vernova's Critical Infrastructure Communications solutions deliver comprehensive networks that are designed to be secure, flexible, and tailored to meet customers' objectives and unique geographic requirements.

Product Categories

- Industrial Wireless

- Hardened Optical Networks

- Teleprotection Signaling Systems

- Ethernet Switches, Converters, Time Synchronization

- Power Line Carrier

- Network Management Systems

- Professional Services

Overview

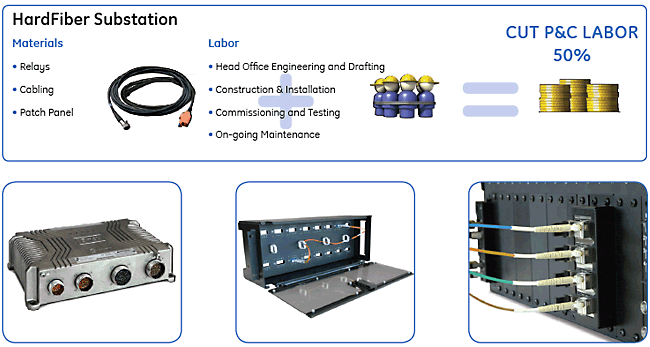

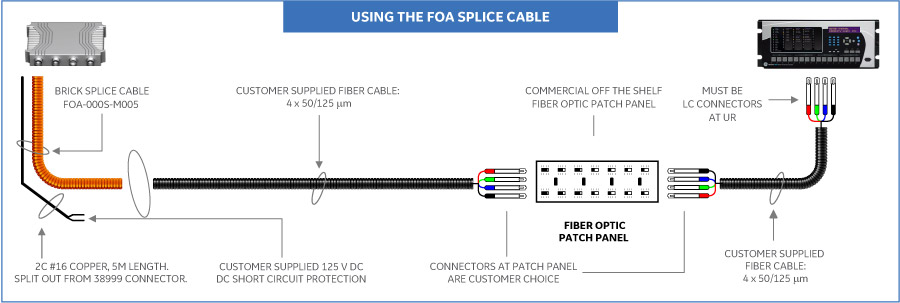

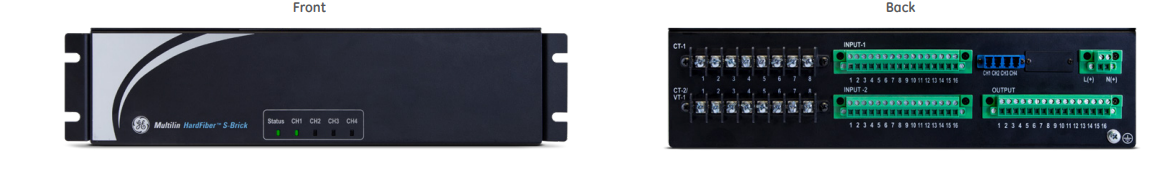

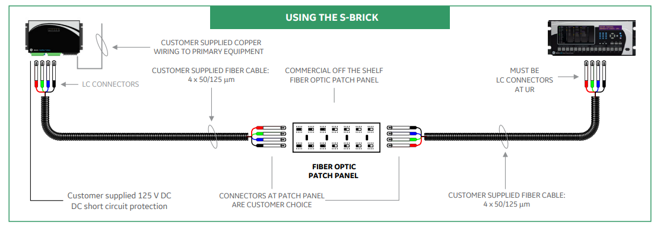

GE Vernova's comprehensive portfolio of solutions for implementing and managing a substation.

Product Categories

Overview

GE Vernova's Asset Lifecycle Management services combine a large set of methodologies to collect condition data off and online, consulting and asset optimization services using digital technology to improve the monitoring, recording and analysis of asset operations and predict asset behavior.

Product Categories

Overview

GE’s innovative and high-quality services help maintain and optimize high-voltage electrical assets throughout their entire lifecycle. Leveraging the design and manufacturing knowledge of our engineers, the customized service solutions ensure substations and networks perform as planned. Experts deliver services for applications across the power system, keeping assets up-to-date, safe, reliable and efficient while improving customers’ return-on-investment.

Overview

GE Vernova provides a full range of services & support tailored to meet a broad range of power system needs across utility and industrial applications. With deep domain knowledge and industry expertise GE’s service application engineers and technical specialists can help plan, design, operate, maintain, and modernize your protection, control, monitoring and automation systems.

Overview

GE Vernova provides comprehensive services throughout the systems lifecycle. The services can be provided by our local team and with the support of our global Competence Centers when the equipment is installed, during the warranty period and beyond.

Overview

Our technical experts are ready to equip customers with the knowledge needed to effectively manage their critical assets and systems, and increase their return on product investments. Our training courses are offered in a variety of ways, including online, onsite at customer locations, and in our state-of-the art training centers around the world.

Overview

GE Vernova's Grid Solutions' Testing Laboratories enable manufacturers and end users to test their primary equipment by leveraging deep domain expertise and testing facilities, to develop enhanced high voltage products and certify their capabilities before market introductions.

Overview

GE Vernova delivers materials and eco-design studies for high voltage solutions to accelerate insulation and environmental innovation. GE’s services provide the expertise and methods that enable new value to support customer engineering, sourcing, quality control and EHS activities.

Overview

With the rapid digitalization of the grid, utility, power generation and industrial operators require cybersecurity solutions to monitor and protect grid asset and systems from increased severity and frequency of cyber attacks. GE Vernova adopted a “defense in depth” approach, providing innovative cybersecurity solutions designed to increase operational integrity, comply with regulations and control costs of security.

Overview

Utilities today seek to create and connect new sources of power generation to meet growing global demand, while also managing grid reliability, costs and regulatory factors.

Overview

Water is central not just to the economy, but to life. As a result, water treatment systems demand secure, dependable power to ensure process uptime. From the grid-connected substation to reliable electrical protection, control, and power quality metering, GE Vernova offers tailored solutions to keep critical plants operational and meet the unique needs of the water and wastewater industry.

Overview

As power systems become increasingly interconnected and complex, utilities need solutions that optimize energy transmission and management while improving reliability.

Overview

Data centers – and the information they store – are becoming increasingly integral to the way we live our lives every day. With rising demand also come rising costs. And more importantly, the information in these centers must remain secure while simultaneously accessible. We provide data centers with electrical infrastructure solutions from the input utility source to the IT server racks. This includes high-voltage switchgear and transformers, medium and low voltage electrical equipment, automatic transfer switches, switchboards, UPS systems, critical power PDUs, static transfer switches, and overhead busway. This chain of electrification products provides high quality and reliable products and services for the entire lifecycle of a data center.

Overview

The oil and gas industry is evolving at a rate never seen before, facing shifting pricing levels, ever-changing regulatory requirements, and increased environmental consciousness. Through reliable, safe, and innovative solutions and a holistic service offering, GE Vernova can help the energy sector thrive in this changing reality.

Overview

Modernizing and digitizing the distribution grid is imperative for utilities and customers to enhance power system stability and safety, while increasingly integrating distributed power and demand response.

Overview

The industry is changing. Simultaneously, so are your utility’s needs. Operational effectiveness, power stability, and critical asset management are key priorities – whether in pulp and paper, steel, or data centers. GE’s holistic portfolio of products and services are designed with reliability, innovation, and sustainability at the forefront, helping you face the energy transition with ease.

Overview

Mining companies require secure communications, efficient asset performance management, and dependable, innovative technology to protect their critical assets. GE Vernova offers a broad product portfolio to help you through each step of the mining process – safely and reliably.